Quarterly/ Bi-annual Maintenance Requirements:

Visually check the performance of the system by checking the red and green lights on the individual

units. If both lights are on, and you can hear the ‘buzz’ of the tubes, then unit is functioning properly. If

not, proceed to the troubleshooting section for repair. Maintain a physical distance between all

personnel and the tubes while system is operating or turned on.

Optional: Checkperformanceusinga highvoltageprobe (minimum of 5000 V)pairedwithamultimeter.

Follow proper safety procedures for dealing with high voltages. If you are uncertain, do NOT perform

any maintenance with the power on and, instead, proceed to the next step. Follow the voltage

measurement guidelines and instructions in this guide. Disconnect the system from the mains power

before performing any maintenance steps.

Inspect the unit box, plastictubecaps, and black tube mounting plate. Removeparticlesfrom mounting

plate, and thoroughly wipe clean any tracks or grooves that may have developed in the plate or caps.

Inspect connections: tightness of all nuts and screws; remove excessive rust onthe connections using

sand paper or wire brush, it may be necessary to remove the tubes for this step.

It may be beneficial to clean thetubes to improve performance.The tubes can be cleaned using an air

compressor for a quick clean, or more thoroughly with cleaning solutions. Read tube cleaning section

for detailed tube cleaning instructions. Do not immerse the tubes in water. Ensure that the MCC and

mesh are completely dry before reinstalling.

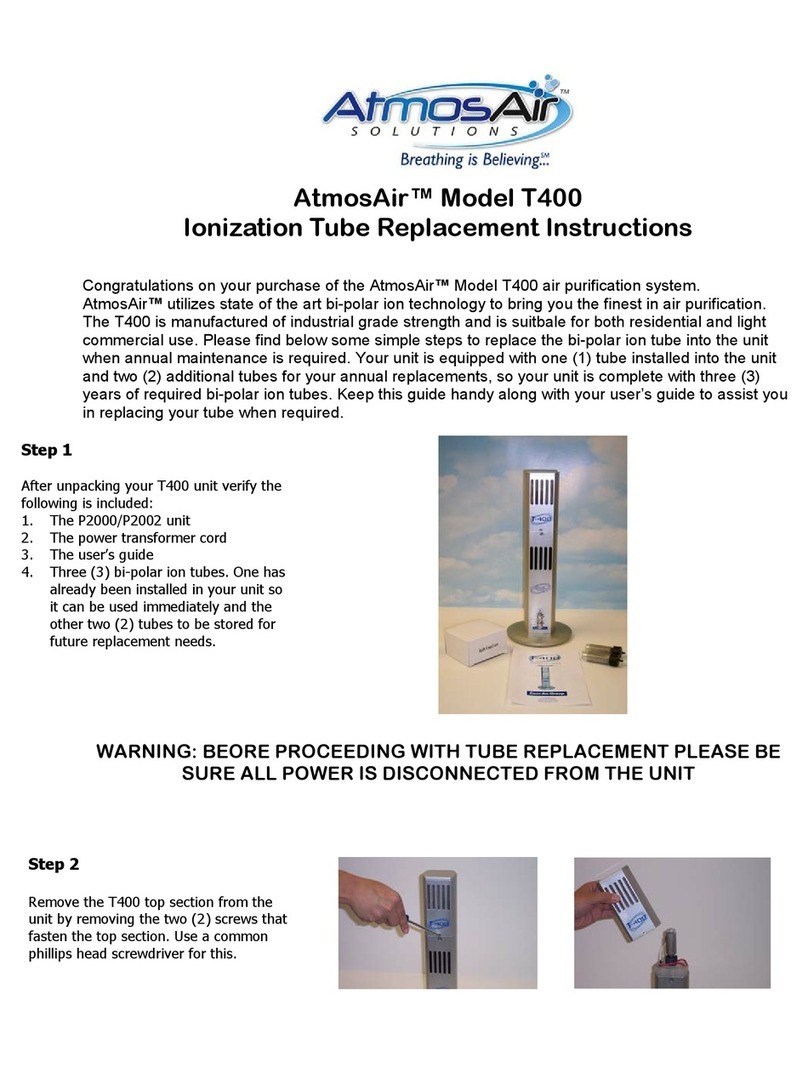

Tube Replacements:

The ionization tubes should be replaced once every 24 months, as the production efficiency slowly

declines over time due to the stress caused by plasma and (lack of) cleanliness of the electrodes.Old

or excessively dirty tubes can also put undue stress on the transformer causing premature failure.

Troubleshooting

In the event that the system is not functioning, the first step is to check the power source and fuse.

•

Check the fuse. If it is blown, replace it as per the label/submittal sheet. The fuse is 5 x 20 mm in

size.

•

Check that the main power supply is sending the correct power to the unit.

•

If the system is controlled by an air pressure switch, and/or a door switch, check that these are

not preventing power from being sent to the system.

If power is reaching the unit and it was necessary to replace the fuse, the next step is to determine

whether there is a fault in the system or atube. First, tocheck thatthe system’s power is functioning,

set the ionization power knob and the power switch both to the ‘off’ position. Make sure all personnel

are clear of the high voltage tubes, then reconnect the power supply. Flip the power switch to ‘on’

and observe the green light. If the light does not turn on, there is still a problem with delivering power

to the system. If all external sources of failure are eliminated, the system should be serviced by a

qualified AtmosAir technician.