Installation

AtmosAir FC-400 series equipment can be mounted in a duct (FC-400 FM) or, air handler wall or in

supply slot FC-400, using the faceplate mounting flange and its weather-strip gasket; or inside a plenum

using a universal mounting bracket. The units operate best when located after all filters, coils, and fans.

Various mounting arrangements are possible; however, the available options may be limited due to size

and configuration restrictions.

When mounted on the side of a duct or air handler wall, the enclosure should not be exposed to direct

sunlight or moisture. If installing outside, a weatherproof enclosure with an access panel for servicing

should be installed over the AtmosAir equipment.

The AtmosAir FC-400 series operates on 110~250 VAC, 50/60 Hz. The tube and electrode contacts

should not come into contact with any conductive surface. A minimum 63.5mm clearance around the

tube is recommended.

Mechanical Installation

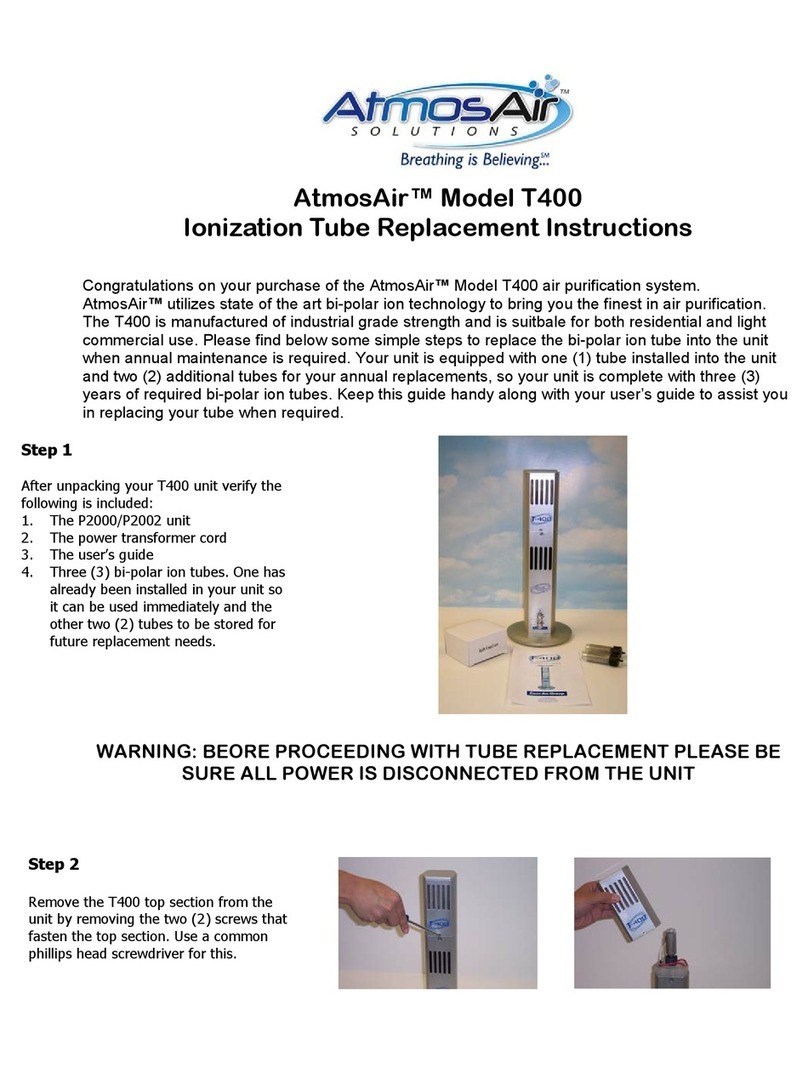

Carefully remove the equipment from its shipping container. Inspect the main components, gasket, and

tube for damage. Verify that the unit’s voltage rating is the same as the available voltage, 110~250 VAC

50/60Hz.

Install the ionization tube: Gently pull the conductor strap back to allow the tube to turn freely; screw the

end screw of the tube into the tube- holder hand-tight. Ensure that the tube is fully seated. Do not over-

tighten the tube! Once the tube is secure, return the conductor strap to its normal position and ensure

solid and continuous contact is made with the tube’s outer mesh. The FC-400 series comes with a MCC

B tube installed.

Location and Orientation: Install the unit downstream of filters, coils, and fans with tubes perpendicular

to airflow whenever possible. If multiple units are installed in the same duct, stagger the units in the

airflow so they are not in the same airflow path.

For in-duct installation: Verify the flange gasket (FC-400FM) is in place and in good shape to ensure

the unit seals properly. Make a 63.5mm Diameter hole in the duct sized at for FC- 400FM use template

provided to locate and cut the cut-out hole, then cut out and with 63.5mm Hole Saw and mark the

locations of the mounting holes for the FC-400 and FC- 400FM. The universal bracket is intended for

duct installations where extra support of the unit is required. It may also be used for sheet-metal ducting.

The optional universal stainless steel bracket is meant to be installed on the inside of the duct, in a

position allowing tool access.