AUMA GS 50.3 User manual

Gearboxes

GS 50.3 –GS 250.3

GK 10.2 –GK 40.2

SFC version

Functional safetyManual

NOTICE for use!

This document is only valid with the latest operation instructions attached to the device, the attached declaration

of incorporation as well as the pertaining technical data sheets.They are understood as reference documents.

Purpose of the document:

The present document informs about the actions required for using the device in safety-related systems in

accordance with IEC 61508 or IEC 61511.

Reference documents:

●exida report no.AUMA 15/10-108 R014 and AUMA 12/02-079 R007

●Operation instructions (Assembly, commissioning) and Technical data for gearbox

Reference documents are available on the Internet at: http://www.auma.com.

Table of contents Page

31. Terminology............................................................................................................................ 31.1. Abbreviations and concepts

52. Application and validity......................................................................................................... 52.1. Range of application 52.2. Standards 52.3. Valid device types

63. Architecture, configuration and applications...................................................................... 63.1. Architecture (gearbox sizing) 63.2. Configuration (setting) 63.3. Protection against uncontrolled operation (self-locking/brake) 63.4. Operation mode (low/high demand mode) 63.5. Further notes and indications on architecture 63.6. Applications (environmental conditions)

84. Safety instrumented systems and safety functions........................................................... 84.1. Safety functions

95. Installation, commissioning and operation......................................................................... 95.1. Installation 95.2. Commissioning 95.3. Operation 95.4. Lifetime 95.5. Decommissioning

106. Tests and maintenance.......................................................................................................... 106.1. Safety equipment: check 106.2. Proof test (verification of safe gearbox function) 106.3. Maintenance

117. Safety-related figures............................................................................................................. 117.1. Determination of the safety-related figures

128. SIL Declaration of Conformity (example).............................................................................

16Index........................................................................................................................................

17Addresses...............................................................................................................................

2

Gearboxes

Table of contents

1. Terminology

Information sources ●IEC 61508-4, Functional safety of electrical/electronic/programmable electronic

safety-related systems –Part 4: Definitions and abbreviations

●IEC 61511-1, Functional safety - Safety instrumented systems for the process

industry sector –Part 1:Framework, definitions, system, hardware and software

requirements

1.1. Abbreviations and concepts

To evaluate safety functions, the lambda values or the PFD value (Probability of

Dangerous Failure on Demand) and the SFF value (Safe Failure Fraction) are the

main requirements.Further figures are required to assess the individual components.

These figures are explained in the table below.

Table 1:Abbreviations of safety figures

DescriptionFull expressionAbbrevi-

ation Number of safe failuresLambda SafeλSNumber of dangerous failuresLambda DangerousλDNumber of undetected dangerous fail-

ures

Lambda Dangerous UndetectedλDU

Number of detected dangerous failuresLambda Dangerous DetectedλDD Diagnostic Coverage - ratio between

the failure rate of dangerous failures

detected by diagnostic tests and total

rate of dangerous failures of the com-

ponent or subsystem.The diagnostic

coverage does not include any failures

detected during proof tests.

Diagnostic CoverageDC

Mean time between the occurence of

two subsequent failures

Mean Time Between FailuresMTBF

Fraction of safe failures as well as of

detectable dangerous failures

Safe Failure FractionSFF

Average probability of dangerous fail-

ures on demand of a safety function.

Average Probability of dangerous Fail-

ure on Demand

PFDavg

Ability of a functional unit to execute a

required function while faults or devi-

ations are present.HFT = n means that

the function can still be safely executed

for up to n faults occurring at the same

time.

Hardware Fault ToleranceHFT

Interval for proof testProof test intervalTproof

SIL Safety Integrity Level

The international standard IEC 61508 defines 4 levels (SIL 1 through SIL 4).

Safety function Function to be implemented by a safety-related system for risk reduction with the

objective to achieve or maintain a safe state for the plant/equipment with respect to

a specific dangerous event.

Safety instrumented

function (SIF) Function with specified safety integrity level (SIL) to achieve functional safety.

Safety instrumented

system (SIS) Safety instrumented system for executing a single or several safety instrumented

functions.An SIS consists of sensor(s), logic system and actuator(s).

Safety-related system A safety-related system includes all factors (hardware, software, human factors)

necessary to implement one or several safety functions. Consequently failures of

safety function would result in a significant increase in safety risks for people and/or

the environment.

A safety-related system can comprise stand-alone systems dedicated to perform a

particular safety function or can be integrated into a plant.

3

Gearboxes Terminology

Proof test Periodic test performed to detect dangerous hidden failures in a safety-related system

so that, if necessary, a repair can restore the system to an "as new" condition or as

close as practical to this condition.

MTTR (MeanTimeTo

Restoration) Mean time to restoration once a failure has occurred. Indicates the expected mean

time to achieve restoration of the system.It is therefore an important parameter for

system availability.The time for detecting the failure, planning tasks as well as

operating resources is also included.It should be reduced to a minimum.

4

Gearboxes

Terminology

2. Application and validity

2.1. Range of application

AUMA gearboxes with the safety functions mentioned in this manual are intended

for operation of industrial valves and are suitable for use in safety instrumented

systems in accordance with IEC 61508 or IEC 61511.

2.2. Standards

IEC 61508-2:2010 The safety figures of the devices described meet the requirements of IEC 61508 in

the respective SIL level with regard to failure rates and architecture requirements.

However, this does not imply that all further requirements of IEC 61508 are met.

2.3. Valid device types

The data on functional safety contained in this manual applies to the device types

indicated.

Table 2: Overview on suitable device types

Safety functionDuty classVersionGearboxes Safe operation in direction

OPEN/CLOSE

No indicationsIn SFC versionGK 10.2 –GK 40.2

Safe operation in direction

OPEN/CLOSE

Duty class 1In SFC versionGS 50.3 –GS 250.3

Gearboxes may not be modified without prior written consent by AUMA.Unauthorised

modifications may have a negative impact on both safety figures and SIL capability

of the products.

Information In applications with requirements on functional safety, only AUMA gearboxes in SFC

or SIL version may be used. SFC stands for “Safety Figure Calculated”.This desig-

nation identifies AUMA products for which safety figures were calculated on the basis

of FMEDA from field data and generic data (for detailed information refer to <Determ-

ination of the figures>).

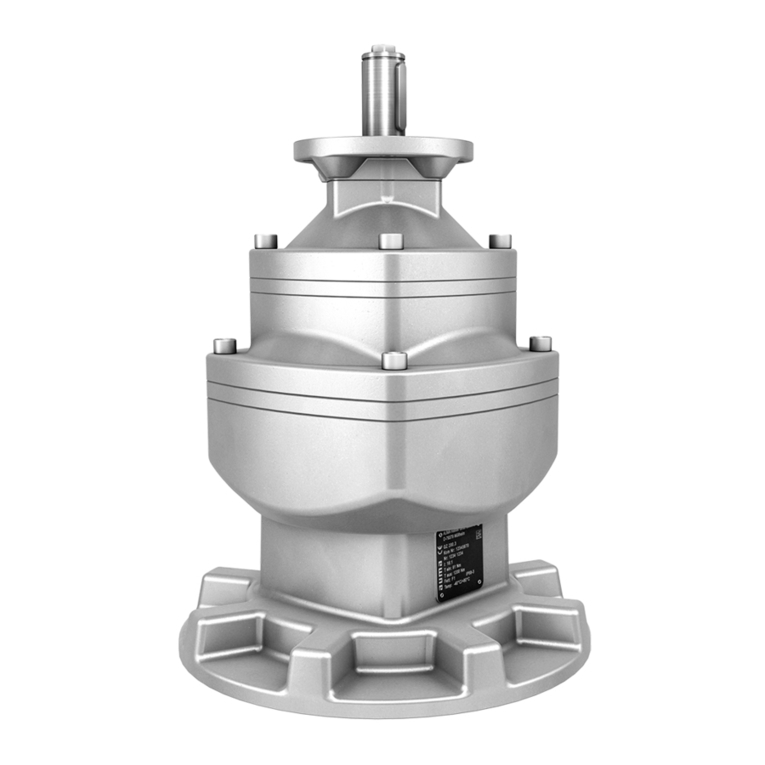

AUMA gearboxes in SFC version can among others be identified from the letters

"SFC" following the type designation on the name plate.

Figure 1: Example of name plate with “SFC”marking

5

Gearboxes Application and validity

This manual suits for next models

3

Table of contents

Other AUMA Industrial Equipment manuals