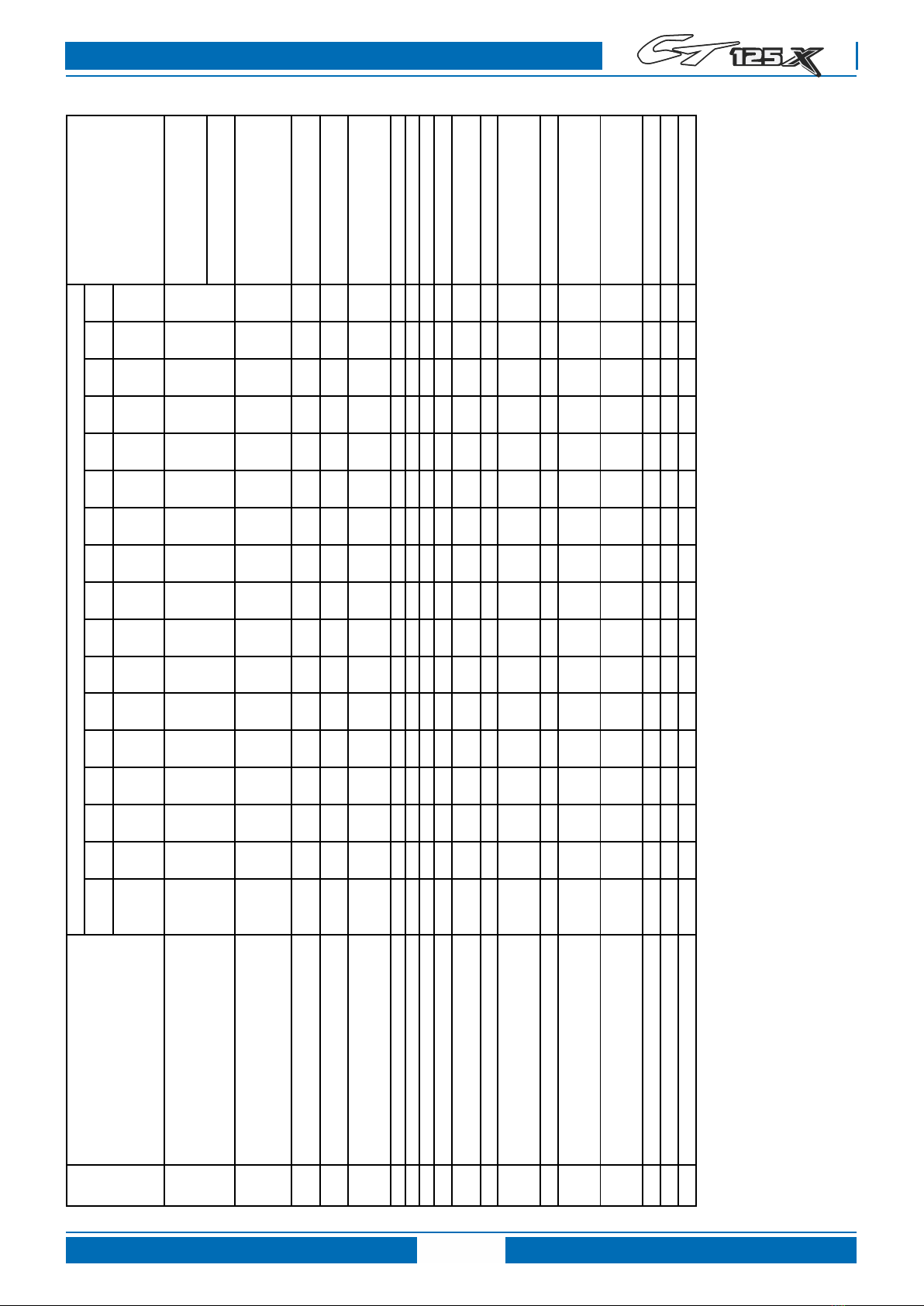

PREVENTIVE MAINTENANCE CHART

4Service Support - M/C

Service Station Manual

PREVENTIVE MAINTENANCE CHART

Sr.

No. Activities / Check points

Recommended frequency -- Service interval & Kms

Remarks

Servicing 1st

(Free)

2nd

(Free)

3rd

(Free) 4th 5th 6th 7th 8th 9th 10th 11th 12th 13th 14th 15th 16th

Kms

500 - 750

4500 -

5000

9500 -

10000

14500 -

15000

19500 -

20000

24500 -

25000

29500 -

30000

34500 -

35000

39500 -

40000

44500 -

45000

49500 -

50000

54500 -

55000

59500 -

60000

64500 -

65000

69500 -

70000

74500 -

75000

1Servicing with water wash √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √

Ensure to prevent water entry in

Petrol tank, Silencer & electrical

parts.

Use caustic free detergent for

washing.

2Engine oil (Bajaj DTSI 10000 oil) Top up, R R Top-up R Top-up R Top-up R Top-up R Top -up R Top-up R Top-up R Top-up

Use BGO 20W50 BS6

Oil level window cleaning at every

10000 kms by petrol spray &

nylon brush.

3Engine oil Filter R R R R R R R R R Replace oil filter in 1st service &

at every 10000 Kms

4Oil strainer CL CL CL CL CL CL CL CL CL Oil strainer cleaning at the time of

oil change.

5Air cleaner element** & air filter cover ‘O’ ring.

Drain tube cleaning. CL,R CL CL CL R CL CL R CL CL R CL CL R CL CL R

Replace air cleaner element at

every 15000 Kms. Replace air

filter cover O ring along with filter.

6Fuel pipes for cracks. C,R C C C R C C R C C R C C R C C R Replace at every 15000kms

7Spark plug clean & check gap CL,A,R CL,A CL,A R CL,A CL,A R CL,A Replace at every 30000 kms

8Valve tappet clearance C,A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A C, A

9Carburettor float chamber cleaning** CL CL CL CL CL CL

10 Carburettor rubber duct (Sleeve) for hard

resulting in loose fitment. C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R Replace if required

11 Engine breather tube for cracks. C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R Replace if required

12 EVAP system Hoses- check for cracks C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R C,R

Drain EVAP "Y" connection drain

tube.Replace if found cut /

damaged

13 Silencer drain hole cleaning CL CL CL CL CL CL CL CL CL CL CL CL CL CL CL

14 Wiring harness connections, routine &

Conduit / PVC sleeve inspection. C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T C,A,T

Damaged conduit / PVC sleeves

protection by applying electrical

tape film.

15 Battery connections & health by load tester.

+ve terminal cap fitment. C,A,L,T C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

C,A,L,

T

Apply Petroleum jelly on battery

terminals.

Use Midtronics battery tester.

16 Ignition switch contacts cleaning CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L CL,L Use recommended WD40 spray

17 HT coil connections (Primary and Secondary) C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T

18 Starter motor & starter relay connections C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T C,T