Avery Weigh-Tronix WP-250 User manual

WP-250 Ticket Printer

Service Manual

TABLE OF CONTENTS

WP-250 Service Manual............................................................................. 1

General Maintenance ........................................................................... 1

Ribbon Replacement............................................................................ 1

Removing Old Ribbon .................................................................... 1

Installing New Ribbon .................................................................... 1

Description and Location of Major Components ......................................... 2

Time and Date Option .......................................................................... 2

Installing Time and Date Option ........................................................... 2

BCD Interface Option ........................................................................... 3

Installing BCD Interface Option ............................................................ 4

Serial Interfacing .................................................................................. 5

Current Loop .................................................................................. 5

Pulse Input..................................................................................... 6

Trouble-Shooting ........................................................................................ 6

Missing Dot Troubleshooting................................................................ 7

Circuit Operation and Test Points......................................................... 7

Print Head Mechanism Replacement/Alignment Procedure ....................... 8

Removal of Print Head Carrier Assembly............................................. 8

Replacement of Assembly ................................................................... 9

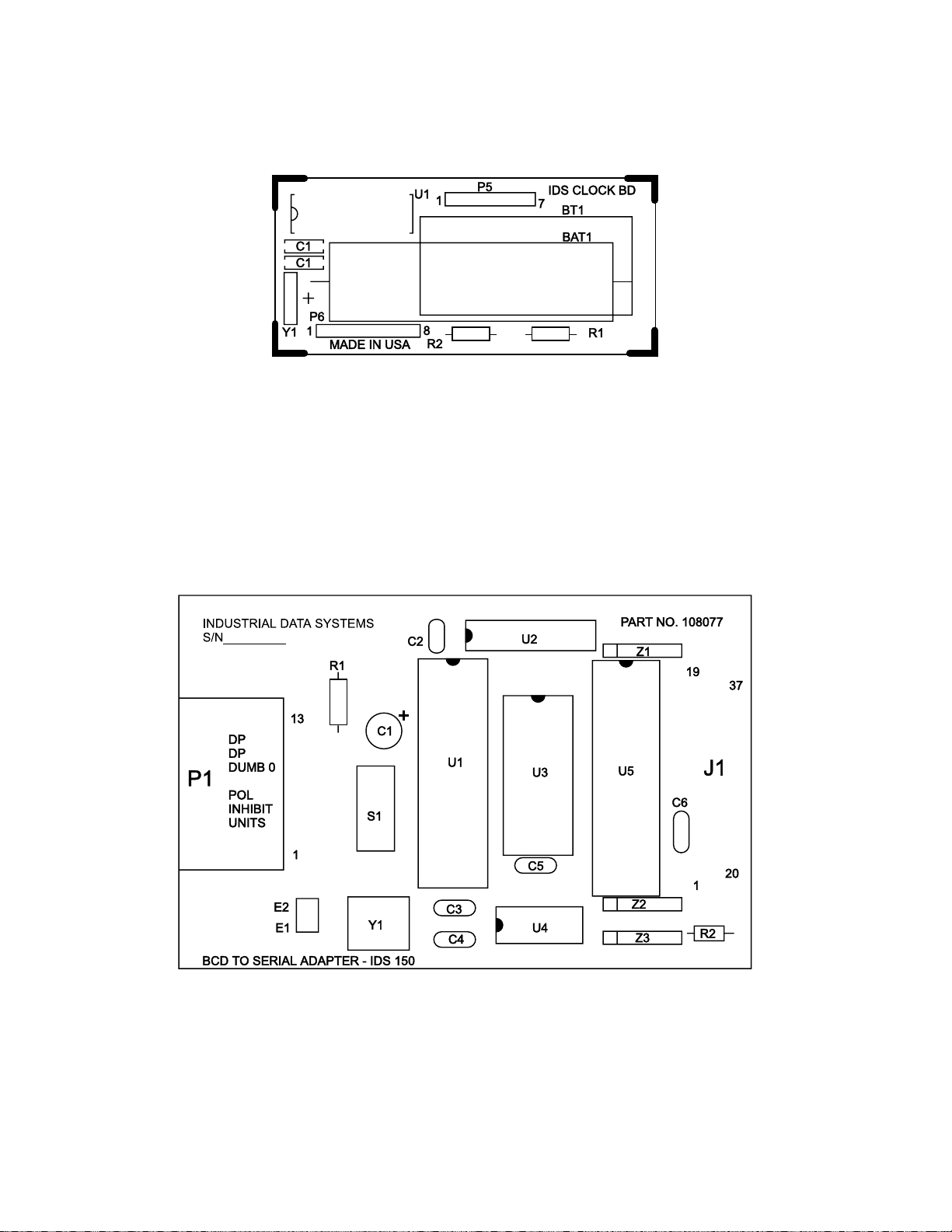

Time and Date PC Board.......................................................................... 10

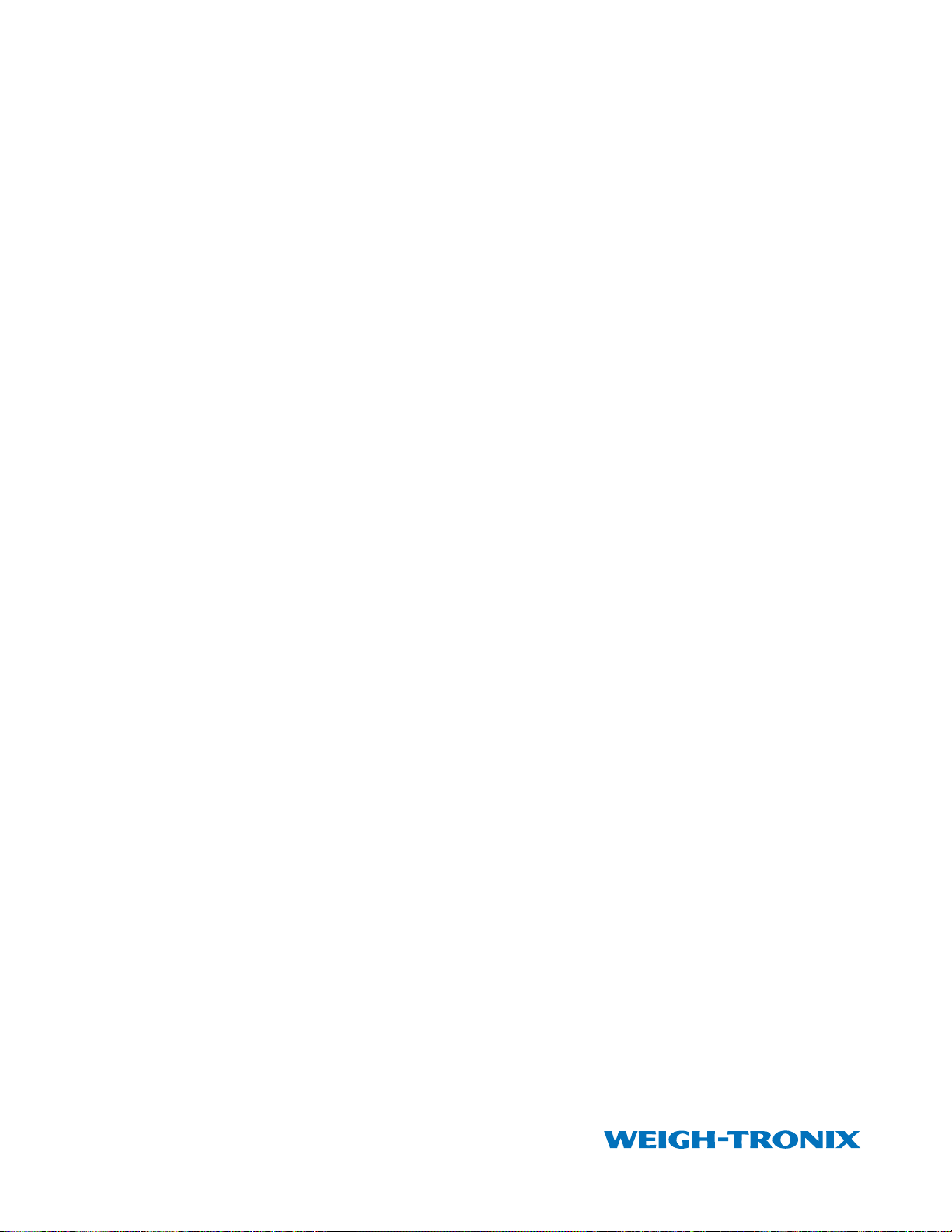

BCD PC Board ......................................................................................... 10

Main PC Board ......................................................................................... 11

1

WP-250 Service Manual

General

Maintenance

Ribbon Replacement

IMPORTANT: When removing

and installing the ribbon, take

care not to stain the printer

parts with ink contained in the

ribbon.

Removing Old Ribbon

Installing New Ribbon

The WP-250 Ticket Printer is designed to operate with a minimal amount of

regular maintenance. However, it is important that the printer remain clean

duringoperation.

The most critical part to be kept clean is the head shaft. The shaft should

be cleaned and fresh lubricant lightly applied two or three times a year.

(LUBRI-PLATE or IBM #23 are recommended lubricants.) The nylon gears

used in the printer do not require any lubrication.

The ribbon can be changed at the user's discretion. The ribbons supplied

by Weigh-Tronix are rated for 1,000,000 characters of standard text.

Ribbon life will vary depending on usage.

1. Pull the two ribbon spools forward to separate them from the spool

drive pins.

2. Take the old ribbon off the ribbon guide of the ribbon frame.

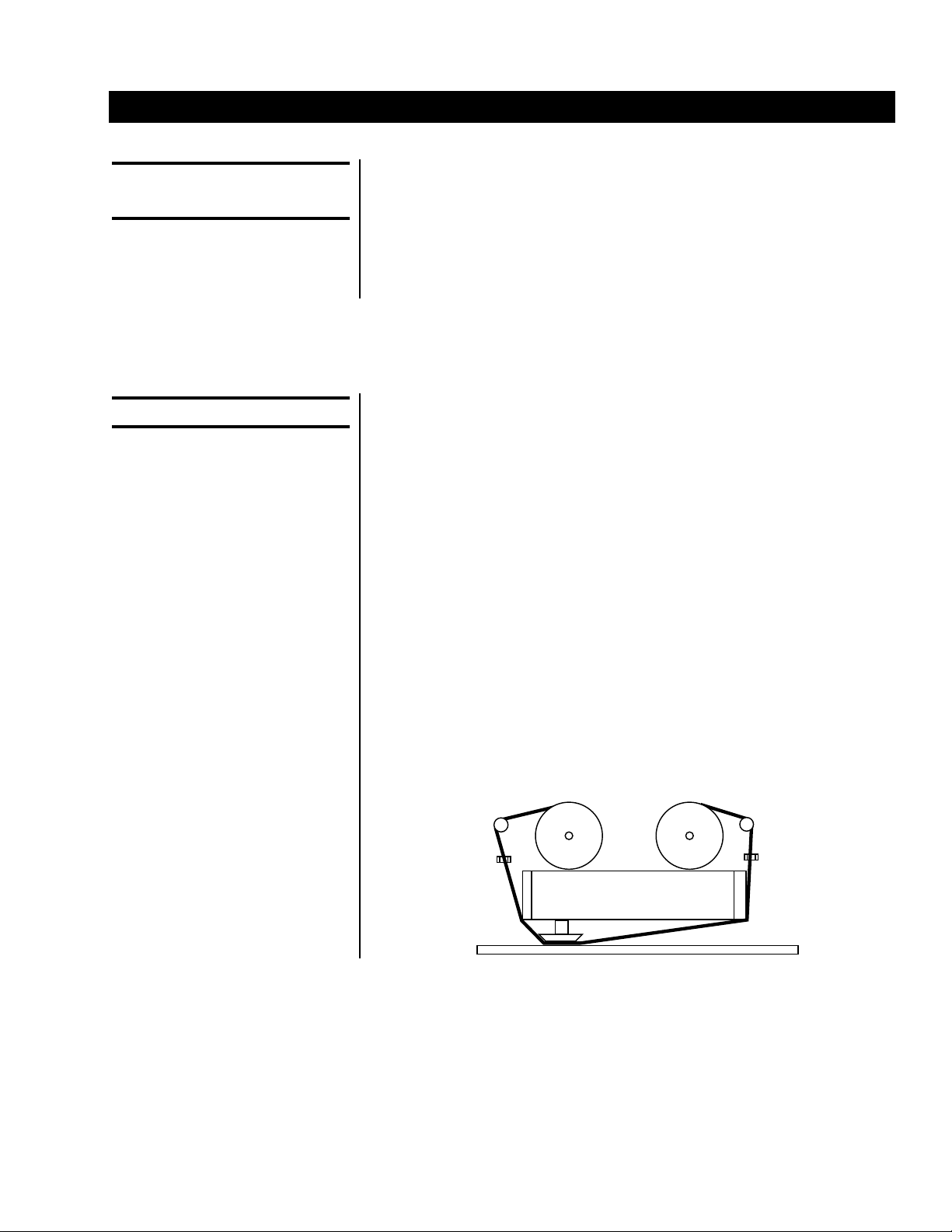

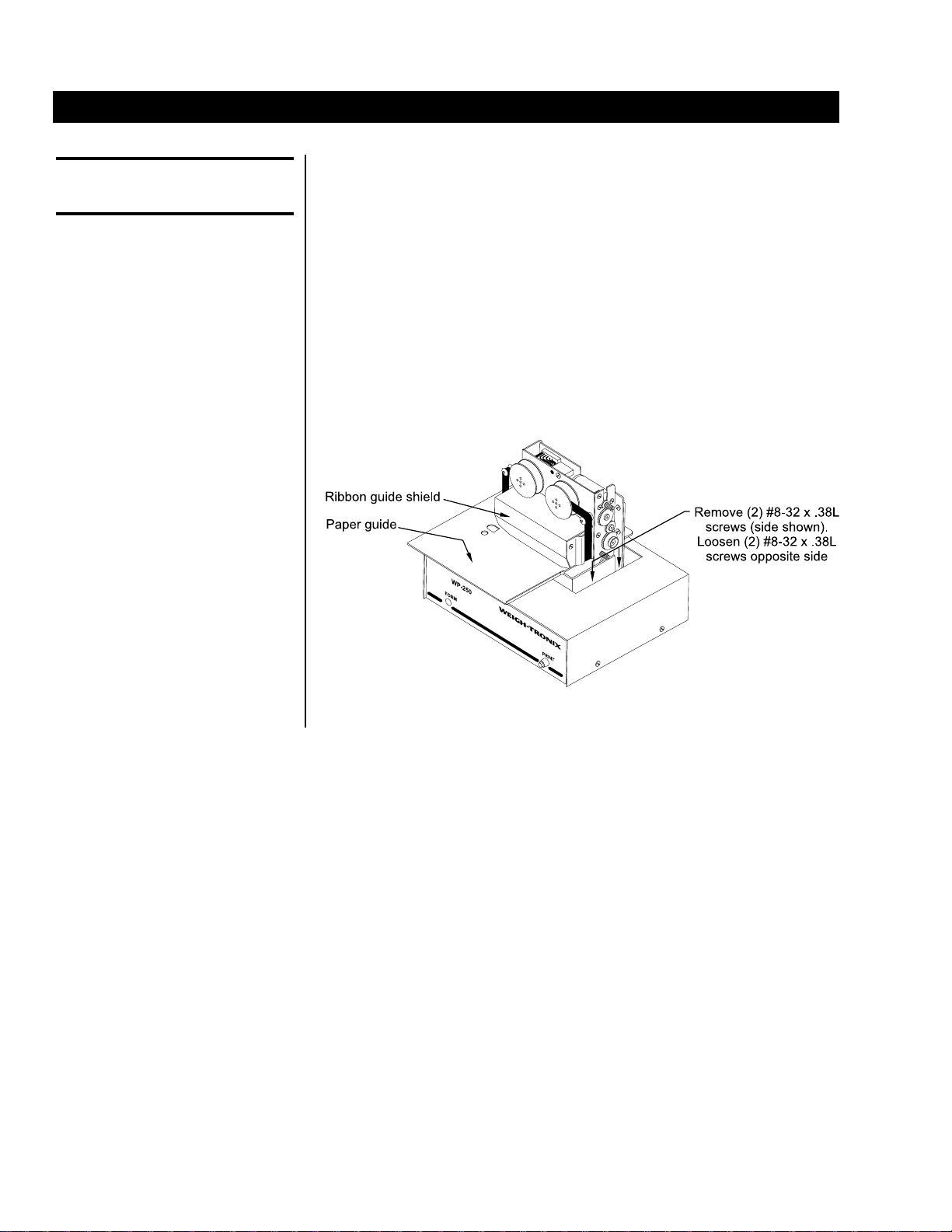

1. Position the ribbon along the ribbon guide as shown in the illustration

below.

2. Make sure the ribbon spools have been properly seated on the spool

drive pins.

2

Description & Location Of Major Components

Time And Date Option

Installing Time and

Date Option

1. Main PC Board

There is one main circuit board which is mounted in the bottom of the

WP-250 Ticket Printer cabinet. It contains all of the power supply

circuitry except the transformer. It also contains all of the logic circuitry

except the BCD input which is an external, optional BCD board.

2. BCD Option

The BCD option is composed of an additional circuit board that

attaches to the rear of the printer. This board is attached by a cable.

Major Components

Description W-T Part #

Ticket Print Mechanism 45009-1020

Paper Feed Solenoid 45009-1061

Paper Hold Solenoid 45009-1079

Time and Date Ass'y (w/ battery) 45009-1004

Time and Date Battery Only 45009-1095

Main PC Board 45009-1087

BCD Adapter with EPROM 45009-1012

Print Switch 45009-1129

Power Transformer 45009-1095

The time and date option provides the current time and date in both a 12

hour and 24 hour version. For systems that involve an intelligent host

device that can provide the time and date, this option is not needed.

If you planned to use the Time and Date Option at the time you ordered

the WP-250, the option was probably purchased and installed before the

unit was shipped. If you purchased the WP-250 without the options, it can

be easily installed:

1. Unplug the printer from the wall outlet.

2. Remove 4 screws on the print mechanism cover and remove the

cover by lifting up.

3. Connectors J5 and J6 will be empty if the printer does not have the

Time and Date Option installed.

4. Install the Time and Date Option board with the battery close to the

front of the printer.

5. Replace the print mechanism cover to its original location. Hold the

cover in place with the four screws, which should be snug but not too

tight.

6. Perform a self-test to verify printer operation.

7. Refer to User's Manual to set the Time and Date.

3

The BCD Option is used to interface electronic weigh scales that have only

a BCD type interface. Parallel BCD is not a general data interface and does

not use the ASCII control codes. It is a numeric interface meant to obtain

the weight, units, and motion indication from electronic weigh scales.

BCD stands for Binary Coded Decimal. It was one of the first interfaces

made available for electronic weigh scales when the big push for electronic

conversion of mechanical scales began in the 1970's. The interface basi-

cally began as a latched TTL (transistor transistor logic) output of the seven

segment scale display.

The BCD Option converts a 5 1/2 active digit BCD input into a 20 mA

current loop output. The interface cable is a 29 wire conductor cable. For

each of the five digits tranferred the cable contains four wires. Digit six is a

single wire that is the 100,000 input. The other wires include the PRINT

input, the SIGN input, PRINT INHIBIT or MOTION input and LOGIC

ground. In addition, a bank of switches controls the assumed decimal place

setting, the imposing of a trailing dumb zero, and kg/lb unit printing.

BCD Interface Option

4

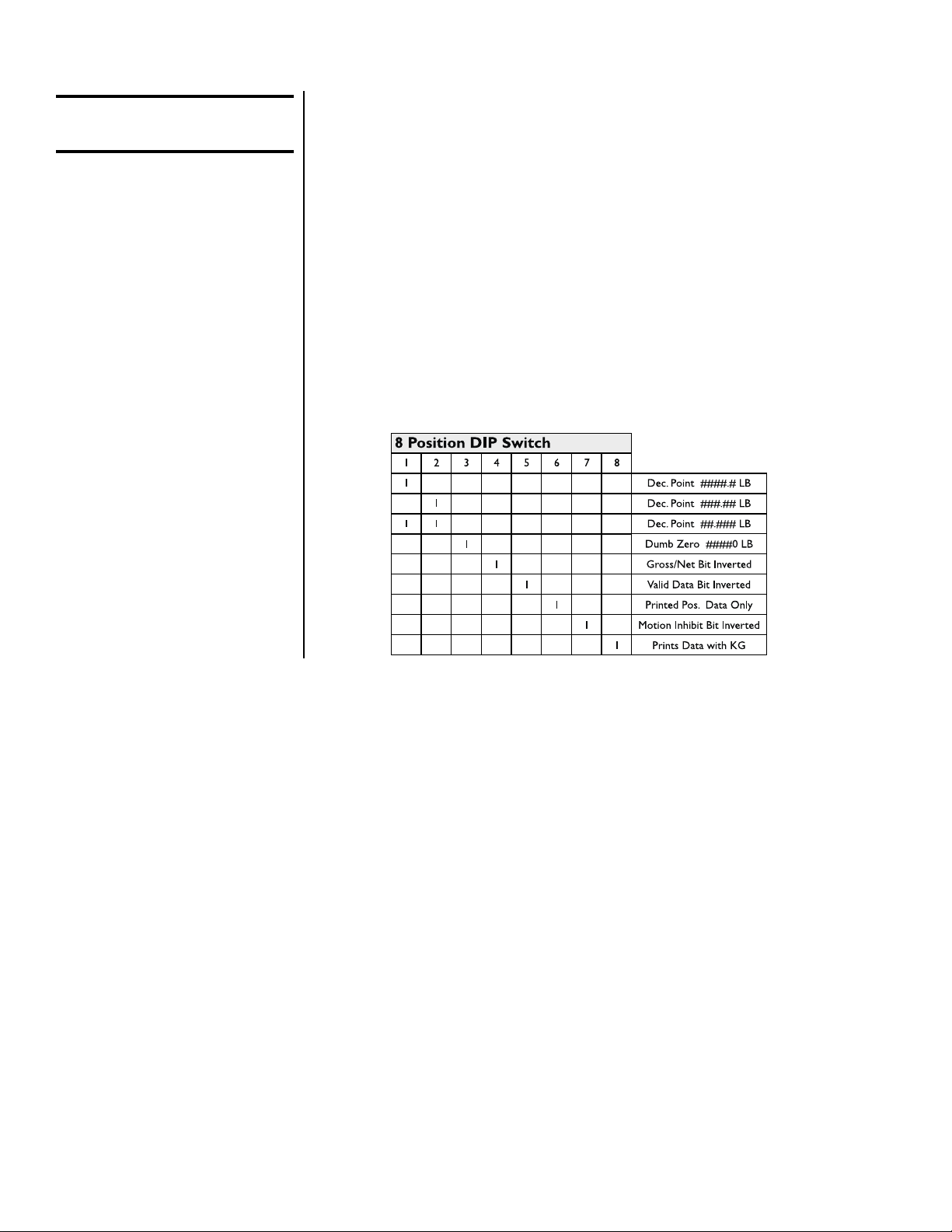

1 = ON

# - number 0-9

For the WI-110/120 Switch 6

must be on. Switches 1, 2, 3 &

8 must be set to match your

indicator's display mode.

Installing The BCD

Interface Option

If you planned to use the Parallel BCD Interfacing at the time you ordered

the WP-250, the option was probably purchased and installed at the

factory. If you purchased the WP-250 without the option, it can be easily

installed.

1. Unplug the printer from the wall outlet.

2. Program the 8 Position DIP Switch in the BCD Module.

3. Connect the cable from the BCD interface board to the indicator.

4. Connect the cable from the BCD interface board to the printer.

5. Configure the printer for current loop 1200 baud, 8 data bits, no parity.

6. Perform a self-test to verify printer configuration and operation.

5

Serial Interfacing The RS-232C, Current Loop, RS-485, and Pulse Input are standard in

every WP-250 Ticket Printer.

The WP-250 serial input port is connector J1. It has an industry standard

DB-25 female connector wired

as a DTE device. The WP-250 has a 4000 character input buffer and

unless you plan to send more characters than this per ticket, you will not

overflow the input buffer. If you will be sending a large amount of data

or sending data continuously, as with some electronic weigh scales, you

may want to implement some type of handshaking.

The printer supports XON/XOFF handshaking. The XON/XOFF handshak-

ing requires no additional wiring to implement. The host device only needs

to support the XON/XOFF protocol.

Serial Interface Connections

PIN Signal Description

1Chassis Ground

2TXD Transmit data

3RXD Receive data

4 RTS

5CTS Clear to send

6+5R

7Ground

8+20 mA in

22 -20 mA in

15 + Pulse Input

22 - Pulse Input

16 Remote Print (active low)

13 Ground

20 DTR +8V

11 + RS-485

12 - RS-485

The 20 mA Current Loop, which is standard in the WP-250, is a good

interface for systems that will require long distances between the host

device and the printer.

Data is sent between the transmitter and receiver as a series of pulses.

The set-up of a 20 mA serial connection is much like an RS-232C inter-

face. The number of data bits, parity, stop bits, and baud rate must match

at both the transmitting and receiving ends.

The only real difference between the two is that RS-232C serial is a

voltage based interface while 20 mA serial is a current based interface.

Current Loop

6

Pulse Input:

The current for the interface is provided by one of the two devices in the

interface. The device that supplies the current is called the active side and

the device on the other end is called the passive side. It does not matter

which side is passive and which is active as long as there is only one of

each. The WP-250 has the hardware needed to be the passive side of the

20 mA interface for the receive loop.

20 mA Current Loop is frequently run on a twisted pair of wires. There is

no busy line or reverse channel for XON/XOFF for the 20 mA interface.

The connections for the 20 mA interface are on connector J1 on the back

of the WP-250 printer.

Pins 8 and 22 are the 20 mA Current Loop receiver connections.

Pulse input must be 0 - 24 VDC. A current leakage resistor may be

necessary for proper switching. The printer must be set for Current Loop

and the Intelligent Printer Mode for Pulse Input must be enabled. Be sure

to select the correct division size, decimal point place, and unit of measure

to match your indicator.

Troubleshooting

Problem Solution

1. Head will not cycle smoothly 1a. Defective drive transistors or motor, possibly 24V

supply is gone

1b. Mechanical problem. For example: gears are

binding

2. Dots missing in print 2. Defective drive transistors or printhead

3. Printing darker on one side 3. Adjust head gap (platen adjust)

4. Prints time and date but no weight information 4. Wrong baud rate, data bits, stop bits, or parity

5. Print isn't dark enough regardless of head gap 5. Replace ribbon

6. Printer locks up when PRINT button is depressed 6. Thumbwheel switch is in wrong position

7. Paper feed is inconsistent 7. Feed roller is worn

7

Missing Dot

Troubleshooting

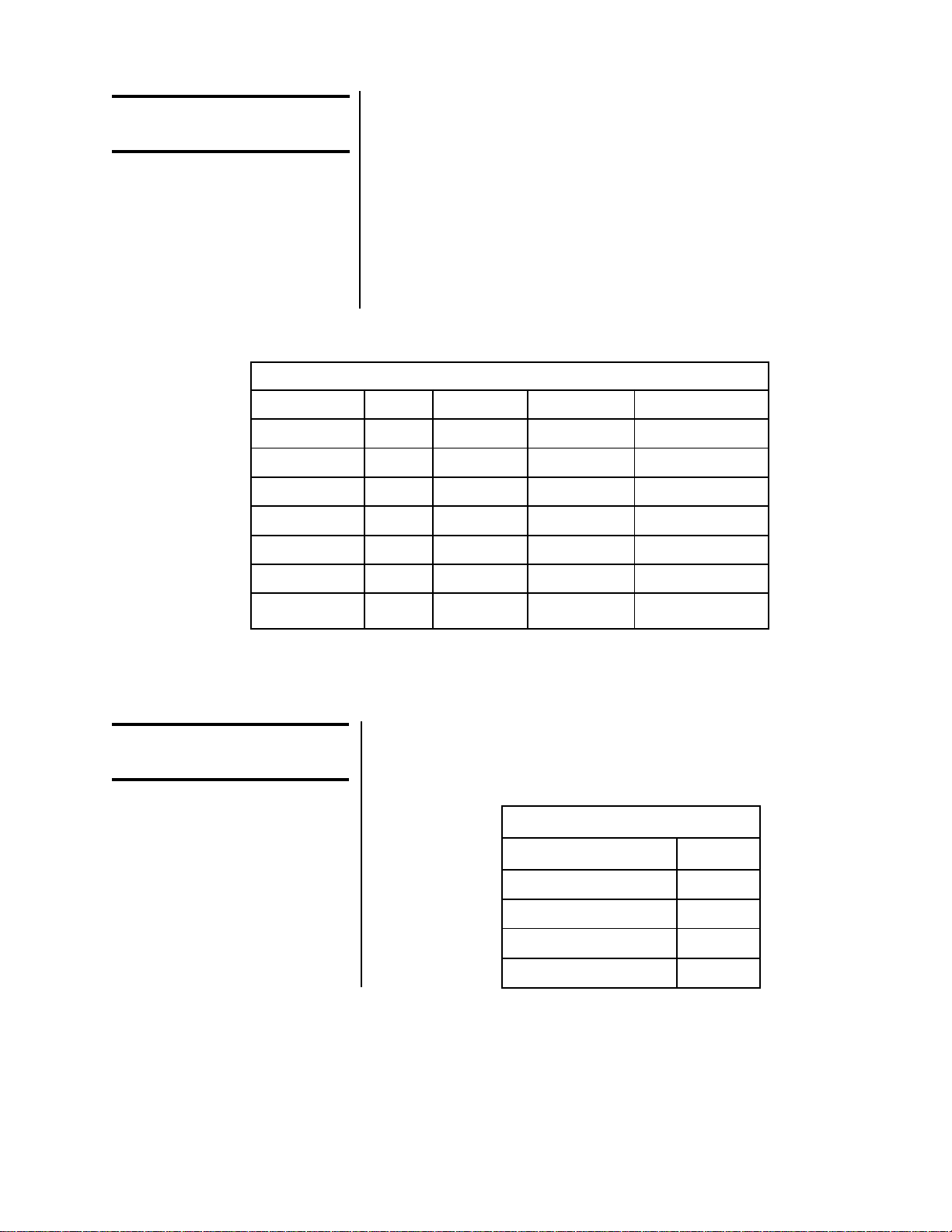

WP-255 Dot Driver Components

Dot Position Fuse Transistor Drive Diode Snubber Diode

7 F7 Q7 CR17 CR28

6 F6 Q6 CR16 CR27

5 F5 Q5 CR15 CR26

4 F4 Q4 CR14 CR25

3 F3 Q3 CR13 CR24

2 F2 Q2 CR12 CR23

1 F1 Q1 CR11 CR22

Circuit Operation And

Test Points

This table contains test points found on the main board and the voltage that

is associated with each test point. All voltage measurements are taken

utilizing signal ground located at pin 1 of U13.

Missing dots are caused by 1 or more of the following:

1. Broken needle

2. Blown transistor

3. Blown drive diode

4. Blown fuse

The table below lists the dot driver components in order of dot position.

If a dot is missing, check ALL of the dot driver components for the missing

dot.

Power Supplies

Test Point Voltage

Anode CR 31 -8 vdc

Cathode CR9 +5 vdc

Pin 3 of U13 +24 vdc

Pin 2 of U13 +8 vdc

8

1. Remove power from the printer, then remove the ribbon.

2. While looking at the printer from the front, loosen the two screws on

the left side of the print head assembly, then remove the two screws

on the right side. (8-32 x 3/8", 4 pieces UNC) See Figure 1 below.

3. Slide the print head assembly to the right and lift up. Carefully unplug

the print head assembly.

4. Remove the four screws that hold the paper guide in place. (CS: M4 x

6, 4 pieces metric)

5. Carefully remove the two plastic pins that hold the ribbon guide shield

in place.

6. Carefully remove the ribbon guide shield.

Figure 1

Print Head Mechanism Replacement/Alignment Procedure

Removal of Print Head

Carrier Assembly

9

Replacement of Assembly

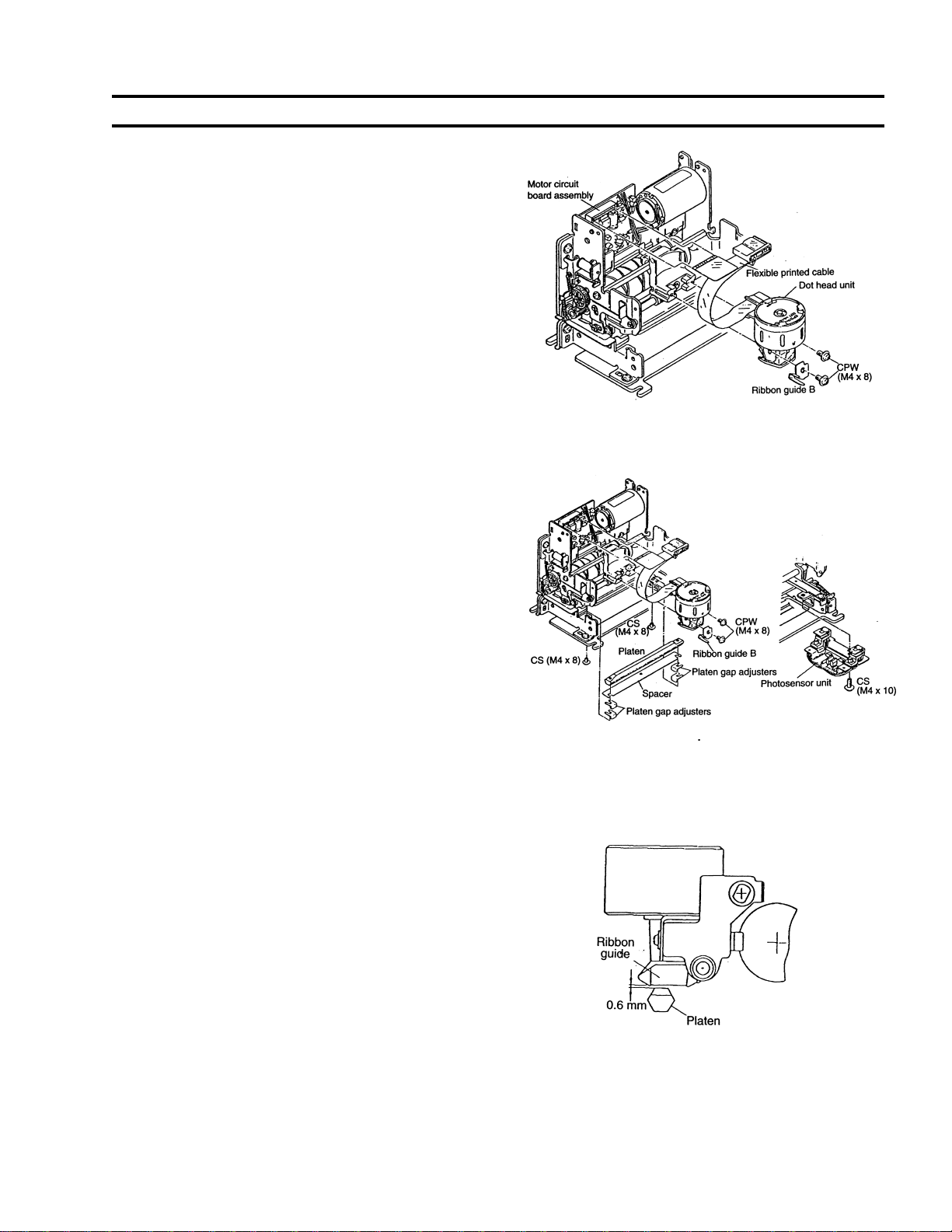

1. Replace the dot head unit on the print head carrier

assembly as follows:

1a. Screw the dot head unit together with the ribbon

guide assembly (B) to the print head carrier

assembly. Tighten the screws.

CPW: M4 x 8 (2 pieces metric)

1b. Plug the terminal end of the flexible cable into the

connector on the motor circuit board.

2. Install the platen as follows:

2a. Screw the spacer and platen to the frames. Install

the photosensor unit. Tighten the screws. (CS of

M4 x 10, 2 pieces metric)

If the total thickness of the sheets of paper to be

used is 0.25--0.45mm, it is not necessary to use

the spacer.

2b. By moving the print head carrier assembly from

end to end, check if the dot head unit and the

platen are parallel to each other (check if the dot

head/platen gap is of the same amount at both

ends of the print head carrier assembly).

The print head carrier should move freely from end

to end. Do not force.

3. Adjust the dot head/platen gap as follows:

3a. If the gap is appreciably different from end to end,

make adjustment by increasing or decreas-

ing the number of platen gap adjusters on one end.

3b. Move the print head carrier assembly to one end of

its stroke and make positional adjustment so that

the gap between the ribbon guide face and the

platen is 0.6mm.

3c. Move the print head carrier assembly to the

opposite end of its stroke and check the above-

mentioned gap.

10

Time and Date Board

W-T P/N 45009-1004

BCD Board

11

Main PC Board

W-T P/N 45009-1087

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-4195

e-mail: [email protected]

www.weigh-tronix.com

217 Brunswick Blvd.

Pointe Claire, QC H9R 4R7 Canada

Telephone: 514-695-0380

Facsimile: 514-695-6820

Weighing Products & Systems

Weigh-Tronix

Weigh-Tronix Canada, ULC

Weigh Bar®is a registered trademark of Weigh-Tronix Inc.

04/17/00 WP205SER.P65 PN 29549-0015e1 Printed in USA

Table of contents

Other Avery Weigh-Tronix Printer manuals

Avery Weigh-Tronix

Avery Weigh-Tronix WP-234 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix ZG310 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix ZG110 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix WP-234 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix WP-233 Series User manual

Avery Weigh-Tronix

Avery Weigh-Tronix ZG354 User manual

Avery Weigh-Tronix

Avery Weigh-Tronix TM-295 User manual