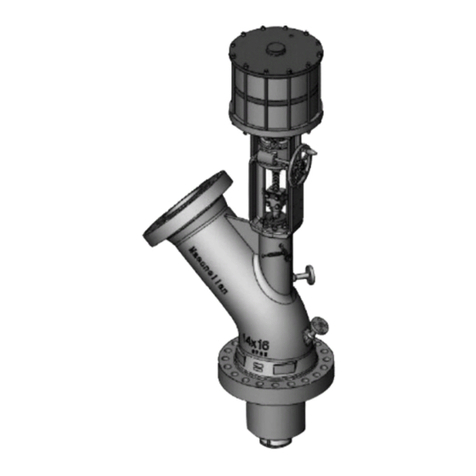

Masoneilan 37002 Series MiniTork II with Actuator 35 Instruction Manual | 7

Copyright 2020 Baker Hughes Company. All rights reserved.

Valve Maintenance

MiniTork butterfly valves are a standard line of control valves, i.e.

standard parts and materials cover a wide range of applications.

If emergency repairs ever become necessary, parts can probably

be taken from any MiniTork valve of the same size in your stock.

In addition, some parts such as packing, bearings (for the same

shaft diameter) are the same for Camflex, MiniTork and Ball

valves

Body Disassembly

(Figures 5, 6, and 7)

1. Bypass the MiniTork valve and relieve fluid pressure from

the body. Disconnect air (or electric lines) from the actuator

(or its accessories) and remove the valve from the line

Note: In the case of an air-to-close valve, turn the

handwheel or apply air pressure to set the disk to the

closed position.

2. Remove front cover (21), rear cover (18) and bottom cover

(30).

3. Remove clip (22) and back off the clevis pin (24). Remove

air supplied at step 1.

4. If a positioner is mounted on the valve, disconnect the cam

from the plug shaft (8) (Caution: see instruction sheet of

positioner before removing cam). If the valve is not equipped

with positioner, remove the screw (27) and the shaft cover

(26). Remove screws (101) and lock washers (102), then

remove the actuator from the yoke (34).

5. Before continuing the disassembly procedure, mark the

exact position of the arm (35) on the shaft (light punch mark,

pencil mark, etc.).

Note: the slot located at the end of the shaft indicates

the position of the disk in the valve body.

6. Loosen the cap screw (37) and remove the nuts (13) from

the packing box studs (17) and the yoke studs (14). Using a

mallet, gently tap the side of the yoke on the body end and

remove the yoke (34) and lever (35) assembly.

7. Drive out the disk studs (4) and remove the shaft from

the valve body. If this proves difficult, remove the packing

(10), then by using a pipe nipple of suitable size between

the flange and disk arm tightened firmly on the shaft, and

reversing the packing flange and nuts (13), the shaft may be

drawn out of the body by unscrewing nuts (13) (See Figure

3).

8. Remove the valve body (4), the packing-box ring (9) and

the spacer tube (7). If the valve body has an elastomer

sleeve (2), remove the sleeve and the two O-rings (3).

Lastly, disengage the bearings (6) and the spring (50).

(There is no spring (50) on valves with an elastomer sleeve.

See Figure 5).

9. Examine all parts for damage due to erosion corrosion or

wear. Replace all defective parts, pins (51) and all packing.

Clean all reused parts thoroughly prior to reassembly.

Body Reassembly

(Figures 5 and 6)

1. Fit the spring (50) (only on valve bodies without sleeve)

and the lower bearing in the body. Coat the shaft (8) with

Molykote G (or equivalent) along the entire surface roughly

corresponding to the spacer tube

2. If the valve is equipped with a sleeve, coat the two O-rings

(3) with silicone grease and fit them inside the sleeve. Slide

the sleeve into the body and align the shaft entry bore holes

with those of the body (see Figure 5).

3. Slip the upper bearing and spacer tube onto the shaft. Place

the disk in its normal position inside the body and feed

the shaft all the way into the body, together with the parts

previously fitted with it.

Note: The pin holes in the disk must be facing the

packing box. If the valve is equipped with a sleeve, coat

the perimeter of the disk with silicone grease so that the

disk can be fitted more easily.

4. Secure the body assembly on a vise and lock the disk in the

closed position (i.e. disk centerline on the plane of the body).

Note: If the shaft and disk are reused, check that the pin

hole taper matches that of the shaft holes.

If reusing the shaft and disk, fasten the two parts together

using new pins.

Note: When replacing a shaft, the old disk may be used as

a guide for drilling and reaming the pin holes. If a new disk

is required, the holes of the old shaft cannot be used. For

this reason, a new disk may not be ordered without a shaft.

5. Install the packing box ring (9), the packing (10) and the

packing gland (15). The oblique section of each ring must be

shifted 120° in relation to that of the previous ring.

6. Slip the yoke (34) some of the way over the end of the shaft,

at the same time fitting the following parts in the order shown

below: packing box flange (16), disk arm (35) and ring (5).

Lastly, finish fitting the yoke on the studs (14) by fitting the

shaft into the bearing (25). Apply the lever (35) against the

spacer tube (5) and tighten the yoke nuts (13). Screw the

packing box nuts onto the studs (17) but do not tighten them.

Note:

a) During this operation, make sure that the position of the

yoke on the studs complies with the action and position

selected for the actuator.

b) Also make sure that the arm (35) is in the correct

position on the shaft. Refer to the markings made during

disassembly. If parts have been replaced, assess their

final relative position by holding them one in front of the

other before fitting them. For this purpose, if the shaft

or disk or both have been replaced and the two parts

are not pinned together, remember to align the slot at

the end of the shaft with the disk (the disk being locked

in the closed position).