Page 5 of 15

Copyright © AVK Holding A/S, original version, rev. 1, 21-Jan-2023

4. Principle of operation

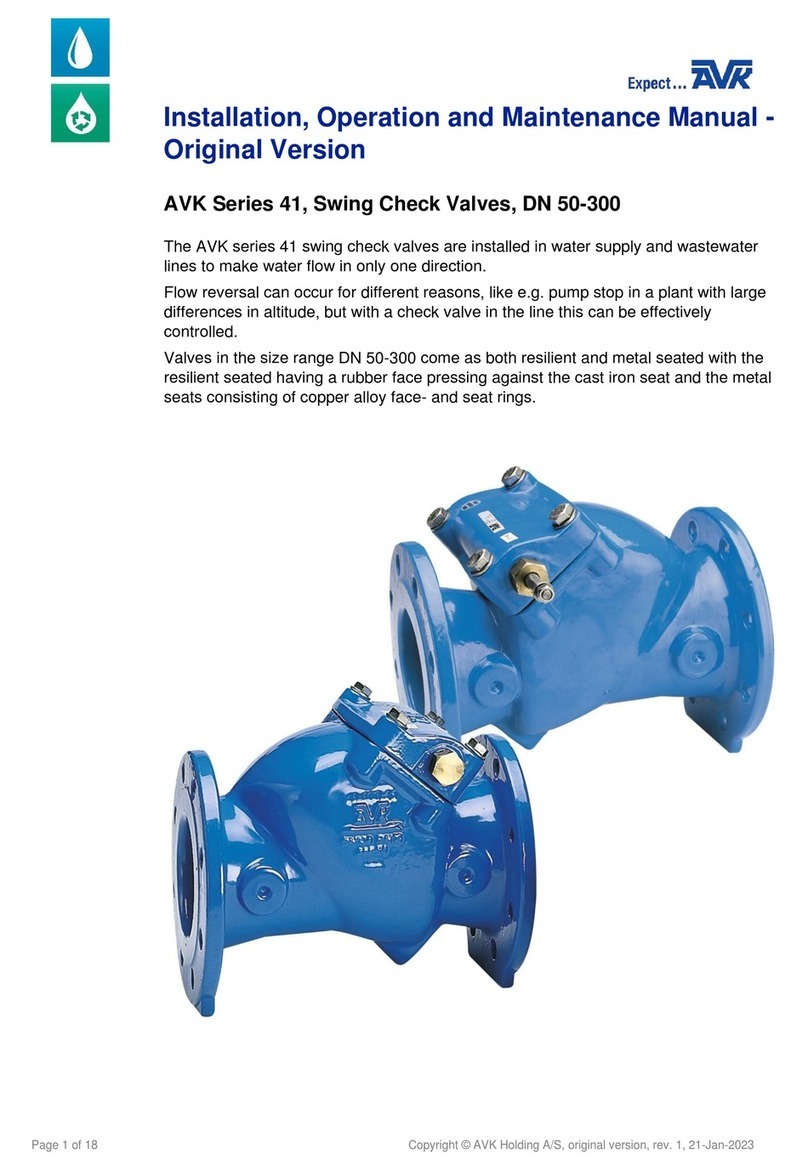

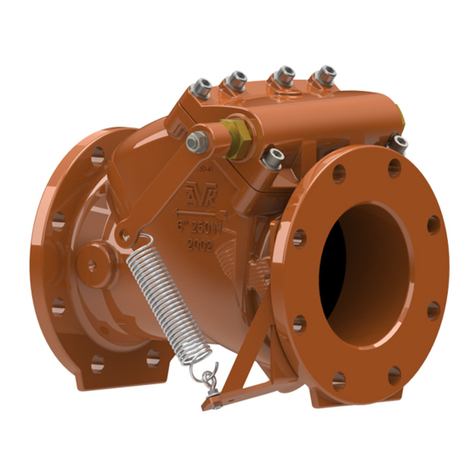

The main operating principle is simple and reliable: a hinged disc in the water stream swings

open when the flow is forward and shuts off against the valve seat if the flow tends to reverse.

If the reverse water flow is the driving force to close the disc there is risk of water hammer. To

mitigate this a weighted lever can be attached to the hinge shaft. This helps force the valve

closed before the flow reverses and thus results in quiet operation. A drawback is higher

pressure loss when the water is flowing, but correct adjustment of weight position can minimise

this.

Adding a weight also makes it possible to operate in vertical installations with downwards flow.

The valve seat consists of copper alloy rings with the disc mounted in a flexible bushing

allowing it to tilt slightly in all directions and adjust exactly to the valve seat.

5. Health and safety at work

Make sure all relevant Health and Safety issues and regulations are adhered to prior to and

during installation or maintenance work carried out on this product. It is the end user's

responsibility to ensure that safe working practices are followed at all times.

Whenever AVK’s products are installed, operated or maintained the inherent dangers of

pressurised liquids and gasses must be addressed. Before work on a valve or other piping

component is undertaken, that may involve the release of internal pressure, the valve or line

must be fully isolated, depressurised and drained prior to commencing the work. FAILURE TO

COMPLY WITH THIS MAY RESULT IN SEVERE INJURY OR DEATH.

All workers handling the product must be aware of the weight of the components or assemblies

to be handled and manipulated during installation and maintenance.

It is essential that staff undertaking these operations are adequately trained and it is the

responsibility of the end user that only trained and competent staff undertake these duties.

This manual has been designed to assist, but it cannot replace quality training in the workplace.

However, the AVK technical staff is always available and ready to answer questions relating to

specific problems that may not be covered by this manual.

AVK’s products are designed to be fit for purpose and to a high reliability standard. This

provides a safe, low risk product when used correctly for the purpose for which it was designed.

However, this assumes that the equipment is used and maintained in accordance with this

manual, and the user is advised to study it and to make it available to all staff that may need to

refer to it.

AVK cannot be held responsible for incidents arising from incorrect installation, operation or

maintenance. The responsibility for this rests wholly with the end user.