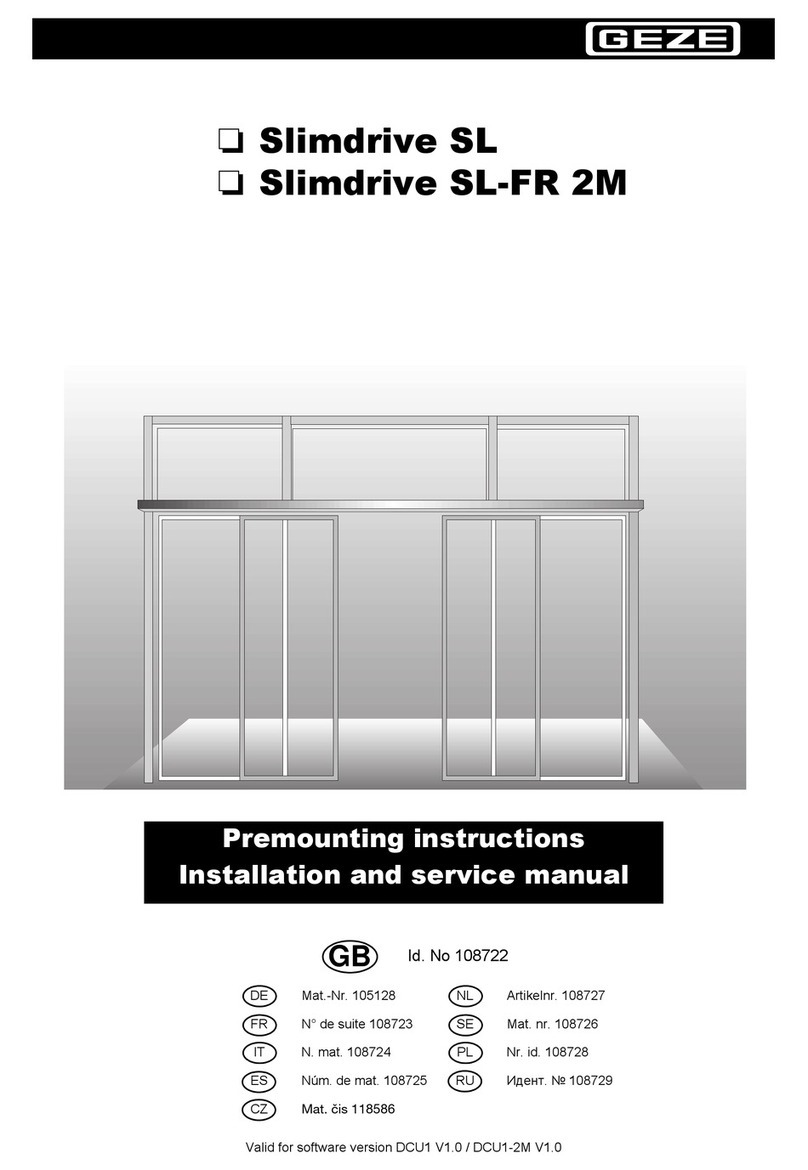

Slimdrive SL NT product family

2

Contents

1 Introduction...............................................................................................................................................................3

1.1 Symbols and illustrations...............................................................................................................................................................................3

1.2 Revisions and validity......................................................................................................................................................................................3

1.3 Product liability .................................................................................................................................................................................................3

1.4 Reference documents.....................................................................................................................................................................................3

2 Fundamental safety precautions .......................................................................................................................4

2.1 Intended use.......................................................................................................................................................................................................4

2.2 Safety instructions ...........................................................................................................................................................................................4

2.3 Safety-conscious working.............................................................................................................................................................................5

2.4 Environmentally conscious working .........................................................................................................................................................5

2.5 Safety instructions related to transportation and storage ...............................................................................................................5

2.6 Qualication .......................................................................................................................................................................................................5

3 About this document.............................................................................................................................................6

4 Overview.....................................................................................................................................................................6

4.1 Diagrams..............................................................................................................................................................................................................6

4.2 Tools and aids.....................................................................................................................................................................................................6

4.3 Torques.................................................................................................................................................................................................................6

4.4 Components and assembly groups...........................................................................................................................................................7

4.5 Bill of material VP-Kit.......................................................................................................................................................................................7

5 Pre-mounting............................................................................................................................................................8

5.1 Machining the track and cover....................................................................................................................................................................8

5.2 Preparing the track ..........................................................................................................................................................................................8

5.3 Mounting the stop buers............................................................................................................................................................................8

5.4 Connecting the contact on the tooth belt lock (optional)................................................................................................................9

5.5 Mounting the module mount......................................................................................................................................................................9

5.6 Mounting cable guides ............................................................................................................................................................................... 10

5.7 Connecting motor gear unit and control unit.....................................................................................................................................11

5.8 Pre-positioning the pre-mounted module mount, left and right................................................................................................12

5.9 Connecting transformer and control unit.............................................................................................................................................12

5.10 Connecting the tooth belt locking mechanism (optional) and control unit............................................................................14

5.11 Installing transformer earthing .................................................................................................................................................................15

5.12 Connecting rechargeable battery and control unit ......................................................................................................................... 16

6 Device safety test and production test..........................................................................................................16

6.1 Unplugging the cables.................................................................................................................................................................................17

7 Preparation for installation.................................................................................................................................17

7.1 Processing the cover for tooth belt locking mechanism (optional) ............................................................................................17

7.2 Mounting the suspension pieces .............................................................................................................................................................18

7.3 Installing the cover earthing ......................................................................................................................................................................19

7.4 Installing the side panels.............................................................................................................................................................................19