AUMA GK 10.2 User manual

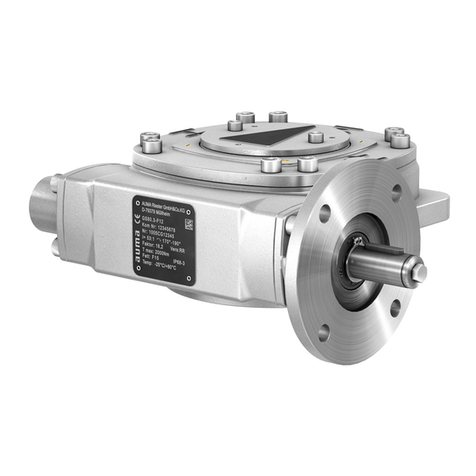

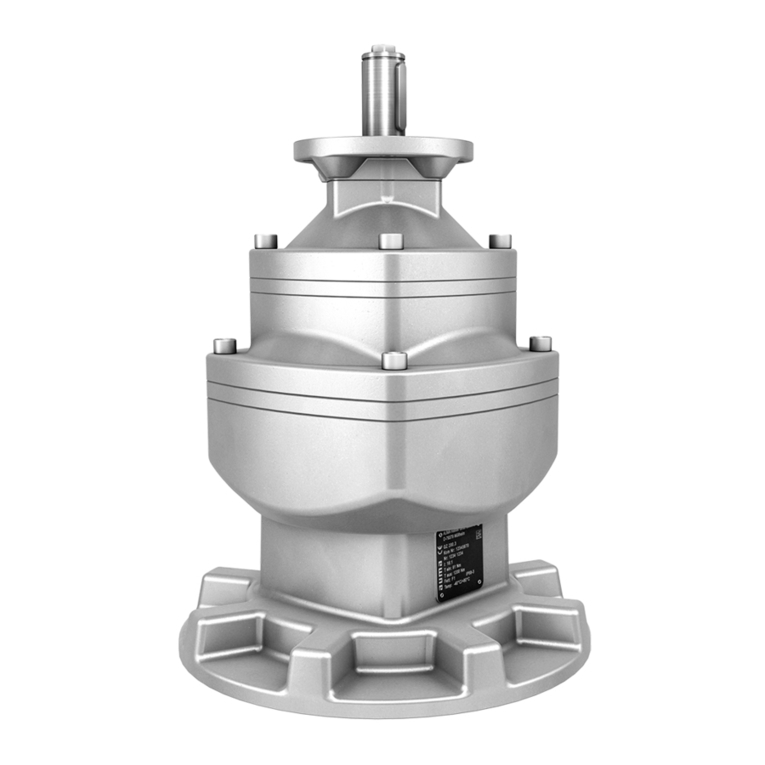

Multi-turn gearboxes

Bevel gearboxes

GK 10.2 – GK 40.2

Operation instructions

Table of contents Page

1. Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Range of application 3

1.2 Maintenance 3

1.3 Warnings and notes 3

2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Transport, storage and packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Transport 6

3.2 Storage 6

3.3 Packaging 6

4. Fitting the handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Mounting multi-turn actuators SA/SAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Mounting to valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Operation of valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8. Enclosure protection IP 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

9. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.1 General references 13

9.2 Change of grease 14

10. Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12. Spare parts list bevel gearboxes GK 10.2 – GK 25.2 . . . . . . . . . . . . . . . . . . . . . 16

13. Spare parts list bevel gearboxes GK 30.2 – GK 40.2 . . . . . . . . . . . . . . . . . . . . . 18

14. Declaration of Conformity and Declaration of Incorporation. . . . . . . . . . . . . . . . . 20

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Scope of these instructions: These instructions apply to multi-turn gearboxes of type range:

GK 10.2 – GK 40.2.

1. Safety instructions

1.1 Range of application AUMA bevel gearboxes GK 10.2 – GK 40.2 are used for the operation of

valves (e.g. gate valves and globe valves).

They are designed for manual operation as well as motor operation in

conjunction with electric actuators.

For other applications, please consult AUMA. The manufacturer is not liable

for any possible damage resulting from use in other than the designated

applications. Such risk lies entirely with the user.

Observance of these operation instructions is considered as part of the

designated use.

Explosion-proof products are specially marked. The service conditions

mentioned in these operation instructions and in the technical data sheet

have to be respected during use. Other service conditions require explicit

and written confirmation by the manufacturer.

1.2 Maintenance The maintenance instructions (refer to page 13) must be observed, other-

wise a safe operation of the bevel gearbox is no longer guaranteed.

1.3 Warnings and notes Failure to observe the warnings and notes may lead to serious injuries or

damage. Qualified personnel must be thoroughly familiar with all warnings

and notes in these operation instructions.

Correct transport, proper storage, mounting and installation, as well as

careful commissioning are essential to ensure a trouble-free and safe

operation.

The following references draw special attention to safety-relevant proce-

dures in these operation instructions. Each is marked by the appropriate

pictograph.

This pictograph means: Note!

“Note” marks activities or procedures which have major influence on the

correct operation. Non-observance of these notes may lead to consequen-

tial damage.

This pictograph means: Warning!

“Warning” marks activities or procedures which, if not carried out correctly

can affect the safety of persons or material.

3

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

2. Technical data

Features and functions

Type of duty Short-time duty S2 - 15 min (open-close duty)

Intermittent duty S4 - 25 % (modulating duty)

with the following maximum input speeds:

GK 10.2 – GK 16.2 ≤45 rpm for 50 Hz

GK 25.2 – GK 30.2 ≤11 rpm for 50 Hz

Direction of rotation Standard: Clockwise rotation at input shaft results in clockwise rotation at output shaft

Option: GK 10.2 – GK 25.2

Reversal of rotational direction using a reversing gearbox GW 14.1

GK 30.2 – GK 40.2

Alternatively, counterclockwise rotation of direction possible

Stages One stage: GK 10.2 – GK 25.2

Double stage: GK 30.2 – GK 40.2

Input shaft GK 10.2 – GK 25.2:

For standard reduction ratios, the input shaft is made of stainless steel.

Standard: Cylindrical with parallel key according to DIN 6885.1

Option1): Square: -tapered (DIN 3233)

-cylindrical

Output torques

Operation

Motor operation With electric multi-turn actuator, directly

Flanges for mounting the multi-turn actuator, refer to separate technical data sheets.

Manual operation Standard: Via handwheel, directly

Option: Remote lever arrangement (not included within the AUMA product range)

Valve attachment

Output drive types A, B1, B2, B3, B4 according to EN ISO 5210

A, B, D, E according to DIN 3210

C according to DIN 3338

Special output drive types: AF, AK, AG, IB1, IB3, IB4

1) For size, please contact AUMA

2) At max. output torque

3) Conversion factor for output torque to input torque

4

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Type Output torque Reduction ratio Input torque2) Factor3)

Nominal

torque

max. Nm

Modulating

torque

max. Nm

Nominal

torque

Nm

Modulating

torque

Nm

GK 10.2 120 60 1 : 1 135 66 0.9

2 : 1 67 33 1.8

GK 14.2 250 120 2 : 1 139 66 1.8

2.8 : 1 100 48 2.5

GK 14.6 500 200 2.8 : 1 198 80 2.5

4 : 1 139 55 3.6

GK 16.2 1 000 400 4 : 1 278 111 3.6

5.6 : 1 198 80 5.0

GK 25.2 2 000 800 5.6 : 1 397 160 5.0

8 : 1 278 111 7.2

GK 30.2 4 000 1 600 8 : 1 556 222 7.2

11 : 1 404 162 9.9

GK 35.2 8 000 – 11 : 1 808 – 9.9

16 : 1 556 – 14.4

GK 40.2 16 000 – 16 : 1 1,111 – 14.4

22 : 1 808 – 19.8

Type GK 10.2 GK 14.2 GK 14.6 GK 16.2 GK 25.2 GK 30.2 GK 35.2 GK 40.2

Handwheel

mm

315/

200

315/

250

400/

315

500/

400

630/

500 800 800 800

Service conditions

Mounting position Any position

Enclosure protection according

to EN 60 529

Standard: IP 67

Options: IP 68 (also refer to page 12)

Corrosion protection Standard: KN Suitable for installation in industrial units,

in water or power plants with a low pollutant concentration

Options: KS Suitable for installation in occasionally or permanently aggressive

atmosphere with a moderate pollutant concentration

(e.g. wastewater treatment plants, chemical industry)

KX Suitable for installation in extremely aggressive atmosphere with

high humidity and high pollutant concentration

Finish coating Standard: Two-component iron-mica combination

Colour Standard: AUMA silver-grey (similar to RAL 7037)

Option: Other colours on request

Ambient temperature Standard: –25 °C to + 80 °C

Options: –40 °C to + 60 °C (low temperature), version L

–60 °C to + 60 °C (extreme low temperature), version EL

– 0 °C to +120 °C (high temperature), version H

Lifetime Open-close duty: Operation (OPEN - CLOSE - OPEN) with 30 turns per stroke

GK 10.2: 20,000 operations

GK 14.2 – 16.2: 15,000 operations

GK 25.2 – 30.2: 10,000 operations

GK 35.2 – 40.2: 5,000 operations

Modulating duty4):

GK 10.2: 5.0 million modulating steps

GK 14.2 – 16.2: 3.5 million modulating steps

GK 25.2 – 30.2: 2.5 million modulating steps

Accessories

Limit switching Limit switching WSH for manually operated valves. For the signalisation of intermediate and

end positions (refer to separate data sheet).

Reversing gearboxes Reversing gearbox GW for reversing the rotation direction for manual and motor operation

Special features for use in potentially explosive atmospheres

Explosion protection II2G c IIC T4 in compliance with ATEX 94/9/EC

Type of duty5) During open-close duty:

Short-time duty S2 - 15 min. at 50 % of maximum nominal output torque up to GK 14.6

and at 35 % of maximum nominal output torque from GK 16.2

During modulating duty:

Intermittent duty S4 - 25 % at maximum modulating torque

Ambient temperature Standard: –20 °C to +40 °C

Options: –40 °C to +40 °C (low temperature)

–20 °C to +60 °C

–40 °C to +60 °C (low temperature)

–60 °C to +60 °C (extreme low temperature)

Combinations with actuators SAExC at ambient temperatures > 40 °C with special sizing.

Further information

Reference documents Product description Bevel gearboxes GK 10.2 – GK 40.2

Dimension sheet GK 10.2 – GK 40.2

Technical data GK 10.2 – GK 40.2

Technical data SA/SAR

Technical data GW

Technical data WSH

4) The lifetime for modulating duty depends on the load and the number of starts. A high starting frequency will rarely improve the modulating accuracy. To reach

the longest possible maintenance and fault-free operation time, the number of starts per hour chosen should be as low as permissible for the process

5) The type of duty must not be exceeded.

5

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

3. Transport, storage and packaging

3.1 Transport .Transport to place of installation in sturdy packing.

.If mounted together with actuator:

Attach ropes or hooks for the purpose of lifting by hoist only to the gearbox

and not to the actuator.

3.2 Storage .Store in well-ventilated, dry room.

.Protect against floor dampness by storage on a shelf or on a

wooden pallet.

.Cover to protect against dust and dirt.

.Apply suitable corrosion protection agent to bare surfaces.

In case gearboxes are to be stored for a long period (more than 6 months),

the following points must be observed additionally:

.Prior to storage: Protect bare surfaces, in particular the output drive parts

and mounting surface, with long-term corrosion protection agent.

.Check for corrosion approximately every 6 months. If first signs of corro-

sion show, apply new corrosion protection.

3.3 Packaging Our products are protected by special packaging for the transport ex works.

The packaging consists of environmentally friendly materials which can

easily be separated and recycled.

For the disposal of the packaging material, we recommend recycling and

collection centres.

We use the following packaging materials:

Wooden material boards (OSB)/cardboard/paper/PE film

4. Fitting the handwheel For gearboxes designed for manual operation, the handwheel is supplied

separately. Fitting is done on site according to figure 1.

6

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Figure 1: Handwheel

Ball handle

(option)

Spacer

(partly required)

Circlip

Handwheel

Gearbox input shaft

Circlip

Spacer

(partly required)

5. Mounting multi-turn actuators SA/SAR

When bevel gearboxes and multi-turn actuators are supplied together, the

mounting can be done in the factory up to gearbox size GK 16.2, if desired.

For sizes GK 25.2 and larger, the mounting of gearboxes is performed as

follows.

In case flange for actuator is not attached to gearbox:

.Thoroughly degrease the mounting faces of the gearbox and flange for

actuator.

.Fit flange for actuator and fasten with bolts and lock washers.

.Fasten bolts crosswise to the appropriate torque according to table 2.

Mounting the multi-turn actuator:

.Thoroughly degrease the faces of the bearing flange at actuator and of

the input flange at bevel gearbox..

.Place the multi-turn actuator on bevel gearbox.

The multi-turn actuator can be positioned on the valve at every 90°.

.Ensure that the spigot mates uniformly in the recess and that the

mounting faces are in complete contact.

.Fasten actuator with bolts and lock washers (see table 1) at the flange of

the bevel gearbox.

.Fasten bolts crosswise with a torque according to table 2.

Do not attach ropes or hooks for the purpose of lifting the

actuator by hoist to the handwheel. If multi-turn actuator is

mounted on gearbox, attach ropes or hooks for the purpose

of lifting by hoist to gearbox and not to multi-turn actuator.

7

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

Figure 2: Mounting multi-turn actuators onto bevel gearboxes

Flange for actuator

Bearing flange

Flange for actuator

Bearing flange

GK 30.2 – GK 40.2

GK 10.2 –

GK 25.2

8

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Gearbox SA/SAR 07.5-F10/G0 SA/SAR 10.1-F10/G0 SA/SAR 14.1-F14/G½

Bolt Lock washer Pcs. Bolt Lock washer Pcs. Bolt Lock washer Pcs.

GK 10.2 M10 x 25 B 10 4 M10 x 25 B 10 4 M16 x 40 B 16 4

GK 14.2 M10 x 25 B 10 4 M16 x 40 B 16 4

GK 14.6 M10 x 25 B 10 4 M16 x 40 B 16 4

GK 16.2 M16 x 40 B 16 4

GK 25.2 M16 x 40 B 16 4

Gearbox SA/SAR 14.5-F14/G½ SA/SAR 16.1-F16/G3 SA/SAR 25.1-F25/G4

Bolt Lock washer Pcs. Bolt Lock washer Pcs. Bolt Lock washer Pcs.

GK 16.2 M16 x 40 B 16 4

GK 25.2 M16 x 40 B 16 4

GK 30.2 M16 x 40 B 16 4 M20 x 50 B 20 4

GK 35.2 M16 x 40 B 16 4 M20 x 50 B 20 4

GK 40.2 M20 x 50 B 20 4 M16 x 50 B 16 8

Table 1: Bolts for mounting AUMA multi-turn actuators on bevel gearboxes

6. Mounting to valve The gearboxes can be operated in any mounting position.

.Prior to mounting, the gearbox must be checked for dam-

age. Damaged parts must be replaced by original spare

parts.

.After mounting to valve, touch up any possible damage to

paint finish.

.Check if mounting flange fits the gearbox.

Spigot at flanges should be loose fit!

The output drive types B1, B2, B3, or B4 (figure 3) are delivered with bore

and keyway (usually according to ISO 5210).

For output drive type A (figure 4), the internal thread of the stem nut must

match the thread of the valve stem. If not ordered explicitly with thread, the

stem nut is unbored or with pilot bore when delivered. For finish machining

of stem nut, refer to next page.

.Check whether bore and keyway match the input shaft of valve.

.Thoroughly degrease mounting faces of gearbox and valve.

.Apply a small quantity of grease to input shaft of valve.

.Place gearbox on valve and fasten. Fasten bolts (quality min. 8.8, refer to

table 2) evenly crosswise.

9

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

Figure 3

Output drive type B1/B2

Plug sleeve

Output drive type B3/B4

Bore with keyway

Thread

Fastening torque TA[Nm]

Strength class

8.8 A2-70/A4-70 A2-80/A4-80

M 8251824

M10 50 36 48

M12 87 61 82

M16 214 150 200

M20 431 294 392

M30 1 489 564 –

M36 2 594 – –

Table 2: Fastening torques for bolts

Finish machining of stem nut (output drive type A):

The output drive flange does not have to be removed from the gearbox.

.Remove spigot ring (80.2, figure 4) from mounting flange.

.Take off stem nut (80.3) together with thrust bearing (80.01) and thrust

bearing races (80.02).

.Remove thrust bearing and thrust bearing races from stem nut.

.Drill and bore stem nut and cut thread.

When fixing in the chuck, make sure stem nut runs true!

.Clean the machined stem nut.

.Apply Lithium soap EP multi-purpose grease to thrust bearing and races,

then place them on stem nut.

.Re-insert stem nut with thrust bearings into the mounting flange. Ensure

that dogs are placed correctly in the slots of the hollow shaft.

.Screw in spigot ring until it is firm against the shoulder.

.Press Lithium soap EP multi-purpose grease on mineral oil base into the

grease nipple with a grease gun (for quantities, please refer to table):

Protection tube for rising valve stem

.Seal thread of protection tube with hemp, Teflon tape, or thread sealing

material.

.Screw protection tube (1) into thread (figure 5) and tighten it firmly.

.Push down the sealing (2) to the housing.

.Check whether cap (3) is available and without damage.

10

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Output

drive A 07.2 A 10.2 A 14.2 A 16.2 A 25.2 A 30.2 A 35.2 A 40.2

Qty1) 1.5 g 2 g 3 g 5 g 10 g 14 g 20 g 25 g

1) For grease with density ρ= 0.9 kg/dm³

Table 3: Grease quantities bearings output drive type A

Figure 4

80.3

80.2

Output drive type A

Plug sleeve

80.01/80.02

3

1

2

Figure 5: Protection tube for rising valve stem

7. Operation of valves

The max. output torque (refer to technical data, page 4 or name plate) refers

to the peak values and should not be applied over the whole travel.

Clockwise rotation at input shaft results in clockwise rotation at output drive

For motor operation:

.Observe operation instructions pertaining to multi-turn actuator.

.The setting of the torque switching within the multi-turn actuator may not

exceed the max. permissible input torque for both directions (refer to tech-

nical data, page 4, or name plate).

.Set the torque switching within the multi-turn actuator to the following

value to prevent any damage to the valve:

TValve

TTorque switch =

Factor

Factor = Conversion factor from output torque to input torque.

Refer to values in technical data, page 4.

11

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

8. Enclosure protection IP 68

Definition According to EN 60 529, the conditions for meeting the requirements of

enclosure protection IP 68 are to be agreed between manufacturer and

user.

AUMA gearboxes in enclosure protection IP 68 fulfil the following require-

ments in compliance with AUMA definitions:

.Head of water max. 6 m.

If submersed in other media, additional measures for corrosion protection

may be necessary; please consult AUMA. Submersion in aggressive media,

e.g. acids or alkaline solutions, is not permitted.

Inspection AUMA gearboxes in enclosure protection IP 68 undergo a routine testing for

tightness in the factory.

After submersion .Check gearbox.

.In case of ingress of water, dry actuator correctly and check for proper

function.

Notes .The enclosure protection IP 68 refers to the interior of the gearbox.

.If the gearboxes are likely to be repeatedly submersed, a higher corrosion

protection KS or KX is required.

.We strongly recommend to select the higher corrosion protection KS or

KX for gearboxes for buried service.

.Use suitable sealing material between valve flange and gearbox.

.Stem protection tubes and telescopic protection tubes should not be used

during submersion, instead use a screw plug made of aluminium.

.When using output drive types A and AF (stem nut), it cannot be

prevented that during submersion water enters the bore of the hollow shaft

along the thread of the valve stem. This leads to corrosion. The water also

enters the thrust bearings of output drive type A, causing corrosion and

damage of the bearings. The output drive types A and AF should therefore

not be used for gearboxes in enclosure protection IP 68.

.For submersion in water, AUMA recommends to use grease suitable for

use in drinking water.

.For continuous submersion, the seals should be changed at shorter inter-

vals.

12

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

9. Maintenance

9.1 General references After commissioning, check gearbox for damage to paint finish.

Do a thorough touch-up to prevent corrosion.

Original paint in small quantities can be suppled by AUMA.

AUMA gearboxes require only very little maintenance.

To ensure that the gearbox is always ready to operate, we recommend –

provided that on an average not more than 10 operations are performed per

year – the following measures:

.Approximately six months after commissioning and then every year check

bolts between multi-turn actuator, gearbox, and valve for tightness. If

required, tighten applying the torques given in table 2, (page 9).

.Perform a test run as well as a visual inspection for grease leakage every

six months.

.Carry out a detailed functional test for each gearbox every 5 years.

Record the results for future reference.

.For gearboxes permanently exposed to ambient temperatures above

40 °C, maintenance must be performed at shorter intervals.

.For gearboxes with output drive type A: At intervals of approx. six months

from commissioning, press in Lithium soap EP multi-purpose grease on

mineral oil base at the grease nipple with grease gun (for quantity, refer to

table 3, page 10).

Seals:

The seals must be changed when changing the grease.

Seal kits may be obtained from AUMA.

Grease:

A grease and seal change is recommended after the following operation

times:

.if operated seldom, after 10 – 12 years

.if operated frequently, after 6 – 8 years

.Only original AUMA grease must be used.

.For the grease type, refer to name plate.

.Lubricants should not be mixed.

The removed lubricant and the cleaning agent used must be

disposed of according to the relevant regulations.

For safe operation of explosion-proof products, the gear

housing has to be lubricated in compliance with the manu-

facturer specifications. In the event of lubricant loss, repair

measures have to be initiated without delay.

13

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

GK 10.2 14.2 14.6 16.2 25.2 30.2 35.2 40.2

Qty dm³ 0.33 0.66 0.66 1.1 4.1 14.1 20.0 22.2

Weight1) kg 0.3 0.6 0.6 1.0 3.7 12. 18.2 20.2

1) for ρ= approx. 0.9 kg/dm3

Table 4: Grease quantities for bevel gearboxes

9.2 Change of grease .For gearboxes with multi-turn actuator: Remove multi-turn actuator.

.Remove gearbox from valve:

During this time, the valve/pipeline must not be under pres-

sure!

.Mark position of the gearbox on the valve, loosen connecting bolts to the

valve and remove the gearbox.

Remove old grease:

Grease type, see name plate; grease quantities see page 13, table 4.

The numbers used in the following text refer to the spare parts list(s) of

these operation instructions.

.Remove bolts at bearing flange (002.1).

.Remove bearing flange with hollow shaft (002.2) from housing.

.Remove old grease completely from the housing and the individual parts

and clean gear housing. For this purpose, kerosene or a similar cleaning

agent may be used.

.Replace seals S1(008, 009, 012, 016 or 007, 008, 010, 013) by new ones.

.Clean mounting faces at housing and bearing flange and apply a small

quantity of grease.

.Mount bearing flange (002.1) with hollow shaft (002.2) into housing, whilst

paying attention to the O-ring S1(008 or 009) at bearing flange and O-ring

S1(012 or 013) in the housing.

Screw in bolts with lock washers and fasten them evenly crosswise to the

appropriate torque according to table 2, page 9.

Fill with new grease f:

.Remove screw plug (539.0) at housing.

.Fill with new grease.

.Clean mounting faces at housing and insert screw plug (539.0) with new

sealing S1(014) and fasten them to the appropriate torque according to

table 2, page 9.

After maintenance:

.Fasten gearbox to valve again.

.If applicable, mount multi-turn actuator.

.For gearboxes with multi-turn actuator, check the setting of the limit

switching according to the operation instructions for multi-turn actuators; if

required, re-set.

.Perform test run to ensure proper function.

.Check the gearbox for damage to paint finish. Do a thorough touch-up to

prevent corrosion. Original paint in small quantities can be supplied by

AUMA.

14

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

10. Disposal and recycling

AUMA gearboxes have an extremely long lifetime. However, they have to be

replaced at one point in time.

Our gearboxes have a modular design and may therefore easily be disas-

sembled, separated and sorted according to materials, i.e.:

.various metals

.plastics

.greases and oils

The following generally applies:

.Collect greases and oils during disassembly. As a rule, these substances

are hazardous to water and must not be released into the environment.

.Arrange for controlled waste disposal of the disassembled material or for

separate recycling according to materials.

.Observe the national regulations for waste disposal.

11. Service AUMA offers extensive services such as maintenance and inspection for

gearboxes. Addresses can be found on page 22 et seqq. and on the Internet

(www.auma.com).

15

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

12. Spare parts list bevel gearboxes GK 10.2 – GK 25.2

16

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Note: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original

AUMA spare parts may be used. Failure to use original spare parts voids the warranty and exempts AUMA from any

liability. Delivered spare parts may slightly vary from the representation.

17

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

No. Designation Type

001.0 Housing Sub-assembly

002.0 Bearing flange Sub-assembly

003.0 Hollow shaft Sub-assembly

005.0 Input shaft Sub-assembly

005.1 Pinion shaft Sub-assembly

511.0 Screw plug Sub-assembly

512.0 Flange for actuator Sub-assembly

513.1 Grub screw

514.0 Output drive form A (without stem nut) Sub-assembly

514.1 Axial needle roller bearing Sub-assembly

516.1 Output drive shaft D

535.1 Snap ring

539.0 Screw plug Sub-assembly

549.1 Output socket B3/B4/E Sub-assembly

551.1 Parallel key

568.1 Stem protection tube (without cap)

568.2 Cap for stem protection tube

568.3 V-seal

574.1 Radial seal output drive A for ISO flange

575.1 Stem nut type A

S1 Seal kit Set

13. Spare parts list bevel gearboxes GK 30.2 – GK 40.2

18

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Note: Please state type and commission no. of the device (see name plate) when ordering spare parts. Only original

AUMA spare parts may be used. Failure to use original spare parts voids the warranty and exempts AUMA from any

liability. Delivered spare parts may slightly vary from the representation.

19

Operation instructions Bevel gearboxes GK 10.2 – GK 40.2

No. Designation Type

001.0 Housing Sub-assembly

001.1 Ring nut

002.0 Bearing flange Sub-assembly

003.0 Hollow shaft Sub-assembly

005.0 Input shaft Sub-assembly

005.1 Pinion shaft Sub-assembly

018.0 Intermediate stage Sub-assembly

511.0 Screw plug Sub-assembly

512.0 Flange for actuator Sub-assembly

513.1 Grub screw

514.0 Output drive form A (without stem nut) Sub-assembly

514.1 Axial needle roller bearing, from GK 35.2: axial cylinder roller bearing Sub-assembly

516.1 Output drive shaft D

535.1 Snap ring

539.1 Screw plug Sub-assembly

549.1 Output socket B3/B4/E

551.1 Parallel key

568.1 Stem protection tube (without cap)

568.2 Cap for stem protection tube

568.3 V-seal

574.1 Radial seal output drive A for ISO flange

575.1 Stem nut type A

S1 Seal kit Set

14. Declaration of Conformity and Declaration of Incorporation

20

Bevel gearboxes GK 10.2 – GK 40.2 Operation instructions

Other manuals for GK 10.2

2

This manual suits for next models

7

Table of contents

Other AUMA Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB SACE Emax 2 E1.2 Instruction handbook

Hunter

Hunter Revolution Series Operation instructions

Spectris

Spectris PARTICLE MEASURING SYSTEMS HPGP 101-C Operation manual

Siemens

Siemens SITOP UPS501S operating instructions

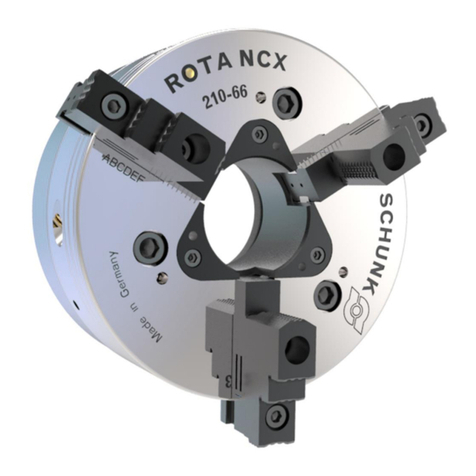

SCHUNK

SCHUNK ROTA NCX Assembly and operating manual

Kitagawa

Kitagawa BS300 instruction manual