123

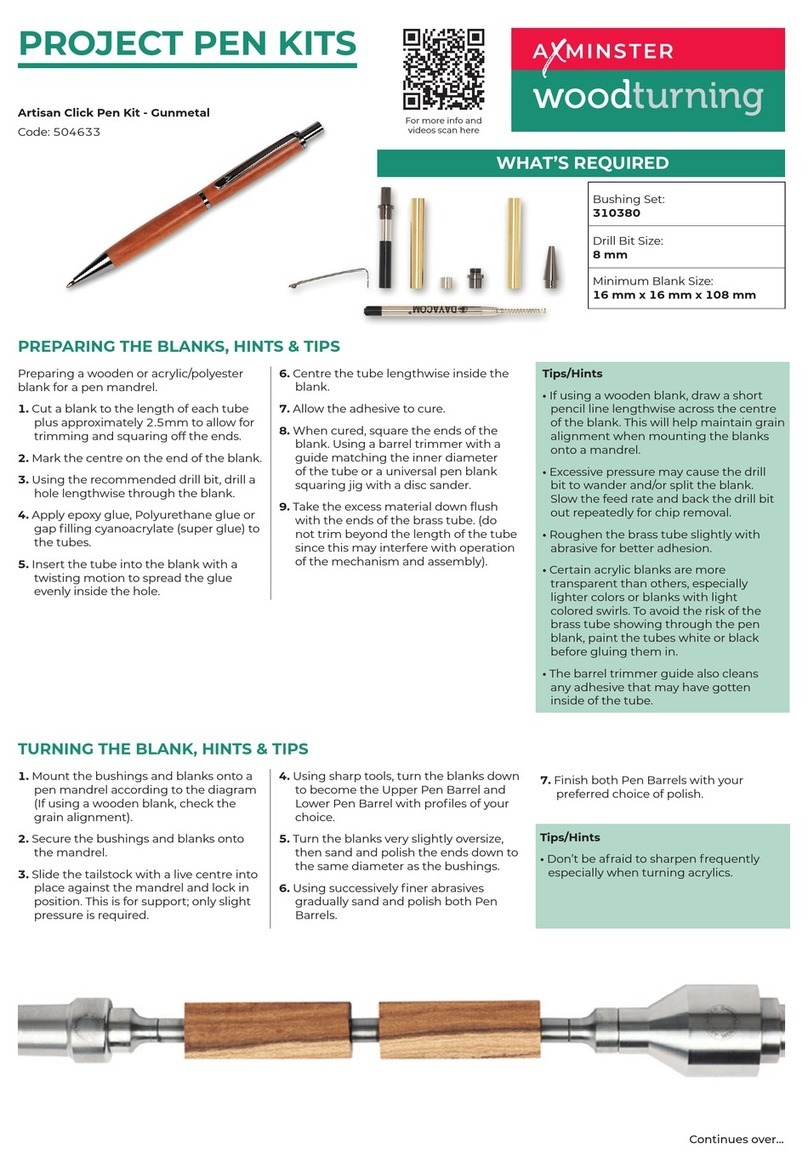

Instructions for 10ct Click Pen Kit...

Preparing the Bodies...

Turning the Bodies...

Kit No. 400316 10ct European Pen Kit (A logo)

Pictures of the finished sample articles, in both timber and acrylic, can be found in our

catalogue in the ‘Woodturning Projects’ Section.

Below is a list of the items required to make the finished items from the purchased

kits. (Not including the body blanks). If you do not possess these items we have

offered our catalogue stock code numbers alongside the items as a quick guide.We

have tried to include everything in the list, although we realise that many

woodturners will already have most of them.

Required items...

E

y

e

P

r

o

t

e

c

t

i

o

n

E

a

r

D

e

f

e

n

d

e

r

s

D

u

s

t

M

a

s

k

Alternatives are listed to cater for different lathe configurations.

Order No:

Deluxe Pen Mandrel 1MT 211322

Deluxe Pen Mandrel 2MT 211323

60˚ Live Tail Stock Centre 1MT 340202

60˚ Live Tail Stock Centre 2MT 340203

60˚ Live Tail Stock Centre 3MT 340204

Bushing Set (4 pieces) 310380

8mm Drill Bit (we recommend the Colt Pen Drill) 702555

Axminster Universal Barrel Trimmer 700265

2 Part Rapid Epoxy Resin Adhesive 340282

Alternative Zap-A-Gap Adhesive (Cyanoacrylate) 990095

Recommended Accessories...

Quick Action Pen Blank Vice 600771

Pen Blank Sizing and Cutting Jig 600623

Axminster Pen Assembly Press 200205

What’s in the Kit...

2 Brass Tubes (50mm Long)

1 Lower Joining Bush

1 Pen Clip

1 Pen Clip Securing Cap

1 Silver Tube

1 Threaded Insert Bush

1 Tip

1 Ballpoint Refill

1 ‘Click’ Mechanism

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

Using 16mm (5/8”) Square stock; cut the blanks to the length of the brass tubes

adding 2-3mm to allow for trimming.The Pen Blank Sizing and Cutting Jig makes this

process very much easier.

Drill an 8mm diameter hole through the centre of the blank.Care must be taken not

to force the drill bit,(this may cause it to ‘wander’ from the centre line), and

remember to back out the drill frequently to clear the debris from the hole.If you are

using a pillar drill the Quick Action Pen Blank Vice is a very useful accessory for this

task, it ensures that the blank is held upright and firmly in position. Moreover,if the

vice is clamped to the table of the drill, it will provide accurate repeatability for all the

blanks that require drilling.

When the hole is drilled, spread the adhesive randomly over the brass tube and insert

the tube into the blank using a twisting motion to ensure the glue is spread evenly

between the two surfaces. Over insert the tube into the blank by approximately 1mm

giving an allowance for the blank to be trimmed to size and the excess glue to be

removed (See Fig 1).

a

f

e

i

h

g

c

d

b

Zap Z-7

Debonder

Blank

Brass tube

8mm ø

Warning. If you are using cyanoacrylate adhesive,exercise extreme caution and

do not allow the adhesive to come into contact with the skin. If this happens

keep the affected area from contact with any other surface,until the glue has

hardened or you can treat the area with a softening agent similar to Zap Z-7

Debonder (990099), and you can remove the glue.

Allow the adhesive to dry thoroughly.

Using the Barrel Trimmer trim the ends of the blanks squarely and neatly to the ends

of the brass tubes; this will also remove any excess glue that may have exuded from

the joint.Take care not to undercut the brass tubes.

Slide a mandrel spacer onto the shaft. Add a bush from the Bushing Kit. Mount a Pen

Body next, add two more bushes (back to back) then the other Pen body, finally the

last bush of the set. Add the mandrel spacer and the locking nut; tighten finger tight.

Mount the assembly onto your lathe.Tighten the lock nut to allow the assembly to

be turned without moving (See Fig 2).

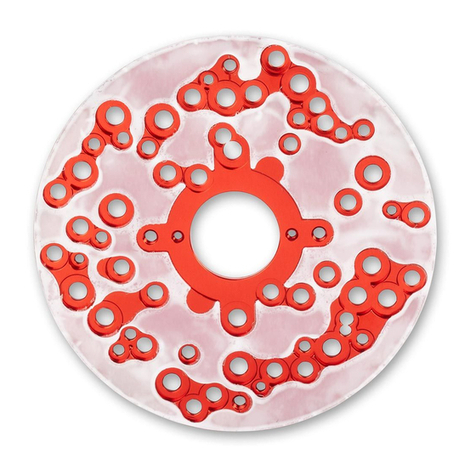

Fig 1

Morse taper shaft

Mandrel bush Pen bodys

Mandrel spacer

Bushing

Bushing

Locking nut

Live tail stock centre

Do not overtighten, this may cause the assembly to distort, the bodies to split, strip

the thread on the lock nut, etc. Similarly do not advance the tailstock centre with too

much force.The current bulk of the blanks may be adding strength to the assembly

but as the body diameters are reduced, too much force on the mandrel may cause it

to distort/bow. Turn the main bodies, finish and sand to the guide diameters of the

pen bushings. Remove the finished bodies from the pen mandrel (See Fig 3).

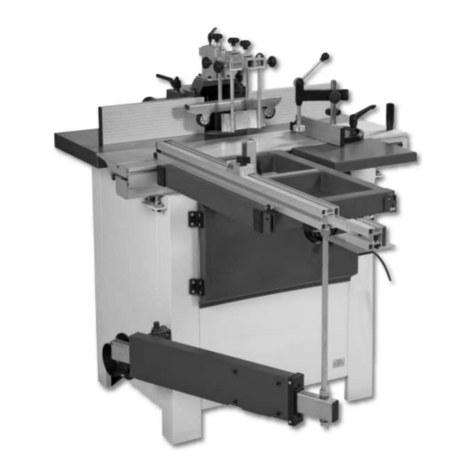

Fig 2

Fig 3

General Assembly...

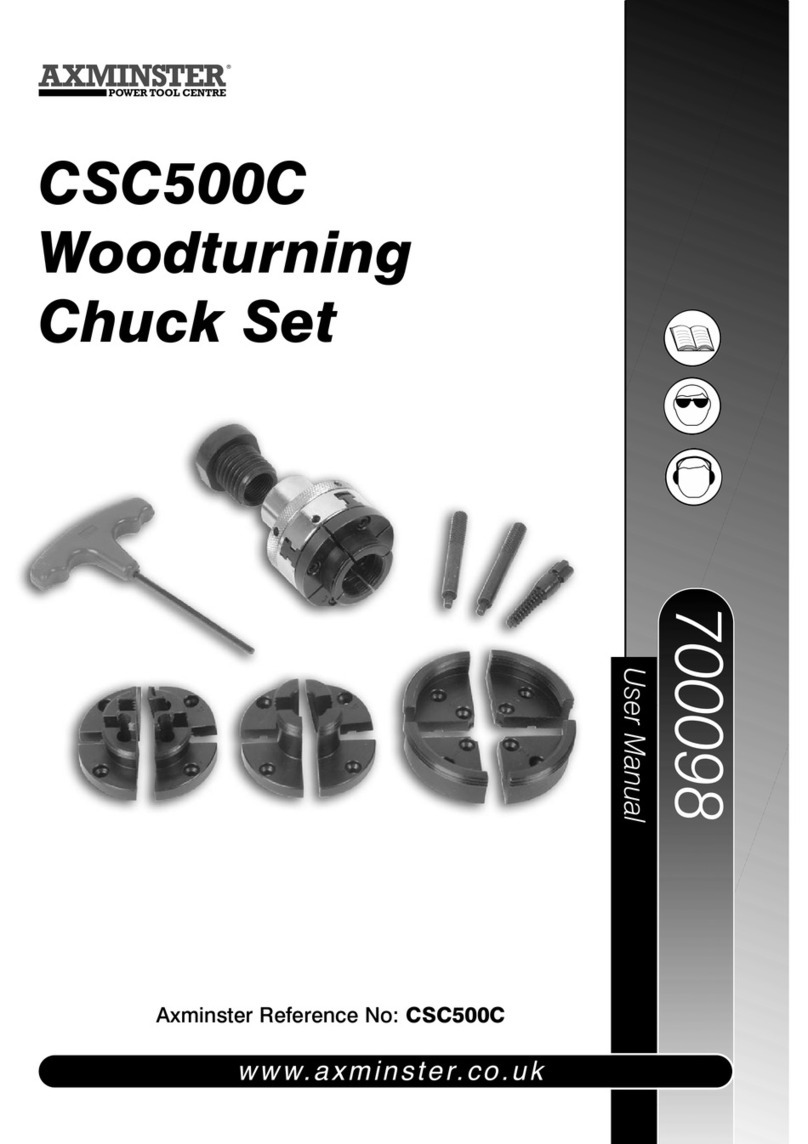

Axminster Pen Assembly Press

Fig 4

Note.The Axminster Pen Assembly Press (200205) is a very useful accessory for

these operations,as it gives greater control over the applied force and keeps

the components in line (See Fig 4).

In the illustration that follows the upper and lower body of the pen have dissimilar

profiles; and the instruction is oriented to this fact. If your body profiles are the same

then the instruction applies to either, ensure however, that the correct parts are

fitted to each body. Line up the Lower Pen Body components as shown in (Fig 5).

Make sure the body and the tip (g) are aligned and gently but firmly, press the

Ballpoint End Tip home. (Force Fit), repeat at the other end with the lower joining

bush (b) (thread out).

Fig 5

gb

Lower body

Continues Over....