CLEARANCES

The appliance area must be kept free and clear of all combustibles.

2.2 Recommendations before installation

Before installing the gas supply system, observe the pipes and fittings, check the

components for dirt, clean internally with compressed air to eliminate possible particles,

and prevent burners and valves from becoming clogged.

After cleaning, use thread sealant to connect the equipment to the gas network. For

correct application, avoid concentrating the compound on the first two threads of the

pipe, otherwise it may generate particles that will clog the system injectors.

07

2.3 Gas installation

Your gas appliance will give you peak performance when the gas supply line is of

sufficient size to provide the correct gas pressure. The gas line must be installed to meet

the local building codes or National Fuel Gas Code ANSI Z223.1 Latest Edition. In

Canada, install the appliance in accordance with CAN/CGA-B149.1 or .2 and local

codes. Gas line sizing requirements can be determined by your local gas company or, in

North America, by referring to the National Fuel Gas Code, Appendix C, Table C-4 (for

natural gas) and Table C-16 (for propane). The gas line needs to be large enough to

supply the necessary amount of fuel to all appliances without losing pressure to any

appliance.

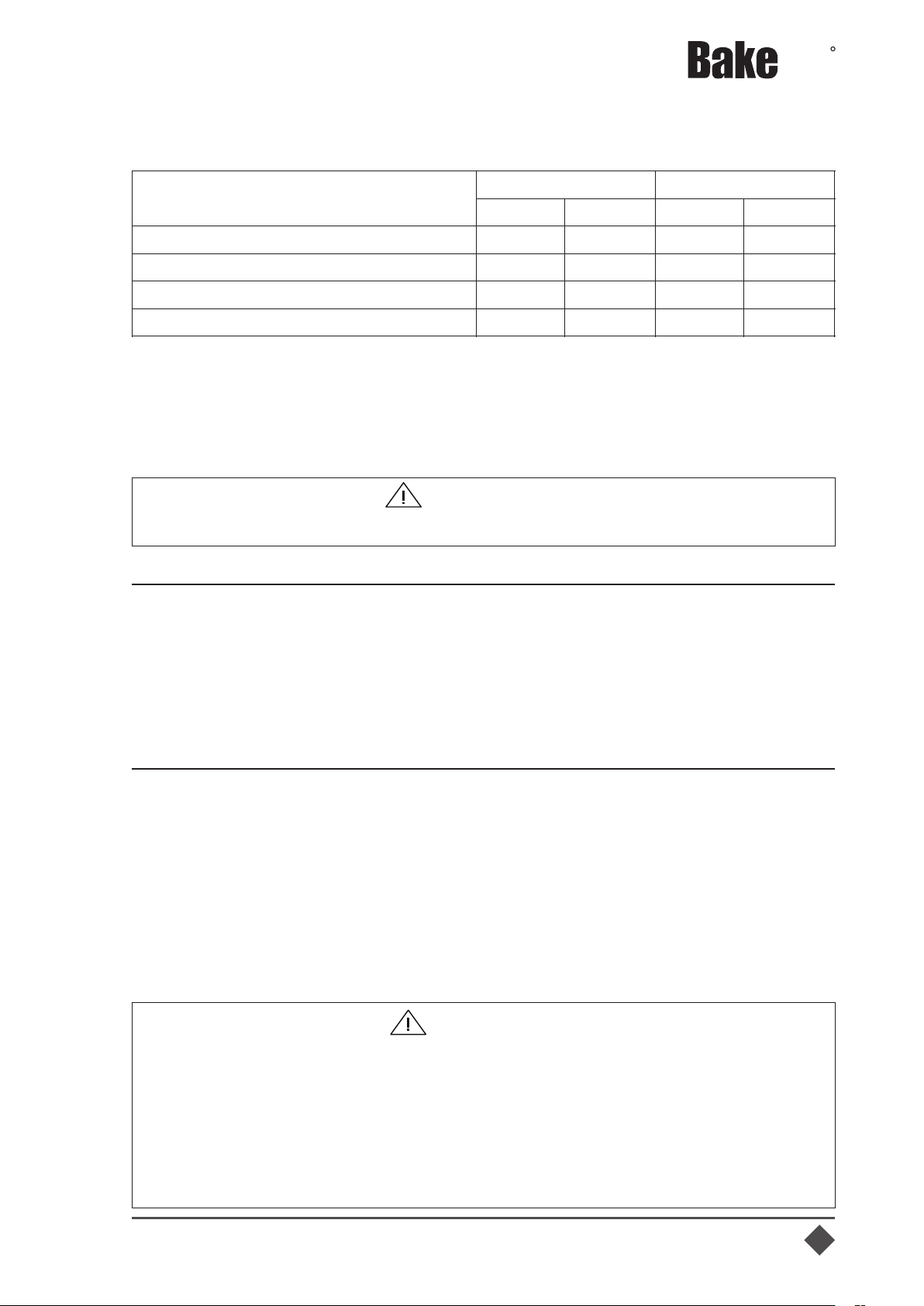

Max

MaxMax

R

WARNING

Never supply the appliance with a gas other than the one that is indicated on the data

plate. Using the incorrect gas type will cause improper operation and could result in

serious injury or death. If you need to convert the appliance to another type of fuel,

contact the dealer your purchased it from.

Never use an adaptor to make a smaller gas supply line fit the cooker connection.

This may not allow the correct amount of gas flow for optimum burner operation,

resulting in poor cooker performance.

NAMEPLATE

Information in the Nameplates includes the model, serial number, BTU/h input of the

burners, operating gas pressure in inches WC, and whether the appliance is orificed for

natural or propane gas. When communicating with factory about a unit or requesting

special parts or information, rating plate data is essential for proper identification.

THIS APPLIANCE MUST BE INSTALLED UNDER A VENTILATION HOOD.

IMPORTANT

Countertop Thermostatic Gas Griddle

Countertop Manual Gas Griddle

Countertop Radiant Gas Charbroiler