8(16)

Make sure that all three couplings are properly connected, otherwise the hydraulic

motors of the attachment may get damaged.

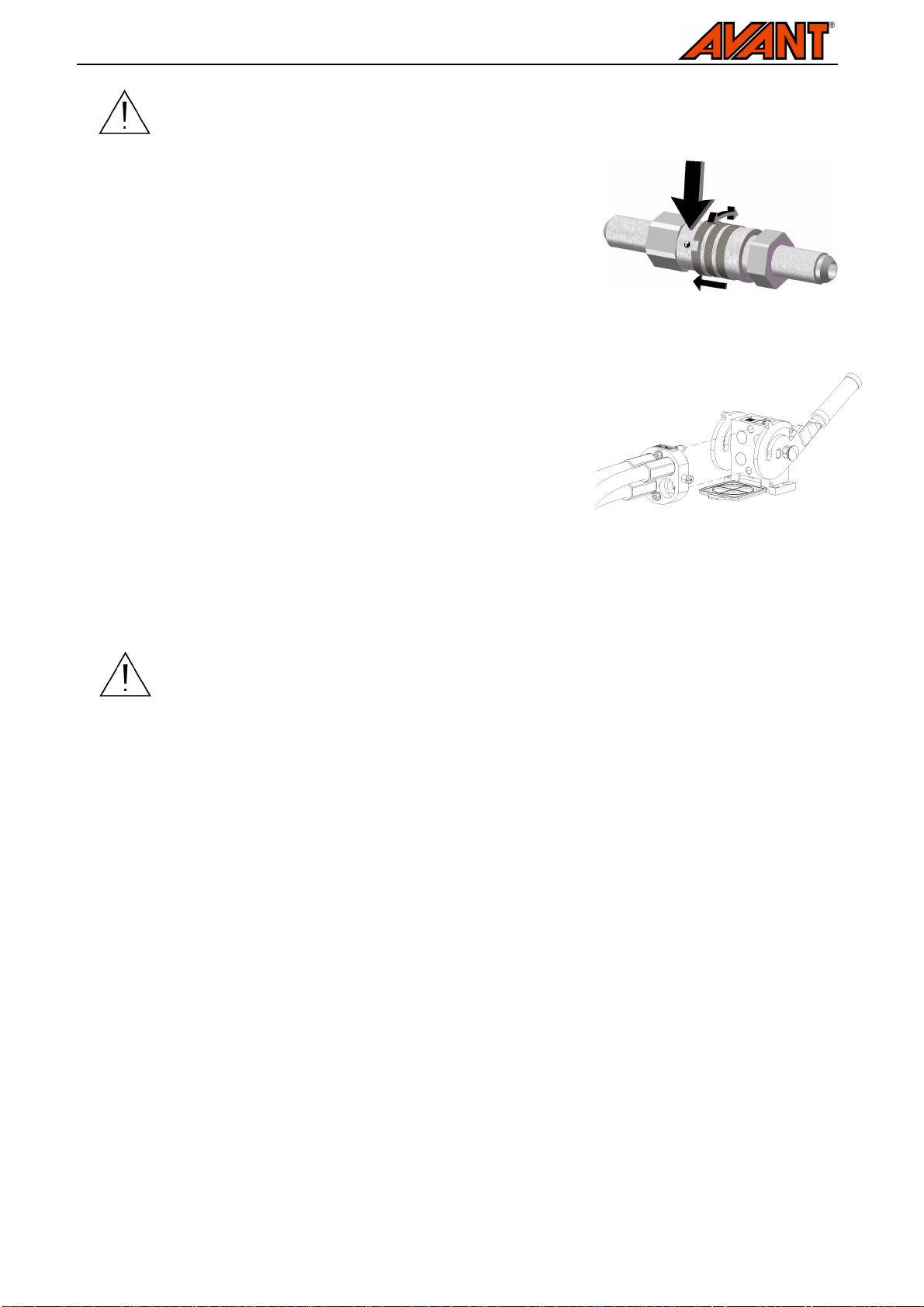

In a 200-series machine, the hose can be connected by pushing the

coupling directly into its counterpart. When connecting and disconnecting

the 200-series hydraulics quick couplings, you should pay attention to

their locking. There is a small groove in the collar of all female couplings,

and a small ball near the collar. When connecting or disconnecting, the

groove and the ball must be aligned. The locking prevents the couplings

from being disconnected from each other by accident when the

attachment moves. The collar may also turn by accident into the locking

position, making it impossible to connect or disconnect the couplings.

Connecting the multiconnector system:

Align the pins of the attachment connector with corresponding holes of

the loader connector. The multiconnector will not connect if the

attachment connector is upside down. Connect and lock the

multiconnector by turning the lever towards the loader.

The lever should move easily all the way to its locking position. If the

lever does not slide smoothly, check the aligment and position of the

connector and clean the connectors. Also shut down the loader and

release the residual hydraulic pressure.

Disconnecting the hydraulics:

Before disconnecting the fittings, lower the attachment on solid and level surface. Turn the control levers of

the auxiliary hydraulics to its neutral position.

When removing the attachment, always disconnect the hydraulic couplings before

unlocking the quick attach plate, to prevent hose damage and any oil spills. Reinstall the

protective caps on the fittings to prevent impurities from entering the hydraulic system.

Releasing residual hydraulic pressure:

In case residual pressure is left in the hydraulic system of the attachment, it is often possible to disconnect the

hydraulic couplings, but it may be difficult to connect them the next time. If the fittings will not connect, the

residual pressure must be released by turning the auxiliary hydraulics control lever of the loader, when the

engine is turned off. To make sure that there will not be residual pressure in the hydraulic system of the

attachment, shut down the loader engine and move the auxiliary hydraulics control lever of the loader before

disconnecting the couplings.

5.3. Electrical connection

In broom models equipped with hydraulic side slewing, to operate the slewing, the electric harness of the

broom must be connected to the loader. There are two options for the electrical connection:

- The cable harness, delivered with the attachment and equipped with a switch, is connected to the

power plug on the loader. Instructions concerning the loader plug are provided in the loader manual.

Select the location of the switch in the cab to ensure that it is easily accessible but will not be used

inadvertently.

- Alternatively, the optional attachment control switch pack, available for 400-700 loader models, can be

used to control the slewing cylinder. In this case, the separate cable with the switch is not needed,

and the plug of the system can be connected directly to the socket on the loader boom.

Route the selected cable in a way that it cannot get stuck or squeezed or stretch when the equipment moves.

With the help of the attachment control switch pack available for the loader, the attachment control switches

are easily accessible at the end of the boom control lever.