Autotrol 255-960 User manual

Water Conditioning Control System

Operation and Maintenance Manual

Series 255 Valve / 960 Control

®

2

Table of Contents

Table of ContentsTable of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Special Features . . . . . . . . . . . . . . . . . . . . . . . 3

General Conditioner Information . . . . . . . . . . . 3

How Your Conditioner Works

Model 960 Control Front Panel

Control Settings. . . . . . . . . . . . . . . . . . . . . . . . 4

General Information

Time Of Day Clock

Time of Regeneration

Hardness Setting

Salt Setting

Capacity Setting

Water Conditioner Regeneration . . . . . . . . . . . 7

Automatic Regeneration

Manual Regeneration

Care of Your Water Conditioner. . . . . . . . . . . . 7

General

Cleaning the Injector/Injector Screen

Maintaining the Drain Line

Manual Valve Operation. . . . . . . . . . . . . . . . . . 9

Additional Features . . . . . . . . . . . . . . . . . . . . . 9

Disinfection of Water Conditioners . . . . . . . . . 9

Replacement Parts . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . 14

Alarms

Troubleshooting Procedures

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 17

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . 17

Safety

SafetySafety

Safety

Important: The plug-in transformer for this equipment

is rated for indoor use only.

Important: Never attempt to work on this control while

standing in or near water without disconnecting

electrical power to the control.

3

Introduction

IntroductionIntroduction

Introduction

The Model 960 control provides sophisticated,

demand-based water conditioning by incorporating a

microprocessor and a water meter to electronically

monitor the amount of water used daily. Each day, at

Time of Regeneration, the control determines if the

capacity remaining is sufficient to provide conditioned

water for the next day. If the remaining capacity is too

small, the control automatically regenerates the resin

bed.

If water usage changes, the computer automatically

compensates for the change and regenerates as

needed. Regeneration is based on actual water usage.

The control provides efficient, trouble-free,

uninterrupted soft water luxury.

The Series 255 valve combines design simplicity with

glass reinforced Noryl* plastic construction to provide

an uncommonly reliable appliance.

If maintenance becomes necessary, the Model 960

Series 255 water conditioning system offers a unique

“separation” capability for quick repairs.

*Noryl is a trademark of General Electric Company.

Special Features

Special FeaturesSpecial Features

Special Features

•Memory Retention. During a power outage,

critical operating information in the control’s

memory is stored in a special electronic device

called a NOVRAM. This information includes the

time of day, water usage amounts, daily average

waterusage,allprogrammingdataandthenumber

of days since the last regeneration. When power is

restored, the information is returned to the

microprocessor and operation resumes as if an

outage never occurred. The time of day will be late

by the length of the power outage. Because most

power outages are less than one minute in

duration, it may be months or years before the time

display requires resetting. If an outage of one or

more hours occurs, the time of day should be reset

but no other reprogramming is necessary.

•Design Reliability. Solid-state electronics assure

many years of trouble-free performance. The

metering system has only one moving part – a

rotating turbine that measures water usage.

•Time and Capacity Display. During normal

conditioning operation, the correct time of day

alternates with capacity on the display. The

capacity value is the number of gallons (cubic

meters for metric units) of water that the unit can

condition before another regeneration is needed.

•Flow Indicator. The colon between the hours and

minutes in the Time of Day display flashes to

indicatetheflowofservicewater throughthevalve.

This provides an easy determination of proper

meter operation.

•Hardness and Capacity Settings. Once the

hardness and capacity settings are entered, the

information cannot be lost due to a power outage,

so reprogramming is not necessary.

•Guest Cycle. An extra regeneration can be

achieved at any time by pressing the REGEN

button on the front panel. It takes a few minutes for

the regeneration to start. The unit completes the

regeneration in about two hours. This feature is

beneficial when you expect to use more than the

normal amount of water; for example, guest visits

or an extra heavy laundry day.

General Conditioner Information

General Conditioner InformationGeneral Conditioner Information

General Conditioner Information

How Your Conditioner Works

In general, your water conditioner works in the

following manner. Hard water flows into the conditioner

and through the resin bed where calcium and

magnesium hardness minerals are exchanged. The

conditioned water flows out of the resin bed into your

plumbing system. After a certain amount of hard water

has passed through the conditioner, the resin cannot

remove any more minerals. This resin state is called

exhaustion and indicates that the resin needs to be

regenerated. The regeneration process restores the

conditioner’s ability to soften water. The control

monitors the amount of water that flows through the

conditioner and automatically calculates when to

regenerate the resin bed.

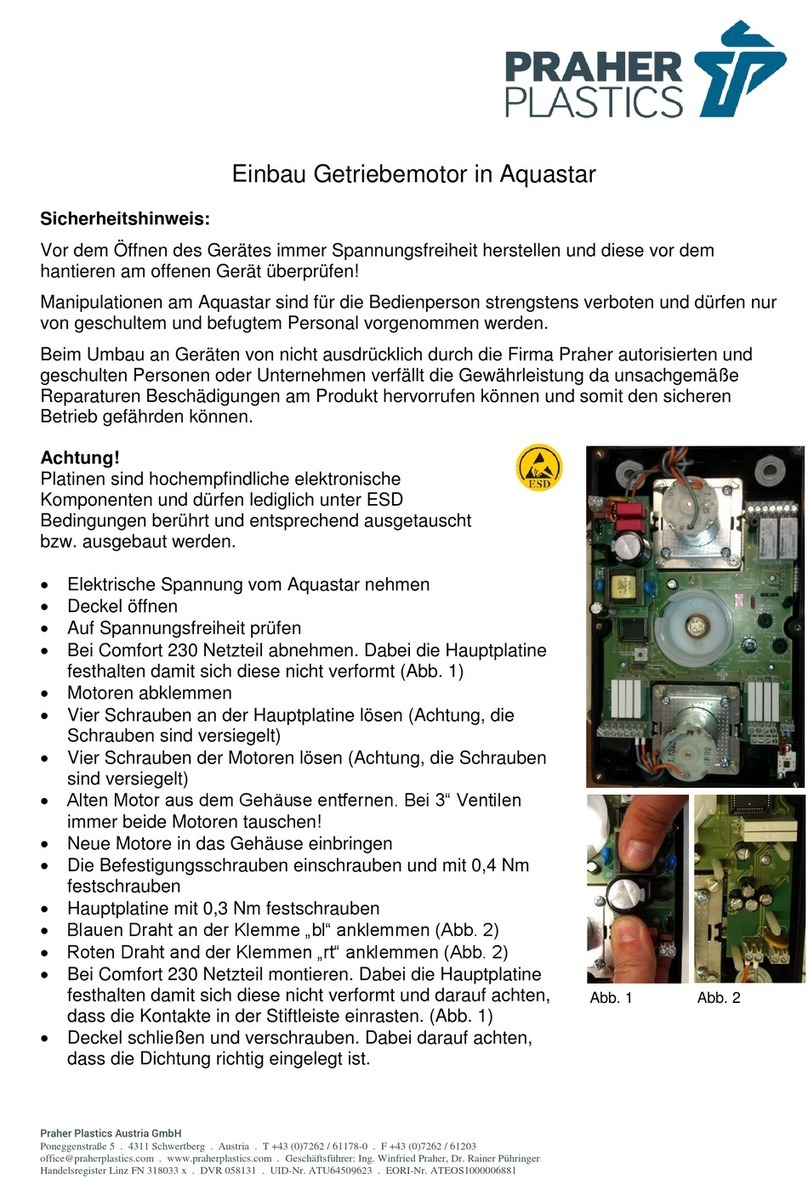

Model 960 Control Front Panel

Figure 1

The main components of the Model 960 control front

panel are:

•Regeneration Cycle Indicator

•Green Indicator Lights

•Four-Digit Display

•Programming Push Buttons

•REGEN Push Button

Refer to Figure 1 or your conditioner for the location of

these features.

4

The front panel incorporates several important features

which allow you to know the status of your water

conditioner. These features are:

•RegenerationCycleIndicator.Thewhiteindicator

points to the status of the conditioner. Soft water is

available when the indicator points to

REGENERATION COMPLETE. Other positions

indicate that the conditioner is regenerating the

resin bed and only hard water is available.

•Four-Digit Display. The four-digit red LED display

shows system information such as time of day,

gallons of conditioned water available, time the

conditioner will regenerate, or any error alarms.

•Green Indicator Lights. The green indicator lights

are located at the right of the control panel.

•TIME OF DAY

•TIME OF REGEN

•HARDNESS

•SALT AMOUNT

•CAPACITY

•REGEN TIME REMAINING

When a green light is on next to one of the six control

legends, the LED display provides information

pertaining to that legend. When conditioned water is

available, the display alternates between TIME OF DAY

and CAPACITY and the corresponding green lights

alternate between these control legends.

•Programming Push Buttons. The programming

buttons are located at the bottom of the panel

under the display. Use the buttons to look at or

change the conditioner settings.

•REGEN Push Button. The REGEN button is

located at the bottom of the panel below the six

indicator lights. Press the button to start a

regeneration of the water conditioner.

Note: If you press the button again a minute or more

after regeneration begins, a second regeneration will

start when the first regeneration is complete. The

display freezes with the REGEN TIME REMAINING

information. After the firstregenerationiscomplete, the

second regeneration begins immediately. The display

will alternate between the TIME OF DAY and REGEN

TIME REMAINING.

Control Settings

Control SettingsControl Settings

Control Settings

General Information

Use the four programming push buttons to change any

of the control settings. Settings can only be changed if

the regeneration cycle indicator is pointing at

REGENERATION COMPLETE. If you try to change a

setting when the cycle indicator is in any other position

or if the setting is not valid, the control beeps to let you

know that the new setting has been ignored.

To change a setting: Press the down arrow [↓] button

until the green light is illuminated next to the control

setting you want to change. That control setting value

shows on the display. Press the SET button and the far

right number on the display starts flashing. If you want

to change the number, press the up arrow [↑] button to

increase the number or the down arrow [↓] button to

decrease the number. To skip the number without

changing, press the left arrow [←] button.

Note: If you press and hold either the up arrow [↑]

button or the down arrow [↓] button for more than one

second, the flashing number will scroll up or down.

When the number is correct, press the left arrow [←]

button. The first number stops flashing and the next

number starts flashing. You can only change the

flashing number. Continue changing numbers until you

reach the desired setting. Press the SET button. The

numbers stop flashing and the control accepts the new

setting. After approximately 30 seconds, the control

starts alternating the display between TIME OF DAY

and CAPACITY.

Note: If abeepsounds,thenewsettingisnotaccepted

because it was outside the range of allowable values.

The old setting will be shown on the display.

Time of Day Clock

The control uses the Time of Day clock and the amount

of conditioned water remaining to decide when to

beginaregeneration.Whenaregenerationisnecessary

and the Time of Day clock is at the same time as the

Time of Regeneration setting, the control starts the

regeneration.

When the green light is on next to the TIME OF DAY

legend, the display is showing the time that the control

thinks is correct. Ifyou need to change the Time of Day,

refer tothe instructionslaterinthissection.TheTimeof

Day displays time in hours and minutes separated by a

colon[:]. When the colon is flashing on and off, water is

flowing through the conditioner. There is a small red dot

in the upper left corner near the p.m. letters to indicate

p.m. for 12-hour clocks. When the dot is off, the time is

a.m. You can set the clock for any time, a.m. or p.m.

Complete the following steps to change the Time of

Day:

1. Press the down arrow [↓] button until the green light

next to the TIME OF DAY legend is on.

2. Press the SET button and the minute number on

the display starts flashing. If you want to change

this number, press the up arrow [↑] button to

increase the number or the down arrow [↓] button

to decrease the number. To skip the number

without changing, press the left arrow [←] button.

3. When the number is correct, press the left arrow

[←] button. The first number stops flashing and the

5

next number starts flashing. You can only change

the flashing number.

4. Continue changing numbers until you reach the

desired setting.

5. Press the SET button. The number stops flashing

and the control accepts the new setting. After

approximately 30 seconds, the control starts

alternating the display between TIME OF DAY and

CAPACITY.

Note: If a beep sounds, the new setting is not

accepted.

Reminder: The control does not keep time during a

poweroutagebutwillresumeitstime,keepingfromthe

time of day power was lost. A short power outage

should not cause a problem. If the outage is several

hours, the control will regenerate at the wrong time of

day. All other memory is stored in the NOVRAM and

maintained during power outage. Refer to page 3.

Time of Regeneration

The control uses the Time of Regeneration to decide

when to begin a regeneration. When a regeneration is

necessary and the Time of Day clock is at the same

time as the Time of Regeneration setting, the control

starts regeneration. The factory setting for Time of

Regeneration is 2:00 a.m. If this time is inconvenient,

you can select any other time of day. Remember that

soft water is not available during a regeneration of the

water conditioner. Time of Regeneration can be set for

any time, a.m. or p.m.

Note: The control may be programmed for an

immediate regeneration option. In this case, the control

does not wait for the Time of Regeneration but

regenerateswhentheremainingcapacityreacheszero.

Contact your dealer for more information regardingthis

option.

Complete the following steps to change the Time of

Regeneration:

1. Press the down arrow [↓] button until the green light

next to the TIME OF REGEN legend is on.

2. Press the SET button and the minute number on

the display starts flashing. If you want to change

this number, press the up arrow [↑] button to

increase the number or the down arrow [↓] button

to decrease the number. To skip the number

without changing, press the left arrow [←] button.

3. When the number is correct, press the left arrow

[←] button. The first number stops flashing and the

next number starts flashing. You can only change

the flashing number.

4. Continue changing numbers until you reach the

desired setting.

5. Press the SET button. The number stops flashing

and the control accepts the new setting. After

approximately 30 seconds, the control starts

alternating the display between TIME OF DAY and

CAPACITY.

Note: If a beep sounds, the new setting is not

accepted.

Hardness Setting

The Hardness Setting refers to the amount of hardness

minerals in your water before it is conditioned. The

control uses this setting to calculate how many gallons

of water can be conditioned before a regeneration is

necessary.

Your water treatmentdealertestedthewaterat thetime

of installation and entered a Hardness Setting in the

control. We recommend that you consult your dealer or

have your water retested before changing this setting.

You can see the Hardness Setting the dealer enteredby

pressing the down arrow [↓] button until the green light

next to the HARDNESS legend is on. The number on

the display is the measure of water hardness in grains

per gallon (milligrams per liter for metric).

Complete the following steps to change the Hardness

Setting:

1. Press the down arrow [↓] button until the green light

next to the HARDNESS legend is on. The setting

range is 3 to 250 grains/gallon (30 to

2500 milligrams/liter for metric).

2. Press the SET button and the first number starts

flashing. If you want to change this number, press

the up arrow [↑] button to increase the number or

the down arrow [↓] button to decrease the number.

To skip the number without changing, press the left

arrow [←] button.

3. When the number is correct, press the left arrow

[←] button. The first number stops flashing and the

next number starts flashing. You can only change

the flashing number.

4. Continue changing numbers until you reach the

desired setting.

5. Press the SET button. The number stops flashing

and the control accepts the new setting. After

approximately 30 seconds, the control starts

alternating the display between TIME OF DAY and

CAPACITY.

Note: If a beep sounds, the new setting is not

accepted.

Reminder: Whenever the HARDNESS or CAPACITY

setting is changed, you should regenerate the

conditioner by pressing the REGEN button.

6

Salt Setting

The Salt Setting refers to the total amount of salt, in

pounds, that the control uses during a regeneration of

the resin bed. The amount of salt used in a regeneration

determines the amount of water that the conditioner

softens between regenerations. If this setting is

changed, it may be necessary to change the Capacity

Setting as well. Refer to Table 1 for SALT and

CAPACITY information.

Complete the following steps to change the Salt

Setting:

1. Press the down arrow [↓] button until the green light

next to the SALT legend is on. The display shows a

number with a zero or a five to the right of the

decimal point, no other number can be entered in

this position. The setting range is 0.5 to 99.5 pounds

(0.1 to 25.5 kilograms for metric).

2. Press the SET button and the first number starts

flashing. If you want to change this number, press

the up arrow [↑] button to increase the number or

the down arrow [↓] button to decrease the number.

To skip the number without changing, press the left

arrow [←] button.

3. When the number is correct, press the left arrow

[←] button. The first number stops flashing and the

next number starts flashing. You can only change

the flashing number.

4. Continue changing numbers until you reach the

desired setting.

5. Press the SET button. The number stops flashing

and the control accepts the new setting. After

approximately 30 seconds, the control starts

alternating the display between TIME OF DAY and

CAPACITY.

Note: If a beep sounds, the new setting is not

accepted.

If the control does not display this setting, your dealer

has disabled it. Some municipalities require that the

Salt Setting not be adjustable. Contact your dealer for

additional information.

Capacity Setting

The Capacity Setting refers to the kilograins of

hardness that can be removed by the conditioner

between regenerations. Yourdealerentered this setting

when the control was installed. Please consult with

your dealer before changing this setting.

*Consult factory for specific settings information.

Table 1 – Suggested Salt Settings (Pounds of Salt for Various Size Conditioners)

Kilograins

ofHardness

Capacity

Setting

0.5 ft30.75 ft31.0 ft31.25 ft31.5 ft31.75 ft32.0 ft3*2.5 ft3*3.0 ft3*3.5 ft3

124.5- --------

169.05.0--------

20-8.56.0-------

24-14.08.57.0------

30 - - 15.0 11.0 10.0 - - - - -

32 - - 18.5 13.0 11.0 9.0 - - - -

35 - - - 17.0 13.0 11.0 10.0 - - -

40 - - - 23.0 18.0 14.0 13.0 - - -

48 - - - - 28.0 22.0 18.0 14.0 - -

60 - - - - - - 30.0 23.0 18.0 -

72-- -----35.026.023.0

78-- ------30.028.0

81-- ------36.030.0

90-- ------45.038.0

95-- -------42.0

105-- -------56.0

7

Complete the following steps to change the Capacity

Setting; refer to Table 1:

1. Press the down arrow [↓] button until the green light

next to the CAPACITY legend is on. The setting

range is 0.1 to 140.0 kilograins (0.1 to 14.00

kilograms for metric).

2. Press the SET button and the first number starts

flashing. If you want to change this number, press

the up arrow [↑] button to increase the number or

the down arrow [↓] button to decrease the number.

To skip the number without changing, press the left

arrow [←] button.

3. When the number is correct, press the left arrow

[←] button. The first number stops flashing and the

next number starts flashing. You can only change

the flashing number.

4. Continue changing numbers until you reach the

desired setting.

5. Press the SET button. The number stops flashing

and the control accepts the new setting. After

approximately 30 seconds, the control starts

alternating the display between TIME OF DAY and

CAPACITY.

Note: If a beep sounds, the new setting is not

accepted.

Reminder: Whenever the HARDNESS or CAPACITY

setting is changed, you should regenerate the

conditioner by pressing the REGEN button.

If the control does not display the Capacity Setting,

yourdealerhasdisabledit.Somemunicipalitiesrequire

that the Salt Setting be disabled, which also disables

theCapacitySetting.Contactyourdealerforadditional

information.

Water Conditioner Regeneration

Water Conditioner RegenerationWater Conditioner Regeneration

Water Conditioner Regeneration

Your water conditioner regenerates for one of two

reasons:

•The control determines that the conditioner

does not have enough capacity remaining to

satisfy your soft water needs for the next day.

•The REGEN button was pressed.

In eithercase, the REGENERATION INDICATOR makes

one complete counterclockwise rotation and returns to

REGENERATION COMPLETE. The indicator pauses at

some or all of the different positions shownon the label

around the indicator. The display alternates between

TIME OF DAY and REGEN TIME REMAINING, as

indicatedby thegreenlights nextto thelegends. Regen

Time Remaining is shown in minutes on the display.

When the indicator reaches REGENERATION

COMPLETE and the time remaining is zero, the

regeneration is complete, conditioned water is

available for use, and the control starts alternating the

display between TIME OF DAY and CAPACITY. No

settings can be changed during a regeneration. The

settings can be viewed, but the control beeps and

ignores any attempt to change settings.

Automatic Regeneration

Thecontrolmakesregenerationdecisionsbasedonthe

amount of water that has flowed through the

conditioner. The control uses the Hardness and

Capacity settings to calculate the number of gallons

(cubic meters for metric) which can be conditioned. At

the Time of Regeneration, the control updates the

average usage for the previous day and adjusts the

reserve capacity accordingly. The reserve is kept at a

minimum for optimum economy. The control reacts to

a sudden increase in water usage. If a day’s usage is

more than double the current average, the control

anticipates that a second day of high usage is likely to

occur. The high usage amount is used as the reserve

when the control performs the regeneration

computation.

The Guest Cycle option and the Calendar Override

option may override this computation. Refer to the

Additional Features section in this manual or contact

your dealer for more information about these options.

The factory setting for Time of Regeneration is

2:00 a.m. You can change this time. Refer to the Time

of Regeneration section in this manual for additional

information.

Manual Regeneration

Toforcethecontroltoperformaregeneration,pressthe

REGEN push button. This button is located on the front

of the control. When you press the REGEN button, the

control performs a full regeneration of the conditioner.

You can use this feature if you need a large amount of

conditioned water but the capacity remaining is low.

Note: If you press this button again a minute or more

after regeneration begins, a second regeneration will

start when the first regeneration is complete. The

display shows only the REGEN TIME REMAINING

information.

Care of Your Water Conditioner

Care of Your Water ConditionerCare of Your Water Conditioner

Care of Your Water Conditioner

General

Checkthesaltlevelinthesaltstorage tankafewweeks

after installation and weekly after that. Always maintain

the salt level above the water level for a consistent salt

dosage and proper water conditioner operation. Don’t

allow the conditioner to run out of salt before refilling.

When filled, the salt storage tank contains enough salt

to support numerous resin bed regenerations. Use

pellet, block, or nugget water conditioner salt. Do not

9

Be sure that the drain line remains unrestricted so that

regeneration water and brine can flow freely to the

drain. Do not set objects on the drain line that could

crimp the line and restrict flow.

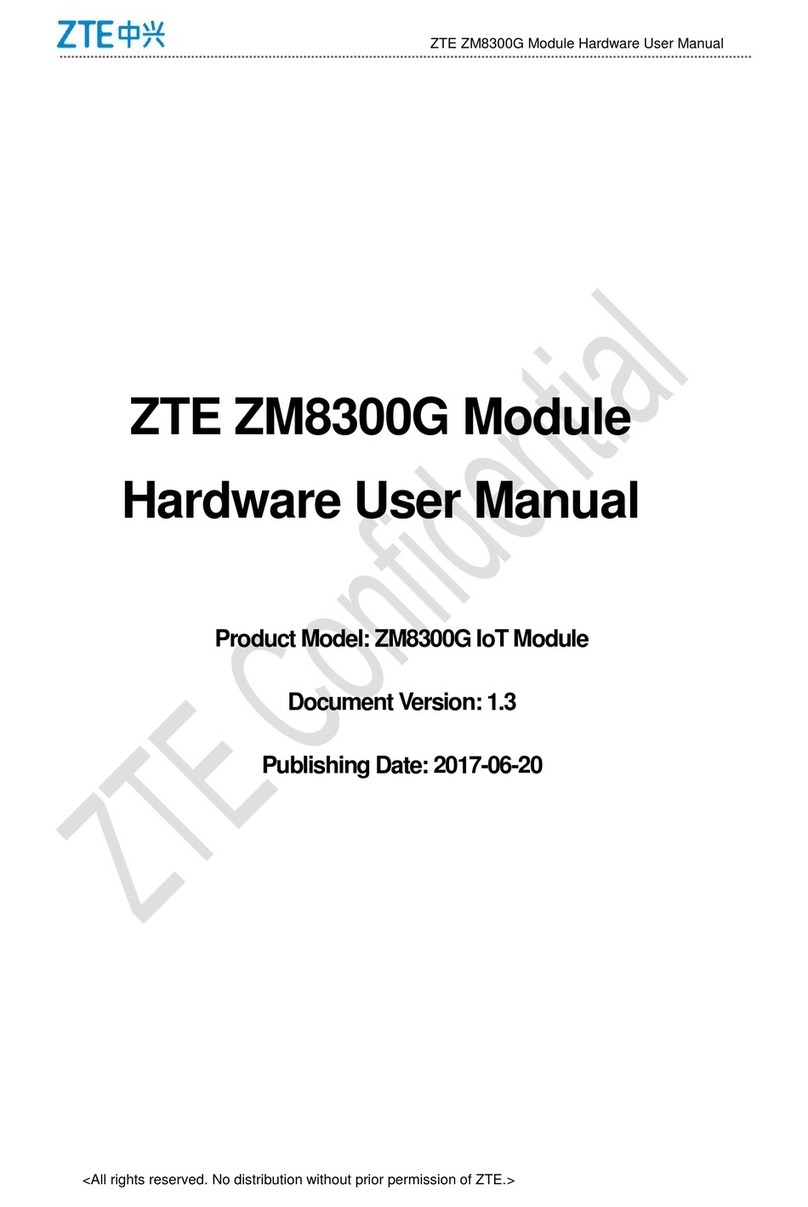

Manual Valve Operation

Manual Valve OperationManual Valve Operation

Manual Valve Operation

The camshaft may be rotated manually to actuate the

valve functions for service purposes.

1. Unplug the wall-mount transformer.

2. Remove the rear cover by pulling back on the tab

provided on the cover. Next, lift the rear cover off

the valve, Figure 2.

3. Rotate the camshaft COUNTERCLOCKWISE until

the appropriate valve is opened by the camshaft

lobe. Use the regeneration cycle indicator as a

guide to which valve discs are open.

4. When the service is complete, rotate the camshaft

so the regeneration cycle indicator is pointing to

the end of the refill cycle.

5. Reinstall cover, reconnect electric power, and reset

the time of day.

6. The display will show Err3 and the motor will start

up. After approximately five minutes, the indicator

will point to REGENERATION COMPLETE and the

control starts alternating the display between TIME

OF DAY and CAPACITY.

7. The conditioner is now in operation.

Additional Features

Additional FeaturesAdditional Features

Additional Features

When your dealer installs the conditioner, the control

settings are adjusted to meet your soft water needs.

However, there are additional features which your

dealer can incorporate into the control. These features

are 12- or 24-hour clock, U.S. or metric units of

measure, Calendar Override and Immediate

Regeneration.

12 or 24-Hour Clock

The standard clock is a 12-hour with a p.m. indicator.

An optional 24-hour clock without a p.m. indicator is

available. Time can be set from 00:00 to 23:59. This

option applies to both the Time of Day and Time of

Regeneration settings.

U.S. or Metric Units of Measure

The standard units of measure are U.S. values.

Hardness is in grains per gallon, salt is in pounds, and

capacity is in kilograins. The metric option changes

these to milligrams per liter, kilograins to kilograms

respectively. All control settings use the metric values

when the metric option is selected.

Calendar Override

TheCalendarOverrideoptionisamethodofforcing the

control to regenerate after a preset number of days, if a

normal demand-based regeneration does not occur

first. This feature is not set at the factory; your dealer

can set it at one to 30 days.

Immediate Regeneration

The control is factory set to wait until the Time of Day

reaches the Time of Regeneration to begin a

regeneration. Your dealer can program the control to

regenerate any time the capacity remaining reaches

zero. Remember that you do not have soft water

available during any regeneration.

Disinfection of Water Conditioners

Disinfection of Water ConditionersDisinfection of Water Conditioners

Disinfection of Water Conditioners

The construction materials of the water conditioning

system do not support bacterial growth or contaminate

the water supply. However, we recommend that your

conditioner be disinfected after installation and before

the conditioner is used to treat potable water. In

addition, a conditioner can become fouled with organic

matter during normal usage or with bacteria from the

watersupply.Periodicdisinfection is recommendedfor

all conditioners.

Use one ofthe following methods of disinfection based

onoperatingconditions,styleofconditioner,typeofion

exchanger, and disinfectant available.

Sodium Hypochlorite

Sodium hypochlorite, 5.25% solutions, can be used

withpolystyreneresin,synthetic gelzeolite,greensand,

and bentonites and are available under trade names

such as Clorox, Linco, Bo Peep, White Sail, and Eagle

Brand Bleach.

The recommended dosage for 5.25% solutions is:

•Polystyrene resin: 1.2 fluid ounces per cubic foot

•Non-resinous exchangers: 0.8 fluid ounce per

cubic foot

Calcium Hypochlorite

Calcium hypochlorite, 70% available chlorine, is

available in several forms including tablets and

granules. These solid materials can be used directly

without dissolving before application. The

recommended dosage for calcium hypochlorite is two

grains (approximately 0.1 ounce) per cubic foot.

Complete the following steps to disinfect the

conditioner:

1. Add the disinfectant to the brine well of the brine

tank. Make sure that the brine tank has water in it so

the solution is carried into the conditioner.

2. Press the REGEN button.

11

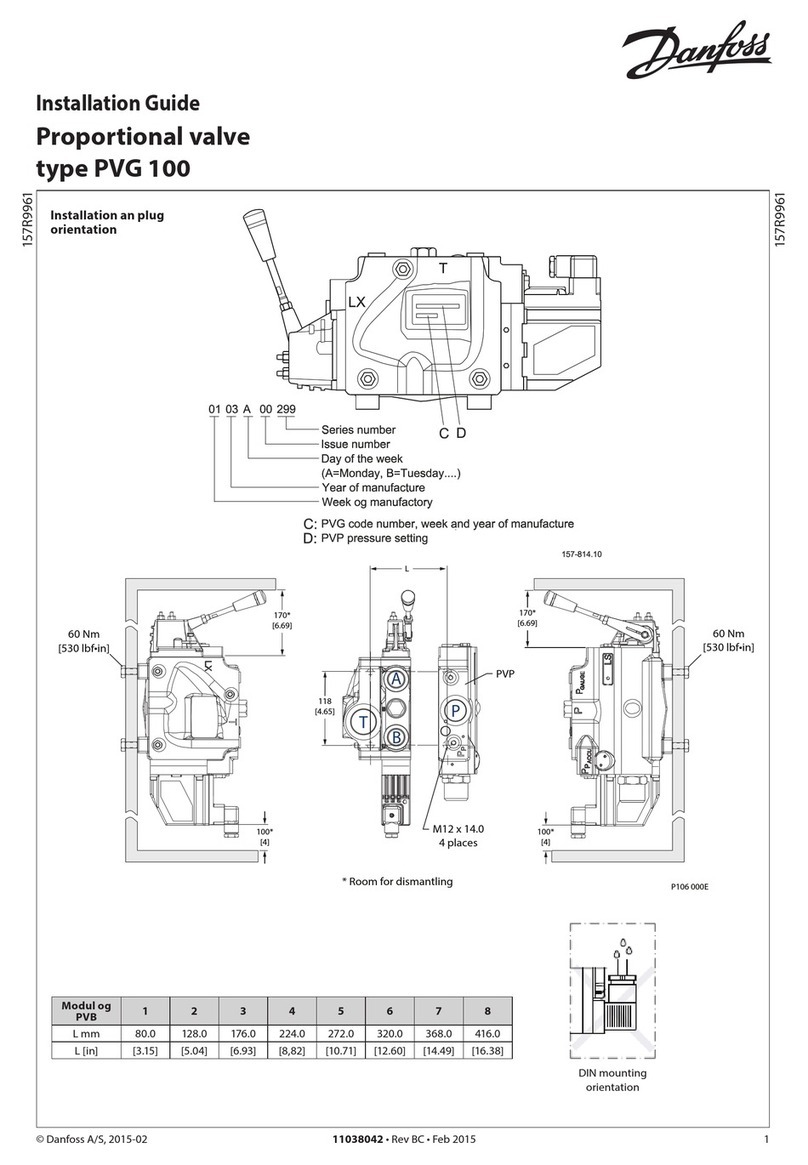

Valve Body and Tank Adapter Module

Valve Body and Tank Adapter ModuleValve Body and Tank Adapter Module

Valve Body and Tank Adapter Module

*Not Shown

Code Part

No. Description Qty. Code Part

No. Description Qty.

1 1000238 Valve Assembly w/o Flow Controls 1 9 Injector Cap with O-Ring: 1

2 1000824 Camshaft, Standard, One-Piece 1 1000217 “A” Cap

3 1000827 Valve Cover, Black 1 1000218 “B” Cap

4 Brine Refill Flow Control Assembly: 1 1000219 “C” Cap

1000221 .14 gpm 10 1033784 Tank Adapter Assembly 1

1000223 .40 gpm 11 1010429 O-Ring, 3-1/8 x 3-1/2 x 3/16 BN 1

5 1000226 Screen/Cap Assembly w/O-Ring 1 12 1010428 O-Ring, 3/4 x 1 x 1/8 EP 1

6 Drain Control Assembly w/O-Rings 1 13 1031402 Locking Bar: English Language 1

1034162 No. 6 for 6-inch Diameter Tank 14 1006093 Screw, No. 8 x 9/16 inch 1

1000209 No. 7 for 7-inch Diameter Tank 15 1001580 Spring, Valve Discs 9

1000210 No. 8 for 8-inch Diameter Tank Kits:

1000211 No. 9 for 9-inch Diameter Tank 16 1033066 New to Old Air Check Adapter

1000212 No. 10 for 10-inch Diameter Tank 17 1032416 Air Check Assembly 1

1000213 No. 12 for 12-inch Diameter Tank 18 1001404 O-Ring Group: Tank Adapter

1000214 No. 13 for 13-inch Diameter Tank 19 1040459 O-Ring Group: Piping Boss

1000215 No. 14 for 14-inch Diameter Tank 20 1041010 13/16 Rubber Insert (Optional)

7 1030502 Ball, Flow Control 1 * 1000250 Valve Discs Replacement

8 Injector Assembly with O-Rings: 1

1032970 “A” Injector – White

1032971 “B” Injector – Blue

1032972 “C” Injector – Red

12

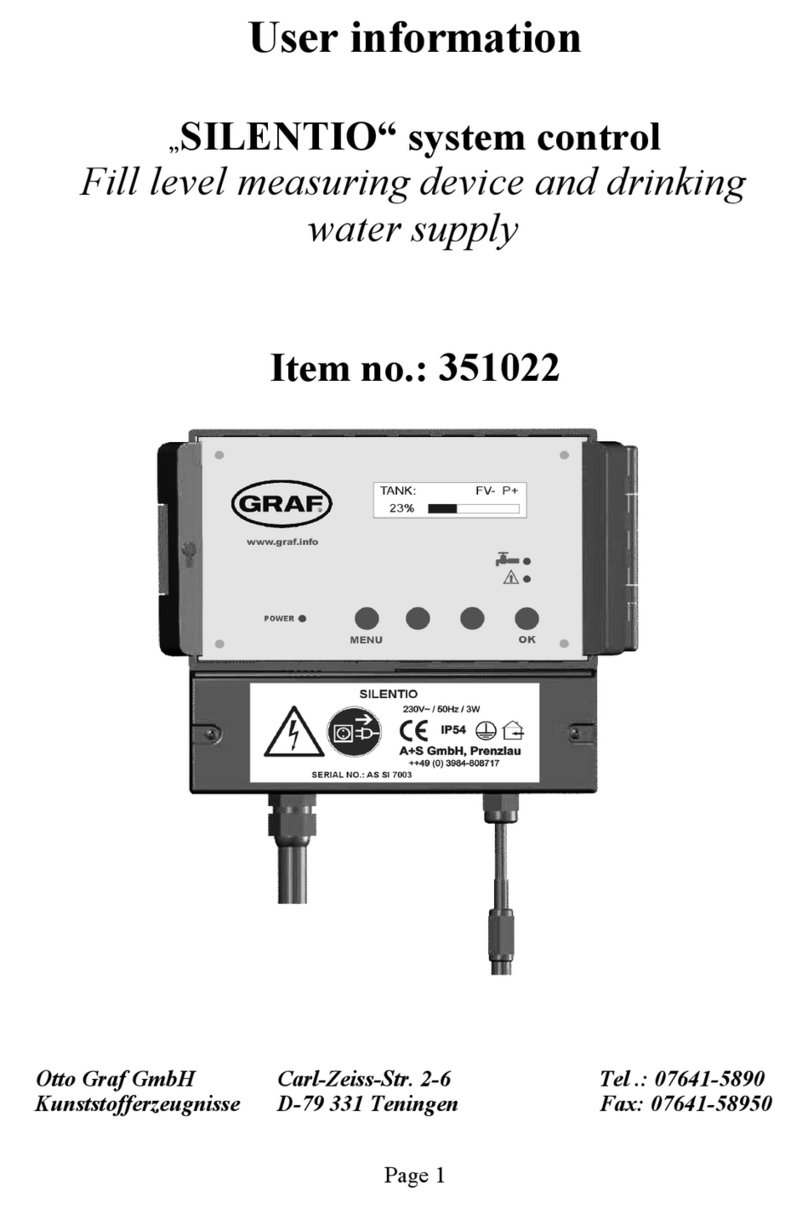

Meter Adapter, Bypass Valve and Piping Boss

Meter Adapter, Bypass Valve and Piping BossMeter Adapter, Bypass Valve and Piping Boss

Meter Adapter, Bypass Valve and Piping Boss

B

Y

P

A

S

S

B

Y

P

A

S

S

Bypass Valve

Piping Boss

Meter Adapter

960 Control

Wall-Mount Transformer

Inlet

Drain Outlet

Inlet

Drain Outlet

2

1

1

2

3

4

1

2

13

Meter Adapter, Bypass Valve and Piping Boss

Meter Adapter, Bypass Valve and Piping BossMeter Adapter, Bypass Valve and Piping Boss

Meter Adapter, Bypass Valve and Piping Boss

*Not Shown

Code Part

No. Description Qty. Code Part

No. Description Qty.

1 1040769 Bypass 1 Kit Piping Boss (includes hardware): 1

2 1040524 Installation Kit-Bypass 11040277 3/4-inch NPT, Brass

1040278 1-inch NPT, Brass

* Plumbing Adapters 1040281 3/4-inch BSPT, Brass

1001606 3/4-inch Copper Tube Adapter Kit 11040282 1-inch BSPT, Brass

1001670 1-inch Copper Tube Adapter Kit 11040279 3/4-inch NPT, Noryl

1001608 22-mm Copper Tube Adapter Kit 11040280 1-inch NPT, Noryl

1001609 28-mm Copper Tube Adapter Kit 11040283 3/4-inch BSPT, Noryl

1001613 3/4-inch CPVC Tube Adapter Kit 11040284 1-inch BSPT, Noryl

1001614 1-inch CPVC Tube Adapter Kit 12 1040339 Installation Kit-Piping Boss

1001615 25-mm CPVC Tube Adapter Kit 1* 1001408 Elbow Adapter

1001769 3/4-inch NPT Plastic Pipe Adapter Kit 11 1032350 Kit, Meter Adapter 1

1001603 1-inch NPT Plastic Pipe Adapter Kit 12 1032351 Installation Kit-Meter Adapter 1

1001604 3/4-inch BSPT Plastic Pipe Adapter Kit 1

1001605 1-inch BSPT Plastic Pipe Adapter Kit 1

1001611 3/4-inch BSPT Brass Pipe Adapter Kit 13 960 or 960B Electronic Timer 1

1001610 1-inch NPT Brass Pipe Adapter Kit 14 Wall-Mount Transformer 1

1001612 1-inch BSPT Brass Pipe Adapter Kit 11000810 100V Japanese Plug

1000811 120V North American Plug

1000812 220V Australian Plug

1000813 220V British Plug

1000814 220V European Plug

Bypass Valve

Bypass ValveBypass Valve

Bypass Valve Piping Boss

Piping BossPiping Boss

Piping Boss

Meter Adapter

Meter AdapterMeter Adapter

Meter Adapter

15

Table 3 Troubleshooting Procedures

Problem Cause Solution

Hard Water at the Tap. a. Low or no salt in the salt storage tank.

b. Salt setting too low to accommodate

water hardness or water usage.

c. Unit did not regenerate.

d. Plugged injector !

e. Air check valve prematurely closed.

a. Refill the salt storage tank and manually

initiate a regeneration. Refer to the

Manual Regeneration section in this

manual.

b. Change the salt setting. Refer to the Salt

Setting section in this manual.

c. Check power.

d. Clean injector and screen. Refer to the

Cleaning the Injector/Injector Screen in

this manual. Briefly put control into brine

refill status. Refer to the Manual Valve

Operation section in this manual.

e. Replace or repair air check if needed.

Check brine line connections.

Hard water leakage during

service. a. Improper regeneration.

b. Leaking of bypass valve !

c. O-ring around riser tube damaged !

a. Check that the correct salt dosage is

used. Repeat Regeneration.

b. Contact dealer.

c. Contact dealer.

Loss of power to the system. a. Transformer unplugged.

b. Fuse blown, circuit breaker open, or

circuit switched off.

a. Connect power.

b. Correct the electrical problem.

Control does not regenerate

automatically. a. Transformer unplugged.

b. Defective control. a. Plug transformer into outlet; plug

transformer cable into control.

b. Contact dealer.

Control regenerates at the

wrong time of day. a. Clock set incorrectly. a. Reset clock. Refer to the Time of Day

clock/Time of Regeneration sections in

this manual.

Control does not draw brine. a. Low water pressure.

b. Restricted drain line.

c. Injector or injector screen plugged !

d. Injector defective !

e. Valve disc 2 and/or 3 not closed.

f. Air check prematurely closed.

a. Increase water pressure.

b. Remove restriction.

c. Clean injector and screen. Refer to the

Cleaning the Injector/Injector Screen

section in this manual.

d. Replace injector. Contact dealer.

e. Manually operate valve stem to flush out

foreign matter holding disc open. Briefly

put control into brine refill status. Refer to

the Manual Valve Operation section in

this manual.

f. Replace or repair air check if needed.

Check brine line connections.

16

Problem Cause Solution

Intermittent or irregular brine

draw. a. Low water pressure.

b. Defective injector !a. Increase water pressure.

b. Replace both injector and injector cap.

Contact dealer.

Brine tank overflow. a. Brine valve disc 1 held open.

b. Valve disc 2 and/or 3 not closed

during brine draw, causing brine refill.

c. Air leak in brine line to air check.

d. Salt setting too high.

a. Manually operate valve stem to flush out

foreign matter holding disc open.

b. Manually operate valve stem(s) to flush

out foreign matter holding disc(s) open.

c. Check all connections in brine line for

leaks.

d. See Table 1 for suggested salt settings.

System using more or less

salt than salt setting. a. Inaccurate setting. a. Correct salt setting. Refer to the Salt

Setting section in this manual.

Control backwashes at

excessively low or high rate. a. Incorrect backwash controller.

b. Foreign matter affecting controller

operation !

a. Contact dealer.

b. Remove backwash controller. Clean and

replace.

Flowing or dripping water at

drain line after regeneration. a. Drain valve (5 or 6) held open by

foreign matter.

b. Weak valve stem return spring.

a. Manually operate valve stem to flush out

foreign matter holding disc open. Contact

dealer.

b. Contact dealer.

Table 3 Troubleshooting Procedures

17

Specifications

SpecificationsSpecifications

Specifications

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 to 132 VAC, 60 Hz

Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 to 120oF (1 to 49oC)

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 to 100% condensing allowed

Water Meter Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 to 23 gpm (1.9 to 87 Lpm)

Note: Wall-mount transformer is rated for indoor use only.

Glossary of Terms

Glossary of TermsGlossary of Terms

Glossary of Terms

Alarms

Alarms are beeps which alert you to operating

conditionsrequiringattention.Thebeepsareon forone

secondandofffornineseconds.Thedisplayshowsthe

type of error. Referto the Alarms section in this manual

for additional information.

Backwash

An upward flow of water which expands the resin bed

to remove foreign particles.

Brine

The salt solution which regenerates the conditioner’s

resin bed.

Brine Draw

The process of drawing the brine solution from the salt

storage tank into the resin tank.

Calendar Override Regeneration

If a normal demand-based regeneration does not

occur, the Model 960 Control regenerates the system

after a preset number of days. Your dealer can set this

feature at one to 30 days.

Fast Rinse (Purge)

Aflowof waterthroughtheresin bedwhichpropelsany

remaining brine solution out of the resin tank to the

drain.

Hardness

A common quality of water containing dissolved

calcium, magnesium and other elements. Water

hardness is usually expressed in grains per gallon or

milligrams per liter as calcium carbonate equivalent.

Manual Regeneration (Guest Cycle)

Forces the control to regenerate by pressing the

REGEN button.

Regeneration

Includes the backwash, brine draw, and fresh water

rinse steps necessary to prepare the resin bed for

conditioning after exhaustion. Abbreviated as

“REGEN” in this manual.

Regeneration Indicator

The mechanical component which indicates the

regeneration cycle status.

Resin Bed

The supply of synthetic organic ion exchange material

used in water conditioners.

© Copyright 2000, 1999 Osmonics

Printed in the USA P/N 1017934 Rev. C

Table of contents

Other Autotrol Control Unit manuals