Page 4 Version 2.00 Assembly Instruction PLG7

1. Introduction

This assembly instruction is designed to assist you during the installation of the platform stair lift PLG7.

Although the information and photographs printed in this manual illustrate a particular stair lift, the

description is still relevant for all other installations.

Please note that this manual contains instructions for the installation of parts and equipment which are not

supplied with all our lifts (optional extras).

The instructions in this assembly manual describe equipment and tools which were available at the time of

writing. Due to the continuous development of our products, we reserve the right to alter the contents and

technical data without consultation or prior warning.

This part of the user manual is dedicated to trained installation technicians who are used to the installation of

this product.

1.1 Health and safety regulations

! N O T E !

In the interest of your own well being and the safety of third parties, please observe international health and

safety regulations and the applicable national laws at all time.

! A T T E N T I O N !

This lift is manufactured in compliance with the relevant international and national health and safety

directives. However that alone cannot guarantee safety and security. Incorrect operation or misuse of this

product can eventually cause heavy injuries of the user or third parties and result in damage to the lift and its

surroundings.

1.2 Notes for installation

•The installation of the platform stair lift may only be carried out by the trained personal of an

Ascendor partner.

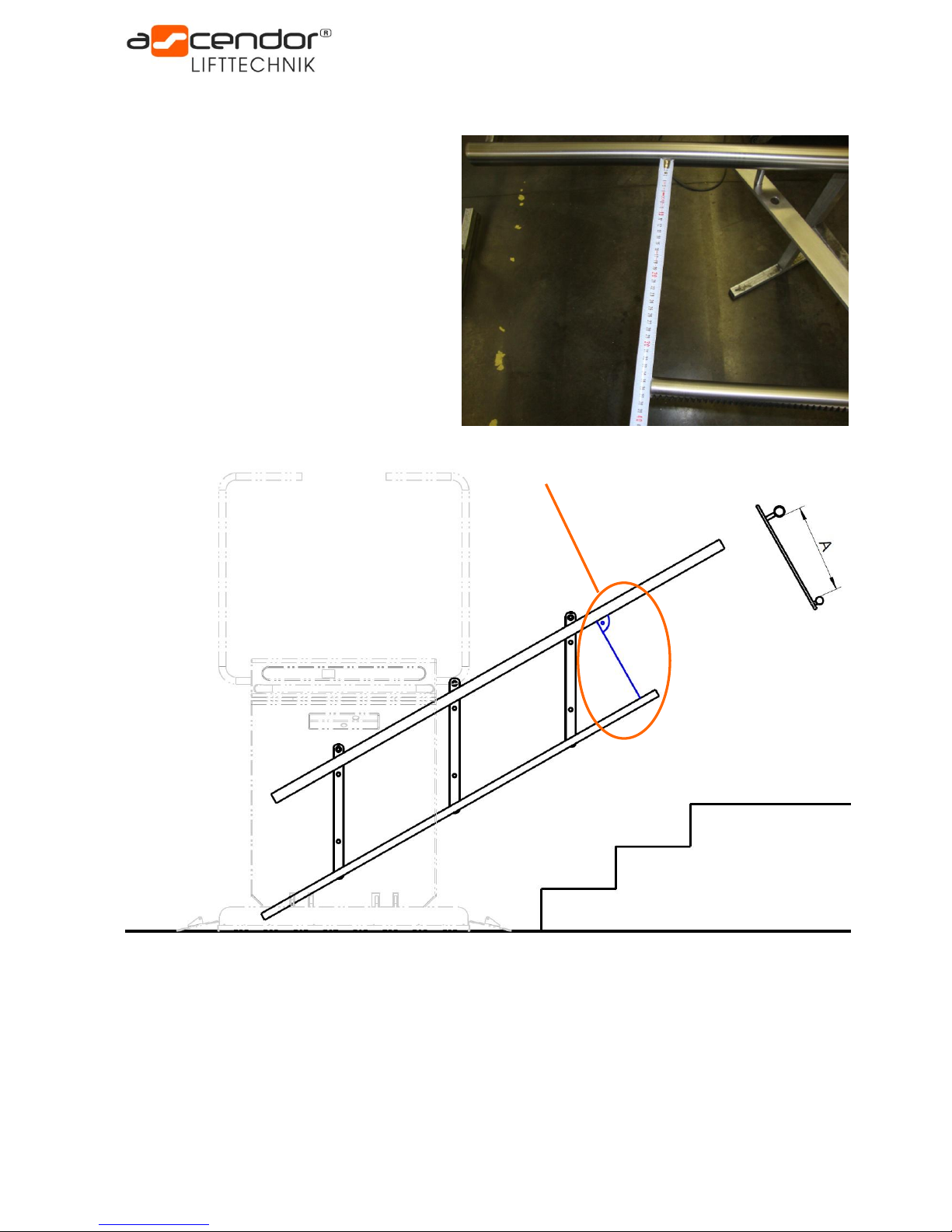

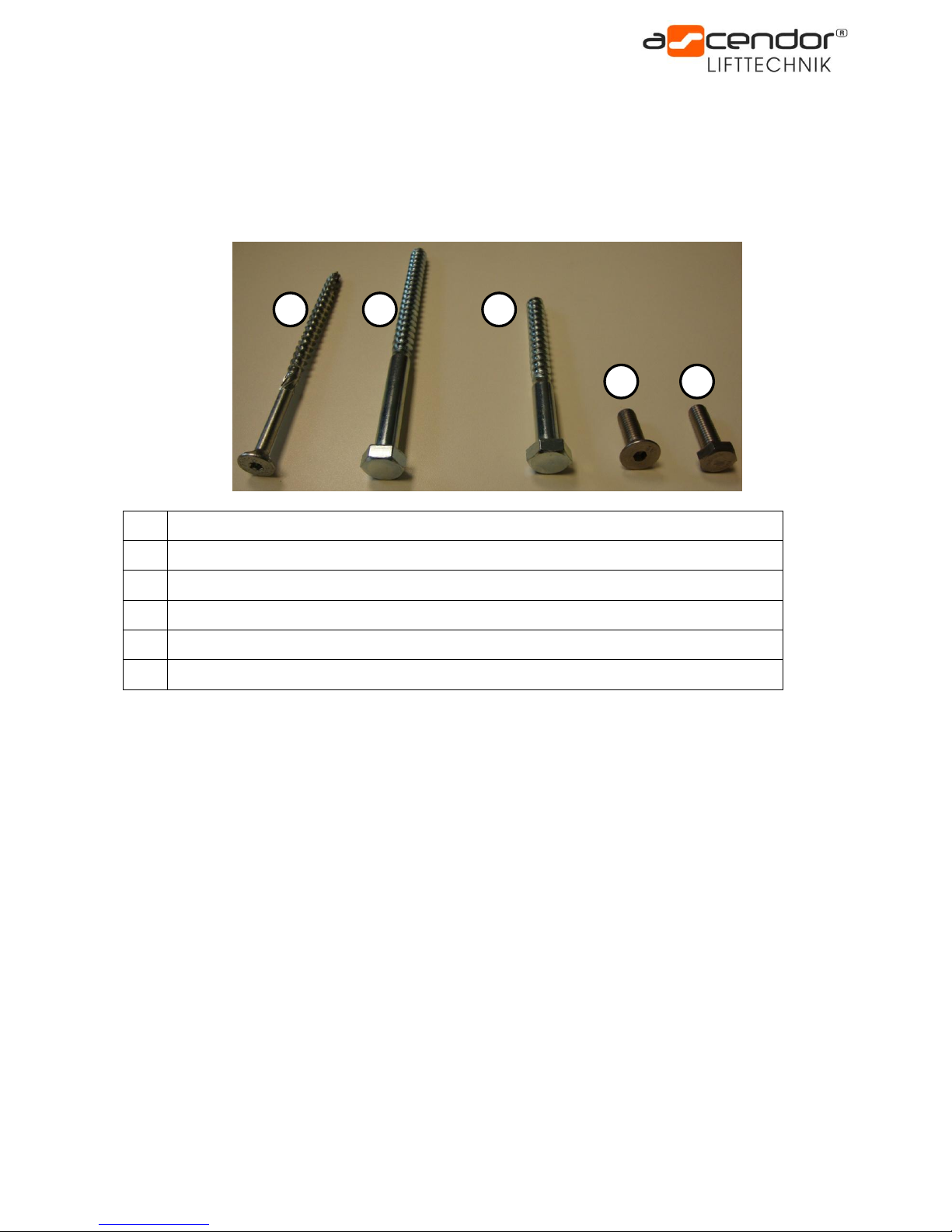

•This manual is designed to assist you with the installation and especially during the installation of the

travel rails of the stair lift.

•The travel rails of the stair lift may not be altered (extended or shorted).

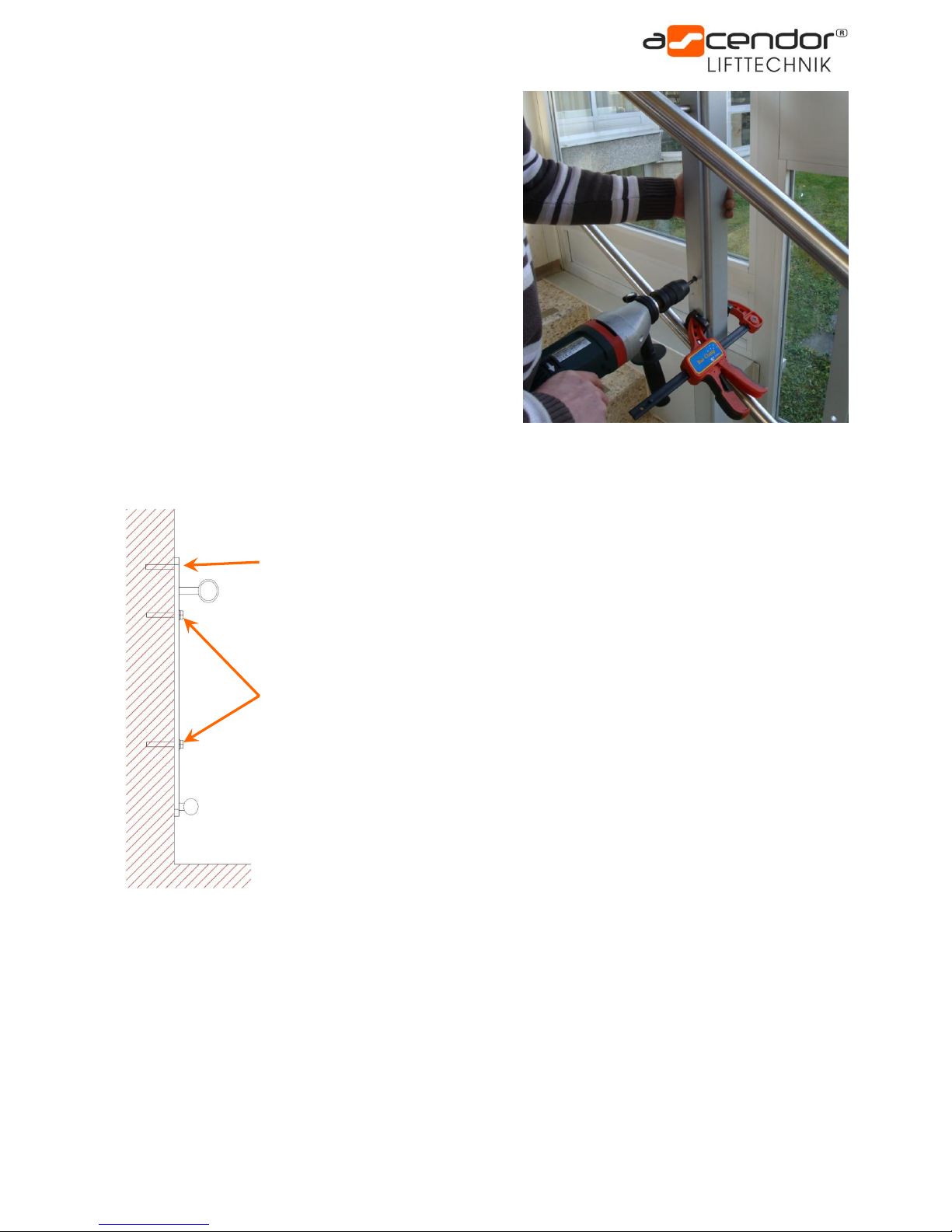

•The stability of the walls, onto which the stair lift is to be mounted, must be assessed on site by a

qualified fitter. Ascendor accepts no responsibility and liability for this work.

•The exact installation dimensions are clearly specified in the drawing delivered with each stair lift and

must be observed at all times.

•A 230 V power socket or supply cable L/N/PE 3x1,5mm² must be either present or fitted at one of the

two lift stations (upper or lower station) during the installation.

1.3 Specific demands on the installation fitters

The installation fitters must be employed and trained by an Ascendor approved partner.

The fitters must be able to assess on site the load bearing capabilities of the walls and supporting elements to

which the lift and its equipment will be attached. They must be capable of reading and understanding the

provided installation drawings.

Ascendor accepts no responsibility or liability for this work.