4 of 13

A

VK

UK,

8

Rushmills,

Northampton,

England,

UK,

NN4

7YB,

T

:

+

44

(0)

1604

601188.

[email protected] www

.avkuk.co.uk

COPYRIGHT©AVK GROUP A/S 2018

The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development.

O&M 020818

4. HEALTH AND SAFETY PRECAUTIONS

Please ensure that all relevant Health and Safety issues and regulations are strictly adhered to, prior to and during any

installation or maintenance work carried out on these valves.

It is essential that wherever work is being undertaken on a valve that may involve the release of any internal pressure, the

valve is fully depressurised prior to any work being carried out, and the line drained.

It is also essential that the user handling the valve is aware of the weight of the components or assemblies to be handled and

manipulated during installation and maintenance. It is the end users responsibility to ensure that safe working practices are

followed at all times.

Whenever AVK Valves products are installed, operated, or maintained, the inherent dangers of pressurised liquids and gasses,

which can be severe, must be addressed.

Therefore, it is essential that staff undertaking these operations are adequately trained and it is the responsibility of the end user to

ensure that only trained and competent staff undertake these duties.

This manual has been designed to assist, but it can never fully replace quality training in the workplace. However AVK Valves

technical staff are always available to answer any questions relating to specific problems that may not be covered by this manual.

AVK Valves products are designed and manufactured to be for purpose, and to a high and reliable standard. This provides a safe

product with minimum risk to health when used correctly for the purpose for which it was designed.

However, this assumes that the equipment is used and maintained in accordance with this manual, and the user is advised to

study this manual, and to make it available to all staff that may need to refer to it.

AVK Valves cannot be held responsible for any incidents arising from incorrect installation, operation or maintenance. The

responsibility for this must rest wholly with the end user.

Note: These valves are NOT designed for “end of line” services.

5. SPARE PARTS

The use of inferior materials or parts in a valve can have serious consequences. Therefore it is absolutely essential that in order to

guarantee the highest level of safety and performance, only genuine AVK Valves spare parts are be used.

AVK Valves cannot accept any responsibility whatsoever for the fitting and subsequent failure of any non-AVK Valves or non-

approved parts.

6. DESIGN CONSTRAINTS

Please consider the following points when selecting your valve:

• Consideration should be given at the design stage where valves will be located to give access for operation, adjustment,

maintenance and repair.

• If a valve is installed less than 6 diameters downstream of an elbow or tee etc., it will experience very high-localised velocities

that are far in excess of the average velocity. This high velocity will result in excessive turbulence within the valve and

variations in performance may be experienced, therefore installation in this area should be avoided.

• Valves must be provided with adequate support. Adjoining pipework must be supported to avoid the imposition of pipeline

strains on the body which may impair its performance

• Heavy Valves may need independent support or anchorage

7. STORAGE AND HANDLING

Storage

• If valves are to be stored in the open for some time, protection should be provided to keep the valve clear of sand and mud

• Protection against weather should be provided. Ideally, valves should be kept indoors, with the actual valve temperature

always higher than the dew point. If outdoor storage is unavoidable, valve should be supported off the ground and protected

by a weather proof cover

• Valves may be stacked and the upper open end covered with waterproof material and boarded over

Handling

• When handling valves, it is preferable to lift by means of shackles in the holes provided in the valve body/cover

• Where slings are employed the valves should only be slung by the main body casting. No contact should be made with the

lever or guard fitted

• Valves should be lowered gently onto wooden batten placed on firm ground, clear of mud and water.

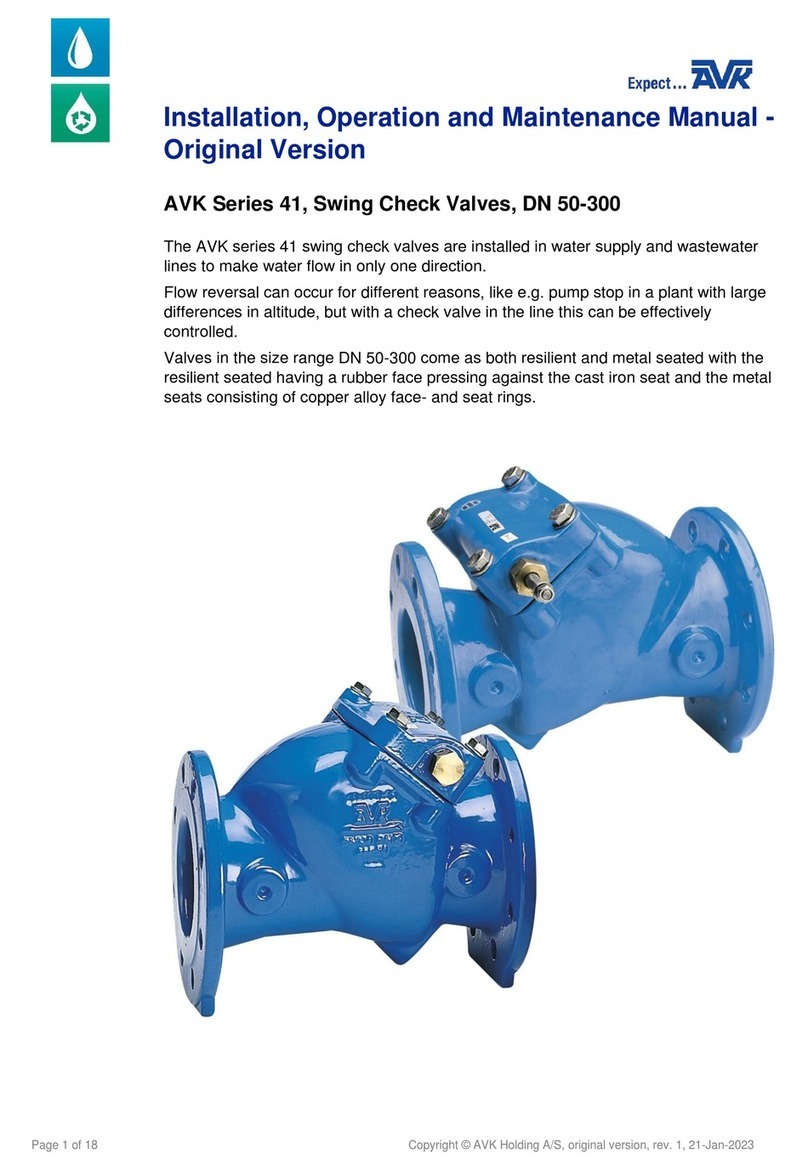

OPERATION AND MAINTENANCE INSTRUCTIONS

AVK SERIES 41 SWING CHECK VALVE FOR WATER AND WASTE WATER

Series 41 DN350-600