B.M.P. DYNAMICROLL FOOD INOX User manual

Operating instructions

Use and maintenance manual

B.M.P. S.r.L.

INDUSTRIAL RAPID DOORS

USE AND MAINTENANCE

MANUAL

UNI EN 13241-1 : 2

•Readthismanualcarefullybefore

installingtheproduct.

•Theserviceofinstallationmustbe

performedonlybyauthorizedpersonnel

andinaccordancewithnationalwiring

standard.

•Afterreadingtheentiremanual,keepit

forfuturereference.

IMPORTANT

ENGLISH

DYNAMICROLL® FOOD INOX

Operating instructions

Use and maintenance manual

CE DECLARATION OF CONFORMITY

Company

BMP s.r.l.

with head office in

Via Torino, 64/ter

12040 VEZZA D'ALBA (CN)

PRONUNCE

under their responsibility responsabilità that the new:

INDUSTRIAL DOOR

Type

Model

Re

g

ister

Year of construction

Customer

In conformit

y

with directive 89/106/CE with the norm

harmonized EN 13241-1:2003 certified with the system 3

By the institute notified CSI specific - 0497

It i salso in line withthe safet

y

reqiurement specified b

y

machinery derective 98/37/CE with particular reference to the disposition

UNI EN 292/1 e 2 Machine safety. Fundamental concepts, general designed principles

CEI EN 60204-1 Machine safety . Electrical equipment of machines

part 1° : general rules

CEI EN 13241-1:2003

DIRECTIVE EMC 89/336/CE

BMP S.r.L. is the exclusive owner of this document – Reproduction and distribution without written permission is forbidden.

Operating instructions

Use and maintenance manual

WRITE BELOW THE DATA OF THE DOOR (*) :

Type

INDUSTRIAL CLOSURE

Model

DYNAMICROLL®

Register

…………

Yearofconstruction

…………..

(*)Thedatacanbefoundonthelabelonboardthedoororonthedeclarationofconformity

Thismaintenanceregistercontainstechnicalreferenceandrecordsinstallation,routinemaintenance,repairs

andmodification,anditmustmadeavailableforinspectionbyauthorizedperson.

ASSISTANCE DESCRIPTION

Tick the box corresponding to the operation performed. Describe any risk and incorrect use

Installation Maintenance Repair Changes

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

__________________________________________________

DATE

TECHNICAL SIGNATURE CUSTOMER SIGNATURE

REGISTER FOR MAINTENANCE AND OPERATION

DATA REMENBER

Operating instructions

Use and maintenance manual

Congratulationtohaveboughtourindustrialdoor.

Thisproductistheresultofstudies,researchandlongexperience.Ithadrigorouscontroltoassureyouan

excellentperformanceintheyears.

Readcarefullythismanualbeforeusingthedoor.Inthiswayyoucanuseitcorrectlyandsafely.Inthemanual

therearethemaindataandthenecessaryinstructiontotheuseandmaintenance.

Intheproblemsolvingtableyoucanfindalotofsolutionstocommonproblems;sooftenisnotnecessaryto

callcustomerservice.

Allworkerthatusethedoorandmaintenancepersonnelhavetoreadcarefullythismanual.

WARNING

-Contacttheauthorizedservicetomakemaintenanceorrepairthedoor.

-Contacttheinstallertoinstallthedoor.

-Childrenordisabledcannotusethedooralone.

-Onlyauthorizedpersonnelcaninstallthedoorandinaccordancewithnationalwiringstandard.

TermsanddefinitionsofEN1070,EN12433‐1edEN12433‐2.

Professionalinstaller:personorcompetentorganizationthatoffersinstallationincludingimprovement.

Competentperson:suitablyeducatedpersonthatcancorrectlyinstallandmaintainthedoor.

Register:bookthatcontainsgeneraldatarelatedtoaspecificdoorandhaveanadequatespacewhereregister

theresultofinspection,testing,maintenanceandanyrepairormodificationtothedoor.

Improvementcomponents:componentssuchasmotors,controlunits,securitydevice,installedonanexinting

doortoimprovemotorizedoperation.

Owner:naturalorlegalpersonthathasthedoorandthatisresponsibleforitsoperationanduse.

Maintenance:alloperation(check,lubrification,cleaning,ecc.)sufficienttoensurecorrectandsafeoperation

ofthedooranditscomponentafterinstallation.Maintenanceincludesadjustements,repairorreplacementfor

usuryoraccidentaldistruction,ofcomponentsnotfoundamentalforthedoor.

Maintenanceoperationarenot:

‐replacementofmajorcomponentalthoughtwithidenticalcomponent;

‐replacement/modernizationoftheproduct.

Preventivemaintenance:allmeasuresnecessarytoensuresafeandcorrectoperationofthedoor.

Failure:itislimitatedorimpossibleusingthedoor.

Thepurposeofthismanualistoprovideadequateinformationtotheowner,thecompanythatmaintainsand

anyotherqualifiedandauthorizedpersonnel,regardingtheuseandmaintenanceofthedoor,beingcarefulto

thepossiblerisksrelatedtotheirfailure.

Thismanualinformsonitsuseandbasicmaintenanceandprovideindicationintheeventoffailureor

emergencysituations.

Itdefinestheoperationforcorrectmaintenanceinaccordancewithallsafetyrules.

Anyotheroperation(adjustment,maintenance,repairs)onthedoormustbeperformedbyqualifiedperson.

Thedoorisinstalledinaccordancewiththerulesofgoodpractice.

Installationisinaccordancewiththeinstallationinstruction

Afterinstallationhavebeensuccessfullypassedallthetestsofthecomponentofthedoor

The door can be used only if it has been affixed the CE marking with CE Declaration of Conformity

PURPOSE

TERMS AND DEFINITIONS

INTRODUCTION

Operating instructions

Use and maintenance manual

drawupandsignedbytheproducer

Thedoorcanbedangerousordonotworkcorrectlyifyoudonotrespecttherulesinthismanual.

Thewarrantywillbevoidifnotauthorizedpersondisassembleormodifythedoor.

Producerandinstallerarenotresponsibleforanydamagecausedbyfailuretocomplyoftherulesinthis

manual.

BMPs.r.l.disclaimsanyresponsibilityfordamagecausedbyadoordisassembledormodifiedbynotauthorized

personoradooruseddifferentpurposesthanthoseforwhichitwasdesigned.

Maintenancemustbeperformedbyaspecializedmaintenancecompanyasspecifiedbyinstaller.

Anymodificationandreplacementofpartsmustberecorderintheappropriatesectionofthismanual.

Onlyoriginalsparepartscanprovidefullsecurityandfunctionality.

Theindustrialdoorsaredesignedandmanufacturedtobeinstalledinbothexternalandinternalindustrial

access.

Theusemustbeforalimitednumberofauthorizedperson.

Besidethedoorusedforvehicle,whenthepassageofpedestrianisnotsafe,theremustbepedestriandoors.

Theindustrialdoorsmustbeusedrespectingsafetyrules.

Topreventinjury,followtheinstructionbelow.

Incorrectuse,causedbyfailuretofollowinstruction,cancausedamageorinjury

Pleasenotethatthestickeronthedoorsareapartofthismanualandshowwarningsandsafetymassageand

shouldnotberemovedordamaged

Theimportanceissoclassified:

ATTENTION

Thissymbolindicatesthepossibilityofdeathorseriousinjury.

WARNINGS

Thissymbolindicatedthepossibilityofinjuryordamage.

ATTENTION

Donotdisassembleortrytorepairthedoor.

Contactservicecenter.

Thedoormustbegrounded.

Thiswillpreventfireorelectricshock

Keepawayflammableorexplosivematerialsfrom

thedoor.

Otherwiseitcancausefireordamagethedoor.

Donotinstallthedoorinplaceswithariskof

flammablegasleak.

Otherwiseitcancauseanexplosionorfire.

Donotinstallthedooronfaultyinstallation

support.

Otherwiseitcancausedamageorinjury.

Unpackandinstallthedoorcarefully.

Sharpedgescancauseinjury.

Fortheinstallationalwayscontacttheseller,

servicecenterorfollowtheinstruction.

Otherwiseitcancausefire,electicshockorinjury.

Forelectricalconnectionalwayscontacttheseller,

servicecenterorfollowtheinstruction.

Otherwiseitcancausefire,electicshockorinjury.

Alwaysinstallacircuitbreakerandamaster

switch.

Failuretoinstallcancausefireorelectricshock

Incaseofabnormalnoise,odororsmokecoming

fromthedoorturnoffthecircuitbreakerand

disconnectthepower.

Otherwiseitcancausefire,electicshockorinjury.

Donotsteponorplaceobjectsonthedoor.

Otherwiseitcancauseinjuryordamagethedoor.

Donotturnoffthecircuitbreakerordisconnectthe

powerduringoperation.

Otherwiseitcancausefireorelecticshock.

SAFETY INSTRUCTION

INTENDED USE

Operating instructions

Use and maintenance manual

Donotwettheelectricalparts.

.Otherwiseitcancausefire,electicshockor

damagethedoor

Donotallowchildrentoplaywithcontroldevice.

Keeptheremotecontroloutofchildren.

Otherwiseitcancausedamageorinjury

WARNINGS

Donottransportthedooryourselforbyhands.

Otherwiseitcancausedamageorinjury

Turnoffthepowerbeforeworkingonthedoor.

Otherwiseitcancausefireorelecticshock.

Donotputobjectaroundthedoor.

Otherwiseitcancauseinjury

Duringinstallationdonotgetoninstableobject.

Otherwiseitcancausepersonalinjury

USE RISCK PREVENT

MECHANICAL RISCKS

FormNotPresent /

Failuretothemechanical

resistanceDeterminationwindresintanceclass

CrushriskDuringdoorinstallation Istructioninsidethemanual

CutriskDuringdoorinstallation Istructioninsidethemanual

ELETTRICAL RISK

Elettricshockrisk/Elettricaltransmission comply

withtherules

MATERIAL AND PRODUCT RISK

Risktocontactorinhalation of

harmfulfluids,gases,mists,

fumesanddust.

Notpresent/

DangerousposesoreccesstrainNot present /

Thesoundpressurelevelproducedbytheindustrialdoorwasmeasuredandvaluedsimulatingtheoperationof

thedoorinthefactoryanditis<70dB(A).

Thiswasmeasuredrespecttoanoperatorwithcontrolboardonthesideofthedoor.

Thedoornoiselevelchangeswith:

-Conditionofuse(place,disposition,ecc.)

-Statusofefficiency

-Dimensionofthedoor

Incaseofdisposalofthedoortheownermustdifferentiateitspart.

Thiscanbedonebyspecializedcompaniesauthorizedtotransportandrecyclingasrequiredbylocalrules.

WARNING:donotleavethewreckageofthedoorintheenvironment,thisisaseriousdangerfor

environmentandpeople.

DISPOSAL

NOISE

RESIDUAL RISK

Operating instructions

Use and maintenance manual

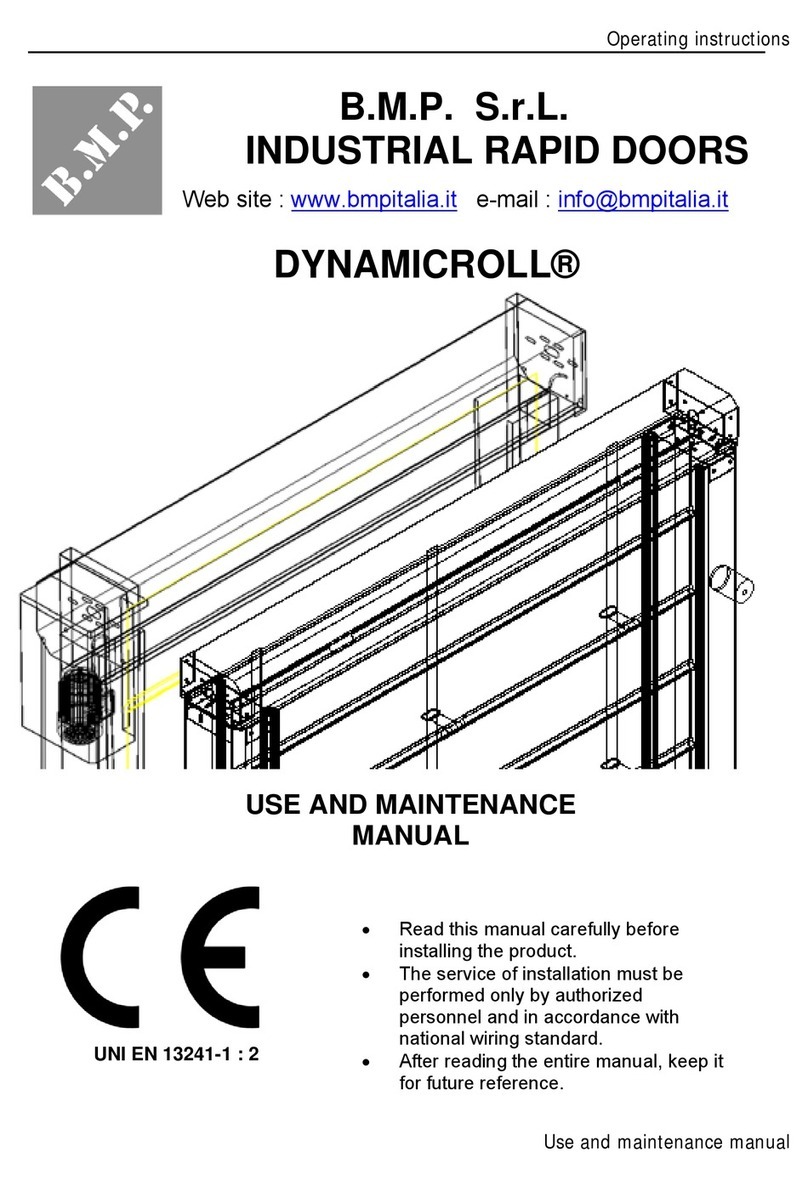

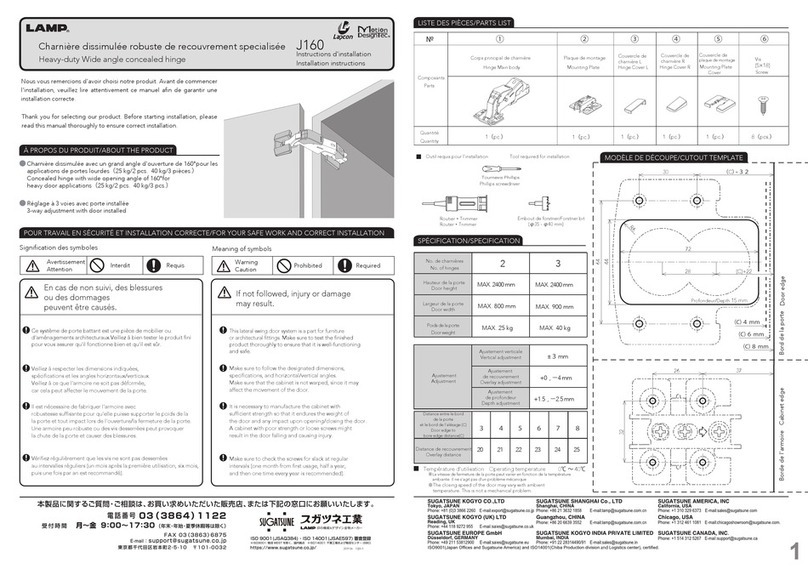

-DYNAMICROLL WITH SIDE-MOUNTED MOTOR

1 Photocell

2 Cable

3 Control board

4 Column

5 Crossbar

7 Porthole

8 PVC curtain

9 Motor cover

10 Pol

y

zene

g

uides

11 Side plate

12 Ball bearin

g

13 Shaft

14 Roller tube

15 Pulley

16 Toothed belt

17 Limit switch

18 Limit switch support

19

A

dapte

r

20 400 V tree-phase motor

21

A

dapter support

22 Key

23 Drive shaft

24 Edge cogged curtain

DESCRIPTION OF COMPONENT

3

2

1

4

5

7

8

910

11

12

13

14

15

22

16

18

12

11

24

19

21

23

20

17

Operating instructions

Use and maintenance manual

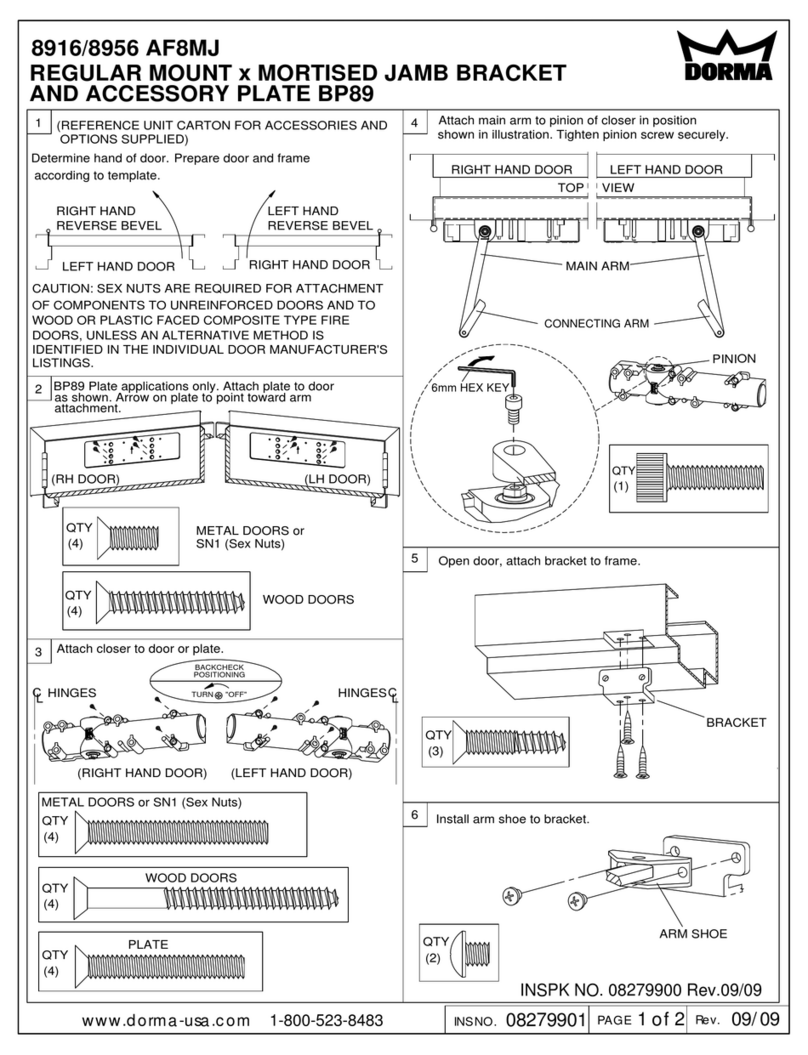

-DYNAMICROLL WITH FRONTAL MOTOR

1 Photocell 11 Side plate 20 Drive shaft

2 Cable 12 Ball bearin

g

21

A

dapte

r

3 Control board 13 Shaft 22 400 V tree.phase moto

r

4 Column 14 Ruler tube 23 Adapter support

5 Crossbar 15 Pulle

y

24 Co

g

wheel

7 porthole 16 Toothed belt 25 Chain link

8 PVC curtain 17 Limit switch 26 Chain

9 Motor cover 18 Limit switch support 27 Key

10 Polyzene guides 19 Shaft key 28 Shaft

11

12

13

14

3

2

1

4

5

7

8

9

10

11

14

15

16

17

18

19

20

21

22

23

24

25

12

26

27 28

Operating instructions

Use and maintenance manual

INSTALLATION INSTRUCTION

-Always use a power circuit specifically dedicated to the door. For wiring follow the

manufacturer's instructions.

-Tighten the screws of the electrical terminals to prevent loosening.

-Make sure the power source has the required capacity.

-Make sure the thickness of the cable conforms to what is stated in the specification of the

power source.

-Never install a differential circuit breaker in wet or damp areas.

EQUIPMENT NEEDED

1 Flexometer 10 Level

2 Suitable lifting equipment (stairs

elevator, ecc.)

11 Set of allen keys (17 mm, 13 mm,

10mm, 8 mm)

3 Screwdriver set 12 Tester

4 Iron drill 13 Hamme

r

5 Hammer drill 14 Cordless screwdrive

r

6 Drill bits (iron and concrete) 15 Grinder

7 Scissors 16 Silicone

g

un

8 Strippin

g

cable 17 Pliers

9 Vices

Elevator Forklift

INSTALLATION

Operating instructions

Use and maintenance manual

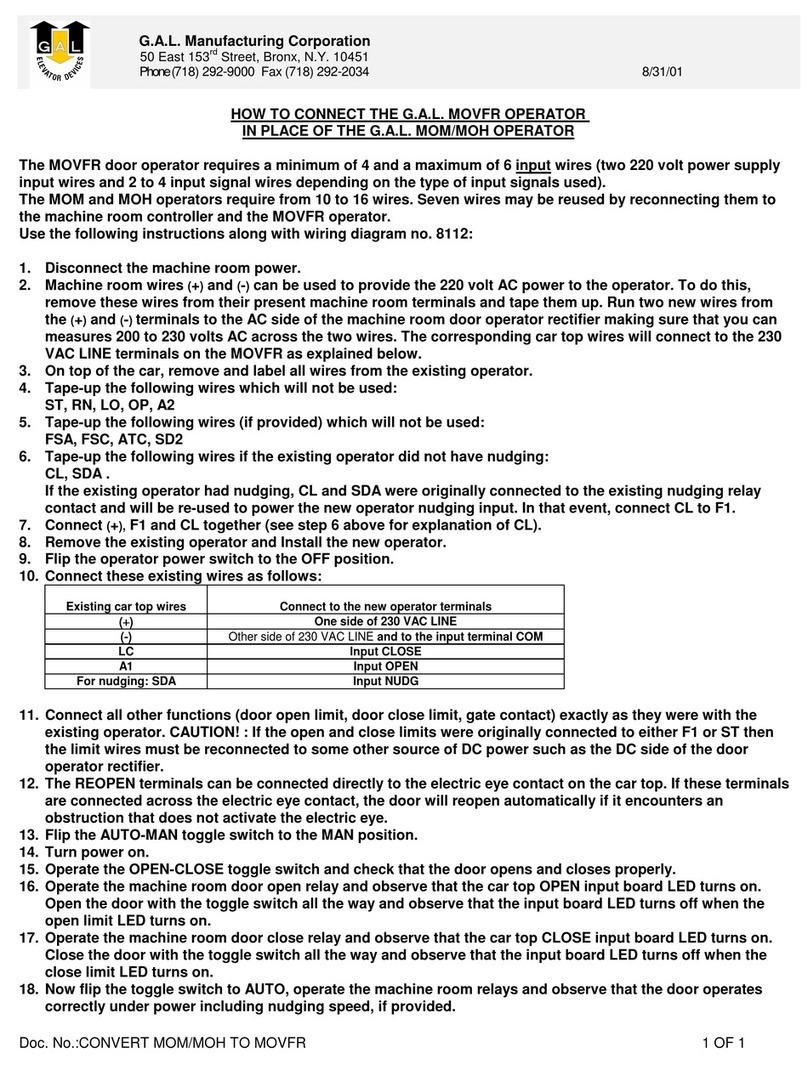

-ThecardinstalledisBMP1_HW

-Thecontrolcardispoweredby230Vsingle‐phase50Hz.

WARNING:Thepowerline230Vsingle‐phase50Hz.mustbededicatedonlytothecontrolboard

andmustnothavecurrentoscillation

-Thecontrolboard,throughmicrocontroller,controlstheoperatingcurrentofthemotorandthe

heatsinktemperature,providingtoreportanymalfunction.

-Allimputsareindicatedbyleds

-Allarmmessagesareindicatedbyflashinglightordisplay

WARNINGAccessories:output24Vac/300mAMAX

output12Vdc/100mAMAX

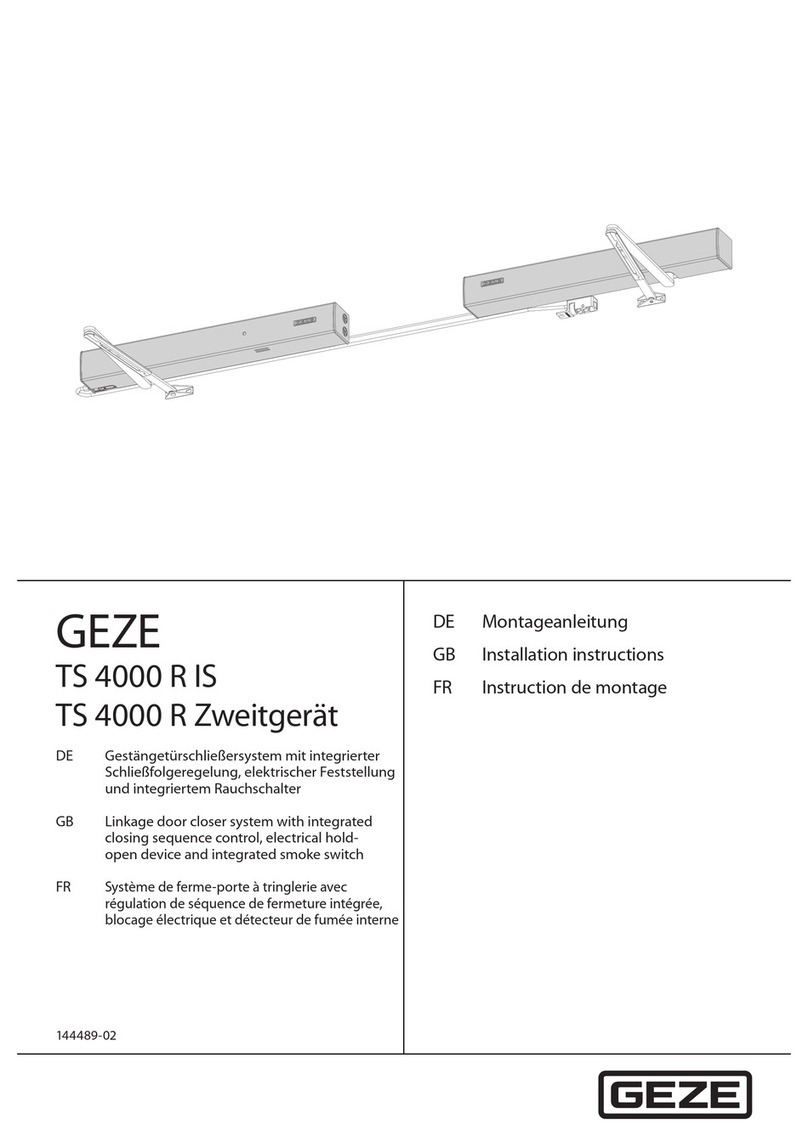

LEGENDA

1

CONTROL CARD 6 MOTOR BRAKE TERMINAL (N°30-31)

+ FLASHING LIGHT (N°29-30)

2

METAL BOARD 7 CONTROL BOARD LOCK

3

MOTOR TERMINAL

(U-V-W) 8 START BUTTON

4

DOOR LOCK 9 EMERGENCY BUTTON

5

GROUNDING TERMINAL

CONTROL BOARD

3

4

5

6

7

8

9

1 2

T

E

CO

E

RMINAL

N°

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Termina

N°

23

24

25

26

27

28

29

30

31

NTROL CA

R

Ju

m

+12 10

0

0 Vdc 10

0

Not used

Signal

-

(op

-

(op

Not used

Photocell /a

n

Opening co

m

Not used

Not used

Start openin

g

Pedestrian s

t

Common im

p

Photocell

Common im

p

Stop

Slow down

o

Slow down

c

Opening lim

i

Closing limit

24 Vac pow

e

24 Vac pow

e

Signal

-(op

t

l

Motor ph

a

Motor ph

a

Motor ph

a

Power p

h

Power n

e

Groundi

n

Flashing li

Phase (C

O

Brake

R

D TERMIN

A

m

per inputs

N

C

0

mA max.

0

mA max.

tion in use 2

0

tion in use 4

0

n

tijamming se

m

mand

g

(standard)

/

t

art

p

uts (+12Vdc

)

p

uts (+12Vdc

)

o

pening limit

s

c

losing limit s

w

i

t switch

switch

e

r accessories

e

r accessories

t

ion in use 20.3

C

a

se

a

se

a

se

h

ase

e

utral

n

g terminal

ght 230

V

O

MMON) flashin

120

V

A

L WITH LI

M

N

.C. not use

d

C

ONNECTI

O

0

.300) opened

0

.300) closed

d

nsor N.

C

/

closing optio

)

)

s

witch

w

itch

300mA max.

300mA max.

00) closed doo

r

C

ONNECTI

O

U

V

W

230Vac

230Vac

V

DC

g light

/

brake

V

DC

Ope

r

Use and mai

M

IT SWITC

H

d

O

N

door signal

d

oor signal

C

.

n in use 000

0

N.O.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

r

signal

O

N

r

ating instruct

i

ntenance ma

n

H

N.O.

0

08

N.O.

i

ons

n

ual

Opera

t

Use a

n

Ter

m

N

t

ing instructio

n

n

d maintenan

c

C

m

inal

N

°

1 +

2 0

3 N

o

4

5 S

I

6 N

o

7 P

h

8 O

9 N

o

10 N

o

11 S

t

12 P

e

13 C

o

14 P

h

15 C

o

16 S

t

17

e

18

e

19 N

o

20 N

o

21 2

4

22 2

4

23

24 S

I

Termina

N°

23

24

25

26

27

28

29

30

31

n

s

c

e manual

C

ONTROL C

A

Ju

m

12 100m

A

Vdc 100m

A

o

t used

I

GNAL

-

(optio

n

o

t used

h

otocell /antija

m

pening comma

n

o

t used

o

t used

t

art opening (st

a

e

destrian start

o

mmon inputs

(

h

otocell

o

mmon inputs

(

t

op

e

ncoder green

e

ncoder

y

ello

w

o

t used

o

t used

4

Vac power ac

c

4

Vac power ac

c

I

GNAL

-

(optio

n

l

Motor ph

a

Motor ph

a

Motor ph

a

Power p

h

Neutral.

Groundi

n

Flashing li

Phase (C

O

Brake

A

RD TERM

I

m

per inputs

N

A

max. encode

A

max. encode

n

in use 20.300

)

m

ming sensor

n

d

a

ndard) / closi

n

(

+12Vdc)

(

+12Vdc)

cable

w

cable

c

essories 300m

A

c

essories 300m

A

n

in use 20.300

)

C

a

se U

a

se

a

se

h

ase

230Vac

n

g terminal

ght 230

V

O

MMON) flashin

120

V

I

NAL WITH

N

.C. not use

d

CONNECTI

r red cable

r black cable

)

opened door

s

N.C.

n

g option in use

N.

N

A

max.

A

max.

)

closed door si

g

C

ONNECTI

O

V

W

230Vac

V

DC

g light

/

brake

V

DC

ENCODER

d

ON

s

ignal

N.O.

000008 N.O.

N.O.

N.C.

N.C.

C.

N

.C.

g

nal

O

N

Operating instructions

Use and maintenance manual

ThisisaverticaloperationhighspeeddoorwithPVCcurtain.

Withthedoorareprovided:

Openingsystem(N.O.):

−Greenbuttononcontrolboardandagreenbuttonintheoppositesidetothecontrolboard,when

pressedtheyopenthedoor.

Securitysystem(N.C.):

−Emergencyredbuttononthecontrolboarditstopimmediatelythedoorifpressed.

−Photocellto40/50cmfromthefloor,itstopandreversethedoorinclosingifinterrupted.

−Asafetysensornearrollertube,itcontrolscurtainwrappinganditstopthecurtainifduringthe

closurecurtainsupportonanobstacle.

CONTROL CARD OPERATION MODE

-AUTOMATIC CLOSING ADJUSTABLE (*)

ThissystemallowtoopenthedoorwithSTARTcommandandadjustmentofpausetimeforautomaticclosing.

Toenablethismodeofoperationpositionthedipswitch1onON

(*)Factory mode operation

-STEP BY STEP

ThissystemallowtoopenthedoorpressingSTARTbutton.

ThedoorclosesafterpressingagainSTARTbutton.

Toenablethismodeofoperationpositiondipswitch1onOFF

WARNING!!!THISLOGICDONOTEXECUTETHEAUTOMATICCLOSING

MANUAL OPERATION

OPERATION

Operating instructions

Use and maintenance manual

SAFETY GENERAL RULES

¾Beforeanyinterventionthemaintenancemanmust:

oDelimittheinterventionareaandaffixtherightsignsinordertosignalthemaintenance

worksonthedoor

oControlthattheelectricitypowerisdisconnectedbeforestartthemaintenance

oControltobecorrectelyinformedaboutthemaintenanceandreadandunderstandthis

manual

¾Themaintenancemancan’tusetheelectricalfittingswithoutadeclarationofhisproved

experience.

¾Don’tallownotauthorizedpeopletorepairormaintenancethedoors.

¾Readthemanualbeforemaintainthedoors.

¾Duringmaintenancedon’tuseheatsourcesthatcouldstartfires.

¾Duringmaintenancedonotsolder.

¾Employmentofcompressairisforbidden.

¾Employmentofanysolventisforbidden.

¾Thepresenceofthemaintenancestaffaroundthedoormustbelimited.

¾Thepresenceofotherpeoplearoundthedoorisnecessaryonlytosupportthemaintenancestaff.

ORDINARTY CLEANING AND MAINTENANCE

Theordinarymaintenanceoperationsarealltheoperationsthatcoulddotheuser.

Themaintenanceandclearingofthedoorarenecessarytoobtainthebestfunctioning,highersafetyforthe

userandalongeroperativenessofthedoor.

COMPONENT DESCRIPTION PERIODICITY

Structure

Verifythatthestructureiscorrectelyfixedtothewallinorder

toavoidincidents.

Ckeanwithsoftclothwithoutusinganysolvent(eventuallyuse

waterandsoap)

Ifthereisiceonthestructureimmediatelyremoveit

Six‐month

Photocellandradar

Cleanwithsoftclothwithoutusinganysolvent(industyareas

couldbenecessarytocleanmorefrequentlythephotocells:

dustonphotocellscouldcausemalfunctioningofthe

photocells)

Six‐month

OblòCleantheoblowithasoftclth andifnecessarywithwaterand

soap(donotuseanysolventthatcoulddamagetheoblo)Six‐month

Curtain

Controltheconditionofthebeltsandofthecurtain.

Cleantheoblowithasoftclthandifnecessarywithwaterand

soap(donotuseanysolventthatcoulddamnagetheoblo)

Six‐month

PERIODICAL CHECKS AND MAINTENANCE

Operating instructions

Use and maintenance manual

CHECK, PLANNED INSPECTIONS AND MAINTENANCE

Onlythemaintenancestafforauthorizedpeoplecoulddochecks,plannedinspectionsandplanned

maintenance.

Theseoperationsarenecessaryforthevalidityofthewarranty

INTERVENTION

POINT DESCRIPTION PERIODICITY

Structure

-Verifytheconditionofthefixingframes,thecorrect

closureofthewallanchorsandofthepassingbars(if

present)

-Controlthattherearen’tanystructuraldeformationsdue

tocrashes

Six‐month

Electrical

components

-Verifytheelectricalconnectionsinthecontrolboardand

verifythatthereisnowaterin.

-Controltheelectricalconnectionsinthejunctionboxand

controlthatthereisnowaterinit

-Controltheconditionsandfunctioningofthesafety

components(photocells,safetyedgeandemergency

button)

-Controltheconditionsandfunctioningoftheopening

components(openingbuttonsandoptionalifpresent)

-Verifythatalltheelectricalcablesareingoodcondition.

Six‐month

Mechanical

components

-Verifytheconditionofthemotor

-Controltheconditionofthemotorbrake

-Controlthewearandtensionofthedrivecjhainofthe

motoradapter.

-Controltheconditionofthereducer:oilleak,fixingtothe

motor,fixingofthestructure.

-Controltheconditionofthelimitswitch:wearofthe

beltwheel,wearandfixingofthepulley,thecorrect

functioningofthecammeandswitches.

-Contro,lthecorrectclampingoftheboltsforanypartof

thestructure.

-Verifytheaxialityofthewinderroller

-Controltheconditionandgreasingofthebearings.

-Controltheconditionoftheantiwearwashersonthe

columns

-Controltheconditionandregulationoftheguides(on

thedynamicdoors)

Six‐month

Curtain

-Verifytheconditionandwearofthecurtainandin

particolarintheareassubjecttorubbing.

-Controlthattherearen’tanytearonthecurtain.

-Controltheconditionandregulationofthebelts,lower

andupperfixingplatesandofthebelts(fortherapid

packdoors)

-Verifytheconditionofthecurtainbars

-Controlthecorrectpackagingorrollingofthecurtain

-Controlthetensioningofthecurtain,theconditionand

wearofthezips(forthedynamicdoors)

Six‐month

Operating instructions

Use and maintenance manual

PROBLEM SOLUTION

1 THE WARNING LIGHTS IN THE

CONTROL BOARD DO NOT

LIGHT UP

1CHECK POWER SUPPLY ( 230 V )

1CHECK FUSE

2 THE DOOR DOES NOT MOVE

WITH P1 AND P2 BUTTON

2CHECK SETTING MOTOR WITH PROGRAMMER

(SETTING PARAMETERS – MOTOR TYPE ……KW)

2RELEASE STOP BUTTON (LED 6 turned on)

2CHECK MOTOR CONNECTION (triangle 230V three-

phase, star 380 three-phase)

3 YOU CAN NOT COMPLETE THE

SETTING OF THE CARD

3CHECK WITH PROGRAMMER PARAMETER

OPTION IN USE 4300 FOR SINGLE PHOTOCELL

4380 FOR DOUBLE PHOTOCELL

(with encoder)

3RELEASE THE STOP BUTTON (LED 6 turned ON)

3MOVE THE DOOR WITH BUTTON P1 AND P2 OF

40/ 50 CM AND LOCATE IT ON CLOSE POSITION (

this operation is useful to recognize the encoder )

3VERIFY THAT THE LED LD13 (radio safety edge or

sensor in the upper case) IS ON

3IF NOT, MAKE JUMPERS 7 /13 AND CONTROL

THEN THE SECURITY COMPONENTS

3INVERT THE ENCODER CABLE (yellow with green )

3FOR DOORS WITH UPPER PHOTOCELL CONTROL

THAT LD 3 IS OFF WHEN THE DOOR IS CLOSE

4 YOU CAN NOT COMPLETE THE

SETTING OF THE CARD

4CONTROL THAT THE LIMIT SWITCH ARE

CORRECTLY REGUALATED ( if FCC and FCRC

aren’t pressed the card can’t be set)

(with limit switch )

4VERIFY THAT THE LED LD13 (radio safety edge or

sensor in the upper case) IS ON

Operating instructions

Use and maintenance manual

4VERIFY THAT THE LED LD7 (safety photocell ) IS

ON

4RELEASE STOP BUTTON (LED 6 turned on)

5 YOU CAN NOT COMPLETE THE

SETTING OF THE RESISTIVE

EDGE

5VERIFY THAT THE JUMPER ON THE

TRANSMITTER J1 IS TAKEN OFF

5RESET THE OLD CODES (close the jumper "MR"

press the PROG button until you hear a beeps tight

series, then remove the jumper)

5VERIFY WITH THE TESTER THE CHARGE OF THE

TRANSMITTER BATTERIES

5VERIFY IF THE RESISTENCE(8.2 KΩ) FOR THE

CABLES THAT COME OUT FROM THE EDGE

CHANGES IF YOU PRESS THE EDGE if it doesn’t

change control that the resistive band is perfectly flat

for all the length of the black profile or take out the

gum and control the

5VERIFY THE CONNECTIONS OF THE RECEIVER

6 THE PHOTOCELL DOESN’T

WORK ( LD 7 OFF)

6VERIFY THE ALIGNMENT

6VERIFY THE CONNECTION OF THE BLACK

RECEIVER CABLE( brown +12Vdc) (blue 0V dc ) (

black: signal that it arrives to the terminal 14 in the

local plant)

(the door doesn’t close )

6VERIFY THE CONNECTION OF THE

TRANSMITTER GREY CABLE ( brown +12Vdc) (blue

0V dc)

( ATTENTION! If you invert the brown and blue cables

you will damage the sensors)

7 THE ANTI-JAMMING SENSOR

DOESN’T WORK (sensor)

7VERIFY THE CONNECTION ( brown +12Vdc) (blue +

white 0V dc ) ( black: signal that it arrives to the

terminal 7 in the local plant)

(the sensor doesn’t light up)

8 THE ANTI-JAMMING SENSOR 8BRING THE SENSOR CLOSER TO THE CURTAIN

Operating instructions

Use and maintenance manual

DOESN’T WORK (sensor) 8PUT THE SENSOR FRONTALLY TO THE TUBE

A

XIS

(the door closes but the sensor

doesn’t work if I press it)

8CONTROL THE CONNECTIONS ( brown +12Vdc)

(blue 0V dc ) ( black connected to the cable 7 in the

local plant)

9 THE DOOR STOPS AT THE

PHOTOCELL LEVEL AND

COMES BACK

9REGULATE THE SLOWING DOWN LIMIT SWITCH:

IT CLOSES 10 CM BEFORE THE PHOTOCELL ( the

contact switch off the functioning )

10 THE DOOR CLOSES ONLY 50

CM AND THEN COMES BACK

10 INCREASE THE INTERVENTION TIME OF THE

ANTI-JAMMING PHOTOCELL USING THE

PROGRAMMER (PARAMETER SETTING- ANTI-

JAMMING PHOTOCELL READING)

10 LOWER THE ANTI-JAMMING PHOTOCELL

SENSOR

11 LD1 REMAINS ON( IN THE TOP

LEFT-HAND )

11 VERIFIY THE FUSE

11 THE CARD IS DAMNAGED ( replace it)

12 THE DOOR DOESN’T CLOSE

AUTOMATICALLY

12 VERIFY DIP 1 ( ON = automatic ) (OFF = manual )

12 CONTROL THE CORRECT FUNCTIONING OF THE

SAFETY COMPONENTS ( LD 7 - LD 13- LD 6 on)

13 THE DOOR WORKS BUT

SOMETIMES IT GETS STUCK

13 VERIFY THE CORRECT SETTING OF THE MOTOR

WITH THE PROGRAMMER (PARAMETER SETTING

– TYPE OF MOTOR ……KW)

(in any position)

13 CONTROL THAT THE FLASHING LIGHTS WIRES

OR THE MOTOR BRAKE WIRES ARE NOT IN THE

SAME CABLE OF THE PHOTOCELL AND LIMIT

Operating instructions

Use and maintenance manual

SWITCH (interference problem) they must have their

own cable and tube ,the 230V must be separated

from 12- 24V

13 VERIFY WITH THE TESTER THAT THE CURRENT

ISN’T LOWER THAN 220V (control when the door’s

working) if the current is lower than 220V control the

input

13 VERIFY WITH THE PROGRAMMER THAT THE BUS

VOLTAGE ISN’T LOWER THAN 300V (SYSTEM

CONDITION – BUS VOLTAGE) (control when the

door’s working) if the voltage is lower than 300V

control the input.

13 VERIFY WITH THE PRORAMMER THE MOTOR

UPTAKE (SYSTEM CONDITION- MOTOR CURRENT

with motor 0,75kw can’t be higher than 7A;with motor

1,5 kw can’t be higher than 9A, control when the

door’s working) if the door exceeds the threshold

lower the opening HZ

14 THE PHOTOCELL DOESN’T

WORK

14 CONTROL THAT IN THE VICINITY THERE AREN’T

ANY OTHER PHOTOCELLS THAT COULD CAUSE

REFLECTION (try to darken the photocells)

(the door closes but the photocell

doesn’t reverse the curtain)

14 CONTROL THAT WITH THE PHOTOCELL CABLES

THERE AREN’T ANY HIGH VOLTAGE CABLES

(motor ,motor brake, flashing lights, power line) (take

to the control board separated cables in different

pipes, separate the low voltage 12-24V from the high

voltage ≥100V)

14 PUT THE MINUS OF THE RECEIVER (black cable,

blue wire) ground

15 WITHOPENDOOR(locked)THE

CURTAINSLOWDOWN

15 SETTHEMOTORBRAKE(removethefancoverandcloseof

aquarterturnofthedialbrakeadjustement,thenmake

teststoreachtheoptimum)

Operating instructions

Use and maintenance manual

Thedoorisdesignedandmanufacturedtouseasanindustrialclosure.Anydissimilarfromtheoriginalprupose

andthefailuretofollowinstructioncontaininthismanualwillvoidthewarranty.

B.M.P.S.r.L.guaranteethedoorfor12monthsfromthedateofthetestandputinto;thereforeitisessential

tokeepthedocumenttestingwiththismanualandtheinvoiceorreceiptfortaxpurposes.Thewarrantyis

avoidifarenotobservedthetermofpayment.

Thewarrantyissubjecttothereport,withfaxorinthewebsite,whenyoudiscoveranydefects,aftercheck

andadmissionbyB.M.P.S.r.L.

B.M.P.S.r.l.repairorreplaceallpartthatweadmitdefectiveforcauseddependenttothematerialor

workmanship:warrantywillbevoidforthepartdamagedafterinstallationandtestingthedoor,orincorrect

installationormaintenanceiftheyarenotdonebyourstaff,actionbynotauthorizedpersonnel,transport

withoutnecessarycautionandanydamagenotattributabletomanufacturingdefects.

Thewarrantydoesnotcoverpartssubjecttonormalwearandteartoweathering.

Thereplacement,theadditionorthemodification,withoutthepermissionofthemanufacturer,theuseof

componentnotidenticaltothoseprovidedoranyotherbrand,willvoidthewarranty.

TheresponsibilityforB.M.P.S.r.L.remains,however,limitedtotherepairorreplacementofdefectiveparts,

B.M.P.S.r.Ldisclaimanyresponsibilityforanyconsequenceordamagecausedfromgoods,includingworkfor

disassemblyandassemblyoradditionalaccessoriesbought.

Thewarrantyexcludesanyrighttoterminatethecontractofsale,pricereductionandcompensationfor

damage,inadditionreplacingapartdoesnotinvolvetherenewalofthewarrantyperiodontheentiredoor

unlesshasnotreplacedthedoor.

Theusermustobservethesafetywarningsinthemanual,inparticular:

-Operatewithinthelimitofuse

-Alwaysmakeacostantanddiligentmaintenance

B.M.P.S.r.Ldisclaimanyresponsibility,directorindirect,arisingfrom:

-Failuretocomplytheinstructioninthismanual

-Usebyuntrainedpersonnel

-Incorrectinstallation

-Defectinpower

-Notauthorizedchanges

-Notautorizedrepairs

-Seriusmaintenancedeficincies

-Usenotoriginalpartsornotspecificforthemodel

-Exceptionalevents

-Usenotinaccordancewithregulationinthecountryofinstallation

WARRANTY CONDITIONS

Table of contents

Other B.M.P. Door Opening System manuals

Popular Door Opening System manuals by other brands

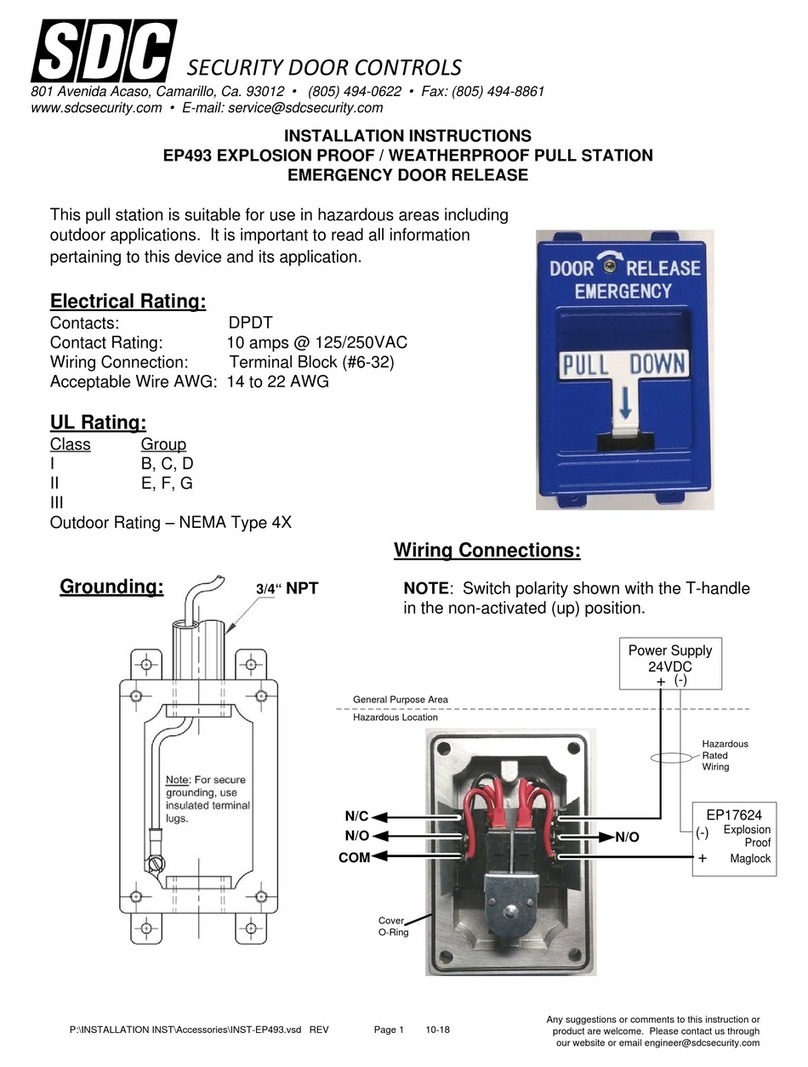

SDC

SDC EP493 installation instructions

Automatic Technology

Automatic Technology DOMINATOR ShedMaster GDO-8V3 instruction manual

BSW SECURITY

BSW SECURITY 1451 Mounting instruction

Assa Abloy

Assa Abloy Corbin Russwin PED5600 Series installation instructions

Assa Abloy

Assa Abloy DC 700G-FT BGS installation instructions

Assa Abloy

Assa Abloy DC340 installation instructions

Nice

Nice AVIO600 Instructions and warnings for installation and use

Taymor

Taymor 13-4000 SERIES installation instructions

Dictator

Dictator DICTAMAT 650 quick start guide

Yakima

Yakima AWNING BRACKET KIT Quick start quide

Dormakaba

Dormakaba 8600 EMF installation instructions

Assa Abloy

Assa Abloy SW200 owner's manual