® Copyright ATH-Heinl GmbH & Co. KG, 2017, All rights reserved. / Misprint and technical changes reserved / Issue: 07/2018

- 2 -

INDEX

INTRODUCTION .............................................................................................................................- 3 -

General information.....................................................................................................................- 3 -

General description .....................................................................................................................- 4 -

Technical data ............................................................................................................................- 7 -

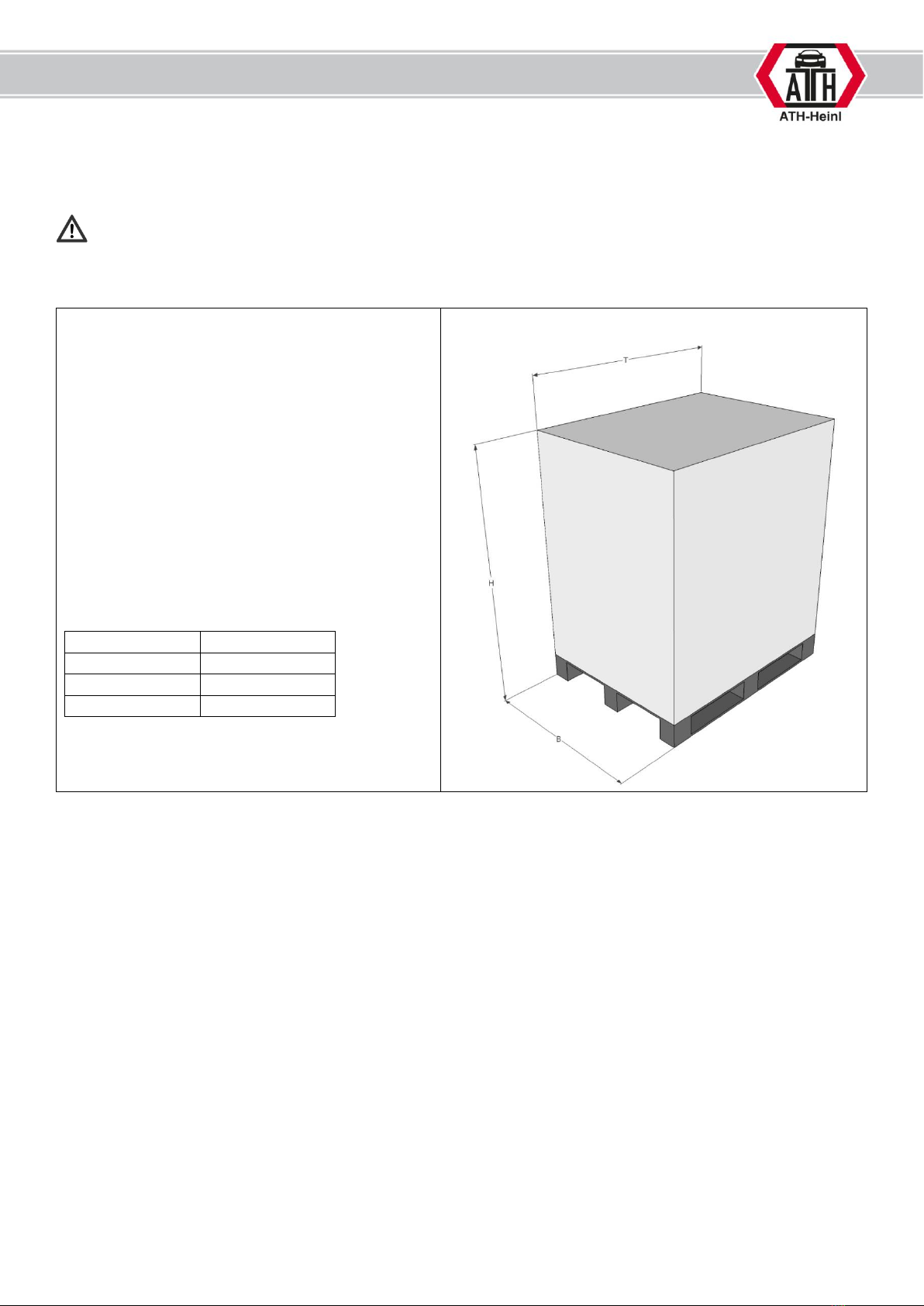

Packing ......................................................................................................................................- 8 -

Scope of delivery.........................................................................................................................- 9 -

INSTALLATION.............................................................................................................................- 11 -

Place of installation ...................................................................................................................- 11 -

Mounting..................................................................................................................................- 12 -

SETTING AND CALIBRATION.........................................................................................................- 16 -

System setting ..........................................................................................................................- 16 -

Adjustment of kind to place adhesive weights..............................................................................- 16 -

Calibration of piezo transducer in TRUCK mode ...........................................................................- 18 -

Service calibration of measuring gauge in TRUCK mode ...............................................................- 18 -

Calibration of piezo transducer in CAR mode ...............................................................................- 20 -

Service calibration of measuring gauge in CAR mode....................................................................- 21 -

OPERATION .................................................................................................................................- 23 -

Operation instruction.................................................................................................................- 23 -

Safety instructions.....................................................................................................................- 24 -

Utilization .................................................................................................................................- 25 -

MAINTENANCE .............................................................................................................................- 32 -

Error and remedy......................................................................................................................- 32 -

Troubleshooting........................................................................................................................- 33 -

Maintenance and service instructions ..........................................................................................- 34 -

DECLARATION OF CONFORMITY ...................................................................................................- 35 -

WARRANTY NOTE.........................................................................................................................- 36 -

EXPLODED DRAWING ...................................................................................................................- 38 -

Machine body ...........................................................................................................................- 39 -

Display.....................................................................................................................................- 41 -

Protective cover ........................................................................................................................- 42 -

Pedal .......................................................................................................................................- 43 -

Laser........................................................................................................................................- 44 -

Mainshaft .................................................................................................................................- 45 -

Backpack..................................................................................................................................- 46 -

Inner gauge assy ......................................................................................................................- 47 -

Brake assy................................................................................................................................- 48 -

Sensor .....................................................................................................................................- 49 -

CPU .........................................................................................................................................- 50 -

Power board .............................................................................................................................- 51 -

Motor assy................................................................................................................................- 52 -

Photoelectricity .........................................................................................................................- 53 -

Air regulator assy ......................................................................................................................- 54 -

Dolly ........................................................................................................................................- 55 -

Lifting ......................................................................................................................................- 56 -

Accessory box...........................................................................................................................- 58 -

NOTES.........................................................................................................................................- 60 -