4Unpacking 27

5Installation 33

5.1 General Notes on Installation.............................................................................33

5.2 Determining the Permissible Load and Workspace ...........................................35

5.3 Attaching the Snap-on Ferrite.............................................................................36

5.4 Mounting the Hexapod on a Surface..................................................................36

5.5 Grounding the Hexapod and the Hexapod Controller........................................38

5.6 Affixing the Load to the Hexapod .......................................................................39

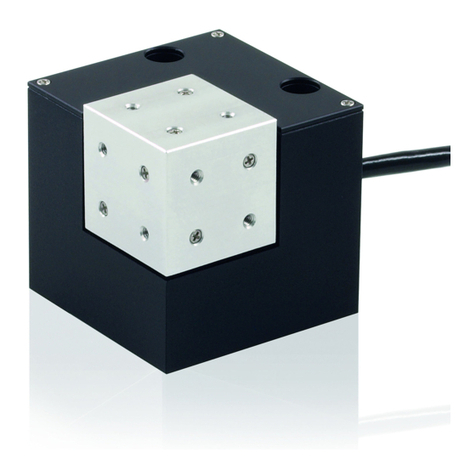

5.7 Optional: Removing the Coordinate Cube..........................................................40

5.8 Connecting the Hexapod System.......................................................................41

6Start-Up 43

6.1 General Notes on Start-Up.................................................................................43

6.2 Starting Up the Hexapod System.......................................................................45

6.3 Switching Off the Hexapod System....................................................................46

7Maintenance 47

7.1 Performing a Maintenance Run..........................................................................47

7.2 Packing the Hexapod for Transport....................................................................48

7.3 Replacing the Fuses of the M850B0448 Power Supply.....................................52

7.4 Cleaning the Hexapod........................................................................................54

8Troubleshooting 55

9Customer Service 57

10 Technical Data 59

10.1 Specifications......................................................................................................59

10.1.1 Data Table Hexapod.........................................................................59

10.1.2 Maximum Ratings Hexapod .............................................................61

10.1.3 Data Table Hexapod Controller........................................................61

10.1.4 Maximum Ratings Hexapod Controller.............................................62

10.1.5 Data Table M850B0448 Power Supply ............................................62

10.1.6 Maximum Ratings M850B0448 Power Supply.................................62

10.2 Ambient Conditions and Classifications .............................................................63

10.2.1 Hexapod ...........................................................................................63

10.2.2 Hexapod Controller...........................................................................63

10.2.3 M850B0448 Power Supply...............................................................64

10.3 Dimensions.........................................................................................................64

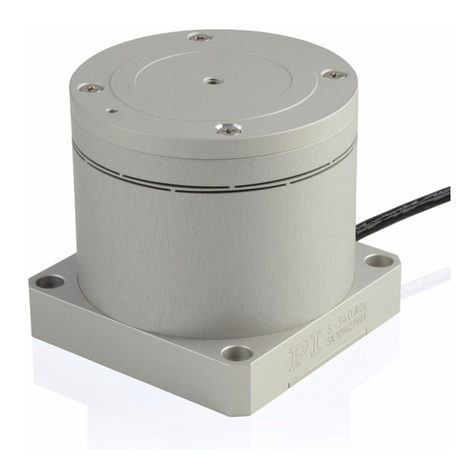

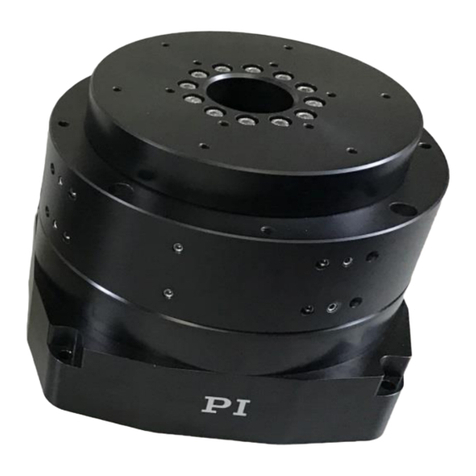

10.3.1 Hexapod ...........................................................................................65

10.3.2 Hexapod Controller...........................................................................66

10.3.3 M850B0448 Power Supply...............................................................67