9

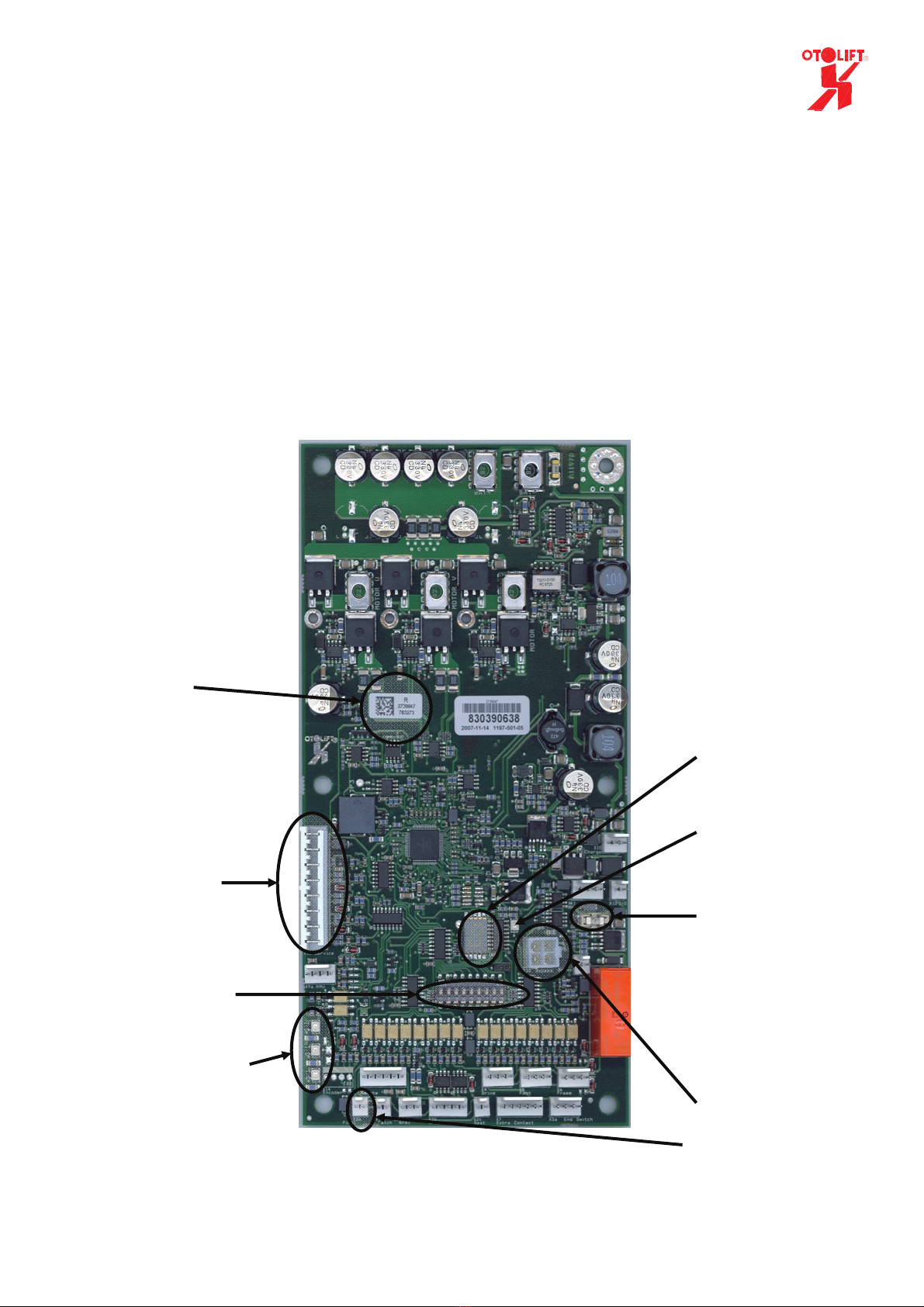

3. Dipswitches on the circuit board

The dipswitches on the circuit board have their own logic functions.

Dipswitch 1= on => The rotation monitor unit is monitored on its functionality.

If the rotation monitor (RMU) does not give an alternating signal,

during 30 cm of moving the lift, the lift stops.

The lift will drive further by re-controlling it.

If the dipswitch is off and a rotation monitor unit is connected, the

PCB will see this as an incorrect combination. Every time when the

signal from the RMU alternates the chair is stopped.

Dipswitch 2 = on => Use for future options. (functionality is already implemented)

If the lift has reached an endpoint and has stopped, the switched logic

output X11 will be active as long as the lift is operated.

When dipswitch 2 = off, output active on upper and lower endpoint.

When dipswitch 2 = on, output only active on upper endpoint.

(If setting dipswitch 9 is correct)

If the lift is operated, the switched logic output X12 will be active as

long as the lift is operated.

When dipswitch 2 = off, output active only when swivel switch

and armrest-contact are closed and control is operated.

When dipswitch 2 = on, output always active when control is

operated.

Dipswitch 3 = on => When the lift has not seen the voltage of the transformer for 1 or 8

hours the lift will go into sleepmode. (low current consumption)

When the dipswitch is on, the sleepmode will be activated after 8

hours instead of the standard 1 hour.

Dipswitch 4 = on => When an extra charge or stoppoint has been programmed, the lift will

stop on this point when it is controlled by a remote-control.

Dipswitch 5 = on => When an extra charge or stoppoint has been programmed, the lift will

stop on this point when it is controlled by the armrest-control.

Dipswitch 6 = on => The beeper will give a continuous alternating alarm signal (1 Hz),

when the lift has not seen the voltage of the transformer for a period of

time after controlling the lift.

When the dipswitch is on, the delay to this alarm is 2 minutes instead

of the standard 15 seconds.

Dipswitch 7 = on => For future developments. Functionality until now not implemented.

Dipswitch 8 = on => The standard lift (130 kg) has its own maximum torch settings.

In future developments, we can give more torch to the motor by

switching this dipswitch on.

Never adjust this dipswitch in the standard 130 kg application.

Dipswitch 9 = on => Depending if a rail is mounted on the left or right side of a staircase

the logic of the remote might have to be reversed.

When the dipswitch is on, the remote-control is adjusted for right rail.

When the dipswitch is in the standard off position the remote-control

is adjusted for a left rail.