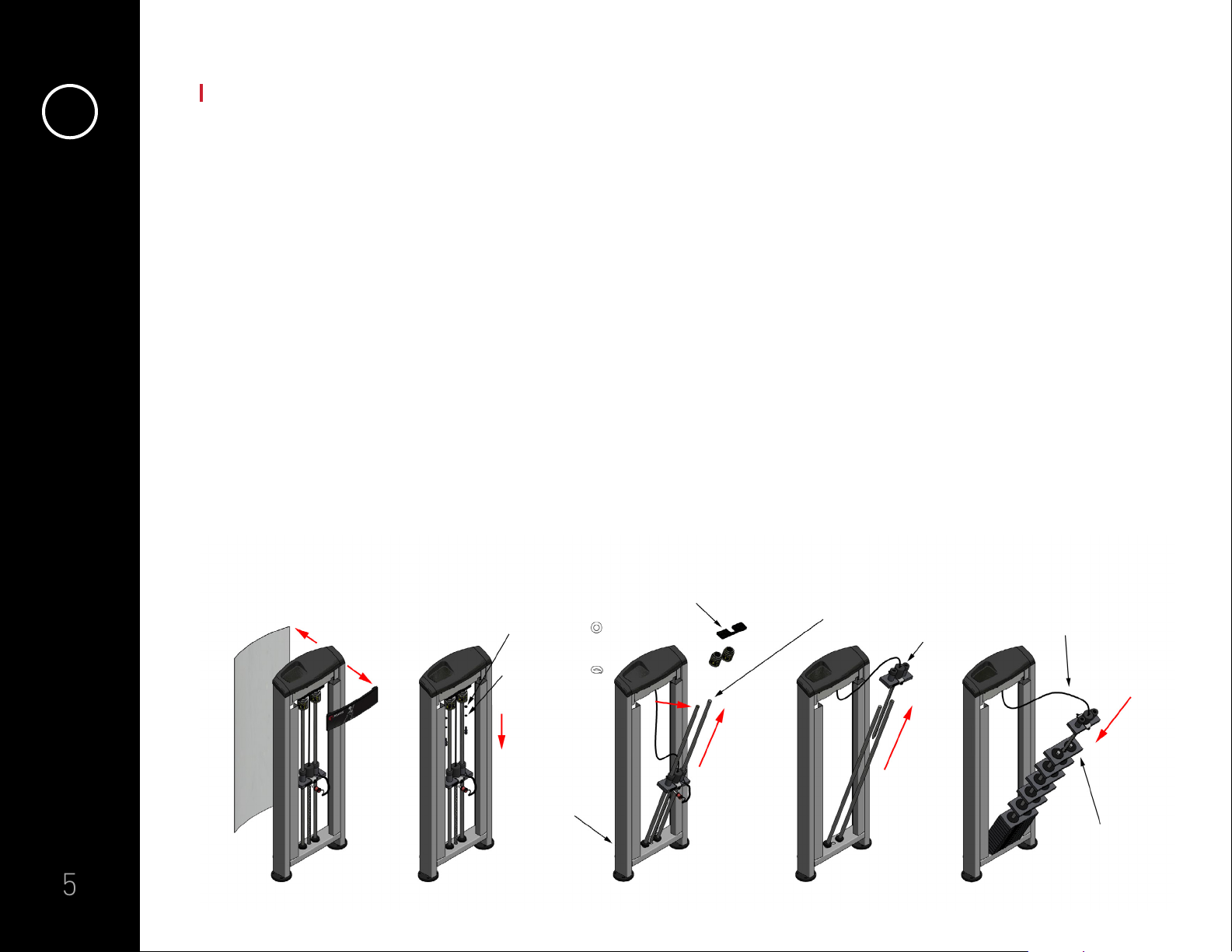

1) First remove the top panel (A)

from the top of the machine.

Next, manually slide out the unit’s

protective shroud (B) from its tracks

on the sides of the frame and put it

aside.

2) Lower the add-on weights so that

they are resting on the top plate. This

will expose the two silver cylindrical

bolts and black plastic bracket (C)

holding the chromed guide rods (D)

in place. Loosen and remove both

cylindrical bolts and the black plastic

bracket.

On most stations, you will find special

“split” washers (also called lock

washers) and “flat” washers between

the cylindrical bolt and the bracket

that are very important. They keep the

bolts from vibrating loose over time.

Securely install the “flat” washer

under the plastic bracket (C) and the

“split” washer between the cylindrical

bolt and the “flat” washer. On other

stations, you will find regular nut and

bolt assemblies that do not require

these washers. Carefully let the guide

rods lean to whichever side of the unit

is easiest to work on. The rods will

lean about 60 degrees and sit safely

in place on an angle.

ASSEMBLY INSTRUCTIONS

1Weight stack units: Installing the weight stack

3) Remove the two add-on weights.

4) Grasp the top plate (hanging on either

a belt or a cable) and slide it off the

top of the guide rods. Let the top

plate (E) hang on the belt or cable and

place it to one side.

5) Slide all the weight plates (F) onto the

guide rods one at a time as per the

diagram. Slide the hanging top plate

back onto the guide rods to complete

the weight stack without twisting the

belt or cable.

(F) WEIGHT PLATES

CABLE OR BELT

(E) TOP PLATE

(D) DOUBLE CHROMED RODS

(C) PLASTIC BRACKET

FLAT WASHERS

SPLIT WASHERS

(B) SHROUD

1 2 3 4 5

(A) FRONT PANEL