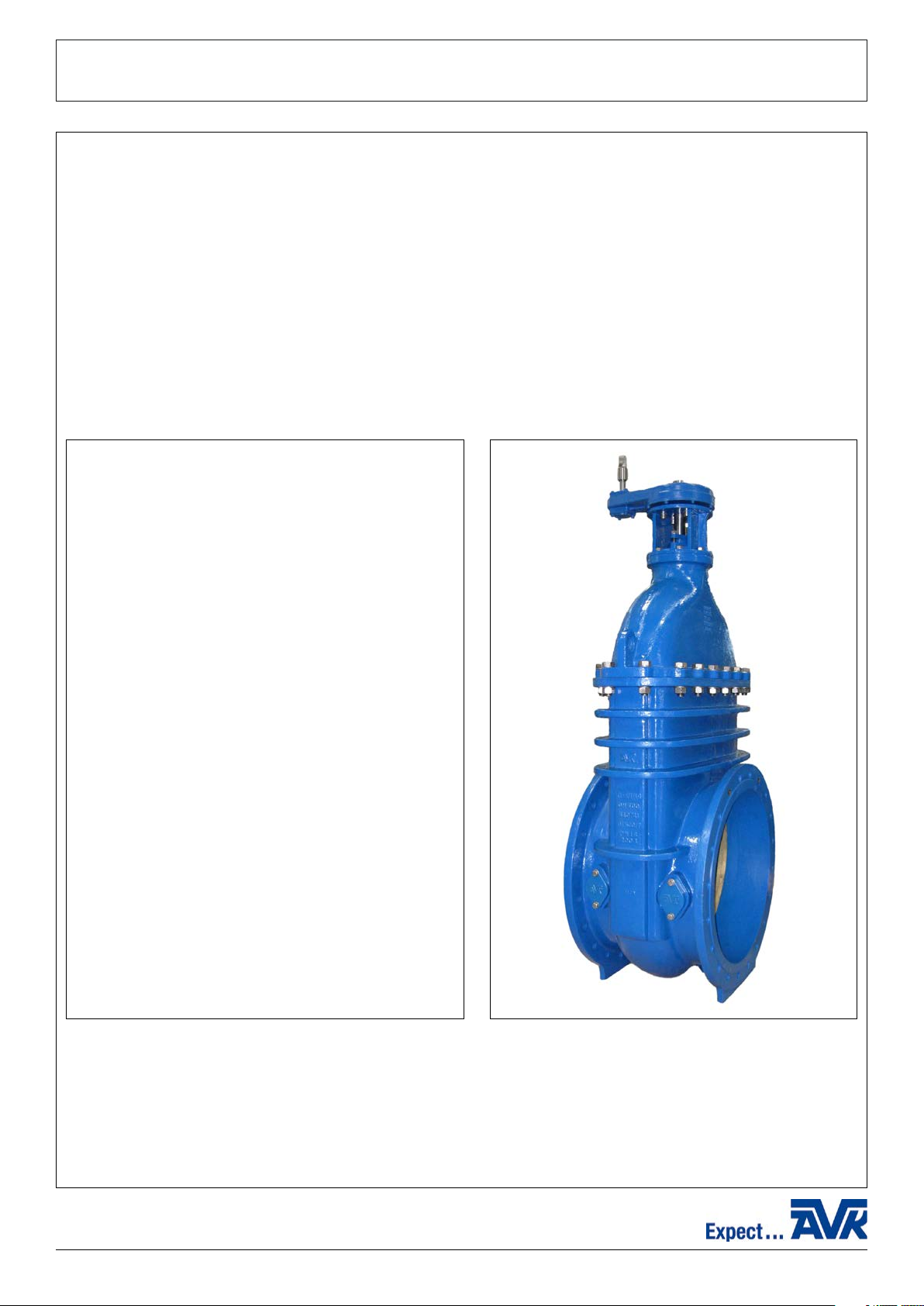

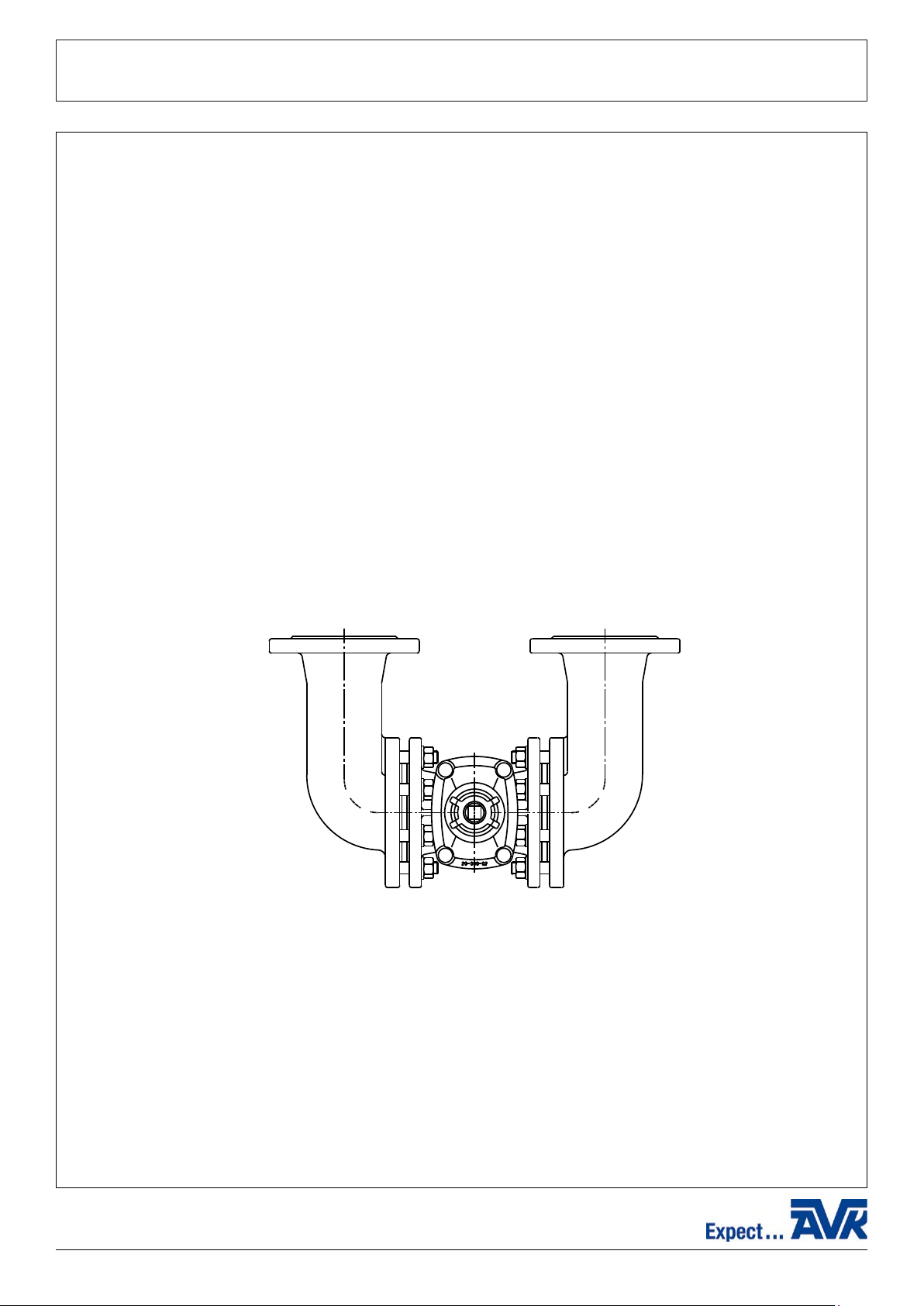

SERIES 54 METAL SEATED GATE VALVES

INSTALLATION, OPERATION & MAINTENANCE MANUAL

4. Maintenance

To improve the life of the Series 54 Gate Valve and ensure satisfactory working at all times the following procedures should be

carried out at regular intervals throughout the life span of the product (every 6 months).

Although some procedures can be carried out with the valve under pressure, it is strongly recommended that there is no

pressure in the pipeline whenever possible.

• The stuffing box should be checked to conclude that there is no leakage from the packing.

An additional strand might be required after a period of service and occasionally repacking may be needed.

• Care should be taken to ensure the gland is tightened up evenly to prevent binding of the spindle, and should be tightened

up just enough to prevent leakage.

• If the valve has been left standing un-operated for lengthy periods and conditions allow, monthly or more frequent

operation of the screw throughout the length of its travel should be carried out. Failing this, at least operation through part

of the travel should be effected if at all possible.

• The bolts on the valve should be checked for tightness, after long periods of operation, where vibration is experienced.

• Visual checks of coating for any signs of damage or corrosion.

Packed Gland (Applies to all sizes)

Packed Glands are the traditional method of sealing stems from the line pressure and are extremely reliable over a long

period of time. However, they do require an initial adjustment during the commissioning period and for this reason we cannot

guarantee “no leakage” until the valve is installed and adjusted.

Adjustment is a simple matter of alternately tightening the gland nuts by a small amount until any weeping creases, this can

be safely carried out whilst under pressure. If the gland is already down and further adjustment is not available or does not

stop the leak, then the gland will need re-packing. If this is necessary, the pressure in the pipeline should be shut off at another

point, and the line drained.

To repack the valve, complete the following:

• Undo the gland nuts and then remove the gland and the packing.

• Lubricate the spindle with WRc Approved Grease.

• Repack the gland using the correct size and type of packing and ensure that there is a snug fit between the spindle and

the stuffing box wall, and that all joints are staggered by 120 degrees.

• Secure the gland but do not tighten the nuts more than necessary to prevent leakage.

Recommended Spare Parts

The use of interior materials or parts in a valve can have serious consequences. It is AVK policy therefore, to use only materials

of the highest quality, manufactured to our own designs and thoroughly checked and tested in accordance with our internal

Quality Assurance system that is approved to ISO 9001:2000. It is absolutely essential therefore, that in order to guarantee the

highest level of safety and performance, only genuine AVK spare parts are used. AVK can accept no responsibility whatsoever

for the fitting and subsequent failure of any non-AVK or non-approved parts.

AVK recommend that these spare parts are purchased when ordering series 54 Gate Valve

• Full set of Gaskets and Seals

• Gland Packing

• Grease for stem

• Touch up Paint

A

VK

V

alves

Pty

Ltd

-

559A

Grand

Junction

Road,

Wingfield,

SA

5013,

Australia

-

T

el:

+61

8

8368

0900

-

Email:

[email protected] -

www.avkvalves.com.au

V

ersion

number

2

COPYRIGHT©AVK GROUP A/S 2017