PennEngineering • www.pemnet.com

9

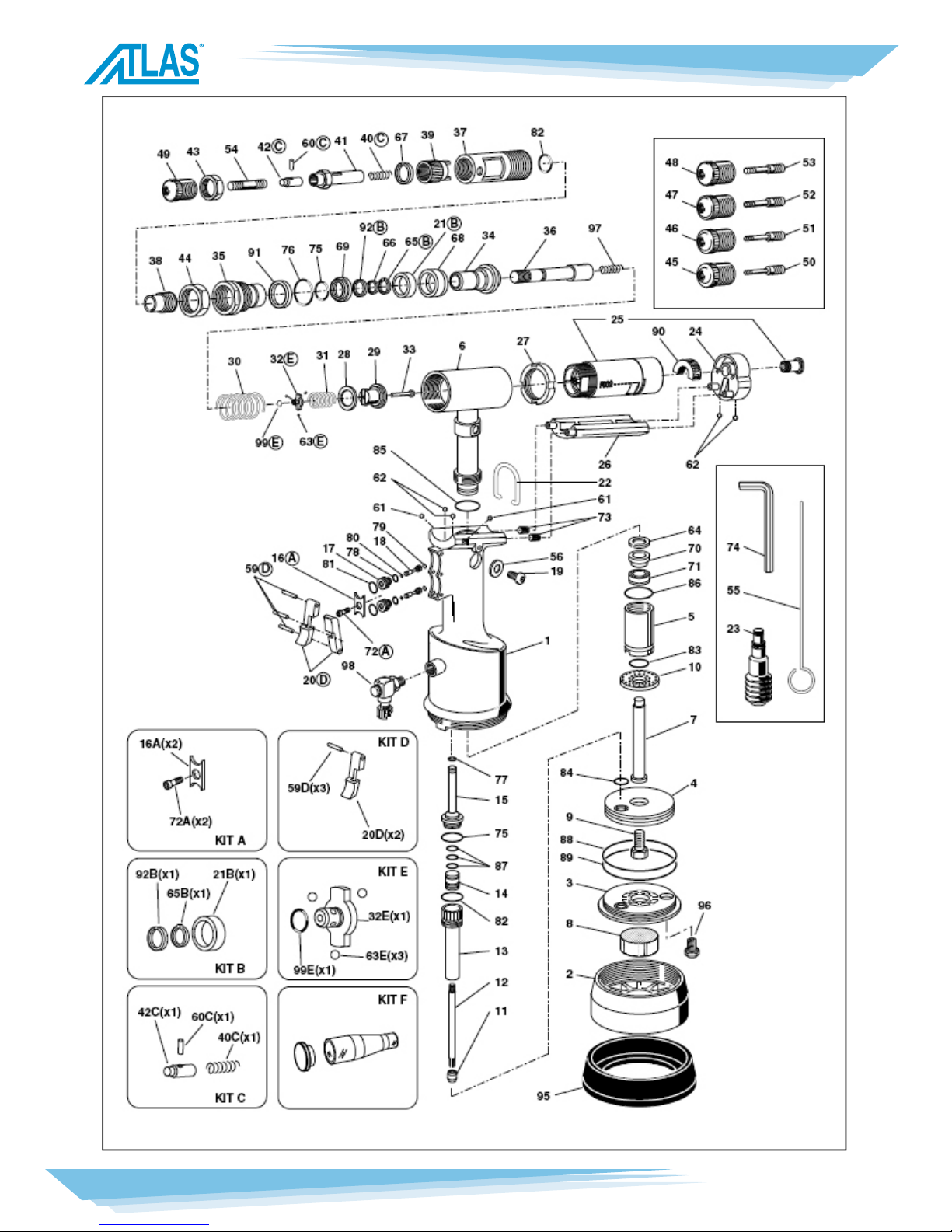

SPARE PARTS - METRIC TOOL

NO. CODE QTY. DESCRIPTION

01 721779 1 Toolbody

02 712269 1 Bodycover

03 711684 1 Cylinderbottom

04 721685 1 Pneumaticpiston

05 711780 1 Connector

06 721689 1 Oleodynamiccylinder

07 711781 1 Stem

08 711691 1 Silencer

09 711692 1 ScrewM7x1

10 711782 1 Dampener

11 711694 1 Lowercoil

12 711695 1 Threadedsleeve

13 721698 1 Valvebody

14 711700 1 Uppercoil

15 711701 1 Uppervalvebody

16A 711702 1 Plate

17 711703 2 Valvebody

18 711704 2 Valvepiston

19 710839 1 Oiltankplug

20D 711705 2 Push-button

21B 711713 1 Spacer

22 710854 1 Balancerhook

23 721387 1 Oilcontainer

24 711783 1 Motorcover

25 720024 1 MotorF002

26 711785 1 Motorprotectionsector

27 711786 1 Ringnutformotor

28 711787 1 Stopring

29 712670 1 Clutch

30 711790 1 Pistonreturnspring

31 711791 1 Balllockingspring

32E 711792 1 Ballbushing

33 712270 1 Rod

34 711794 1 OleodynamicPiston

35 711795 1 Frontconnector

36 711796 1 Shaft

37 711797 1 Milledsleeve

38 711798 1 Strokeadjustingnut

39 711799 1 Strokeadjustingknob

40C 711800 1 Springdisengagementtierod

41 711801 1 Headcarryingtierod

42C 711802 1 Clutchfortierod

43 711803 1 Headringnut

44 711804 1 Ringnut

45 711805 1 HeadM3

46 711806 1 HeadM4

47 711807 1 HeadM5

48 711808 1 HeadM6

49 711809 1 HeadM8

50 711810 1 TierodM3

51 711811 1 TierodM4

52 711812 1 TierodM5

53 711813 1 TierodM6

54 711814 1 TierodM8

55 710876 1 Pindisengagementtierod

56 710906 1 Hermeticwasher400-820

59D 711726 3 Pin2x20UNI1707

60C 710537 1 Springpin4x12

61 711815 2 Ballø3.5

62 710911 4 Ballø4

63E 711816 3 Ballø2.5

64 711817 1 SeegerringI18

65B 710902 1 SeegerringE16

66 711818 1 SeegerringSW11x1

67 711821 1 SeegerringJV20x1

68 711721 1 BalseleB-110078/B/NEO

69 711722 1 BalseleB-094063/B/NEI

70 711819 1 BalseleB-070039/1

71 711820 1 GasketTS-10-18-5.8/L

72A 711727 1 ScrewVSP-4x8UNI5933

73 712037 2 Inoxlterø6x4

74 711092 1 Keymm5

75 711728 2 ORing-2-16P

76 711730 1 ORing-2-119(N552/90)P

77 710367 1 ORing-2-8P