2

TABLE OF CONTENTS

General Safety Information..............................................................................................................................1

Introduction.......................................................................................................................................................3

General Description............................................................................................................................................3

SystemSpecications ........................................................................................................................................3

ConsoleFeatures ...............................................................................................................................................3

Product Specications.....................................................................................................................................4

OperationalSchematic .......................................................................................................................................4

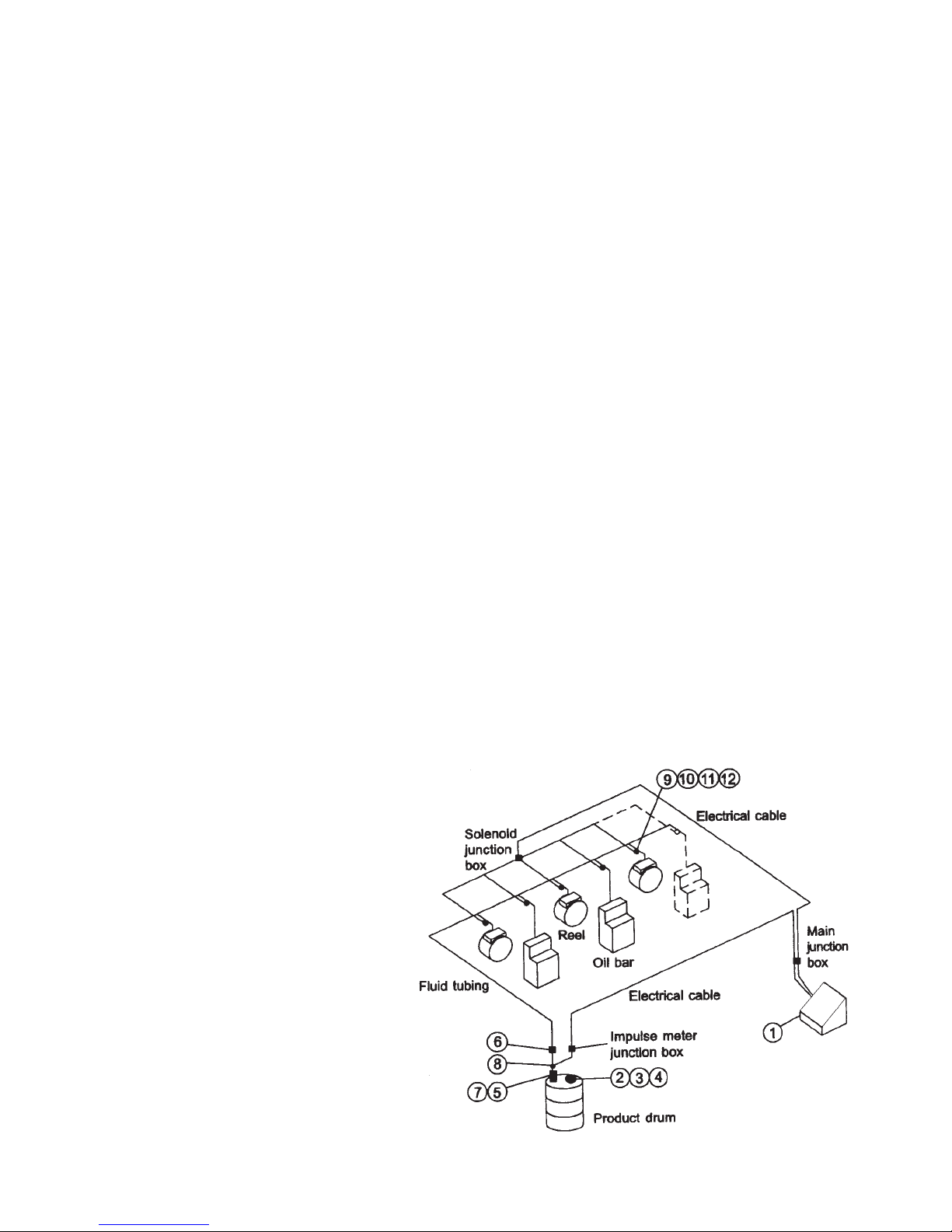

InterconnectionBox............................................................................................................................................5

Impulse Meter.....................................................................................................................................................5

Installation.........................................................................................................................................................5

General...............................................................................................................................................................5

Plumbing.............................................................................................................................................................5

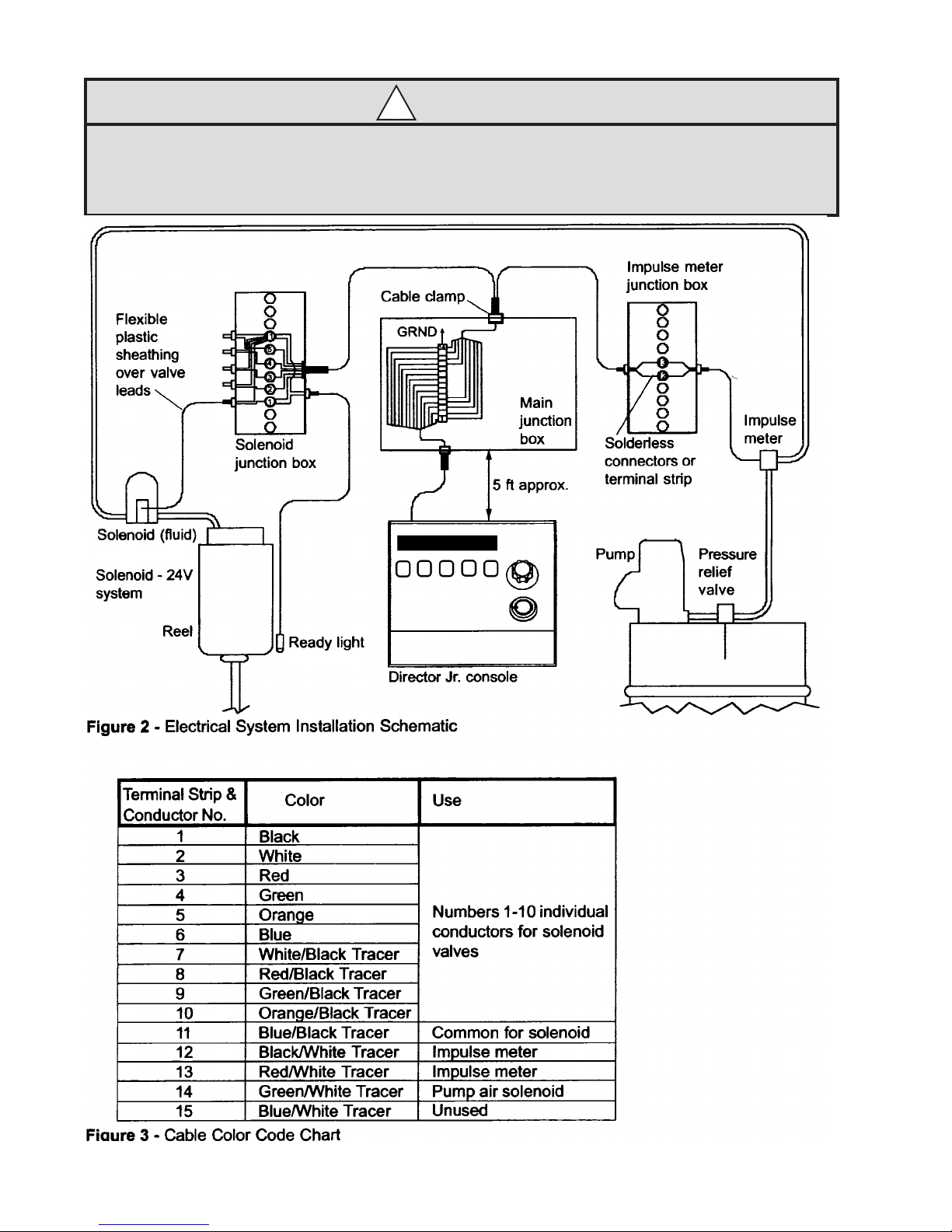

Electrical.............................................................................................................................................................6

Wiring Diagram...................................................................................................................................................7

Console Setup ..................................................................................................................................................8

PulseCalibrationFactor .....................................................................................................................................9

Post Installation Check..................................................................................................................................10

OperationalCheck............................................................................................................................................10

Operation Instructions...................................................................................................................................10

NormalOperation .............................................................................................................................................10

TotalizerOperation ...........................................................................................................................................11

KeylockOperation ...........................................................................................................................................11

ReadyLightOperation......................................................................................................................................11

StationRotarySwitchOperation ......................................................................................................................11

Example............................................................................................................................................................11

Emergency Stop...............................................................................................................................................11

Reset ................................................................................................................................................................12

Service and Maintenance...............................................................................................................................12

General Policy ..................................................................................................................................................12

Periodic Inspection ...........................................................................................................................................12

Troubleshooting................................................................................................................................................12

Troubleshooting Chart ......................................................................................................................................13

Factory Service...............................................................................................................................................15

Repair...............................................................................................................................................................15

Parts List...........................................................................................................................................................15

Associated Components...................................................................................................................................15

Warranty Statement........................................................................................................................................17