Installation, Operation & Maintenance Guide AtmosSmart 10

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

03 STEP BY STEP INSTALLATION

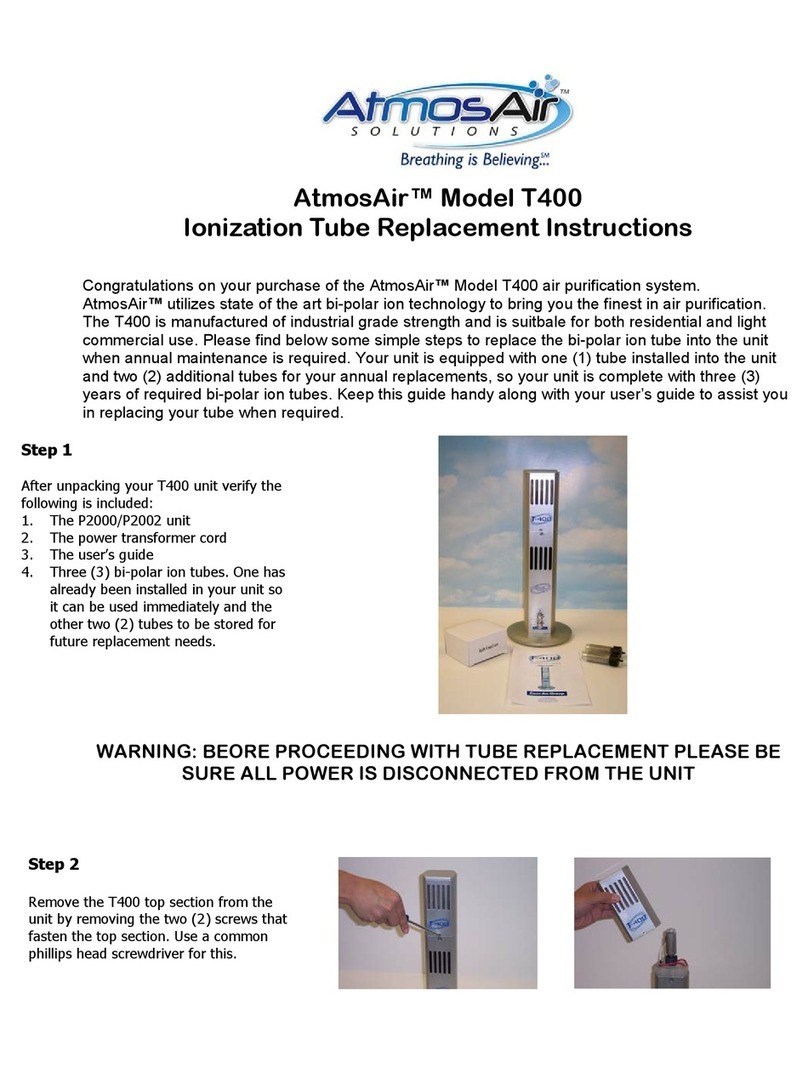

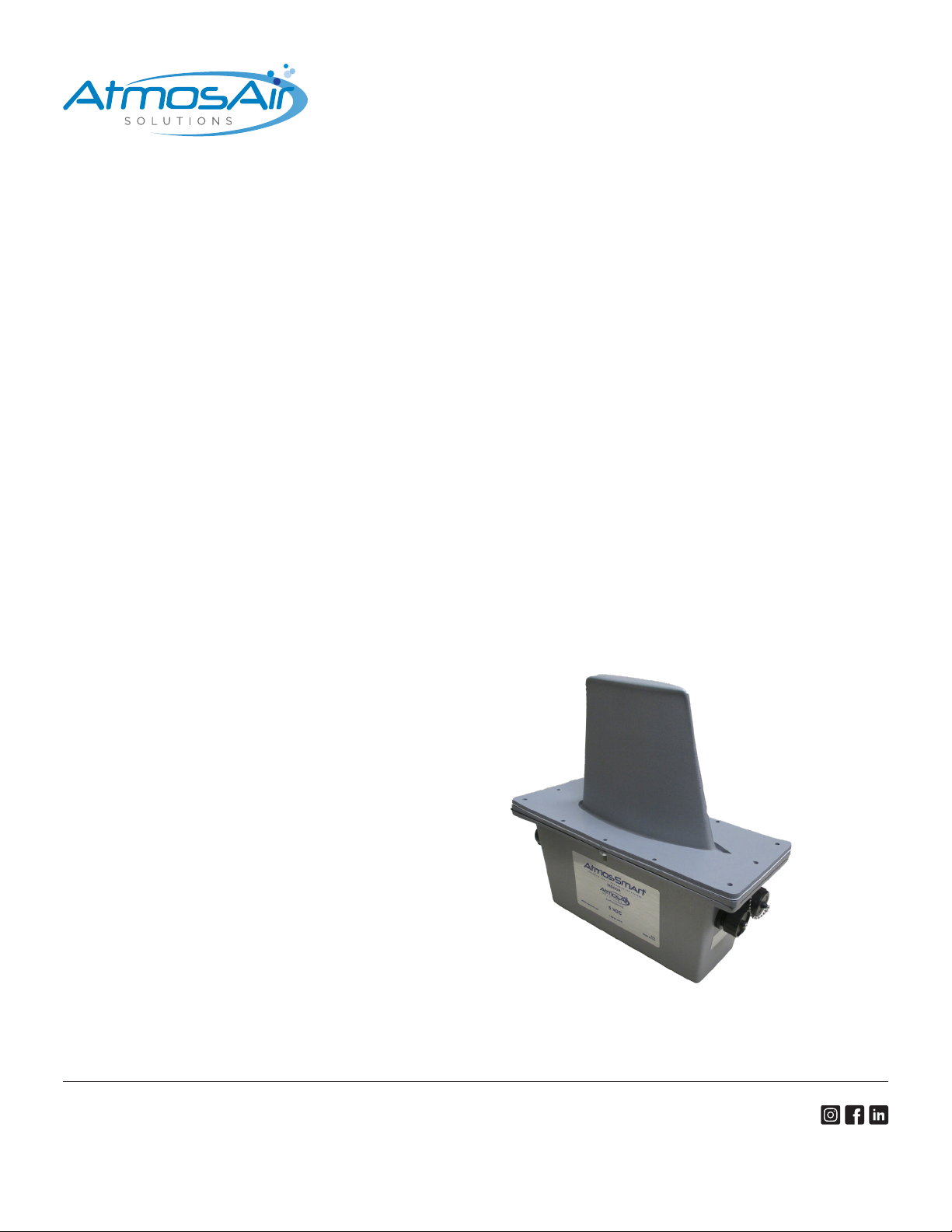

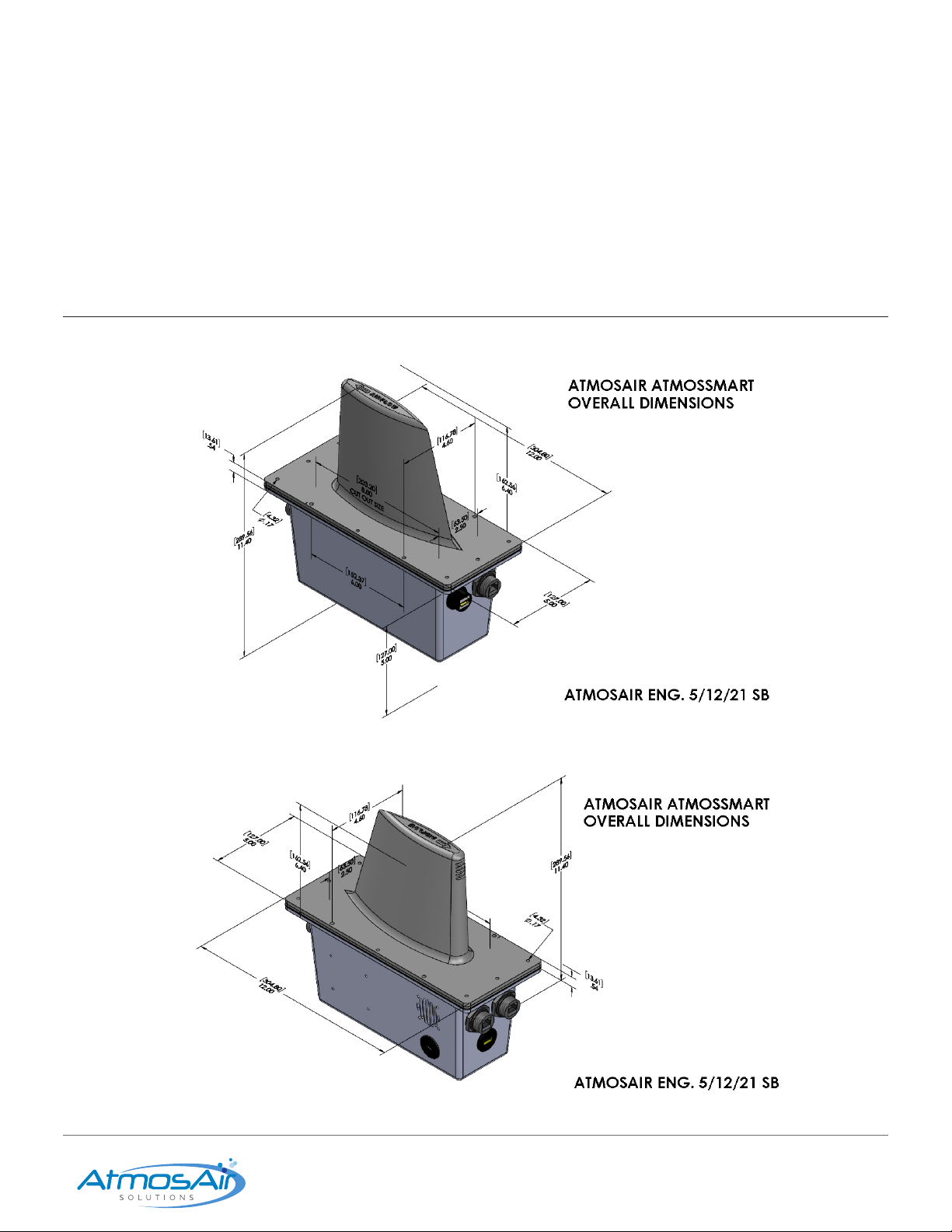

1. Determine centerline of return duct and or transition return duct, mark centerline.

2. Mounting locations shall be at least 4 feet or 1.25 m from lters, obstructions, re sensors, turning vanes or dampers.

3. The AtmosSmart™ aerodynamically shaped sensor head is designed to protrude through any internal insulation typically

found in a HVAC system, and allow a clear unimpeded path so that air can ow to and inside the sensor head.

4. Cut a 3” wide by 8” long (8 cm × 20.5 cm) rectangular slot in the bottom of the duct centered along the duct centerline.

5. It is permissible to cut an 8” long slit in the Fiberglas insulation matting within the duct. Alternately, the full size 3” × 8” (8 cm ×

20.5 cm) rectangular slot can be cut in the insulation.

6. In an EXTERIOR insulated duct, the insulation must be removed from a 6” wide × 13” (15cm × 33cm) long area on the marked

installation centerline.

Warning: This insulation must not interfere with cabling, receptacles, and metering fan airow from Sensor.

7. Attach the Sensor array using the 6 self-tapping screws provided.

8. Assure that the sealing gasket provided is seated securely so that the space between the tower and the duct is sealed and not

leaking. Do not overtighten more than is necessary to seal the gasket.

9. If installing an outside air probe, the air inlet, pictured in the illustration must be facing in towards the incoming outside air.

The probe can also be placed within the outside air plenum if accessible.

Installing AtmosAir 500 Series in a Duct

Note: Refer to the 500 series (or Matterhorn Series) IOM Manual for typical installation recommendations.

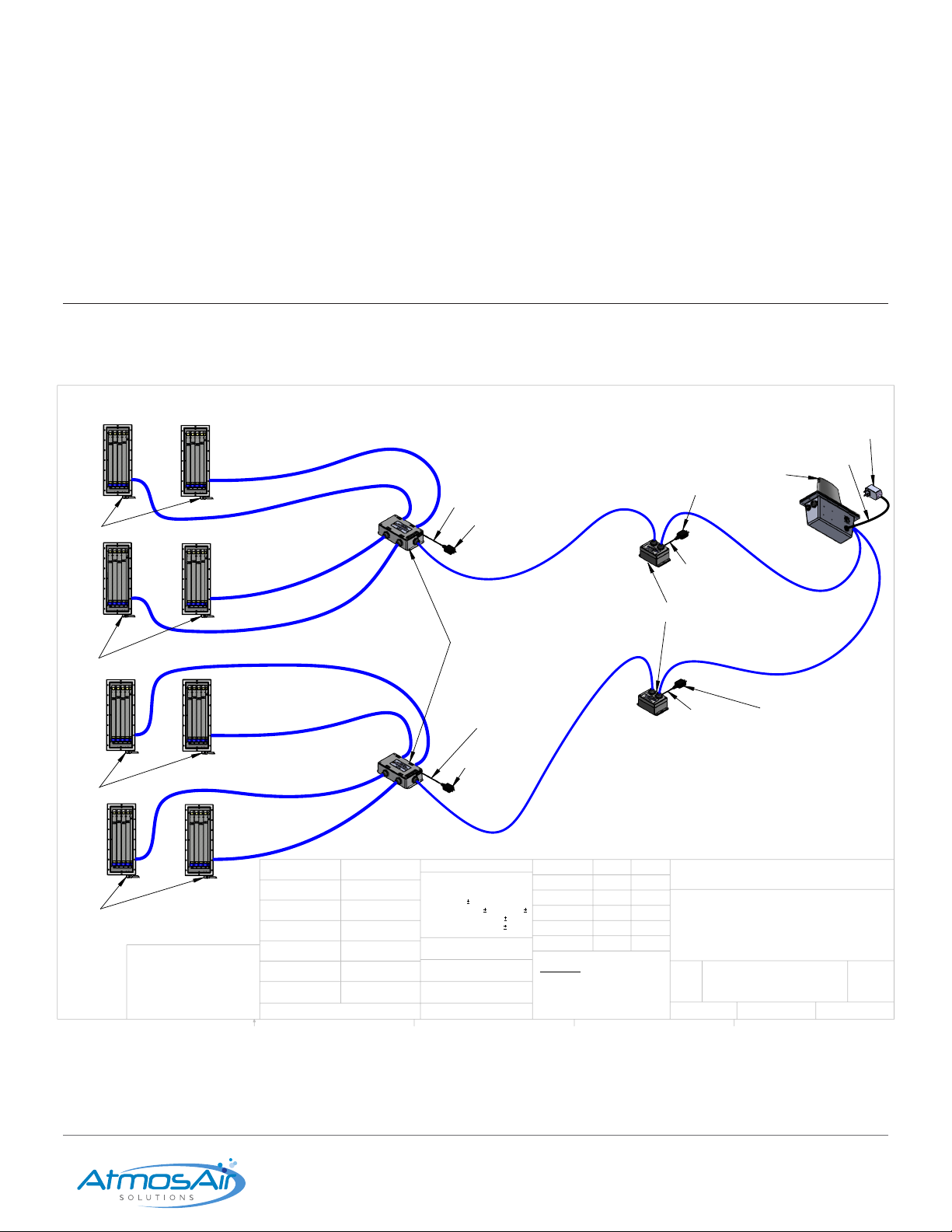

Each AtmosSmart™ enabled 500 series / Matterhorn Series unit has an AtmosComms2 controller module integrally installed. These

controller modules communicate with the sensor array and other 500 series units within the particular AHU in which they are

installed. To provide power to the BPI units as well as the sensor array, each 500 series and/or Matterhorn Series, unit has a 120 Vac /

240 Vac (nominal) power umbilical that should be connected to a dedicated 15-amp well- grounded service.

All AtmosSmart™ sensor arrays have a 120 V/ 240 V, 50/60 Hz small ‘brick-type’ transformer to provide stable, unuctuating power

to the unit’s internal computer. This transformer is provided with a standard plug suitable for the region/country in which the

AtmosAir system is to be installed. This can be dedicated to the same, well-grounded, 15-amp service to which the AtmosAir BPI

systems are connected.

Each 500 series/AtmosComms2 has a RJ-45/Cat5e receptacle in its casework; each unit shall be connected, using the cable

provided, to the input/output (I/O) connector for 1 and 2 BPI systems/arrays.

The I/O master controller module, Multiplier 4 (handling up to 8 BPI systems), may be mounted within the AHU, on its wall or

ceiling. The main Cat5e addressable cable will need to be run through the air handler wall; the wall is usually double thick 2” (5 cm)

and the hole can be formed utilizing a .75” (20 mm) drill. The pass-through hole should be sealed with a suitable sealant such as

silicone or mastic, at both walls of the AHU, running to the AtmosSmart™ Sensor.

The main addressable Cat5e cable from the I/O controller box, AtmosEXTender, may be no longer than 35’ (10.2 meters) and is to

be plugged into the port on the AtmosSmart™ sensor array. A run longer than 35’ requires am HMDI repeater for proper system

performance. It is recommended that that communication cable is secured via ‘P’ clips every 1 m.