Autopilot Pool Pilot Digital Nano+ User manual

INSTALLER: THIS DOCUMENT IS PURCHASER’S PROPERTY AND IS TO REMAIN WITH THE EQUIPMENT OWNER

LTP0086 Rev4 05/11/2017

Pool Pilot®

Digital Nano/Nano+

Digital Nano Models: 75041A, 75041A-xx

Manifolds: PPM1, PPM1M

Cell: PPC1

Digital Nano+Models: 75043A, 75043A-xx

Manifolds: PPM2, PPM2M

Cells: PPC1 or PPC2

Owner’s Manual: Installation / Operation

This manual covers the installation and operation of the Digital Nano/Nano+ Chlorine Generators

Important!

Read This Manual and Product Labels Before Installing or Operating This Equipment

Page i

TABLE OF CONTENTS

SECTION 1 - FACTORY CONTACT INFORMATION...........................................................................................1

SECTION 2 - SAFETY INFORMATION ................................................................................................................1

SECTION 3 - OWNER QUICK START & RUN.....................................................................................................4

3.1 How Your Digital Nano/Nano+ Works ............................................................................................................4

3.2 Optional 863A Expansion Board Additional Features ....................................................................................4

3.3 Owner/Operator Control Buttons, CHECK SYSTEM LED, and Audio Alarm.................................................5

3.3.1 UP and DOWN Arrows.................................................................................................................5

3.3.2 The BOOST Button......................................................................................................................5

3.3.3 MENU and SELECT Button .........................................................................................................5

3.3.4 CHECK SYSTEM Light and Audio Alarm ....................................................................................6

3.4 Normal Display Modes....................................................................................................................................6

3.4.1 Purifier Mode................................................................................................................................6

3.5 Water Balance and Chemistry Recommendations.........................................................................................7

SECTION 4 - SPECIFICATION AND APPROVALS.............................................................................................8

4.1 Specifications..................................................................................................................................................8

4.2 Manifold Pressure Drop Versus Flow .............................................................................................................9

4.3 Agency Approvals...........................................................................................................................................9

SECTION 5 -FEATURES....................................................................................................................................10

5.1 Patented Temperature Compensation..........................................................................................................10

5.2 Water Manifolds Assemblies - Available Options.........................................................................................10

5.2.1 Automatic-Flow Bypass Manifold Assembly (models PPM1, PPM1M and PPM2, PPM2M).....11

5.2.2 CoPilot®Manifold Assembly.......................................................................................................11

5.3 Automatically Reduce Chlorine Output When Pool Cover Closes ...............................................................12

SECTION 6 - MAINTENANCE.............................................................................................................................12

6.1 Fuse Location and Ratings...........................................................................................................................12

6.2 Removing / Inspecting / Cleaning Tri-Sensor...............................................................................................13

6.2.1 Tri-sensor Assembly Overview ..................................................................................................13

6.2.2 Inspect Tri-sensor.......................................................................................................................13

6.2.3 Cleaning Tri-sensor/Salt Sensor................................................................................................14

6.2.4 Test Tri-sensor Flow Switch.......................................................................................................14

6.3 Servicing the Cell..........................................................................................................................................15

6.3.1 Removal.....................................................................................................................................15

6.3.2 Visual Inspection........................................................................................................................16

6.3.3 Manual Cleaning ........................................................................................................................16

6.3.4 Installing.....................................................................................................................................16

6.4 Winterizing ....................................................................................................................................................17

6.4.1 Digital Nano/Nano+ Control Unit and Manifold Assembly .........................................................17

6.5 Spring Start-up..............................................................................................................................................17

6.5.1 Digital Nano/Nano+....................................................................................................................17

SECTION 7 - PROGRAMMING...........................................................................................................................18

7.1 Control Panel................................................................................................................................................18

7.1.1 Button Overview.........................................................................................................................18

7.1.2 MENU Button .............................................................................................................................18

7.1.3 Display Overview........................................................................................................................18

7.2 Menus ...........................................................................................................................................................19

7.3 Basic Operational Programming...................................................................................................................20

7.3.1 Adjusting the Chlorine Output %................................................................................................20

7.3.2 Boost or Super Boost.................................................................................................................20

Page ii TABLE OF CONTENTS

7.3.3 Chlorine Mode............................................................................................................................21

7.3.4 Chlorine % Adjustment Procedure.............................................................................................21

7.4 Test Pool Pilot (Diagnostic Menu) ................................................................................................................22

7.5 View Setup....................................................................................................................................................22

7.6 Review of Installer, Owner, & Maintenance Menu Programming.................................................................23

7.6.1 Set Pool Volume.........................................................................................................................23

7.6.2 Calibrate Salt..............................................................................................................................23

7.6.3 Select Language ........................................................................................................................23

7.6.4 Calibrate Temperature ...............................................................................................................23

7.6.5 Select Units ................................................................................................................................24

7.6.6 Set Temperature Unit.................................................................................................................24

7.6.7 Display Temperature..................................................................................................................24

7.6.8 Set 12/24 Hour Clock (Optional Feature w/ 863A Expansion Board)........................................24

7.6.9 Set Time of Day (Optional Feature w/ 863A Expansion Board) ................................................25

7.6.10 Set Purifier Off (Optional Feature w/ 863A Expansion Board).................................................25

7.6.11 Set Reverse Time.....................................................................................................................25

7.6.12 Force Reverse..........................................................................................................................26

7.6.13 Enable/Disable Audio Alarm ....................................................................................................26

7.6.14 Select System (Optional Feature w/ 863A Expansion Board) .................................................26

SECTION 8 - INSTALLATION.............................................................................................................................27

8.1 Basic System Overview................................................................................................................................27

8.2 Plannning the installation..............................................................................................................................28

8.2.1 Before installing the Digital Nano/Nano+:..................................................................................28

8.3 Check Parts ..................................................................................................................................................28

8.4 Installation Steps...........................................................................................................................................29

8.5 Mounting the Digital Nano/Nano+.................................................................................................................29

8.6 Electrical connections ...................................................................................................................................30

8.6.1 Electrical Connections Overview................................................................................................30

8.6.2 AC Input Voltage........................................................................................................................31

8.6.3 Low Voltage Wiring ....................................................................................................................31

8.6.4 Bonding ......................................................................................................................................34

8.7 Plumbing the system.....................................................................................................................................35

8.7.1 Plumbing the Manifold Assembly...............................................................................................35

8.8 Preparing the Pool Water..............................................................................................................................36

8.8.1 Steps to Prepare Water..............................................................................................................36

8.8.2 Calculating Pool Volume............................................................................................................36

8.8.3 Adding Salt.................................................................................................................................37

8.9 Programming at Installation..........................................................................................................................38

8.10 Language Translation Matrix ......................................................................................................................39

SECTION 9 - TROUBLESHOOTING...................................................................................................................42

SECTION 10 - REFERENCE.................................................................................................................................48

10.1 Basic Water Chemistry ...............................................................................................................................48

10.1.1 Chlorine....................................................................................................................................50

10.1.2 pH.............................................................................................................................................50

10.1.3 Total Alkalinity..........................................................................................................................50

10.1.4 Calcium Hardness....................................................................................................................50

10.1.5 Cyanuric Acid...........................................................................................................................50

10.2 Using the Saturation Index .........................................................................................................................51

Page iii

TABLE OF CONTENTS

10.3 Salt Addition Chart......................................................................................................................................52

10.4 Declaration of Conformity ...........................................................................................................................53

10.5 FCC Compliance.........................................................................................................................................53

Page 1

SECTION 1 - FACTORY CONTACT INFORMATION

If you should need to call AquaCal AutoPilot, Inc. for questions, services, or parts, please have your

model and serial numbers available. Please also have the name of your installer and date of your

equipment’s installation. If you have questions, please refer to our web site for the latest manual

revisions, additional information, and helpful service advice.

Web

www.AutoPilot.com

Pool Volume

(Gallons/Liters)

Phone

(727) 823-5642

8-5 pm, Est., M-F

Installer

Install date

Fax

877-408-8142

Cell Model

Serial #

Address

AquaCal AutoPilot, Inc.

2737 24th Street North

St. Petersburg, Florida 33713

USA

Digital Nano/Nano+

Model

Serial #

SECTION 2 - SAFETY INFORMATION

For personal safety, and to avoid damage to equipment, follow all safety instructions displayed on the

equipment and within this manual. Repair and service of your Digital Nano/Nano+ must be performed

by qualified service personnel. Should you suspect your chlorine generator is not performing properly,

refer to the section in this manual entitled: "Troubleshooting" on page 42 to determine if a call for

service is required. Warranties will be voided if the Digital Nano/Nano+ has been improperly installed.

Failure to properly operate, maintain or repair the Digital Nano/Nano+ will void the factory warranty.

Throughout this manual safety signals are placed where particular attention is required. Please note

"WARNING" signals relate to personal safety, while "CAUTION” signals promote avoiding damage to

equipment.

Follow all state provincial and NEC (National Electrical Codes) and applicable CEC (Canadian

Electrical Codes) unless local guidelines supersede. When installing and using your Digital

Nano/Nano+, basic safety precautions must always be followed, including the following:

WARNING: Failure to heed the following may result in injury or death.

RISK OF ELECTRICAL SHOCK - Disconnect all AC power when installing or servicing

this system. Follow all state, local, and National Electrical Code(s) (provincial and

Canadian Electrical Code(s) if applicable). Use copper conductors only.

RISK OF ELECTRICAL SHOCK - Digital Nano/Nano+ contains no owner-repairable

components. Repairs must not be attempted by untrained and/or unqualified individuals.

If service is deemed necessary, contact installing dealer or AquaCal AutoPilot Customer

Support.

RISK OF ELECTRICAL SHOCK - A bonding lug has been provided on the outside of the

Digital Nano/Nano+. This lug permits the connection of a No. 8 AWG (8.4 mm2) solid

copper-bonding conductor (No. 6 AWG in Canada). Make this connection between the

Digital Nano/Nano+ and all other electrical equipment and exposed metal within 5-feet

(1.5 m) of the Digital Nano/Nano+. All field-installed metal components (such as rails,

ladders, drains, etc.) within 10-feet of the pool, spa, or hot tub, must be bonded to the

equipment grounding bus using copper conductors not smaller than No. 8 AWG

(8.4 mm2) (No. 6 AWG in Canada).

Page 2

RISK OF ELECTRICAL SHOCK - Digital Nano/Nano+ configured to 115 Vac must be

installed at least 10 feet (3 m) from the pool or spa wall. Digital Nano/Nano+ configured

to 230 Vac must be installed at least 5 feet (1.5m) from the pool or spa wall.

RISK OF ELECTRICAL SHOCK - A disconnect device incorporated into the fixed wiring

must be included in the supply circuit (such as a time clock, relay, or circuit breaker).

RISK OF ELECTRICAL SHOCK - Connect only to a branch circuit protected by a

ground-fault circuit-interrupter (GFCI). Contact a qualified electrician if you cannot verify

that the circuit is protected by a GFCI.

RISK OF ELECTRICAL SHOCK - Digital Nano/Nano+ must be connected only to a

supply circuit that is protected by a ground-fault circuit-interrupter (GFCI). The GFCI

must be tested on a routine basis. To test, push the GFCI test button. Power should be

interrupted. Push the reset button. Power should be restored. If the GFCI fails to operate

in this manner, it is defective.

RISK OF ELECTRICAL SHOCK - If the ground-fault circuit-interrupter (GFCI) interrupts

power to the equipment without the test button being pushed, a ground current is flowing

with a possibility of an electrical shock. Do not use equipment. Disconnect the

equipment and have the problem corrected by a qualified service representative before

using.

CHEMICAL HAZARD - To avoid damaging splashes, always add acid to water, never

water to acid. Wear safety glasses and use other appropriate personal protection

equipment.

CHEMICAL HAZARD - Always follow the instructions on the manufacturer's label

whenever handling or using chemicals.

CHEMICAL HAZARD –Heavy pool (or spa) usage and higher temperatures may require

a higher chlorine output in order to maintain proper free available chlorine residuals.

WATER CHEMISTRY SAFETY - Improper water chemistry can present a serious health

hazard. The proper residual chlorine level and water chemistry must be maintained. The

addition of certain pool maintenance chemicals can reduce the effectiveness of chlorine.

Maintain Pool / Spa water per standards detailed later in this manual.

COMBUSTIBLE HAZARD –The AutoPilot®Digital Nano/Nano+ is equipped with an

electronic flow switch that automatically turns the unit off in the event of a “low water

flow” situation. Do not tamper in any way with this safety feature.

PERSONAL SAFETY HAZARD –To reduce the risk of injury, do not permit children to

operate this device.

RISK OF CHILD DROWNING OR INJURY - Children must be closely supervised at all

times around pool or spa equipment.

CAUTION: Failure to heed the following may result in equipment damage.

The AutoPilot®Digital Nano/Nano+ must be installed and operated as specified. Failure

to do so will void the equipment warranty.

To permit proper air circulation, the Digital Nano/Nano+ must be mounted at least 1-foot

(30 cm) above ground level or any other cooling obstruction.

Special measures are required in the event of freezing conditions. Your Digital

Nano/Nano+ may be damaged if measures are not taken in advance of freezing

conditions. Equipment damage due to freezing conditions is NOT covered under the

equipment warranty.

Do not use a pool cleaner or vacuum head with wheels, as wheels can leave track

marks on newly-plastered pools. Do not allow Granular salt to pile up in one location,

without brushing, as staining may occur.

Page 3

Excessively high chlorine levels can cause corrosion damage to pool fixtures and

equipment.

For maximum cell life, maintain water in a balanced condition. Water maintained in a

scaling condition will shorten cell life and may render the Digital Nano/Nano+

inoperative. Damage and/or service calls, caused by improper water balance, will NOT

be covered under the equipment warranty.

Scraping or scratching the titanium blade’s edge or surface will damage the blade

catalyst coating and cause premature failure of the cell... warranty will be voided. Never

use any sharp or metallic objects to remove scale.

Reduced polarity reversing cycle times will reduce cell life, and should only be used due

to uncontrollable scale formation on the cell. ALWAYS test and adjust water balance,

before attempting scale control via shortening reverse period.

The Tri-sensor should not be pulled out at an angle, or the flow paddle or flow post may

be damaged. SAVE THESE INSTRUCTIONS

Page 4

SECTION 3 - OWNER QUICK START & RUN

1) Balance the water chemistry according to the water chemistry parameters on page 7 and salt

recommendations on page 37. The Digital Nano/Nano+ may be started immediately. The salt

reading, however, may initially be inaccurate until the circulation pump has been run for 24

hours to fully dissolve newly added salt.

2) Use the UP and DOWN arrow buttons to set the chlorine percentage to 50%.

3) During the first two weeks, test the water chemistry parameters every 3-4 days. Adjust chlorine

percentage as needed.

4) Once ideal chlorine percentage has been determined, follow normal maintenance procedures.

3.1 HOW YOUR DIGITAL NANO/NANO+ WORKS

The Digital Nano/Nano+ is designed to handle the purification needs of residential swimming pools and

spas. The amount of chlorine required for proper sanitization will vary based on the pool size and

various factors such as water temperature, bather load, exposure to direct sunlight, and special water

features.

The system requires a low concentration of dissolved salt (sodium chloride) in the water. The salt

concentration level is normally maintained below the taste threshold. The Digital Nano/Nano+

automatically converts the salt into chlorine, which your pool/spa requires to remain sanitized and algae

free. The chlorine reverts back to salt after treating the water. Since the salt is constantly recycled,

there is minimal loss during a swimming season. However, salt can be lost due to filter backwashing,

rain water overflow, leaks, or bather splashing/carry out but not through evaporation.

The water circulation pump must be operating for your Digital Nano/Nano+ to produce chlorine, so run

time is one of several key components to maintaining the proper sanitizer levels. Most installations

require a minimum of eight (8) hours-per-day pump run time to properly filter and sanitize the water.

3.2 OPTIONAL 863A EXPANSION BOARD ADDITIONAL FEATURES

When the optional 863A Expansion Board is purchased and installed, your Digital Nano/Nano+ will be

equipped with a variety of additional features.

Once installed, the new board will support the addition of an automatic pool cover switch (not supplied)

that will detect when the pool cover is open or closed. This will allow the Digital Nano/Nano+ to

automatically adjust chlorine output when the cover is closed and avoid over chlorination or premature

cell depletion.

A 12/24 Hour Clock that allows the user to set personal preference for time display. The Set Time of

Day feature can be set to display the correct time zone and/or adjustments for Daylight Saving Time

changes. The optional 863A Expansion Board is also equipped with a Lithium battery backup for real

time clock.

The Set Purifier Off feature will allow the Digital Nano/Nano+ to be programmed to delay chlorine

production if salt will not be added to the pool water for a specified amount of time, from 1-28 days.

More detailed information on these features can be found in section 7.6, Review of Installer, Owner, &

Maintenance Menu Programming, on page 23.

Page 5

3.3 OWNER/OPERATOR CONTROL BUTTONS, CHECK SYSTEM LED, AND

AUDIO ALARM

The following is a brief explanation of owner or operator control buttons.

Please Note: This section assumes the installer has already programmed the system for specific site

parameters, has established proper water balance, and has pretreated water to 1 - 3 ppm (mg/L)

chlorine.

Attention Owner: Should Centigrade vs. Fahrenheit, choice of language, or other owner options require

modification, please refer to the programming information in section 7.6, located on page 23.

3.3.1 UP and DOWN Arrows

Use the UP and DOWN arrows to control the chlorine output level, then press the SELECT

button to save the value chosen. With a properly prepared pool, the recommended starting

output level is 50%.

Upon initial start-up, check sanitizer every 3-4 days and make small output level adjustments as

necessary to maintain 1 - 3 ppm (mg/L) free chlorine levels. Keep in mind, your Digital

Nano/Nano+ does not directly measure or regulate the sanitizer levels in your pool. Rather, the

owner / operator will need to periodically test the water to determine the current chlorine level,

and adjust the output setting as needed.

After the chlorine output level is “tuned in,” the unit will automatically make fine output

adjustments as the water temperature fluctuates. This temperature compensation feature will

adjust output depending on water temperature. See section 5.1 on page 10 for more information

concerning the Patented Temperature Compensation feature.

Please Note: The optimum output setting will vary based upon pool size, location, exposure to

sunlight, number of users, vegetation around the pool, water balance practices, and pump run

time. Your installer should have already taken these factors into consideration when performing

installation programming. Therefore, your adjustments, at this point, should be relatively minor.

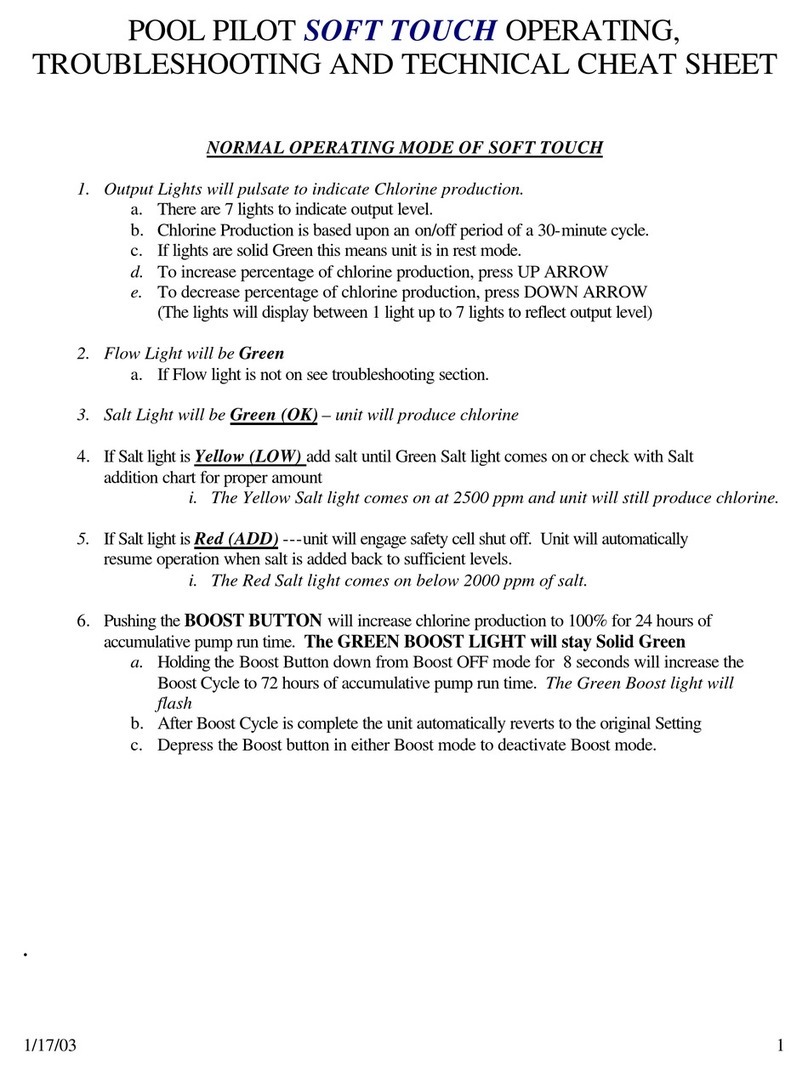

3.3.2 The BOOST Button

The BOOST button increases output to 100%. Use this feature when a heavier than normal

bather load is anticipated.

Press BOOST once ............................. = 24 Hour Boost

Press and hold BOOST for 8 seconds . = 72 Hour Boost

Press BOOST a second time .............. = Deactivate Boost

3.3.3 MENU and SELECT Button

The “MENU” button allows the operator access to the “Test Pool Pilot”, “View setup”, “Owner

options”, “Maintenance” and “Installer” menus. (For full features of the Owner Options Menu,

please see page 23.)

Press the UP and DOWN arrows to scroll through the menus.

The “SELECT” button allows the operator to choose program menu options. The owner /

operator should not normally need to access these features on a regular basis.

Consult the Programming section on page 20 or contact factory customer support for additional

information.

A graphical overview of all the menus & sub-menus is shown in section 7.2 on page 19.

Page 6

3.3.4 CHECK SYSTEM Light and Audio Alarm

The CHECK SYSTEM light will flash to warn the unit may need attention. A warning message

will also be displayed. If enabled, an audio alarm* may also be heard when the system light is

flashing. Unless deemed a normal condition, per below, see the Troubleshooting section on

page 42.

Flashes red when pump is off / water flow is insufficient (It is normal for the light to flash if

the circulation pump is off)

Flashes when salt is low (check salt and add as needed)

Flashes when water temperature exceeds 125° F (51° C), or drops below 10° F (-12° C)

*Note: When enabled, an audio alarm will sound due to any of the above three (3) conditions. If

water flow ceases (or falls below minimum acceptable levels) the alarm will automatically

silence after 10 minutes. To enable or disable audio alarm, see section 7.6.13 “Enable/Disable

Audio Alarm” on page 26 in the programming instructions.

3.4 NORMAL DISPLAY MODES

The Digital Nano/Nano+ is limited to Purifier Mode.

3.4.1 Purifier Mode

Purifier (Chlorine Output %) level.............. Shown in 1% increments

Range with cover open .................... 0% to 100%

Range with cover closed.................. 0% to 20%

Water Temperature................................... Displayed in Fahrenheit or Celsius. The Temperature can

be turned off. See section 7.6.7, “Display Temperature” on

page 24 for more information.

CHECK SYSTEM Light ............................ Off when operating normally. Normally blinking red when

circulation pump is off and supply power to the Digital

Nano/Nano+ remains on. The light will also blink red when

an error has occurred. Refer to the Troubleshooting

section on page 42 for more information.

Example with the Retractable Pool Cover Open and the Temperature Display on.

Example with the Retractable Pool Cover Closed and Temperature Display off.

Display “A”

Display “B”

Cell Status……will show “On” when chlorine is being generated.

Field will be blank when the cell is off.

Page 7

3.5 WATER BALANCE AND CHEMISTRY RECOMMENDATIONS

Water balance is not complicated. It is the relationship between different chemical measurements in

your pool water. A pool that is balanced has proper levels of pH, Total Alkalinity and Calcium Hardness.

Balanced water can also be defined as water that is not corrosive or scaling. Water that is not balanced

can damage equipment and pool surfaces.

Proper water chemistry levels are essential to maintain safe and consistent swimming pool operation.

Sanitizers are used to destroy harmful or otherwise objectionable organisms. Stabilizer is used to

prevent unnecessary loss of chlorine to sunlight. Salt is used by the Digital Nano/Nano+ to generate

chlorine sanitizer.

Please note the following recommended water chemistry parameters are for residential pool/spa

applications only. Follow local regulatory guidelines for any commercial pool applications.

POOL

SPA

PARAMETER

UNITS

MIN

IDEAL

MAX

MIN

IDEAL

MAX

Free Chlorine

ppm (mg/L)

1.0

2.0 - 4.0

5

2.0

3.0 - 4.0

10

Combined Chlorine

ppm (mg/L)

0.0

0.0

0.2

0.0

0.0

0.5

pH

ppm (mg/L)

7.2

7.2 -7.8

7.8

7.2

7.2 -7.8

7.8

Total Alkalinity

ppm (mg/L)

60

80 - 100

180

60

80 - 100

180

Calcium Hardness

ppm (mg/L)

150

200 - 400

1000

100

150 - 250

1000

Salt

ppm (mg/L)

2000

2500 - 4500

**

2000

2500 - 4500

**

Cyanuric Acid (stabilizer)

ppm (mg/L)

0

30 - 50

***

0

30 - 50

***

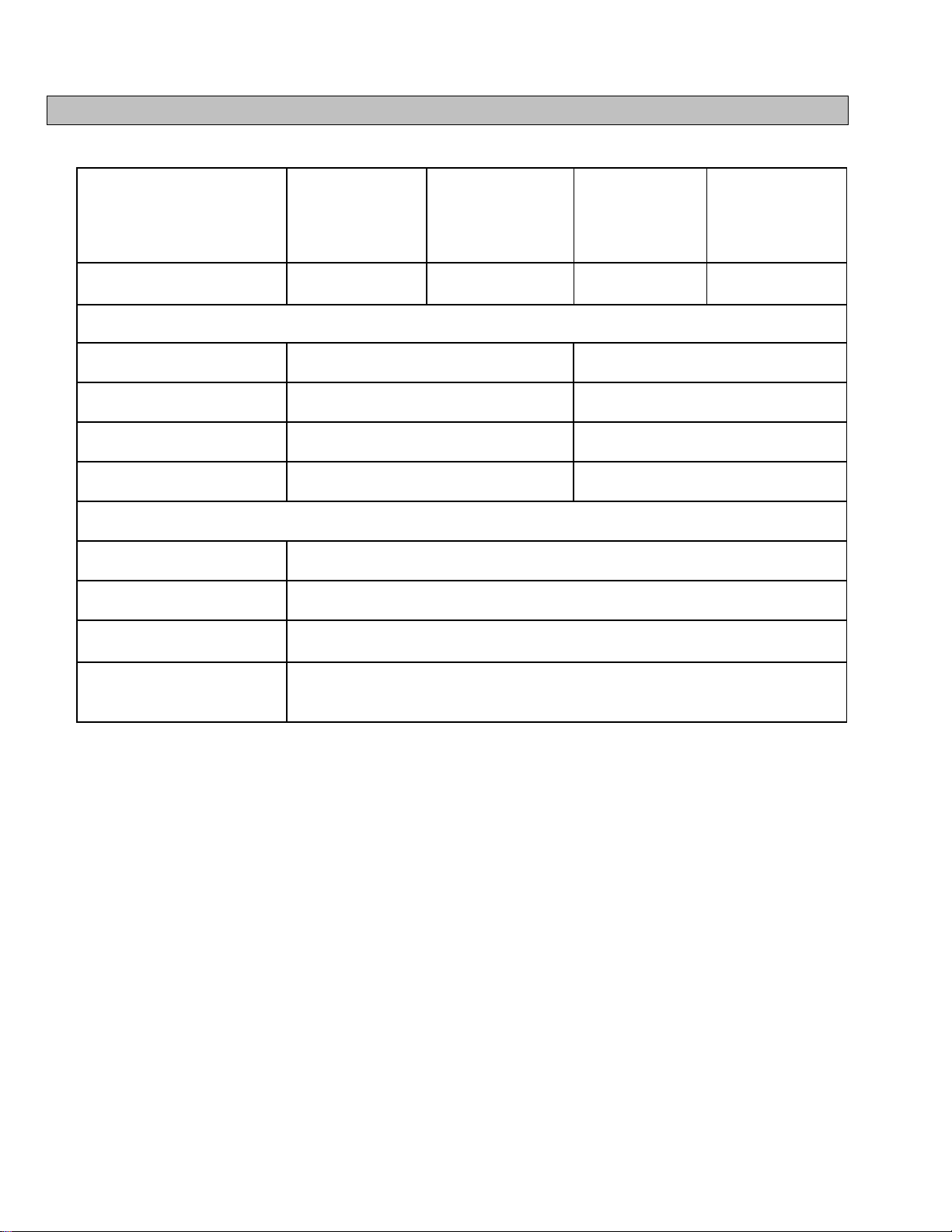

Table 1

** Typically 6000 ppm (mg/L) or less is recommended; unit can operate with levels as high as

35,000+ ppm (mg/L).

*** This is dictated by state or local codes but is typically 100 ppm (mg/L).

See “Basic Water Chemistry”in section 10.1 on page 48, and “Using the Saturation Index”in section

10.2 on page 51 for further information concerning pool/spa water chemistry maintenance

requirements. Refer to the Troubleshooting section on page 42 in the back of this manual for

assistance with resolving low or high chlorine levels.

Page 8

SECTION 4 - SPECIFICATION AND APPROVALS

4.1 SPECIFICATIONS

SPECIFICATION

75041A,

75041-XX

(when converted

to 110V-120V in

the field)

75041A,

75041A-XX

75043A,

75043A-XX

(when converted

to 110V-120V in

the field)

75043A,

75043A-XX

Input Power:

110-120 Vac

2.0 A

220-240 Vac

1.0 A

110-120 Vac

2.0 A

220-240 Vac

1.0 A

Cell Maximum Chlorine Output:

PPC1

0.8 lb. /day (15.1 g/hr.) (standard)

0.8 lb. /day (15.1 g/hr.) (optional)

PPC2

not applicable

1.06 lb. /day (20.0 g/hr.) (standard)

Manifold Type

PPM1 or PPM1M

PPM2 or PPM2M

Standard Cell

PPC1

PPC2

Manifold Flow rates:

PPMxx (standard)

Minimum 15 gpm (57 L/min); Maximum 70 gpm (265 L/min)

CoPilot®Ozone (optional)

Minimum 25 gpm (95 L/min); Maximum 70 gpm (265 L/min)

Maximum Manifold

Pressure:

75 psi (517 kPa)

Cover Switch Compatible

Digital Nano/Nano+

models:

75041A & 75043A (Discontinued models 75040A & 75042A)

Table 2

Page 9

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

15 25 35 45 55 65 75 85 95

PSI

GPM

PPMxx & CoPilot®Ozone

Standard

(941xx)

CoPilot Ozone

0

5

10

15

20

25

30

35

40

50 150 250 350

kPa

LPM

PPMxx & CoPilot®Ozone

Standard

(941xx)

CoPilot Ozone

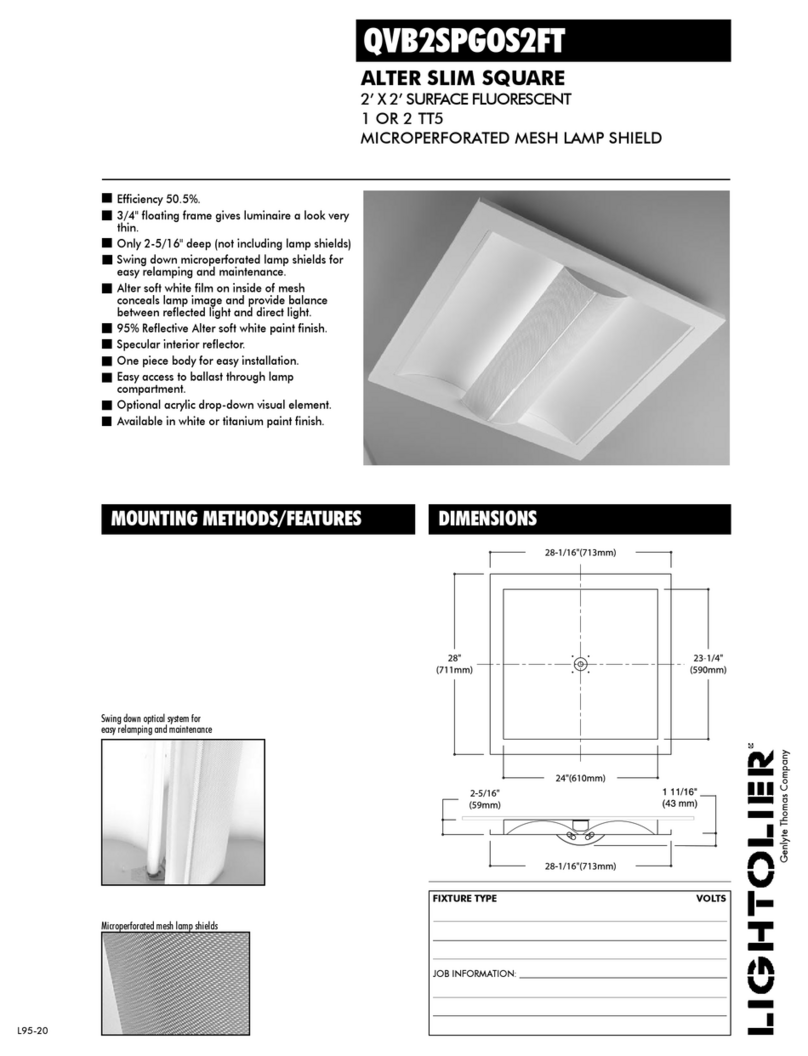

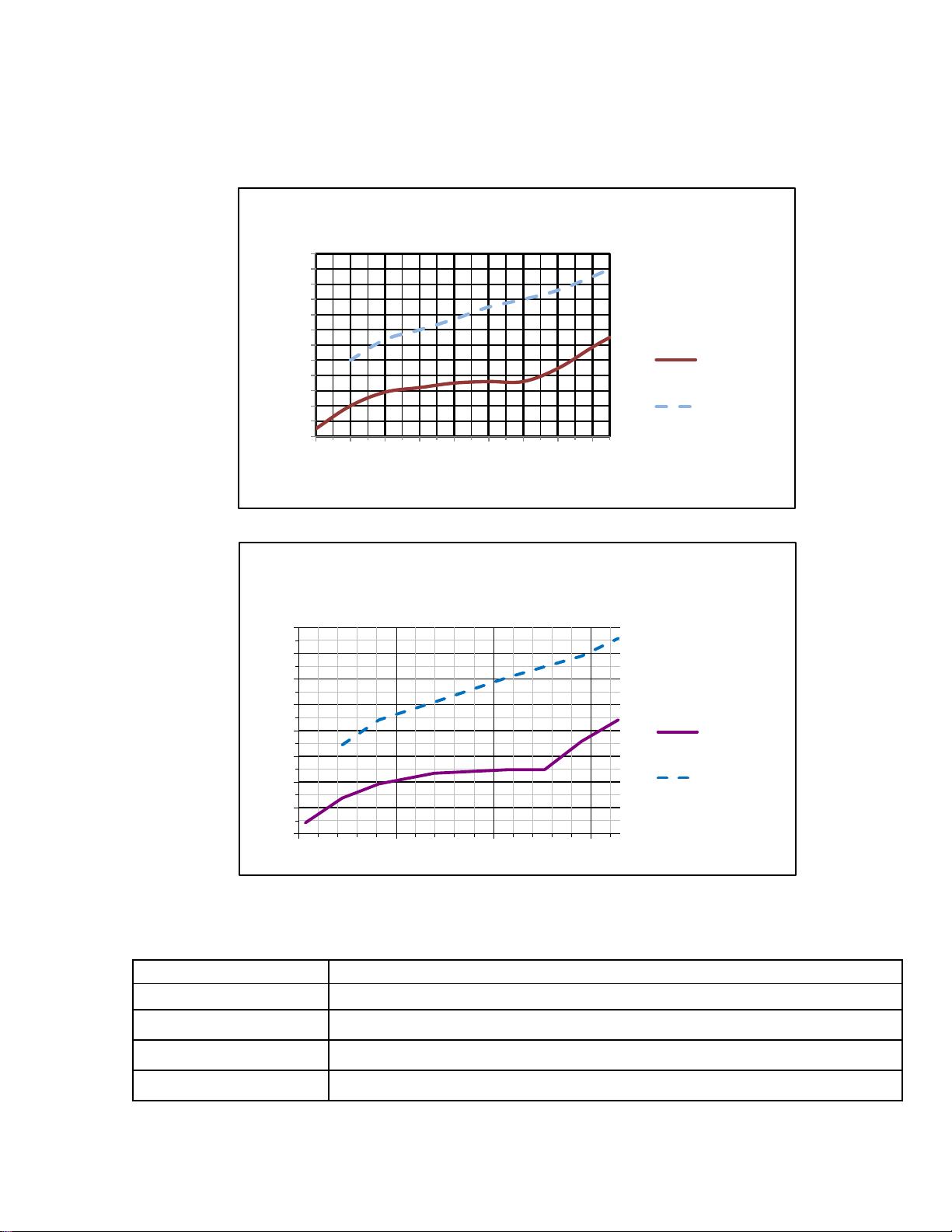

4.2 MANIFOLD PRESSURE DROP VERSUS FLOW

The following chart shows pressure drop versus flow for all Digital Nano/Nano+ manifolds. The optional

CoPilot®Ozone manifold is also listed. Table 3

4.3 AGENCY APPROVALS

Tested to conform to the following specifications:

SPECIFICATION

DESCRIPTION

UL1081

Safety Standard for Swimming Pool Pumps, Filters, and Chlorinators.

CAN / CSA-E60335-1

Safety of Household and Similar Electrical Appliances.

EU

See Declaration of Conformity in section 10.4 on page 53.

FCC

See FCC Compliance Declaration on page 53

PPMxx

PPMxx

Page 10

SECTION 5 - FEATURES

Patented temperature compensation for chlorine output control.

Programmable microprocessor control.

Multi-language digital display (English, Spanish, French, German, Italian and Czech).

Digitally controlled power to the cell.

Tri-sensor circuitry to monitor water flow, water temperature, and salt level.

Calculates and displays amount of salt needed to reach the recommended 3,000 ppm (mg/L)

salt concentration level.

Compatible with the optional 863A Expansion Board.

Can automatically reduce chlorine output when pool cover is closed. (Optional 863A Expansion

Board and Cover Switch must be installed.)

Chlorine production (salt addition) can be delayed for up to 28 days.(Optional 863A Expansion

Board)

Lithium battery (CR-2032) backup for real time clock (Optional 863A Expansion Board).

On board diagnostic and test programs.

Optional CoPilot®upgrade brings ozone to the pool.

5.1 PATENTED TEMPERATURE COMPENSATION

WARNING: Failure to heed the following may result in permanent injury or death.

Pool or Spa water temperature should not exceed 104°F (40°C).

The Tri-sensor temperature sensor works in conjunction with the chlorine % feature to automatically

adjust chlorine output based upon changes in water temperature. The automatic compensation feature

operates between 55°F and 125°F (13°C - 52°C).

As water temperature falls below 65°F (18°C), the controller will automatically reduce the chlorine %

and will reduce the maximum % that can be selected. This feature prevents the controller from

generating excessive chlorine in cold water where it is not needed and prevents premature cell failure.

At 55°F (13°C) or colder water temperatures, the controller will adjust to a fixed 1% output, thus

preventing over-chlorination and premature cell failure.

5.2 WATER MANIFOLDS ASSEMBLIES - AVAILABLE OPTIONS

CAUTION: Failure to heed the following may result in equipment damage.

The Digital Nano manifold may only use the PPC1 cell. The Digital Nano+

may use either the PPC1 or PPC2 cell.

The Digital Nano uses the patented automatic-flow bypass manifold assembly (models PPM1,

PPM1M). The Digital Nano should ONLY use the PPC1 cell.

The Digital Nano+ uses the patented automatic-flow bypass manifold assembly (models PPM2,

PPM2M) with a PPC2 cell. The Digital Nano+ may also use a PPC1 cell but the maximum chlorine

output will be lower. See the Specifications table in section 4.1 on page 8.

The CoPilot®manifold assembly comes with an automatic-flow bypass, check valve assembly and

ozone injector venturi assembly.

Page 11

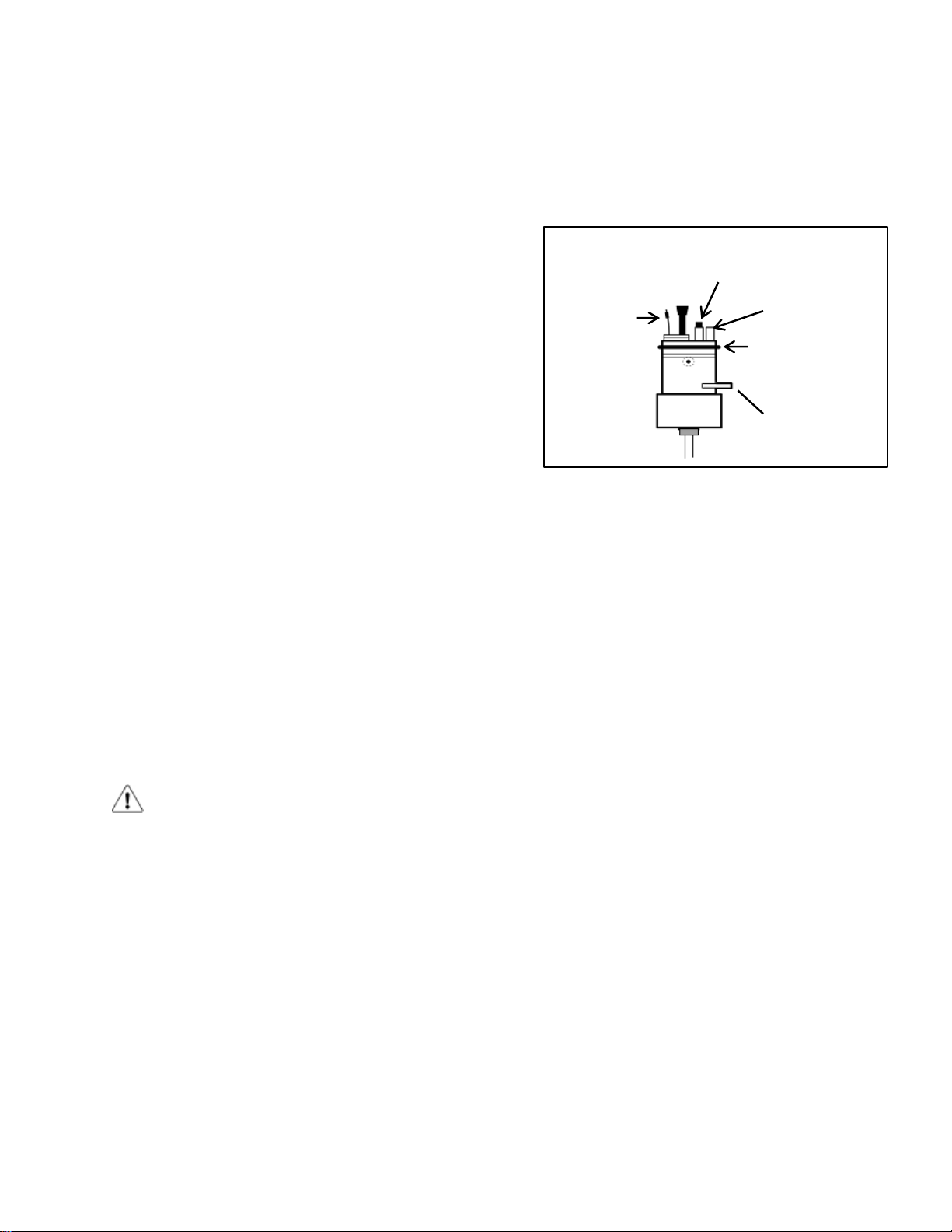

5.2.1 Automatic-Flow Bypass Manifold Assembly

(models PPM1, PPM1M and PPM2, PPM2M)

The AutoPilot®patented manifold is connected into

the plumbing after all other equipment. Water from

the pool/spa is moved though the manifold by the

circulation pump. The manifold uses four key

components:

The Tri-sensor provides data (from electronic

sensors) to the Digital Nano/Nano+ for

monitoring water flow, water temperature, and

salt concentration level. The Digital Nano/Nano+

uses this data to determine if conditions are

suitable for the cell to operate; the signal read

from the temperature sensor allows the

automatic temperature compensation feature to function.

The Cell (PPC1 or PPC2) receives power from the Digital Nano/Nano+ and converts

the salt contained in the water to chlorine.

The Strainer Screen prevents debris in the water from entering the Tri-sensor or cell, and

requires periodic inspection and cleaning.

The Bypass Check Valve allows the water flow rate to be slowed and optimized through the cell,

while permitting the pump to continue to circulate water to-and-from the pool/spa at full flow rates.

The reduced water flow through the cell results in a more efficient "Super-Chlorination” effect,

resulting in improved overall sanitization.

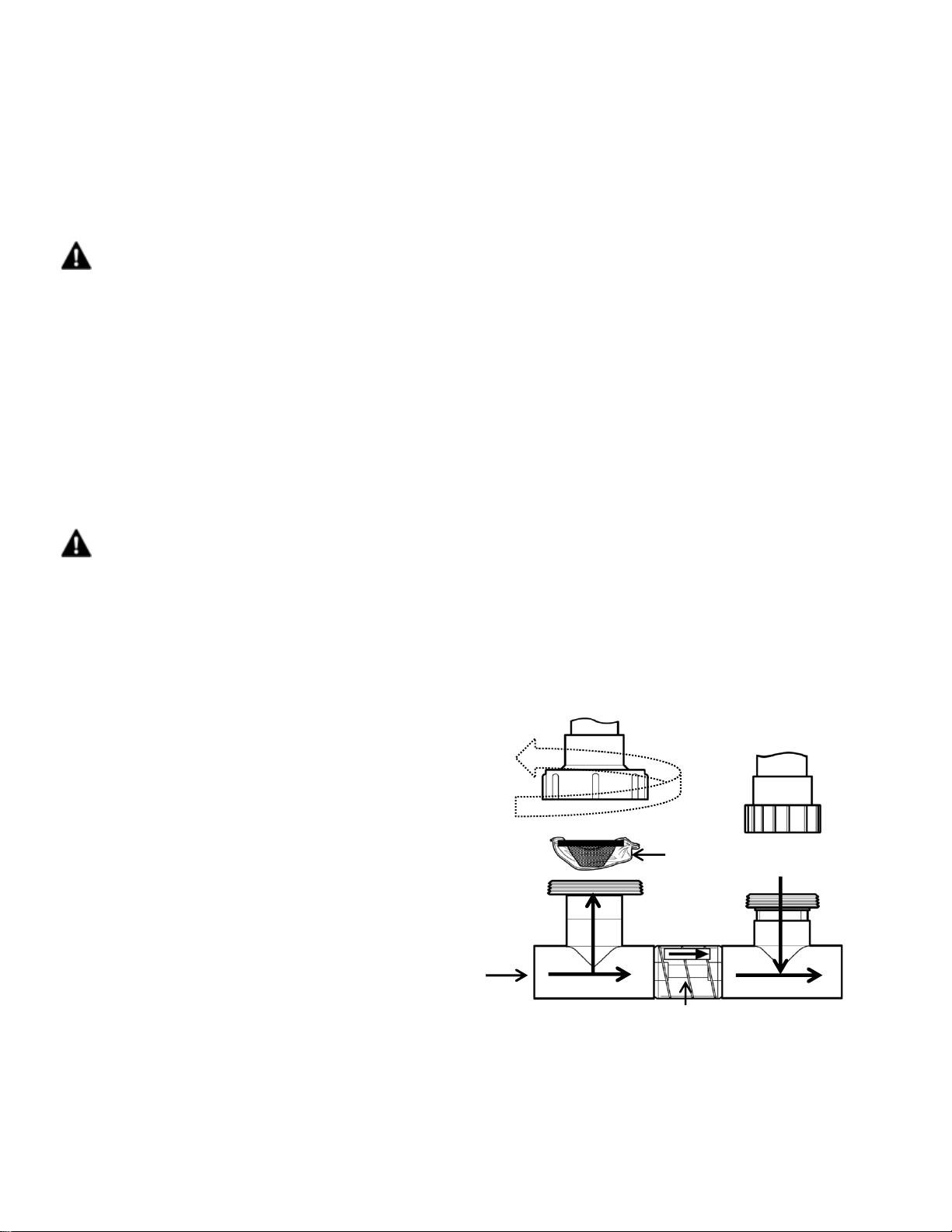

5.2.2 CoPilot®Manifold Assembly

The CoPilot®system is designed to be used in

conjunction with the Digital Nano/Nano+ to reduce

chlorine demand and extend cell life. This system is also

sold separately as an upgrade to existing Digital

Nano/Nano+ systems.

The manifold is connected into the plumbing after all

other equipment. Water from the pool/spa is moved

though the manifold by the circulation pump:

The Tri-sensor provides data (from electronic sensors)

to the Digital Nano/Nano+ for monitoring water flow,

water temperature, and salt concentration level. The

Digital Nano/Nano+ uses this data to determine if

conditions are safe for the cell to operate; the signal

read from the temperature sensor allows the automatic temperature compensation

feature to function.

The Cell (PPC1 or PPC2) receives power from the Digital Nano/Nano+ and converts the salt

contained in the water to chlorine.

The Strainer Screen prevents debris in the water from entering the Tri-sensor or cell, and

requires periodic inspection and cleaning.

The Bypass Check Valve allows the water flow rate to be slowed and optimized through the cell,

while permitting the pump to continue to circulate water to-and-from the pool/spa at full flow rates.

The reduced water flow through the cell results in a more efficient "Super-Chlorination” effect,

resulting in improved overall sanitization.

The Ozone Venturi Injector introduces ozone directly into the water before the Digital

Nano/Nano+ cell. The ozone venturi injector is connected to the CoPilot®via an Ozone Check

Valve and Tube Assembly (not shown).

Tri-sensor

Ozone Venturi

Injector

Cell

Bypass Check Valve

Strainer

Screen

Tri-sensor

Cell

Strainer

Screen

Bypass Check Valve

Figure 1

Figure 2

Page 12

5.3 AUTOMATICALLY REDUCE CHLORINE OUTPUT WHEN POOL COVER

CLOSES

When the pool cover is closed, the Digital Nano/Nano+ will automatically reduce the chlorine output to

20% of the normal open cover setting.

*This only applies to models that are equipped with the optional 863A Expansion Board and the

cover position switch is connected to the unit. See “Connecting the Retractable Cover Switch” in

section 8.6.3 on page 32 for more information.

SECTION 6 - MAINTENANCE

6.1 FUSE LOCATION AND RATINGS

WARNING: Failure to heed the following may result in permanent injury or death.

ELECTRICAL SHOCK HAZARD –Turn off the electrical power to unit before

servicing.

To inspect or service fuse, disconnect power and remove power center cover (see below for location of

fuse). Ratings

BOARD

FUSE SPECIFICATION

DESCRIPTION

Main Power Board When Converted to 115V

75041A, 75043A, 75041A-xx, 75043A-xx

250 Vac 2 Amp Slo Blo

Main AC Power Fuse for

115 Vac operation

Main Power Board (Factory set as 230 Vac)

75041A, 75043A, 75041A-xx, 75043A-xx

250 Vac 1 Amp Slo Blo

Main AC Power Fuse for

230 Vac operation

Location of Fuse

Fuse

Figure 3

Figure 4

Page 13

Tri-sensor Assembly

Flow Paddle

Salt Sensor Blades

Temperature

Sensor Post

Tri-sensor

O-Ring

Indicator of

Flow Direction

6.2 REMOVING / INSPECTING / CLEANING TRI-SENSOR

6.2.1 Tri-sensor Assembly Overview

The Tri-sensor Assembly is used to measure water flow, salt level, and water temperature.

Note: The use of high strength magnet devices in the close proximity of the Tri-sensor can

cause the flow switch to function incorrectly.

When the water flow reaches a minimum

flow rate of 15 gpm (76 L/min), the flow

paddle magnet closes a micro-switch

monitored by the Digital Nano/Nano+.

The CoPilot®Ozone manifold requires a

minimum flow of 25 gpm (95 L/min).

The Digital Nano/Nano+ uses dedicated

salt sensor blades to measure the level

of salt in the water.

The Digital Nano/Nano+ uses the

temperature sensor to determine water

temperature. This measurement is

required for the Patented Automatic

Temperature Compensation feature to

automatically adjust chlorine output as water temperature varies. Less chlorine is needed

in cold water, so chlorine output is automatically reduced as water temperature drops

(avoiding excess chlorine production). Conversely, more chlorine is needed in warmer

water, and production is automatically adjusted higher as water temperature increases.

Please note - The Tri-sensor normally does not require maintenance or cleaning.

6.2.2 Inspect Tri-sensor

1) Disconnect the Tri-sensor cable from the power center.

2) Remove the two (2) screws retaining the Tri-sensor in the Tee joint of the Manifold.

Note the orientation of the Directional of Flow Tab. The Tri-sensor must be installed in

the same orientation when it is reinstalled or replaced.

3) The Tri-sensor can now be pulled out of the Tee.

CAUTION: Failure to heed the following may result in equipment damage.

The Tri-sensor should not be removed from manifold at an angle, or the flow paddle

and/or flow post may be damaged.

Firmly grip the Tri-sensor assembly (this is typically done with a large pair of channel lock

pliers).

Twist the Tri-sensor back-and-forth while simultaneously pulling the Tri-sensor straight

out of the Tee joint.

4) Check the Tri-sensor assembly for any damage to the plastic housing and replace if needed.

5) Inspect the following on the flow switch:

Verify the thin metallic paddle is straight and free from erosion.

Verify the plastic post is straight and free of cracks. (Do not twist or bend the paddle or

the plastic post.)

6) Inspect the two salt sensor blades. The blades should not have any mineral deposits (scale)

or other debris on them.

Figure 5

Page 14

Water

Flow

7) Do not use any metallic objects to scrape the blade surfaces or you will remove or damage

the blade sensor coating.

6.2.3 Cleaning Tri-sensor/Salt Sensor

If required, you can remove a calcium scale buildup by creating a solution of water and muriatic

acid as follows. Do not use any metallic objects to scrape the blade surfaces or you will remove

or damage the blade sensor coating.

WARNING: Failure to heed the following may result in permanent injury or death.

CHEMICAL HAZARD - To avoid damaging splashes always add acid to water, never

water to acid. Wear appropriate personal safety protection including safety glasses

when using pool chemicals.

1) Mix the solution in a small container tall enough to cover the sensor blades. DO NOT add

water to acids; always add acid to water in container.

2) Mix one (1) part muriatic acid into four (4) parts water.

3) Immerse the salt sensor blades in the solution for up to 15 minutes. An effervescing

action indicates the calcium is being dissolved from the blades.

4) Rinse with fresh water and re-inspect. Repeat the acid treatment as necessary until all

scale has been eliminated.

6.2.4 Test Tri-sensor Flow Switch

WARNING: Failure to heed the following may result in permanent injury or death.

Do NOT operate system with a faulty water flow switch.

The Flow Switch is a critical equipment protection device to prevent damage to the cell or

system. When water flow has stopped, power to the cell is automatically turned OFF. It is

important to verify the proper operation of the Tri-sensor’s water Flow Switch protection device.

The following procedure can be used to verify the proper operation of the flow switch, or to flush

debris from the Bypass Valve.

1) Turn off the circulation pump.

2) Slightly loosen the union nut just below the

cell on the side of the manifold that does not

contain the filter screen. (A strap wrench may

be required.)

3) Completely loosen the manifold union nut that

contains the filter screen and pivot the

manifold to gain access to the filter screen.

4) Remove the screen. Clean the screen if dirty.

5) If the screen was dirty, then the system may

need to be purged to remove excess

debris. Leave the manifold off and run

the pump for a few seconds until

clear.

STRAINER SCREEN SHOWN

TEMPORARILY WRAPPED IN PLASTIC

Figure 6

Bypass Valve

This manual suits for next models

3

Table of contents

Other Autopilot Lighting Equipment manuals