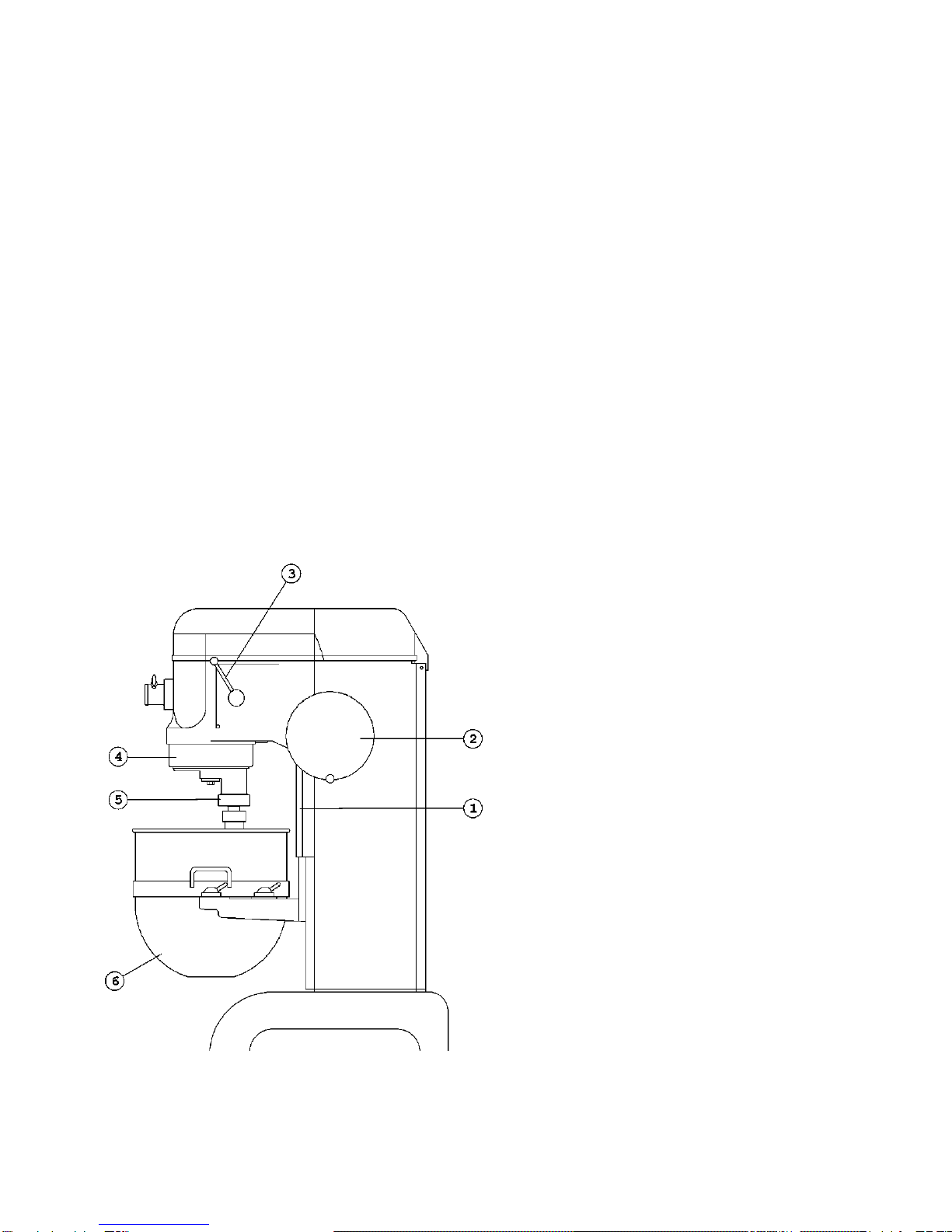

ATTACHMENTS

To install an attachment, loosen the thumb screw on the attachment hub and remove

the plug. Insert the attachment into the attachment hub making certain that the square

shank of the attachment is in the square driver of the mixer. Secure the attachment

by tightening the thumb screw.

Move the gear shift lever to the desired speed and start the mixer to operate the

attachment.

The meat and food chopper attachment should be operated in second or third speed.

If material in the cylinder stalls the mixer, stop the mixer at once. DO NOT attempt to

restart the mixer in a lower speed - remove the adjusting ring, knife, plate, and worm

and clear the obstruction.

MAINTENANCE

NOTE: ALL MAINTENANCE WORK SHOULD BE DONE ONLY AFTER UNIT HAS

BEEN DISCONNECTED FROM ELECTRICAL POWER AND GROUNDING.

Never use a metal or stiff brush to clean the mixer. Never clean the mixer with

a water hose or any fluid pressure.

The mixer should be thoroughly cleaned daily.

Bowls and agitators should be removed from the mixer and cleaned in a link.

The transmission case and planetary mechanism should be inspected weekly for

leaks, damage, etc. Should it become necessary to repack the ball bearings, an

authorized service technician or the manufacturer should be contacted. Use of

unproved grease of lubricants may lead to damage and void the unit's warranty.

The bowl lift slid ways should be lubricated semi-annually, or more often under

heavy usage. Disconnect the unit from the power supply before removing the top

housing or apron. The drip cup (Fig. 1) should be inspected periodically for

moisture or lubricant dripping. Remove the cup and wipe it with a soft cloth.