AUMA GS 315 User manual

Part-turn gearboxes

GS 315 –GS 500

Primary reduction gearing

GZ 30.1 –GZ 40.1

Assembly and commissioningOperation instructions

Read operation instructions first.

●Observe safety instructions.

●These operation instructions are part of the product.

●Store operation instructions during product life.

●Pass on instructions to any subsequent user or owner of the product.

Target group:

This document contains information for assembly, commissioning and maintenance staff.

Table of contents Page

41. Safety instructions................................................................................................................. 41.1. Basic information on safety 51.2. Range of application 51.3. Warnings and notes 51.4. References and symbols

72. Identification........................................................................................................................... 72.1. Name plate 92.2. Short description

103. Transport and storage........................................................................................................... 103.1. Transport 123.2. Storage

134. Assembly................................................................................................................................ 134.1. Mounting position 134.2. Handwheel fitting 134.3. Multi-turn actuators for motor operation 144.3.1. Mounting positions Multi-turn actuators with part-turn gearboxes 154.3.2. Mount input mounting flange 174.4. Mount gearbox to valve 174.4.1. Overview on coupling variants 174.4.2. Mount gearbox with coupling to valve

205. Indications.............................................................................................................................. 205.1. Mechanical position indicator/running indication

216. Commissioning...................................................................................................................... 216.1. End stops in gearbox 216.1.1. Set end stop CLOSED (butterfly valves) 226.1.2. Set end position OPEN (butterfly valves) or modify swing angle at gearbox 246.2. Seating in end positions via multi-turn actuator 246.3. Set mechanical position indicator

267. Servicing and maintenance................................................................................................... 267.1. Preventive measures for servicing and safe operation 267.2. Maintenance intervals 267.3. Disposal and recycling

288. Technical data......................................................................................................................... 288.1. Technical data Part-turn gearboxes

2

GS 315 –GS 500

Table of contents GZ 30.1 –GZ 40.1

319. Spare parts............................................................................................................................. 319.1. Part-turn gearboxes GS 315 –GS 500 339.2. Primary reduction gearing for GS 315 –GS 500

35Index........................................................................................................................................

3

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Table of contents

1. Safety instructions

1.1. Basic information on safety

Standards/directives Our products are designed and manufactured in compliance with recognised

standards and directives.This is certified in a Declaration of Incorporation and an

EU Declaration of Conformity.

The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

Safetyinstructions/warn-

ings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out exclusively by suitably qualified personnel having been authorised by

the end user or contractor of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant are responsible

for respect and control of these regulations, standards, and laws.

Electrostatic charging Highly efficient charge generating processes (processes more efficient than manual

friction) on the device surface must be excluded at any time, since they will lead to

propagating brush discharges and therefore to ignition of a potentially explosive

atmosphere.

This also applies to fireproof coatings or covers available as an option.

Commissioning Prior to commissioning, it is important to check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage.Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe the national regulations.

●During operation,the devicewarms up and increased surfacetemperaturemay

occur.To prevent possible burns, we recommend checking the surface temper-

ature using an appropriate thermometer and wearing protective gloves, if re-

quired, prior to working on the device.

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior written consent of the manufacturer.

4

GS 315 –GS 500

Safety instructions GZ 30.1 –GZ 40.1

1.2. Range of application

AUMA part-turn gearboxes are designed for the operation of industrial valves, e.g.

butterfly valves and ball valves.

Other applications require explicit (written) confirmation by the manufacturer.

The following applications are not permitted, e.g.:

●Industrial trucks according to EN ISO 3691

●Lifting appliances according to EN 14502

●Passenger lifts according to DIN 15306 and 15309

●Service lifts according to EN 81-1/A1

●Escalators

●Continuous duty (S1 in accordance with IEC 60034–1)

●Modulating duty (class D according to EN 15714-2: Continuous modulating)

●Radiation exposed areas in nuclear power plants

●Potentially explosive atmospheres, except the explosion-proof version is explicitly

specified on the name plate

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the device's

designated use.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Wiring diagram Texts extracted from other documents

Texts extracted from other documents are highlighted in a different font.For example

Wiring diagram.

5

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Safety instructions

➥Result of a process step

Describes the result of a preceding process step.

6

GS 315 –GS 500

Safety instructions GZ 30.1 –GZ 40.1

2. Identification

2.1. Name plate

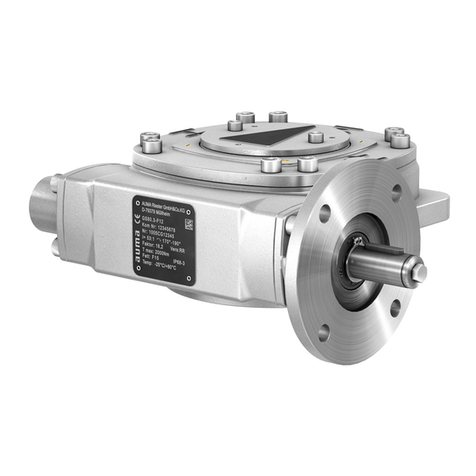

Figure 1: Name plate arrangement

[1] Gearbox name plate

Gearbox name plate

Swing angle

Figure 2: Gearbox name plate (example GS 315)

[1] Name of manufacturer

[2] Address of manufacturer

[3] Type designation - valve attachment (flange)

[4] Order number

[5] Serial number

[6] Reduction ratio

[7] Factor

[8] Max. valve torque (output torque)

[9] Type of lubricant

[10] Permissible ambient temperature

[11] Explosion-proof version (option)

[12] Can be assigned as an option upon customer request

[13] Enclosure protection

[14] Version

[15] Swing angle

[16] Data Matrix code

7

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Identification

Descriptions referring to name plate indications

Type designation Figure 3:Type designation (example)

1. Type and size of gearbox

2. Flange size for valve attachment

Type and size

These instructions apply to the following device types and sizes:

Part-turn gearboxes type GS, sizes 315 –500

Order number The product can be identified using this number and the technical data as well as

order-related data pertaining to the device can be requested.

Please always state this number for any product inquiries.

On the Internet at http://www.auma.com > Service & Support > myAUMA, we offer

a service allowing authorised users to download order-related documents such as

wiring diagramsand technical data (both in Germanand English), inspection certificate

and the operation instructions when entering the order number.

Serial number Description of serial number (example of 0520CG12345)

CG123452005

Positions 1 + 2 : Assembly in week = week 0505

Positions 3+4:Year of manufacture = 202020

Internal number for unambiguous product identificationCG12345

Reduction ratio The reduction ratio within gearing and primary reduction gearing reduces the required

input torques and increases the operating time.

Factor Mechanical conversion factor for actuator size determination:

Input torque = required valve torque (output torque)/factor

Type of lubricant AUMA abbreviation for type of lubricant used in the gear housing.

Danger of explosion when using inappropriate lubricant in potentially explosive

atmospheres!

→Do not use gearboxes with F21 lubricant in potentially explosive atmospheres.

→Do not mix different lubricants.

Explosion-proof version

(option) Gearboxes may only be used in potentially explosive atmospheres if explosion-proof

version is indicated on the name plate. In explosion-proof version, other (reduced)

valve torques and input speeds apply than in weatherproof version.

Version The first letter of the version indicates the position of the worm shaft in relation to

the worm wheel (view on input shaft).

The second letter indicates the direction of rotation at the output drive (view on

housing cover) for clockwise rotation at the input shaft.

8

GS 315 –GS 500

Identification GZ 30.1 –GZ 40.1

Versions:Worm shaft position and direction of rotation of output drive GS 315 –GS 500

LRRLLLRR

Description of the four different versions (view on housing cover):

Direction of rotation at output drivePosition of worm shaftDirection of rotation at input shaftInitials

R= ClockwiseR= RightClockwiseRR

L= CounterclockwiseL= LeftClockwiseLL

L= CounterclockwiseR= RightClockwiseRL

R= ClockwiseL= LeftClockwiseLR

Data Matrix code Whenregistered as authoriseduser,youmayuse our AUMA Assistant App to scan

the Data Matrix code and directly access the order-related product documents without

having to enter order number or serial number.

Figure 4: Link to AUMA Assistant App:

For further Service & Support, software/apps/... refer to www.auma.com.

2.2. Short description

GS part-turn gearboxes are worm gearboxes, converting a rotary movement at the

input shaft into a part-turn movement at the output drive.The worm gearboxes are

driven either via electric motor (by means of a multi-turn actuator) or manually (e.g.

via a handwheel).The required input torques are reduced due to high reduction

ratios within the gearbox.Internal, mechanical end stops limit the swing angle at the

output drive side to 0 ° –135 ° (adjustable).

Worm gearboxes are available in different versions to comply with various mounting

requirements and rotary directions.

9

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Identification

3. Transport and storage

3.1. Transport

For transport to place of installation, use sturdy packaging.

The coupling is not secured within the gearbox. Risk of falling out!

Injury hazard.

→Remove coupling from gearbox housing prior to transport.

→Bores within the coupling allow the use of eyebolts for separate transport.Ensure

that eyebolts are firmly tightened.

Figure 5: Coupling

Hovering load!

Risk of death or serious injury!

→Do NOT stand below hovering load.

→Check eyebolts for tight seat in housing (verify reach of the screw).

→Observe manufacturer specifications for fixing lifting straps and round slings.

→Respect total weight of combination (gearbox, primary reduction gearing).

→Eyebolts are exclusively permitted for the weight of the represented arrange-

ments (gearboxes and primary reduction gearings) of the respective sizes

(gearboxes and primary reduction gearings).

→Secure load against falling down, sliding or tilting.

→Perform lift trial at low height to eliminate any potential danger e.g.by tilting.

General notes

Actuators for worm gearboxes GS 315 –GS 500 are always supplied separately

when leaving the factory and must be transported and lifted separately. For further

information, refer to operation instructions pertaining to actuator.

GS 315 –GS 500

Gearbox sizes 315–500 leave the factory with two eyebolts.The gearboxes are

suspended horizontally or vertically using the two eyebolts.The suspension also

applies to gearboxes with mounted GZ primary reduction gearing.

10

GS 315 –GS 500

Transport and storage GZ 30.1 –GZ 40.1

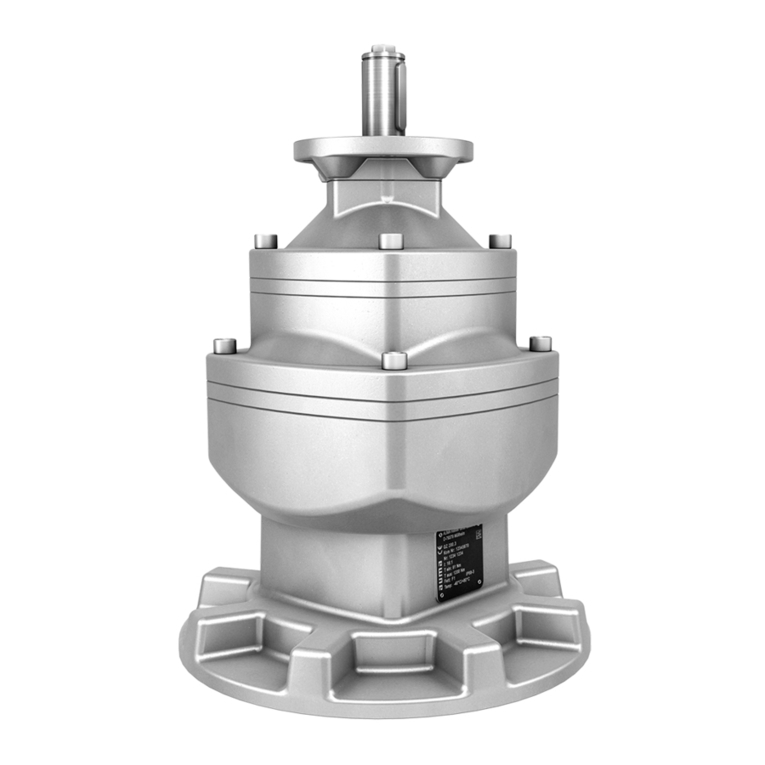

Figure 6: Examples of horizontal and vertical suspension of GS 315 –GS 500

[1] Horizontal suspension

[2] Vertical suspension

GS 315 only

In addition, GS 315 can also be vertically lifted using a combination of an eyebolt

with a round sling.

This type of suspension is only permitted for GS 315 type gearboxes without

primary reduction gearing. Suspension using an eyebolt without round sling

is not permitted.

Figure 7: Example of vertical suspension of GS 315

[1] Permissible:Vertical suspension via eyebolt and round sling

[2] Not permissible:Vertical suspension without round sling

11

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Transport and storage

Table 1:

Gearbox weight with coupling (without bore),grease filling in the gear housing and the smallest

flange size

Weight [kg]Type

520GS 315

630GS 315/GZ 30.1

980GS 400

1,100GS 400/GZ 35.1

1,800GS 500

2,000GS 500/GZ 40.1

2,030GS 500/GZ 16.1 + GZ 40.1

3.2. Storage

Danger of corrosion due to inappropriate storage!

→Store in a well-ventilated, dry room (maximum humidity 70 %).

→Protect against floor dampness by storage on a shelf or on a wooden pallet.

→Cover to protect against dust and dirt.

→Apply suitable corrosion protection agent to uncoated surfaces.

Long-term storage For long-term storage (more than 6 months), observe the following points:

1. Prior to storage:

Protect uncoated surfaces, in particular the output drive parts and mounting

surface, with long-term corrosion protection agent.

2. At an interval of approx. 6 months:

Check for corrosion.If first signs of corrosion show, apply new corrosion protec-

tion.

12

GS 315 –GS 500

Transport and storage GZ 30.1 –GZ 40.1

4. Assembly

4.1. Mounting position

The product described in this document can be operated without restriction in any

mounting position.

Damage due to radial forces!

Risk of gear damage for applications requiring transmission of radial forces to the

input shaft.

→In these cases, do NOT directly mount connection shaft to input shaft but fit a

coupling or a cardan shaft to the input shaft.

4.2. Handwheel fitting

Gearboxes designed for manual operation are supplied with a separate handwheel.

Fitting is performed on site according to the description below.

Figure 8: Handwheel (example)

[1] Retaining ring for input shaft (partly required)

[2] Gear input shaft

[3] Spacer (partly required)

[4] Handwheel

[5] Spacer (partly required)

[6] Retaining ring

[7] Ball handle

1. For input shafts with keyway: Place retaining ring [1] onto input shaft [2].

2. If required, fit spacer [3].

3. Slip handwheel [4] onto input shaft.

4. If required, fit spacer [5].

5. Secure handwheel [4] using the retaining ring [6] supplied.

6. Fit ball handle [7] to handwheel.

4.3. Multi-turn actuators for motor operation

Refer to the operation instructions pertaining to the multi-turn actuator for indications

on how to mount multi-turn actuators to gearboxes.

13

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Assembly

This chapter supplies basic information and instructions which should be considered

in addition to the operation instructions of the multi-turn actuator.

Screws to actuator

Screws are included in the scope of delivery of the gearbox for mounting AUMA

multi-turn actuators.When mounting other actuators, the screws might be either too

long or too short (insufficient reach of screws).

Risk of actuator falling off in case inappropriate screws used should shear.

Risk of death or serious injury!

→Check length of screws.

→Only use screws with strength class specified herein.

The reach of screws must be sufficient for the internal threads to ensure the

supporting strength of the device and to accept the lateral forces due to the applied

torque.

Screws which are too long could make contact with the housing parts, presenting

the risk that the device performs a radial shift with respect to the gearbox.This can

lead to shearing of the screws.

4.3.1. Mounting positions Multi-turn actuators with part-turn gearboxes

Mounting positions A –D for multi-turn actuators with part-turn gearboxes

BA

DC

The mounting positions are not available for all sizes/reduction ratios. Risk of

crushing due to insufficient distance between handwheel ball handle and the

housing for certain sizes.

14

GS 315 –GS 500

Assembly GZ 30.1 –GZ 40.1

Please consider possible space confinements on site when selecting the mounting

position.

Mounting positions may easily be changed at a later date.

4.3.2. Mount input mounting flange

An input mounting flange is required for mounting a multi-turn actuator. Depending

on the version, the flange for mounting the multi-turn actuator is already fitted in the

factory.

Table 2:

Suitable input mounting flanges

Input mounting flange for mounting multi-turn actuatorsInput shaftReduction ratioGearboxes

DIN 3210EN ISO 5210[mm]

–F306053:1GS 315

G3F1640212:1GS 315/GZ 30.1 - 4:1

G1/2F1430/40424:1GS 315/GZ 30.1 - 8:1

G1/2F1430/40848:1GS 315/GZ 30.1 - 16:1

G0F10201,696:1GS 315/GZ 30.1 - 32:1

G0F10202,120.1GS 315/GZ 30.1 - 40:1

–F358054:1GS 400

G4F2550216:1GS 400/GZ 35.1 - 4:1

G3F1640324:1GS 400/GZ 35.1 - 6:1

G3F1640432:1GS 400/GZ 35.1 - 8:1

G1/2F1430432:1GS 400/GZ 35.1 - 8:1

G1/2F14

30

864:1GS 400/GZ 35.1 - 16:1

G1/2F141,728:1GS 400/GZ 35.1 - 32:1

–F4010052:1GS 500

–F2540416:1GS 500/GZ 40.1 - 8:1

G3F1640832:1GS 500/GZ 40.1 - 16:1

G1/2F14

30

1,664:1GS 500/GZ 40.1 - 32:1

G1/2F142,340:1GS 500/GZ 40.1 - 45:1

G1/2F143,328:1

GS500/GZ 16.1 (4:1) +GZ

40.1 (16:1) - 64:1

Assembly steps 1. Clean mounting faces, thoroughly degrease uncoated mounting surfaces.

15

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Assembly

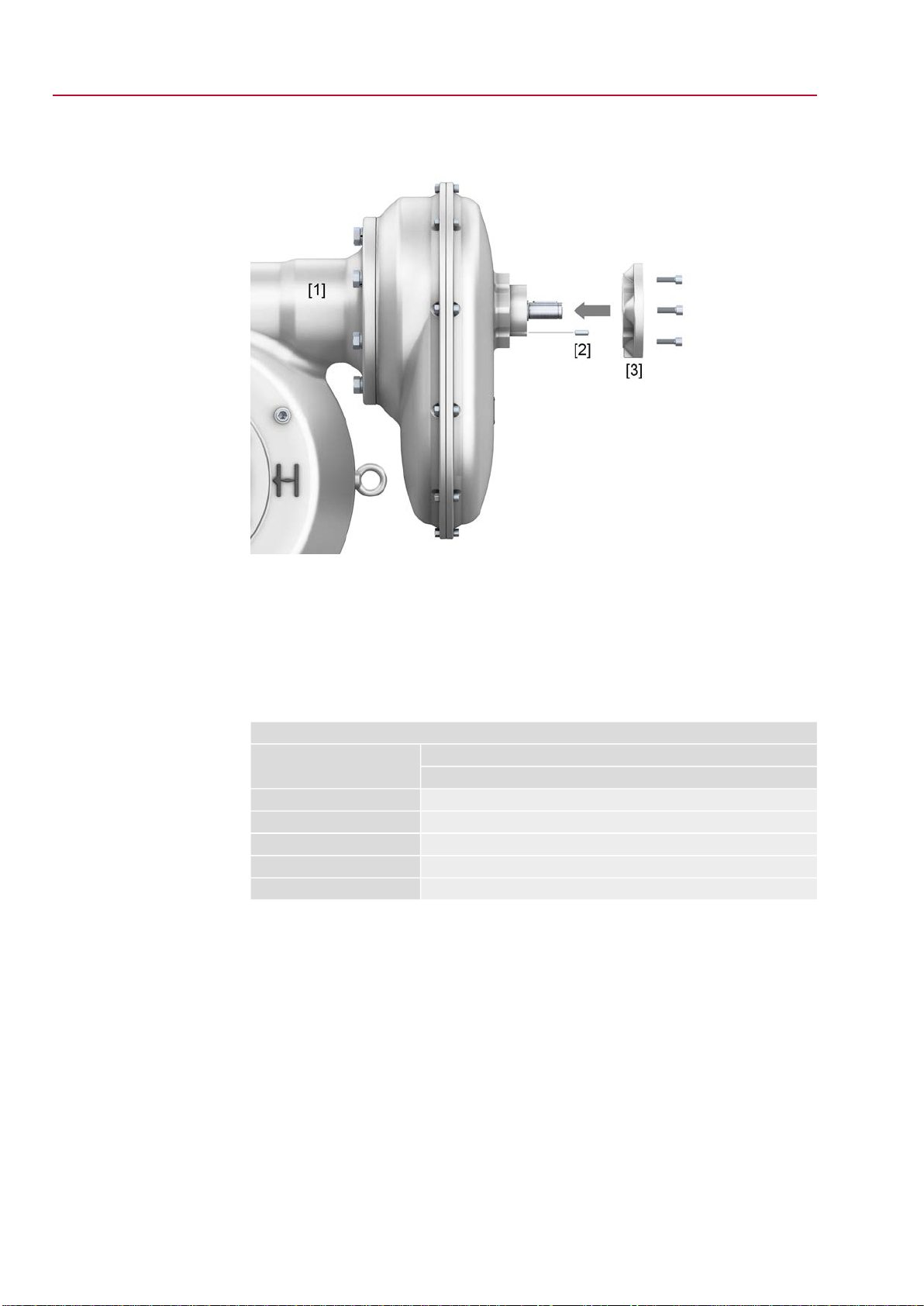

Figure 9: Mounting example, input mounting flange fitted to gearbox with primary

reduction gearing

[1] Gearbox with primary reduction gearing

[2] Parallel pin

[3] Input mounting flange

2. Mount parallel pin [2].

3. Place input mounting flange [3] and fasten with screws.

4. Fasten screws crosswise to a torque according to table.

Table 3:

Tightening torques for screws (for mounting multi-turn actuator and input mounting flange)

Tightening torque [Nm]Threads

Strength class A4-80

48M10

200M16

392M20

1,422M30

2,481M36

5. Mount AUMA actuator in compliance with the operation instructions pertaining

to the multi-turn actuator.

16

GS 315 –GS 500

Assembly GZ 30.1 –GZ 40.1

4.4. Mount gearbox to valve

4.4.1. Overview on coupling variants

Design Figure 10:Valve attachment via coupling

[1] Bore with keyway

[2] Square bore

[3] Bore with two-flats

Application ●For valve attachments according to EN ISO 5211

●For rotating, non-rising valve stem

4.4.2. Mount gearbox with coupling to valve

Unbored couplings or couplings with pilot bore must be machined to match the valve

shaft prior to mounting the gearbox to the valve (e.g.with bore and keyway, two-flat

or square bore).

Information Assemble valve and gearbox in the same end position.As a standard, the gearbox

is supplied in end position CLOSED.

●Recommended mounting position for butterfly valves:End position CLOSED.

●Recommended mounting position for ball valves: End position OPEN.

Damage due to radial forces!

Risk of valve damage for applications requiring transmission of radial forces from

the valve shaft to the coupling.

→In these cases, do NOT directly mount gearbox to valve but use torque reaction

lever as connection.

Assembly steps 1. If required, move gearbox in same end position as valve using the handwheel.

2. Clean mounting faces, thoroughly degrease surfaces.

3. We recommend applying a surface sealing agent to the mounting faces.

4. Use a corrosion protection agent for the valve shaft as well as for the inner and

outer parts of the coupling (recommendation: CorrosionX HD).

17

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Assembly

5. Place coupling [1] onto valve shaft [2] and secure against axial slipping by using

a grub screw [3] or a clamping washer.Thereby, ensure that dimensions X,Y

or L are observed (refer to figure and table <Mounting positions for coupling>).

Figure 11: Example: Fit coupling

[1] Coupling

[2] Valve shaft

[3] Grub screw

Figure 12: Mounting positions for coupling

Table 4: GS 500GS 400GS 315Dimensions [mm]

F60

(F60/AUMA)

F601)

F48F481)

F40EN ISO 5211

403626X max.

000Y max.

375285280L max.

Coupling dimensions not according to EN ISO 5211 specifications1)

18

GS 315 –GS 500

Assembly GZ 30.1 –GZ 40.1

Information

Experience showed that it is difficult to fasten screws or nuts of size M30 or larger

at defined torques.There is a risk that the worm gearbox might shift radially with

regard to the valve mounting flange.To improve adhesion between valve and gearbox

we recommend applying a thin film of Loctite 243 (or similar threadlocking adhesive)

to screw threads.

6. Fit gearbox.If required, slightly turn gearbox until splines of coupling engage.

Figure 13:

Information Ensure that the spigot (if provided) fits uniformly in the recess and that the flanges

are in complete contact.

7. If flange bores do not match thread:

7.1 Slightly rotate handwheel until bores line up.

7.2 If required, shift gearbox position by one tooth on the coupling.

8. Fasten gearbox with screws.

Information: We recommend applying liquid thread sealing material to the

screws to avoid contact corrosion.

9. Fasten screws crosswise to a torque according to table.

Table 5:

Tightening torques for screws

Tightening torque [Nm]Threads

Strength class 8.8

2,600M36

4,000M42

19

GS 315 –GS 500

GZ 30.1 –GZ 40.1 Assembly

5. Indications

5.1. Mechanical position indicator/running indication

Figure 14: Mechanical position indicator

[1] Housing cover

[2] Pointer cover

[3] Indicator mark

[4] Symbol for position OPEN

[5] Symbol for position CLOSED

Properties Mechanical position indicator:

●Used as running indication

(Pointer cover [2] with mark [3] rotates during actuator operation)

●Continuously indicates the valve position

(The marks [3] follows the travel of the valve and rotates from OPEN to CLOSED

and vice versa by approx.90°)

●Indicates that end positions (OPEN/CLOSED) have been reached

(Mark [3] points to symbol for position OPEN [4] or to symbol for position

CLOSED [5].)

20

GS 315 –GS 500

Indications GZ 30.1 –GZ 40.1

This manual suits for next models

6

Table of contents

Other AUMA Industrial Equipment manuals