Installation/Operating Instructions ATB - HSA

ATB WATER GmbH, Südstraße 2, 32457 Porta Westfalica, Germany, www.atbwater.com /

Version: 07.11.2022 / Page 4 of 41

1. Safety regulations

We will mention, in this chapter, the major kind of risks and dangers that might

occur, and the safety precautions to be taken.

•As mentioned in our declaration of conformity and in the warranty regulation, our aerator

can only be used when the installation, into which they need to be incorporated, is declared

conform to the Machinery Directive.

•If ATB did not deliver an explosion proof motor, it is forbidden to use the equipment in areas

where explosive gases might be present.

•At the moment of receipt and acceptance of the goods, you must always check that the

HELICAL IMPELLER can be rotated manually. Always be careful not to put a hand

between the HELICAL IMPELLER and the volute.

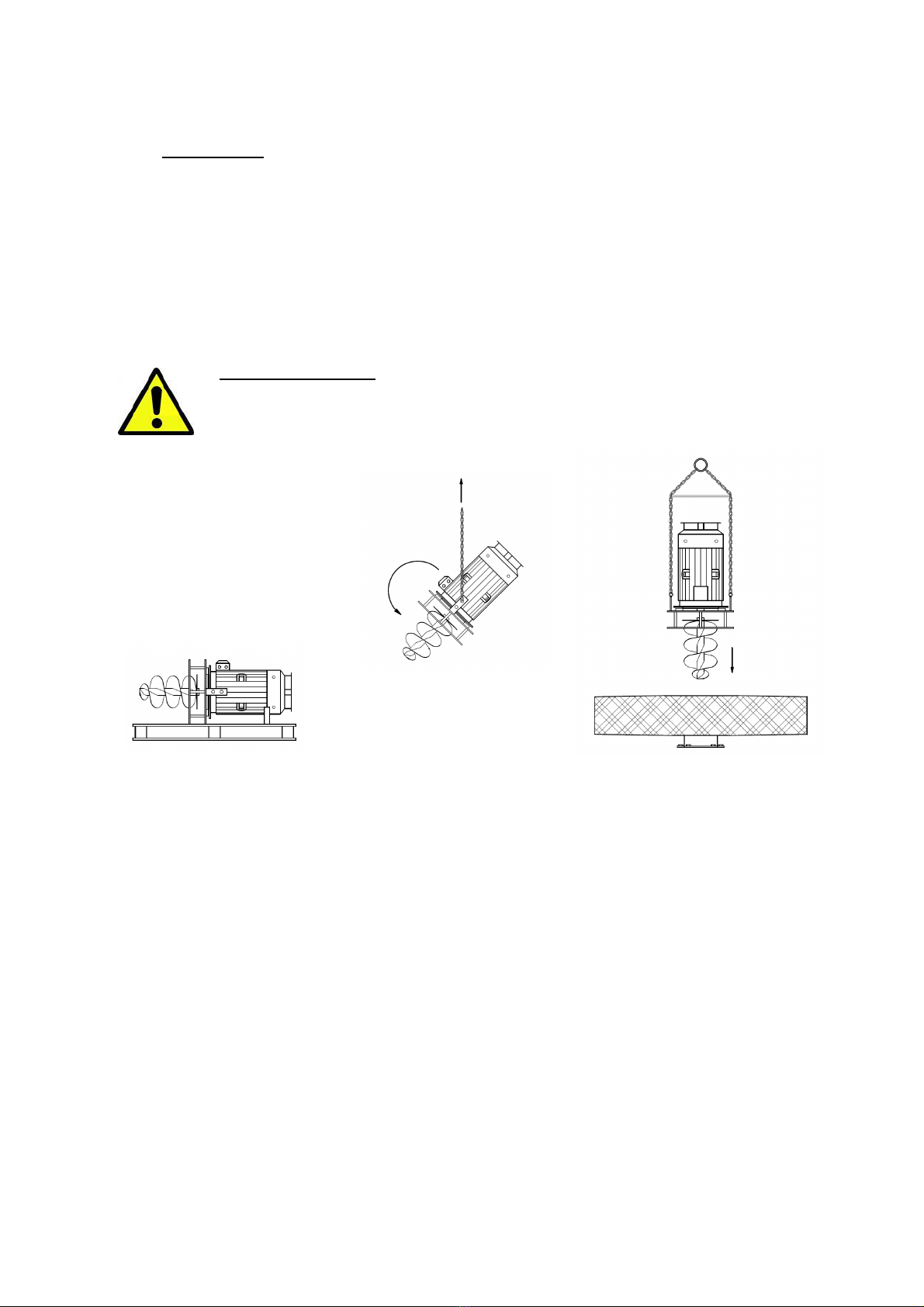

•Because of the weight of the goods, persons who are not directly involved should be kept

out of the handling area.

•Prior to the installation the lifting equipment must be inspected by an official authority, and

found suitable for the job, to allow safe loading, unloading and positioning.

•The complete electrical installation has to be designed in accordance with the European

standard EN 60204 concerning the electrical equipment of machinery, to NEMA, IEC or any

other locally valid directives concerning the electrical installation and connection of

machinery.

•Starting the aerator on dry land, to check the balance of the motor and HELICAL

IMPELLER or to do a last greasing, should not be done without taking radical safety

provisions and has to be performed by a qualified person. Should any abnormality occur,

the aerator must be switched off immediately.

•During the installation of the aerator, all necessary personal protection equipment has to be

at the disposal of all persons involved in the assembly and installation of the equipment.

It is essential to check that the safety switch of the unit that needs to be installed,

and also of all other units located in the basin where the unit needs to be installed,

has been switched off and locked in this position during all work on the electrical

installation, during maintenance or repairs, and during installation.

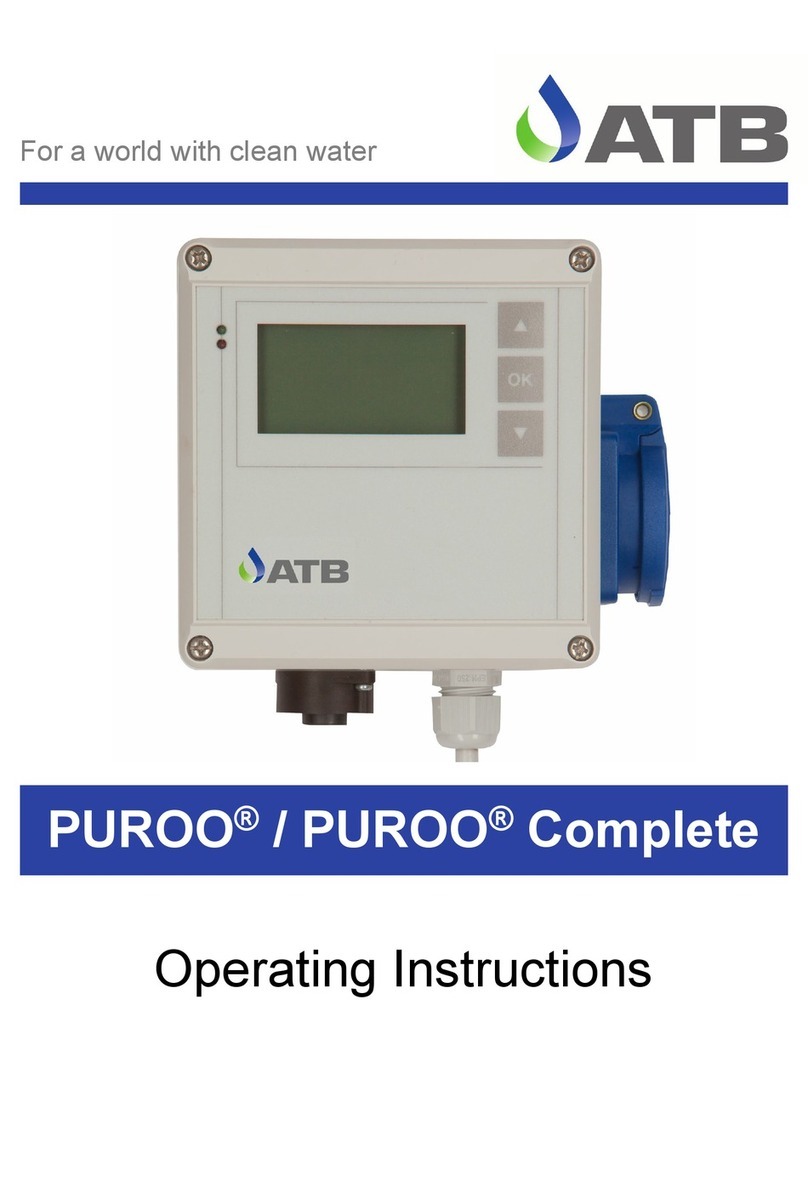

As a safety precaution and also to prevent the unit from tipping, it is absolutely

forbidden to stand on the unit. It is possible to reach the aerator by using a boat as

shown on drawing 1: “Reaching the unit by using a boat.”.

•During any intervention on the electrical installation, maintenance and/or repairs of the unit,

a second person has to be present to verify the safe intervention and eventually assist.

ATB WATER GmbH is not responsible for any kind of incidents.