Installation, operating and maintenance manual AQUAmax®PROFESSIONAL G

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-Nr.: 9060 XXXX / Stand: 08.01.2019 / Seite 4 von 56

Dear customer,

at this point we would like to thank you for the trust which you have shown in us by the purchase of

this product.

On the following pages you will find everything necessary about the installation, operation and

maintenance requirements of your AQUAmax®small wastewater treatment plant.

Please note that the careful installation of the wastewater treatment plant and the later

maintenance are very important for a good treatment performance.

Regular maintenance is laid down by the authorities. Through the conclusion of a maintenance

contract the plant and its biological discharge values are monitored continuously.

General and safety information

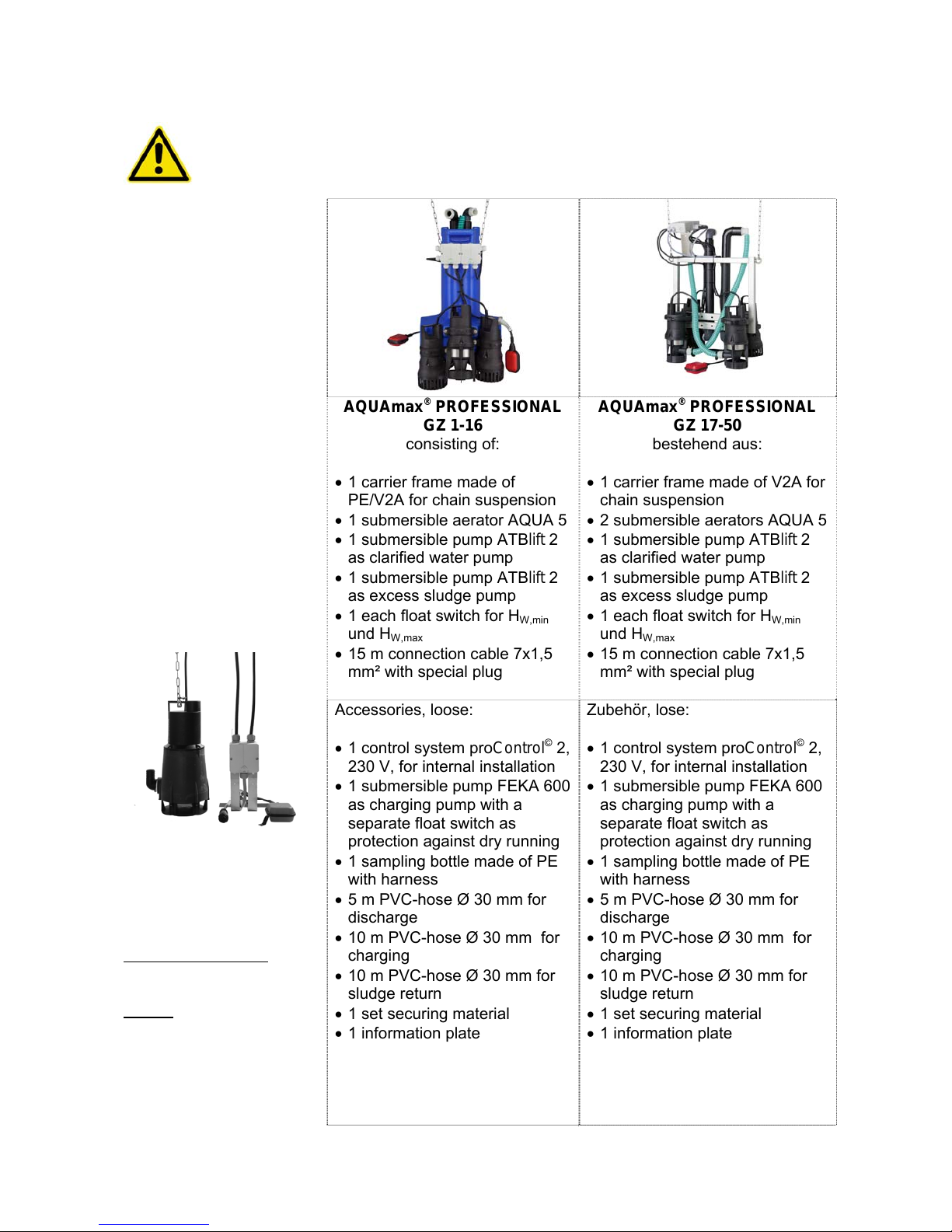

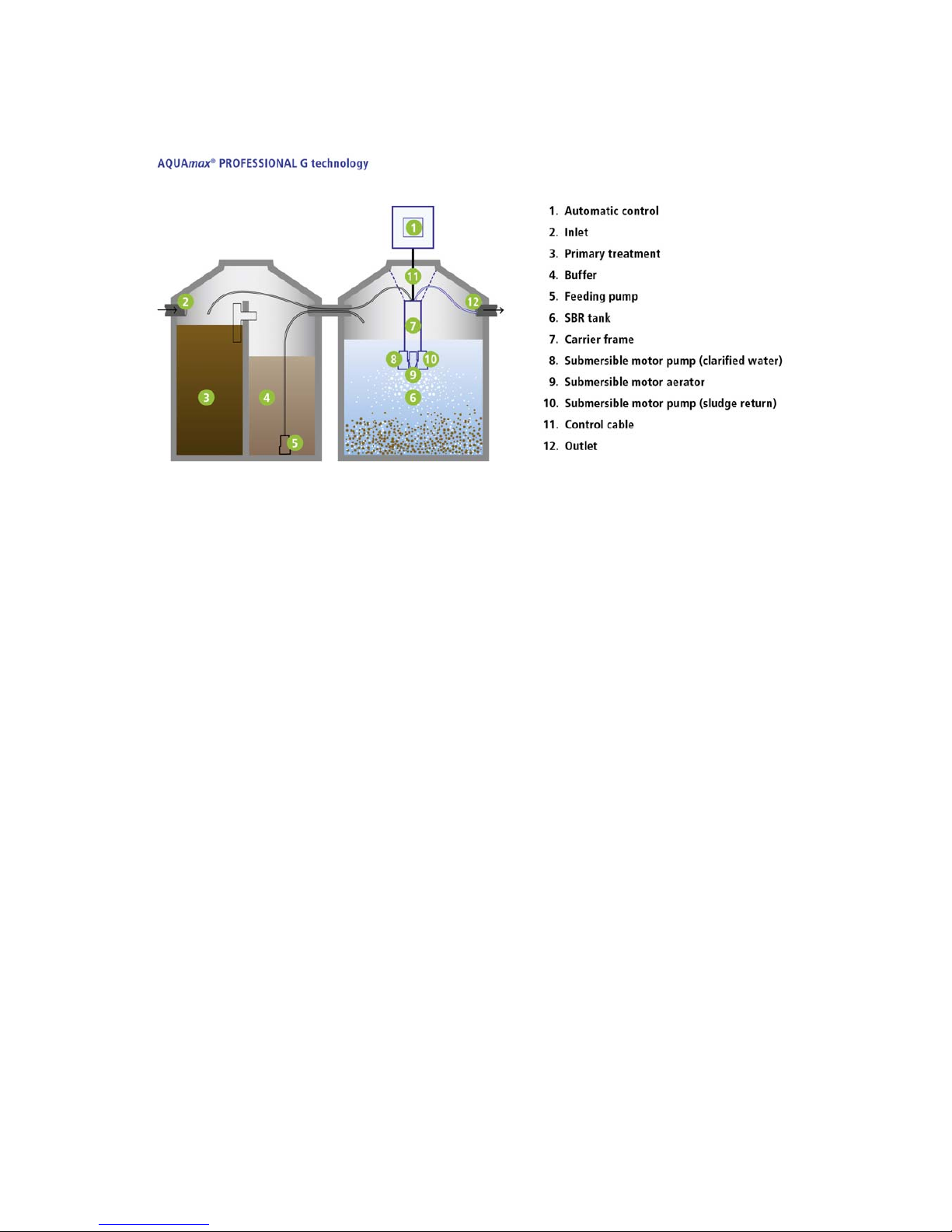

With the AQUAmax®one is concerned with a technical system which, together with a multi-

chamber, can be employed as small wastewater treatment plant for the aerobic biological

treatment of domestic and comparable wastewater of up to 8 m³/d from individual or several

buildings, collected using a separate system. Dimensioning, configuration and operation are to

take place in accordance with DIN EN 12566-3 and the approval of the German Institute for

Structural engineering (DIBt)!

With employment according to regulations no hazards whatsoever emanate from the plant. If the

AQUAmax®is used for other employment purposes without the express approval of ATB

Umwelttechnologien GmbH and/or if the following safety information is disregard, this can lead to

the hazarding or injury of persons and to malfunctions of or defects in the plant. In this case every

liability is excluded. Modifications to the plant or unauthorised conversions are not permitted.

The AQUAmax®and accessories are not intended to be used by persons (including children) with

limited physical, sensory or mental capabilities or without experience and/or knowledge, unless

they are supervised by a person responsible for their safety or receive from him/her instruction on

how to use the AQUAmax®and accessories. Children are to be supervised in order that they do

not play with these.

Before use the AQUAmax®is to be installed correctly and in agreement with the installation

instruction. Installation instructions, operation and maintenance instructions are to be read careful

before assembly and commissioning and the instructions contained therein must be followed

implicitly.

With assembly and installation, commissioning and operation as well as, if necessary,

decommissioning, the customary national standard specifications and provisions are to be

observed. All tasks may be carried out by trained and qualified specialists with an appropriate

certificate of qualification only. The operator of the plant is to be instructed by the service

technician.

With the connection of the control system the national applicable provisions as well as the details

on the specification plate are to be observed (mains voltage, frequency etc.). The equipment is to

be operated only on network configurations which include a protective earth (PE) conductor.

Attention is to be paid to correct phase connection (even with ready-to-plug

configurations)! Connection to the mains must be by means of separate fusing and earth leakage

circuit breaker (ELCB). Before commissioning the faultless function of the electrical safety

measures must be checked! Installation tasks are to be carried out by electrically skilled persons

only. With work on the equipment the mains plug must be disconnected. A separation or extension

of the leads is not permitted. The electrical connection data is to be taken from the specification

plate on the equipment.