11. Setting the Datum Position

NOTE: The door and shuttle must be engaged into the chain index.

The door should be open approximately half way.

NOTE: If Safety Beams are to be used they must be installed before

setting the travel limits.

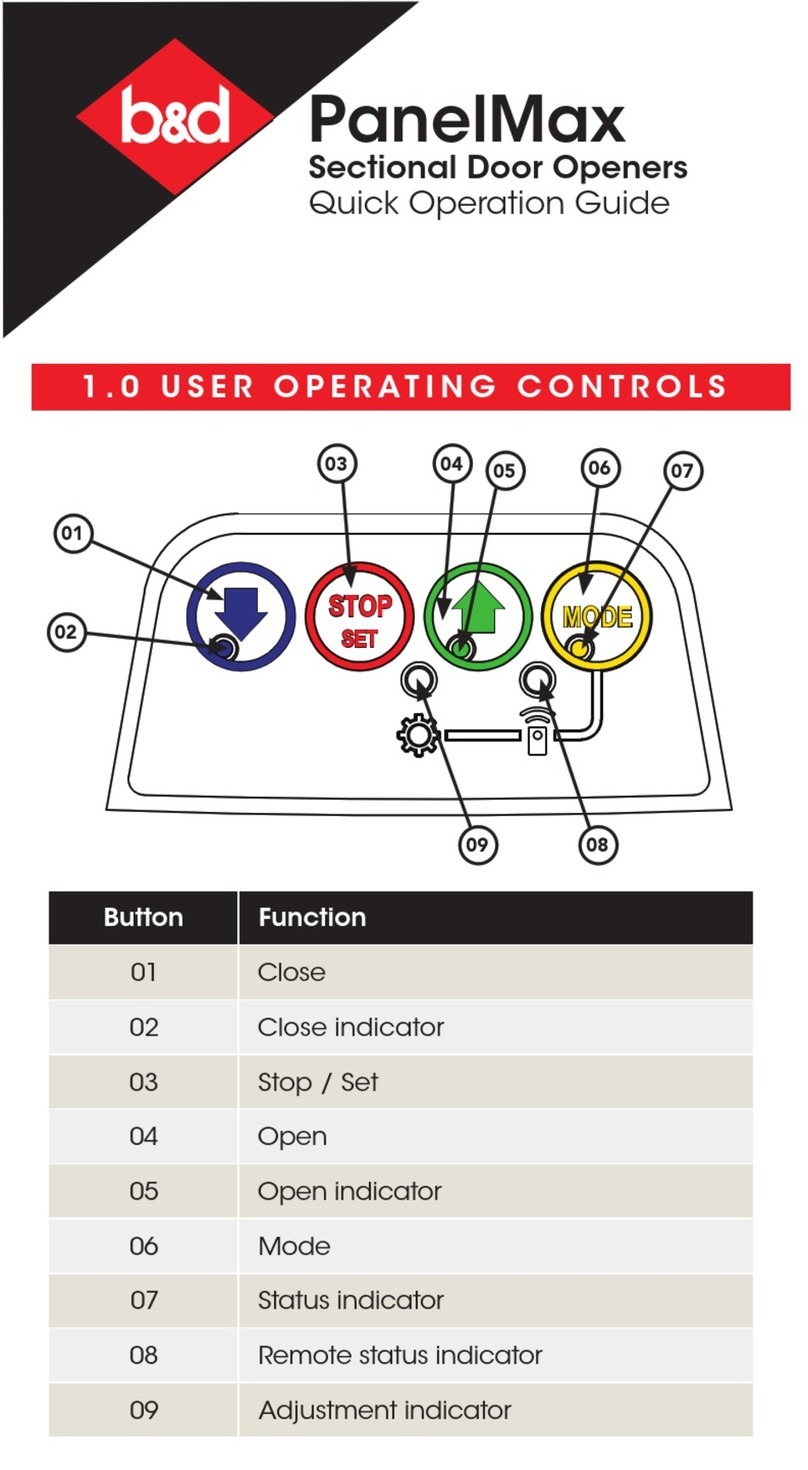

Adjust the Datum

a. Swing open the controls cover to gain the access to the controls

panel and swing back into it position when setup is completed.

b. Plug the power cord into a mains point and switch power on. The

red CLOSE LIMIT LED will be flashing.

c. Press and hold the MINUS (-) or PLUS (+) buttons to move the door

to the halfway position. Ensure that the door, shuttle and chain

index are engaged.

d. Using a small screwdriver, turn the DATUM ADJUST screw until the

STATUS LED comes on.

NOTE: If the STATUS LED is already illuminated when the door is

halfway up, turn the DATUM ADJUST screw until the light goes off,

then turn back one notch to illuminate again.

CAUTION: The OPERATE button will not function until the

open and close limit positions are set.

Set the Limit Positions:

The Limit Positions can vary due to site conditions, such as uneven

ground. When setting the Close limits, ensure the position is when the

door makes first contact with the ground. Alternatively for the Open

limits the position should be at the height of the garage opening.

WARNING! The door will automatically close, open and

close again after the next step. Ensure that nothing is in

the door’s path.

a. Press and hold MINUS (-) button until the door reaches your

desired close limit position. The rubber strip at the bottom of the

door should form a good seal with the ground.

b. Release the MINUS (-) button when the door is near the desired

closed position. Single presses of the MINUS (-) button will inch the

door closer to the ground.

c. If the door overshoots press the PLUS (+) button to move the door

in the open direction.

d. When the door is at the desired close position, press the LIMIT SET

button, the OPEN LIMIT LED will now flash.

e. Press and hold the PLUS (+) button until the door reaches your

desired open limit position. Single presses of the PLUS (+) button

will inch the door open.

f. If the door overshoots press the MINUS (-) button to move the door

in the close direction.

g. When the door is at the desired open position, press the LIMIT SET

button.

WARNING! The safety obstruction detection system is

inoperable while MINUS (-) and PLUS (+) drive buttons are

being used and travel limits are not set.

h. The door will now automatically close and open to calculate the

safety obstruction settings.

Resetting the Door Limit Positions

Limit positions can be deleted by:

a. Press and hold LIMIT SET button for six (6) seconds

until the CLOSE LIMIT LED flashes quickly.

b. Release the LIMIT SET button.

NOTE: If no action is taken within 30 seconds, the

opener will return to normal operating mode and

restore the original settings.

c. Follow steps a - f in Set the Limits Poisitions to set

new limit positions.

Reset all Factory Defaults

a. Turn power to the opener off.

b. Press and hold the LIMIT SET Button.

c. Turn power on while holding the LIMIT SET button.

Continue to hold until all LED’s are off.

d. This will not erase transmitter codes stored in

memory.

Setting the PET Mode position

When activated, PET mode drives the door to a preset

position from the close position, therefore allowing a

pet or parcel to go under the door.

a. Drive and stop the door at the deisred PET mode

open position by pressing the transmitter button

coded for Open/Stop/Close operation.

b. Press and hold the PLUS (+) button on the opener for

six (6) seconds until the OPEN and CLOSE LED’s are lit

to record the new PET position.

c. Release the PLUS (+) button.