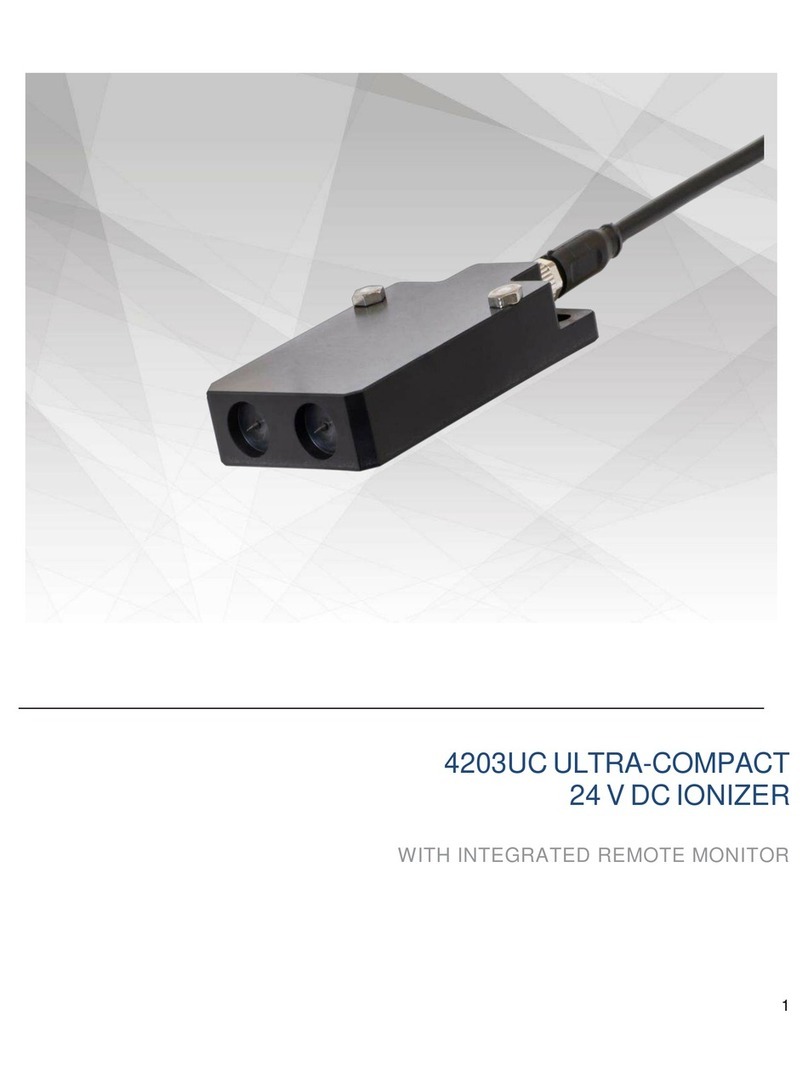

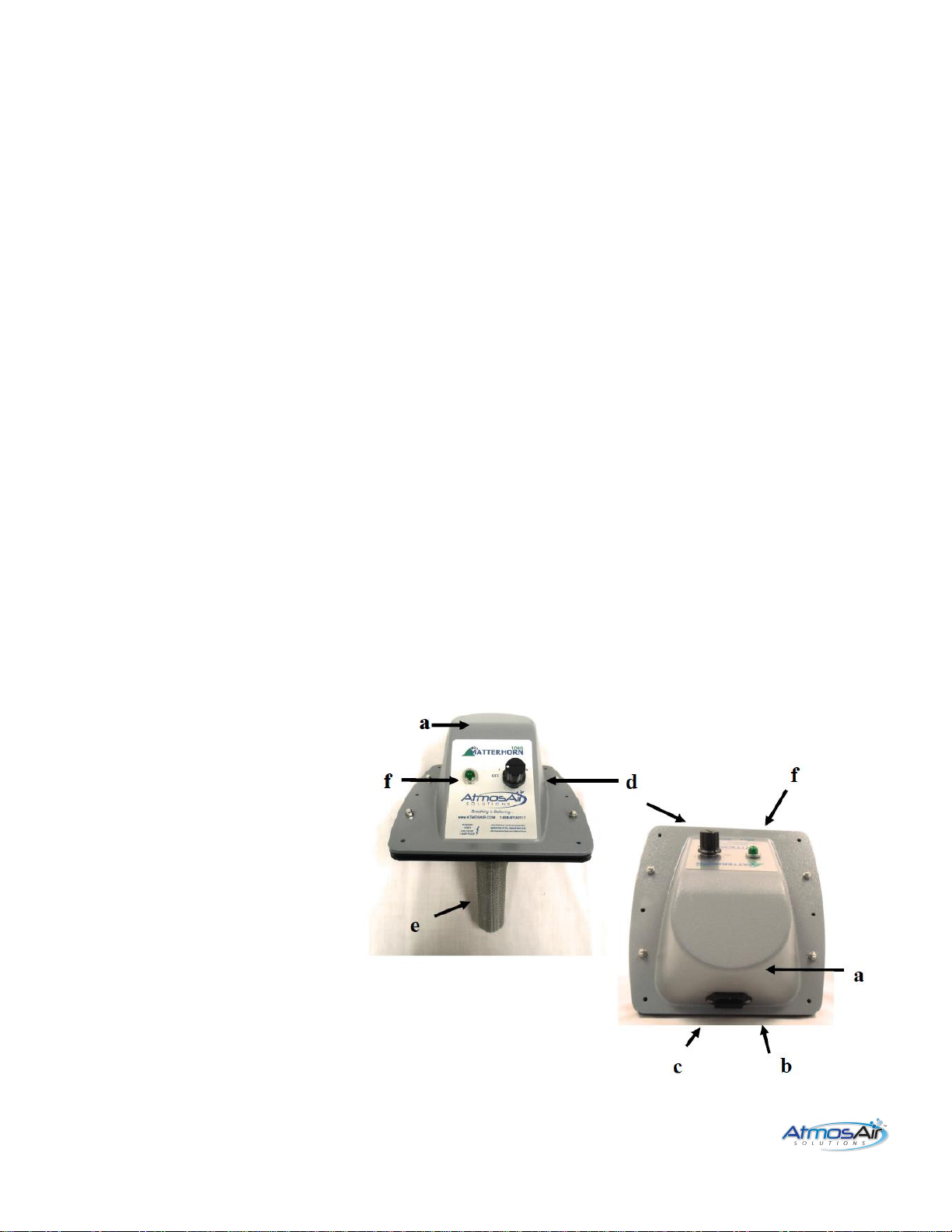

Installation

AtmosAir Matterhorn series equipment can be mounted in a duct or air handler wall, using the

faceplate mounting flange and its weather-strip gasket; or inside a plenum using a semi-custom

mounting bracket. The units operate best when located after all filters, coils, and fans. Various

mounting arrangements are possible; however, the available options may be limited due to size and

configuration restrictions.

When mounted on the side of a duct or air handler wall, the enclosure should not be exposed to

direct sunlight or moisture. If installing outside, a weatherproof enclosure with an access panel for

servicing should be installed over the AtmosAir equipment.

The AtmosAir Matterhorn series operates on 220~250 VAC, 50/60 Hz. The tube and electrode

contacts should not come into contact with any conductive surface. A minimum 101.60mm

clearance around the tube is recommended. All exposed metal parts are grounded.

Mechanical Installation

Carefully remove the equipment from its shipping container. Inspect the main components, gasket,

and tube(s) for damage. Verify that the unit’s voltage rating is the same as the available voltage,

220~250 VAC.

Install the ionization tube: Gently pull the conductor strap back to allow the tube to turn freely; screw

the end screw of the tube into the tube-holder hand-tight. Do not over-tighten the tube! Once the

tube is secure, return the conductor strap to its normal position and ENSURE SOLID CONTACT IS

MADE WITH THE TUBE’S OUTER MESH.

Location and Orientation: Install the unit downstream of filters, coils, and fans with tubes vertical

whenever possible. If multiple units are installed in the same duct, stagger the units in the airflow

so they are not in the same airflow path.

For in-duct installation: Verify the flange gasket is in place and in good shape to ensure the unit

seals properly. Make a cut-out in the duct sized at 139.70mm high x 152.40mm wide. A paper

template is included for ease of installation; use the lines to cut the cut-out hole, then trace the cut-

out and mark the locations of the mounting holes for the Matterhorn series.

Using the marked holes from the backer-plate template, affix the unit securely in the duct using self-

tapping screws (if not using backer-plate). Do not over-tighten, this may strip the screw-hole. The

unit is self-sealing to the duct so no further sealing is needed.

.