7

2 Caution

a) The AVANTI Fall Protection System (hereafter named as FPS) shall

only be operated by users trained in daily inspection, use and work

at heights.

b) A user is trained on the correct usage of the AVANTI Fall Protection

System (FPS) and is familiar with the following standards: EN 353-1,

EN 363 and EN 365.

c) A certied technician has successfully participated in the AVANTI

Fall Protection course.

d) A certied technician is qualied personnel authorised by AVANTI to

perform installation, inspection and maintenance tasks.

e) The installation, maintenance and testing of the FPS may only be

performed by a certied technician.

f) Users are obliged to read and understand this User’s Manual.

g) A copy of the User’s Manual shall be handed out to the FPS users

and shall be available for reference.

h) If more than one person is trusted with one of the above tasks, the

employer shall appoint a supervisor in charge of operation.

i) If the FPS is re-sold outside the original country of destination,

the reseller shall provide instructions for use, for maintenance, for

periodic examination and for repair in the language of the country in

which the product is to be used.

j) The ladder system shall be capable of supporting 15 kN. This shall

be veried by calculations made by a qualied engineer or by static

load testing.

k) The FPS shall not be used by persons under the inuence of alcohol

or drugs that may jeopardise the safety.

l) The FPS shall not be used by persons affected by vertigo, heart or

lung disorders, or other known weakening diseases/conditions.

m) The FPS users shall be aware of the dangers of suspension trauma

should a fall occur.

n) Owner shall ensure that a rescue plan is in place and that the users

are familiar with it. The rescue plan shall deal with any emergencies

that could arise during ascent and descent with the FPS.

o) No warranty is provided against damage resulting from

reconstruction or modication of equipment or use of non-original

parts which are not approved by the manufacturer.

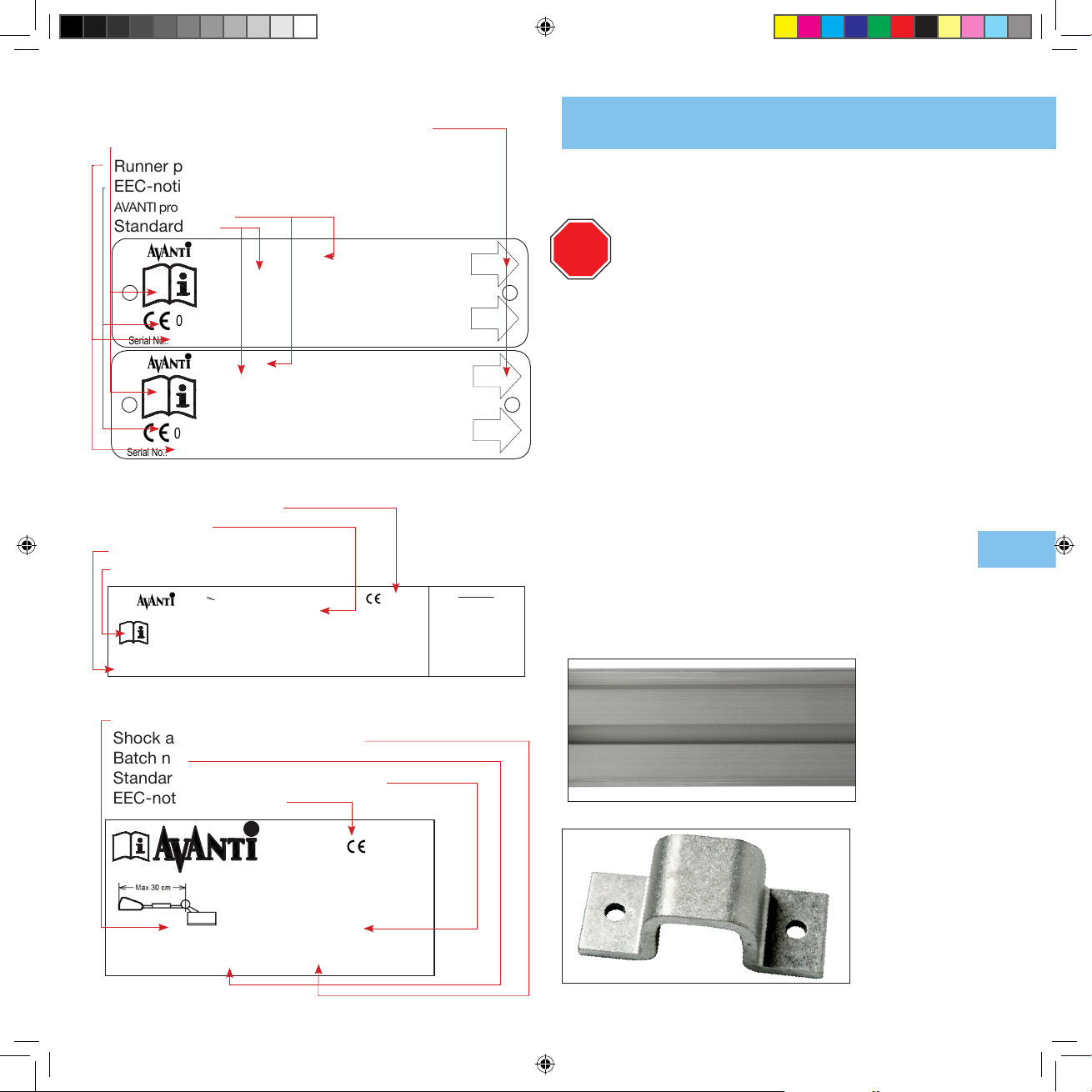

p) The runner shall be handed out and treated as a personal protection

equipment.

q) The weight of the user, excluding tools and equipment, shall not

be less than 40 kg. The weight of the user, including tools and

equipment, shall not exceed 136 kg.

r) The maximum number of multiple users in the ladder system is 3.

The fall arrester must be attached to no more than one personal

fall-arrest system.

s) In the rst two meters above the ground level, the user may not be

protected against hitting the ground if a fall occurs. Other additional

safeties shall be provided for this purpose.

t) Prior to the rst use of the FPS, a certied technician must inspect

and approve the complete FPS.

u) If oil, grease or the like has leaked onto the safety rail – wipe it off.

v) If oil, grease, chemicals or the like has leaked onto the shock

absorber or in any kind been in contact with the webbing, have an

AVANTI FPS certied technician replace the shock absorber.

w) The shock absorber has a limited life. Its date of expiration is printed

on the shock absorber label.

x) The operation temperature of the FPS is -30º / +60º Celsius.

y) The FPS shall only be used in connection with a full body harness

that is approved according to EN 361.

z) The FPS has been tested and approved according to

EN 353-1:2014+A1:2017.

aa) The type-examination of the FPS has been performed by: FORCE

Certication A/S, EC Notied Body 0200, Park Allé 345, DK-2605

Brøndby.

ab) The production control of the FPS is performed by the same notied

body.

ac) These instructions shall be kept together with the permanent

installed parts of the FPS (i.e. the rail system).

Owner shall verify the need for FPS inspections with the local

authority and comply with the standards specified.

ad) When working at heights, the user shall minimise both the risk of

potential falls and the potential fall distance.

ae) In order to avoid collisions with the ground or obstacles should

a fall occur, the user shall verify the free space required beneath

his/her actual position taking into account sharp edges, electrical

conductivity and pendulum falls.

af) The safety of the users depends upon the continued efciency and

durability of the FPS. Thus, regular periodic inspections shall be

carried out, minimum every 12 months.

ag) All the FPS parts have been especially developed and tested for

AVANTI´s FPS. Thus, they shall not be used as part of other Fall

Protection Systems.