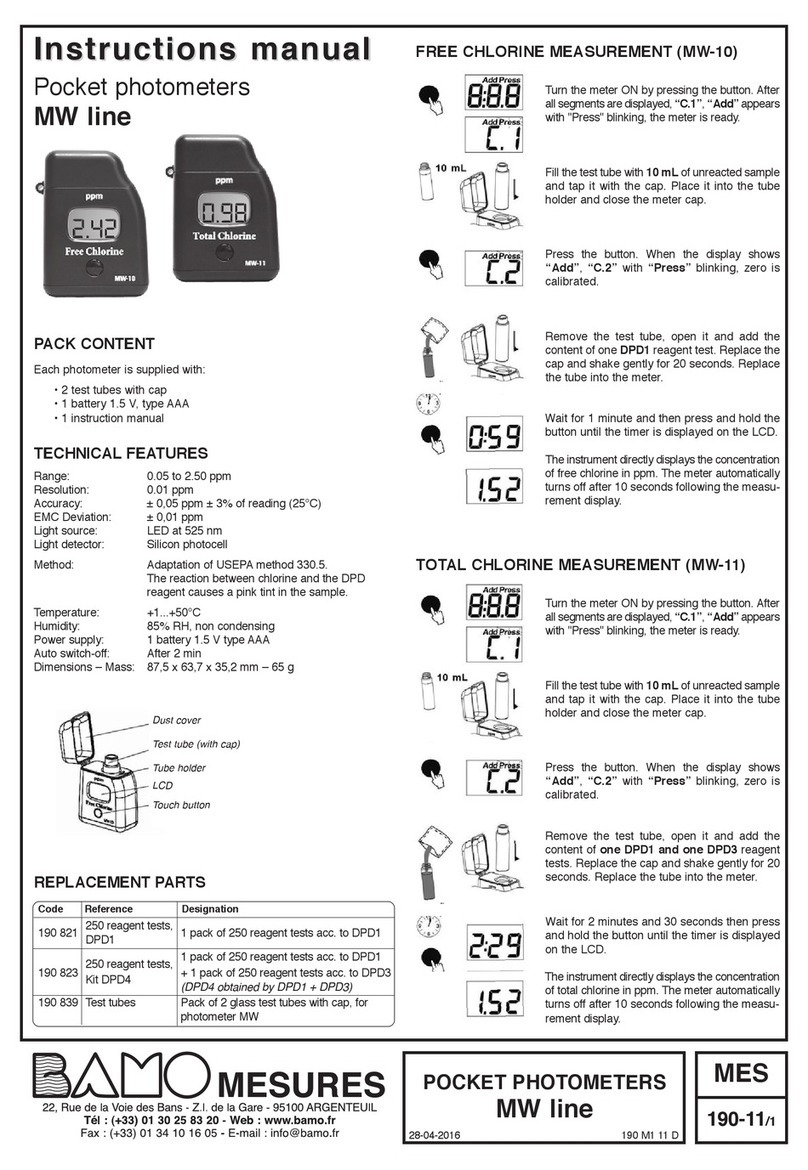

560 M0 01 E 19-03-2014 Page 2

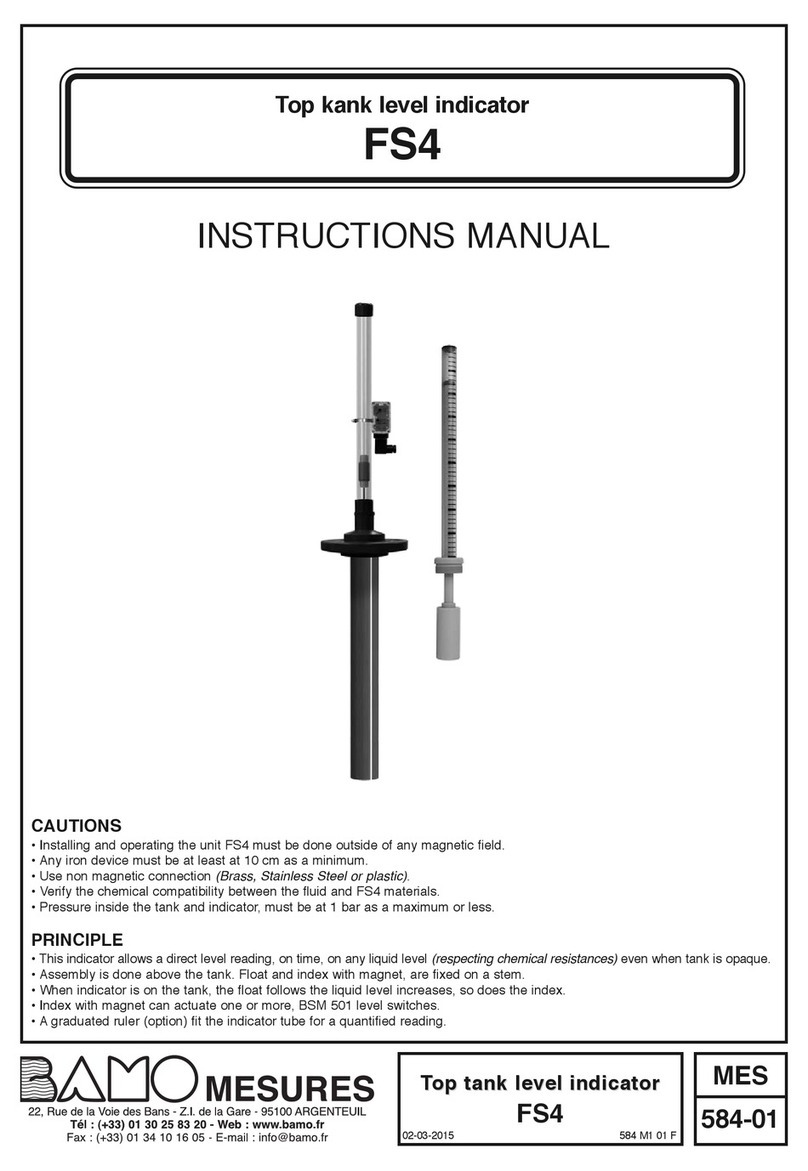

1. MOUNTING

Verify tank flanges compatibility with MAGT P flanges.

Install level indicator on tank side.

Do not forget to set seals (not furnished).

It is highly suggested to set insulation valves, between tank and level indicator, in

order to be able to remove the float in case of jamming.

Insert the float by removing flange 6.

H is indicating float top.

During installation, bi-colours flaps may not be goodly set.

They will get right position on float movement.

They must be red when float is going up, and yellow when float is going down.

In case of bad level reading, flaps rule can be turned around the tube by unlocking

fixing collars.

After re-positioning, lock smoothly collars to avoid damaging this rule.

MAGT P can be equipped with different options which are:

- Graduated ruler, done with agreement, with requested measure unit (cm, % or volume)

- Continuous level output rule with potentiometric or 4-20mA analogic output (RTM)

- Level switches: BSM 515 ; BRK-60 MAG ; BRT-60 MAG

(To set a level switches or other options, see specific starting up notice.)

2. STARTING UP

It is suggested to install level indicator on atmospheric pressure, to avoid to quick

up float movement, which may damage it.

n magnet passage, flaps turn of 180° passing from yellow to red.

Exact level is indicting by flaps which turned only of 90°.

Indicator drain has to be done by unscrewing nut 8.

3. MAINTENANCE

For wast liquids with particles, float might be stopped. Drain level indicator and

tank to eliminate dusts. If the float is steal keep stopped, dismount the MAGT P

for full cleaning.

4. TECHNIICAL FEATURES

Material: Stainless steel

Max. pressure: According to conditions (16 bar at 20 °C)

Max. T° fluid: MAKR L N magnet ruler ––> 120 °C

Aluminium/Plastic magnet ruler ––> 200 °C

Aluminium/St. steel magnet ruler ––> 400 °C

It. Description

1Stainless steel 316 L guiding tube,

Ø 60.3 mm

2 Flanges, ND 15 to ND 32,

nominal pressure NP 10/16

3Magnetic float

4MAKR L N or Aluminum magnet ruler

(according to temperature)

5 Magnet ruler fixing collar, St. steel 304

6Flange for maintenance

7 Draining valve (option)

8BSP 1/2 " draining plug

9Level switches (option)

10 Supplementary support (if L > 4000 mm)

11 BSP 1/2 " Vent hole with tap (option)

Magnet ruler