1. Manufacturer identification

2. General health and safety measures

AC.MO S.r.l.

Headquarters Street: Via Tommaso da Modena, 28 Z.I. - 31056 RONCADE (TV) ITALY

www.acmosrl.com

• Read the IOM manual before using the valve. Comply with the manual at all times.

• The IOM manual must be available in the workplace.

• Non–compliance with the general safety measures can seriously damage human health and

valve functioning. AC.MO S.r.l. will not assume any responsibility or liability for consequential

damage due to the non-compliance with these instructions.

• The valve can be used for drinking water and clean service water. Other uses are prohibited

because they can alter the valve safety.

• Never use the valve in plants where the pressure is higher than the one indicated.

• Only qualified staff can install the valve. Unqualified or underage staff cannot perform the

installation. Always use protective equipment such as safety boots, safety helmets, goggles,

protective gloves, etc... Personnel involved in the installation or maintenance of valves should

be constantly alert to possible damages caused by an improper handling of the valve.

• Before performing any work on the valve, depressurize the pipeline section and ensure it is

free of hazards.

• Unauthorized, unintentional and unexpected actuation, as well as any hazardous movement

caused by stored energy (pressurized air, water under pressure) must be prevented.

• When a valve needs to be dismantled from a pipeline, water may emerge from the pipeline or

the valve. The pipeline must be emptied completely before the valve is dismantled. It is strictly

prohibited to disinstall any component when the system is under pressure (working) or when

there is any fluid inside.

• Statutory and local provisions as well as the safety and accident prevention regulations must

be observed and complied with at all times.

• For equipment that must be monitored, the relevant laws and regulations such as the Industrial

Code, Accident Prevention Regulations, etc. must be complied with. In addition to this, local

accident prevention regulations apply.

PLEASE NOTE: That if the valve closes too rapidly it can generate a water hammer in the pipes.

For product improvement purposes, AC.MO S.r.l. reserves the right to change the data in this

manual at any time and without notice. Unauthorized use of data is forbidden.

Please contact us for up-to-date information.

Thank you for purchasing our product. We kindly invite you to read carefully the operating

instructions and safety rules in this manual, which is part of the product.

ACMO-AVK | IOM Manuals

ACMO-AVK_IOM_879-M100_00-20200520 3

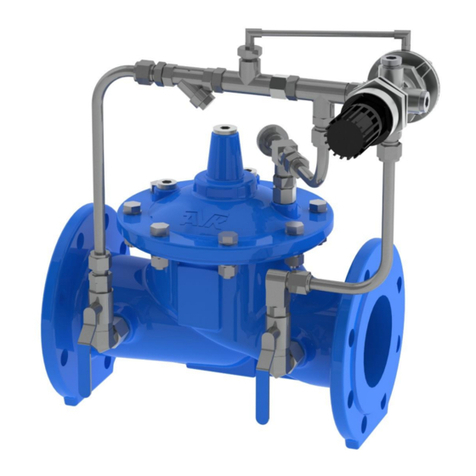

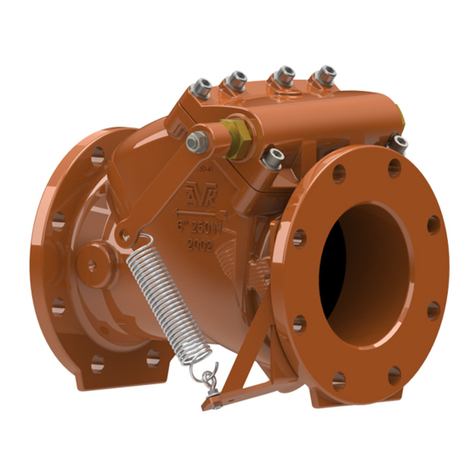

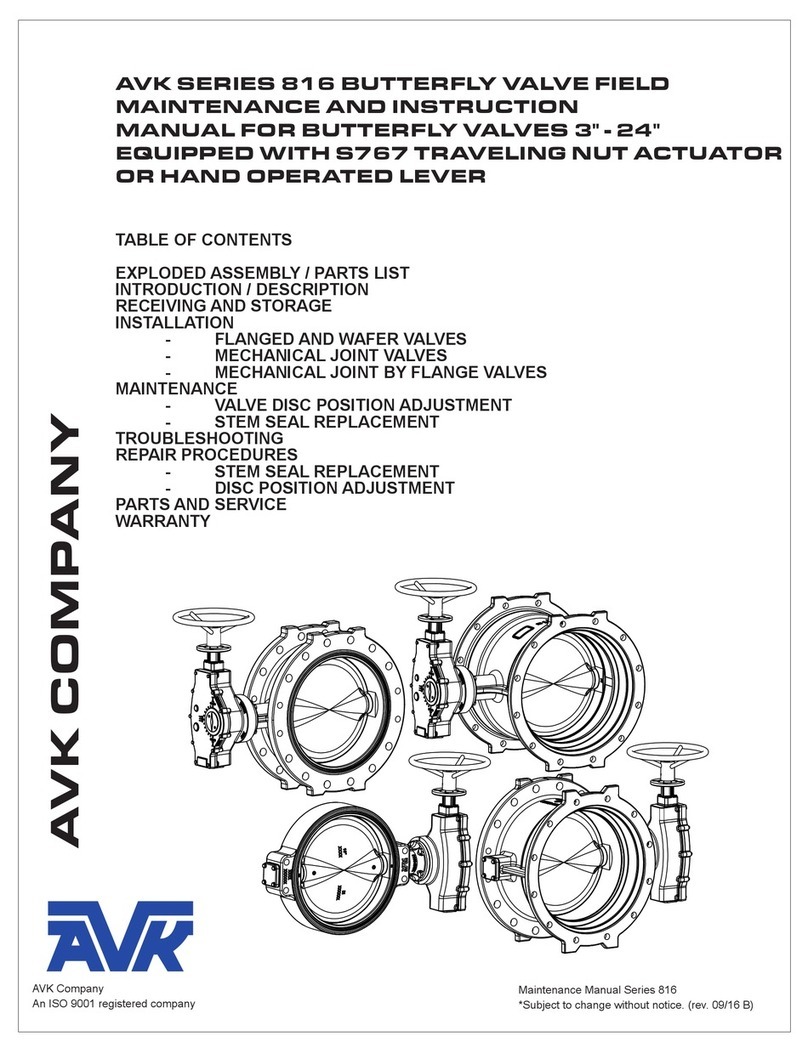

ACMO-AVK CONTROL VALVE SERIES 879

879/BB0X99 - M100 PRESSURE REDUCING VALVE

The designs, materials and specifications shown are subject to change without notice. This is due to the continuous development of our product programme.

Unauthorized use is forbidden.