10

11. Safety Testing

Test the Close Cycle

a. Press the OPERATE button to open the door.

b. If the door closes, press the OPERATE button to stop the door, then

press OPERATE again to open.

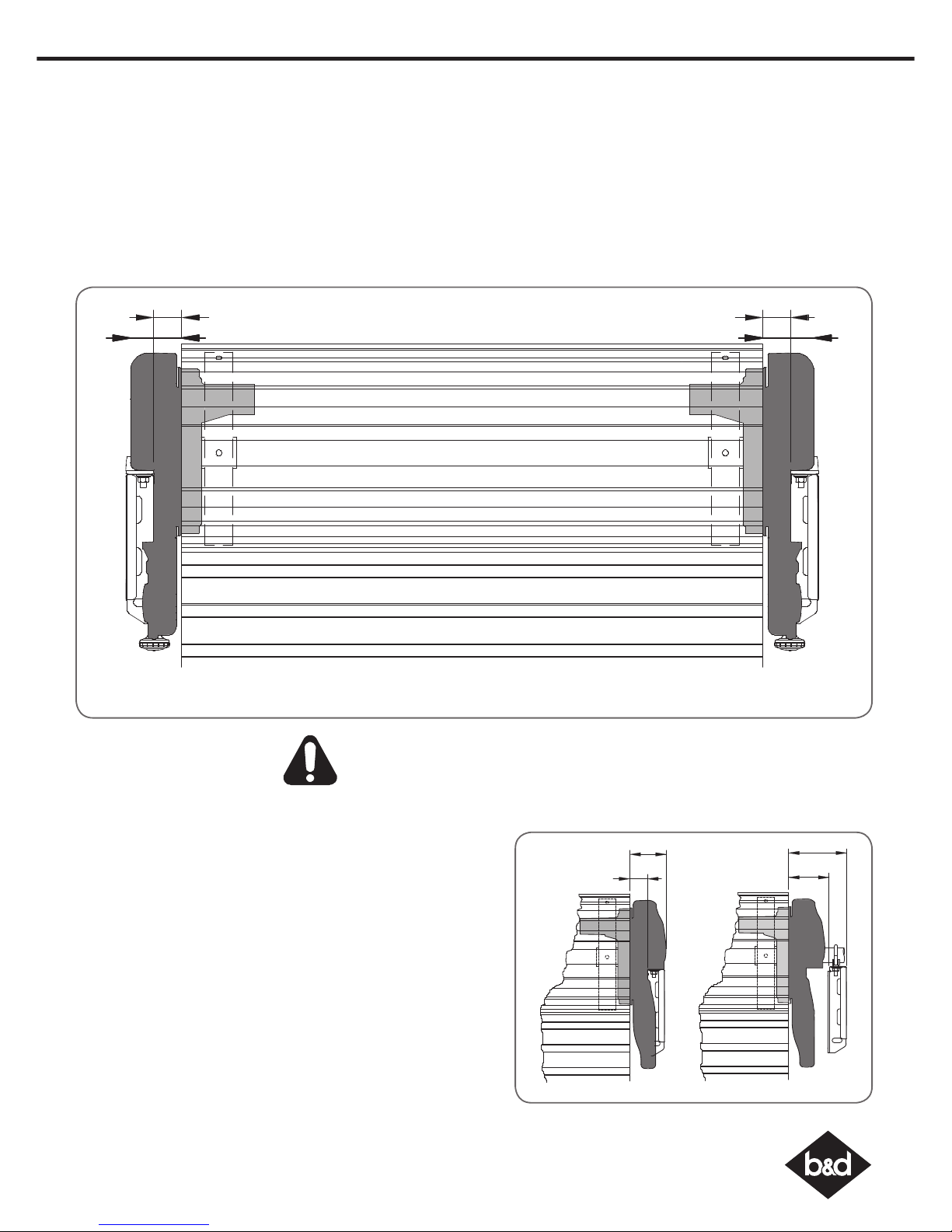

c. Place a piece of timber approximately 40mm high (or the openers

cardboard box) on the floor directly under the door.

d. Press the OPERATE button to close door.

e. The door should strike the object and re-open.

f. Remove the timber or cardboard box.

Testing the Open Cycle

a. Press the OPERATE button to close the door.

b. Press OPERATE again to open the door.

c. When the door reaches approximately half way, firmly grab the

door’s bottom rail - the door should stop.

If the door does not reverse readily when closing, or stop when

opening, put the door into manual by pulling down on the manual

release string to diesengage the motor and contact 1300 300 625

for support.

Test the Manual Door Operation

Periodically disengage the opener and manually operate the door.

The door must be smooth to operate by hand. The force required on

the bottom rail should not exceed 15 kg.

CAUTION: Take care when completing a

safety test. Failure to follow this warning

can result in serious personal injury and/or

property damage.

WARNING! If the door is closing and is unable

to re-open when obstructed, discontinue use.

Do not use a door with faulty obstruction sensing.

Wood 40mm

high or opener

cardboard box

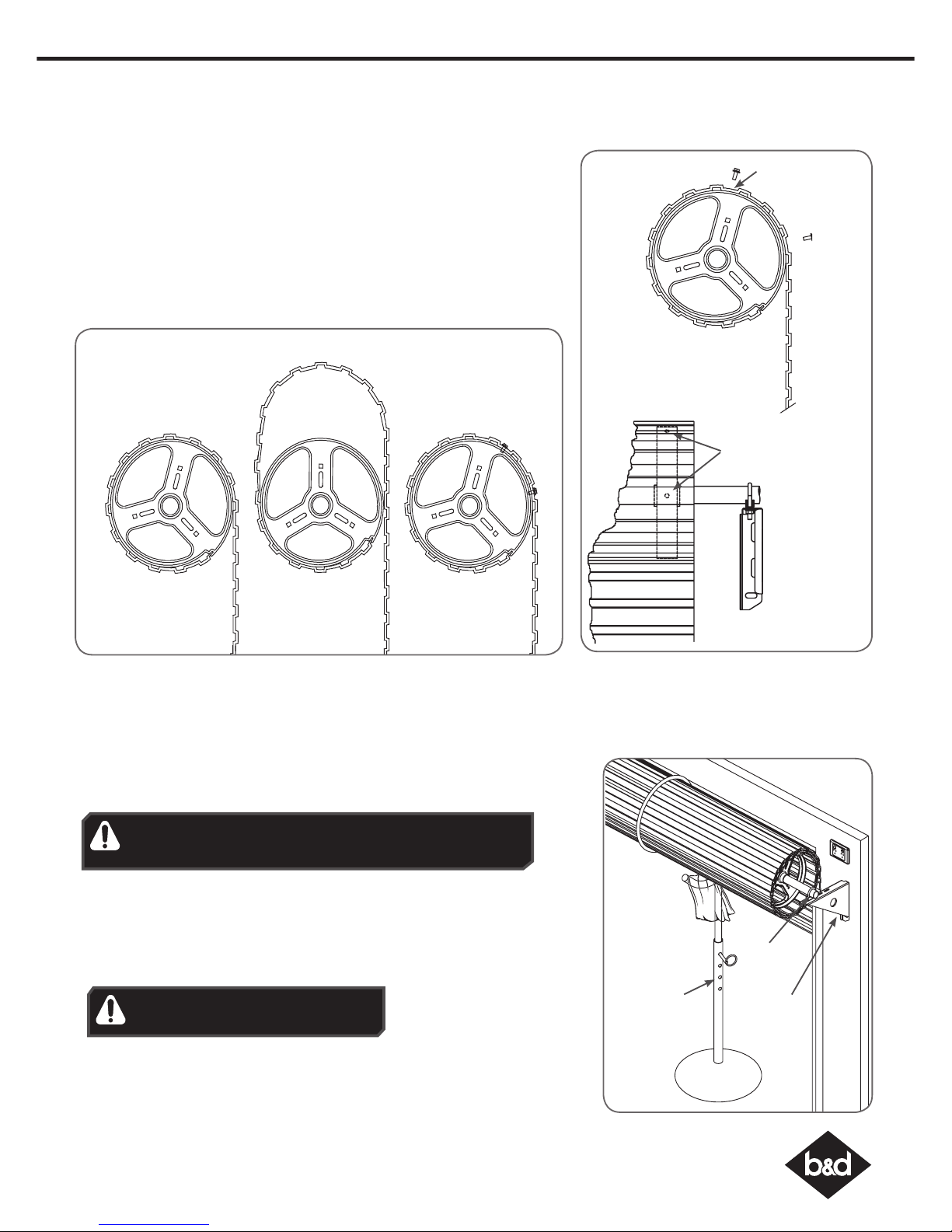

To Recall Factory Set Force

a. Holding down the FORCE MARGIN SET button and

the LIMIT SET button for two seconds.

b. Release both buttons. The default setting should

now be recalled.

To Recalculate Force Margins

a. Press and hold the FORCE MARGIN SET Button for six

(6) seconds, the beeper will sound once.

b. The door will start to move and re-calculate

force margins. The door can move between the

open and close limit positions up to four (4) times

(depending on the position of the door and the

power up condition).

c. A single beep will be heard once the process is

complete.

d. Test the force again as per Testing Close Cycle and

Testing Open Cycle.

Adjusting Safety Obstruction Force

The Safety Obstruction Force is calculated automatically during

setup. Adjusting this is normally only necessitated by environmental

conditions such as windy or dusty areas, and areas with extreme

temperature changes.

To Increase Force Pressure

a. Hold down the FORCE MARGIN SET button.

b. While holding the FORCE MARGIN SET button, press the PLUS (+)

button. Each press will increases the force margin.

c. The OPEN LIMIT LED will flash each time the PLUS (+) button is

pressed to indicate an increase in force.

d. If the OPEN LIMIT LED flashes continuously when the PLUS (+) button

is being pressed, this indicates that the maximum force setting

has been reached.

e. Test the force again as per Testing Close Cycle and Testing Open

Cycle.

To Decrease Force Pressure

a. Hold down the FORCE MARGIN SET button.

b. While holding the FORCE MARGIN SET button, press the MINUS (-)

button. Each press will decrease the force margin.

c. The CLOSE LIMIT LED will flash each time the MINUS (-) button is

pressed to indicate a decrease in force.

d. If the CLOSE LIMIT LED flashes continuously when the MINUS (-)

button is being pressed, this indicates that the minimum force

setting has been reached.

e. Test the force again as per Testing Close Cycle and Testing Open

Cycle.

WARNING! If the door fails these tests,

put the opener into manual mode, only

operate the door by hand and call for

service.