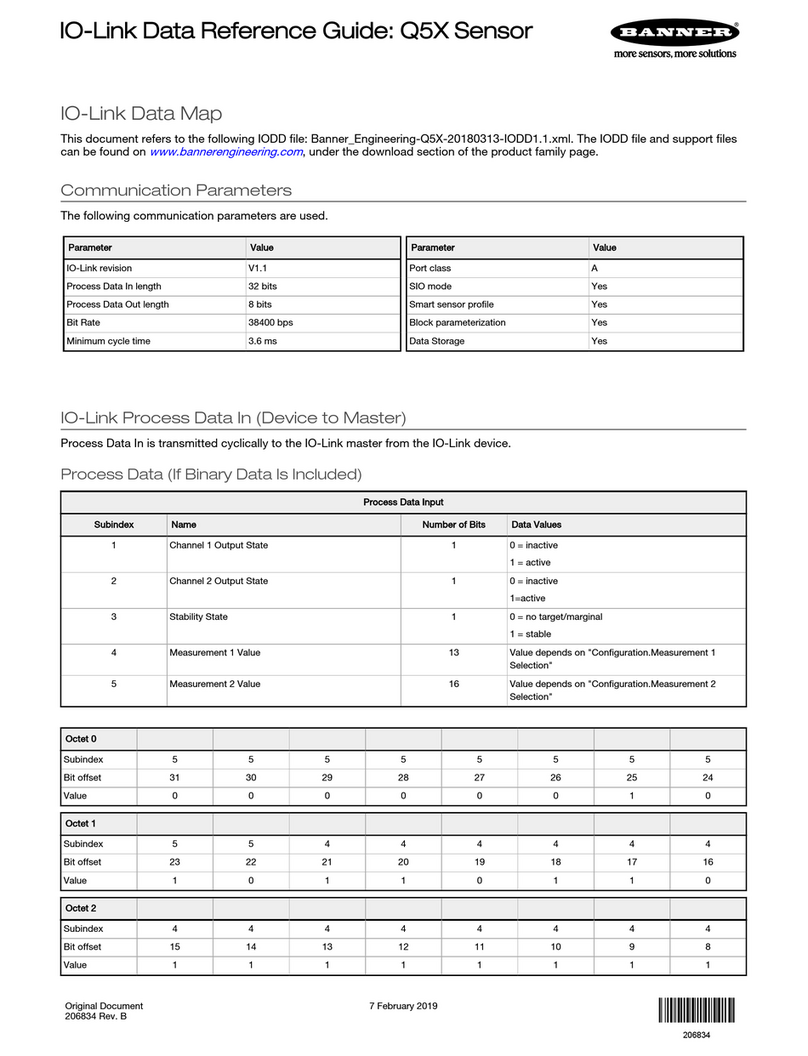

Factory Reset

Resets the sensor to factory defaults.

Remote Input

Use the remote input to program the sensor remotely.

The remote input provides limited programming options. The remote input is either Active High (PNP) or Active Low (NPN) depending on the Input

Active setting. For Active High (PNP), connect the white wire to 24 V DC with a remote switch connected between the wire and 24 V DC. For Active

Low, connect the white wire to ground (0 V DC) with a remote switch connected between the wire and ground. Pulse the remote input according to

the diagram and the instructions provided in this manual.

The length of the individual programming pulses is equal to the value T: 0.04 seconds ≤ T ≤ 0.4 seconds.

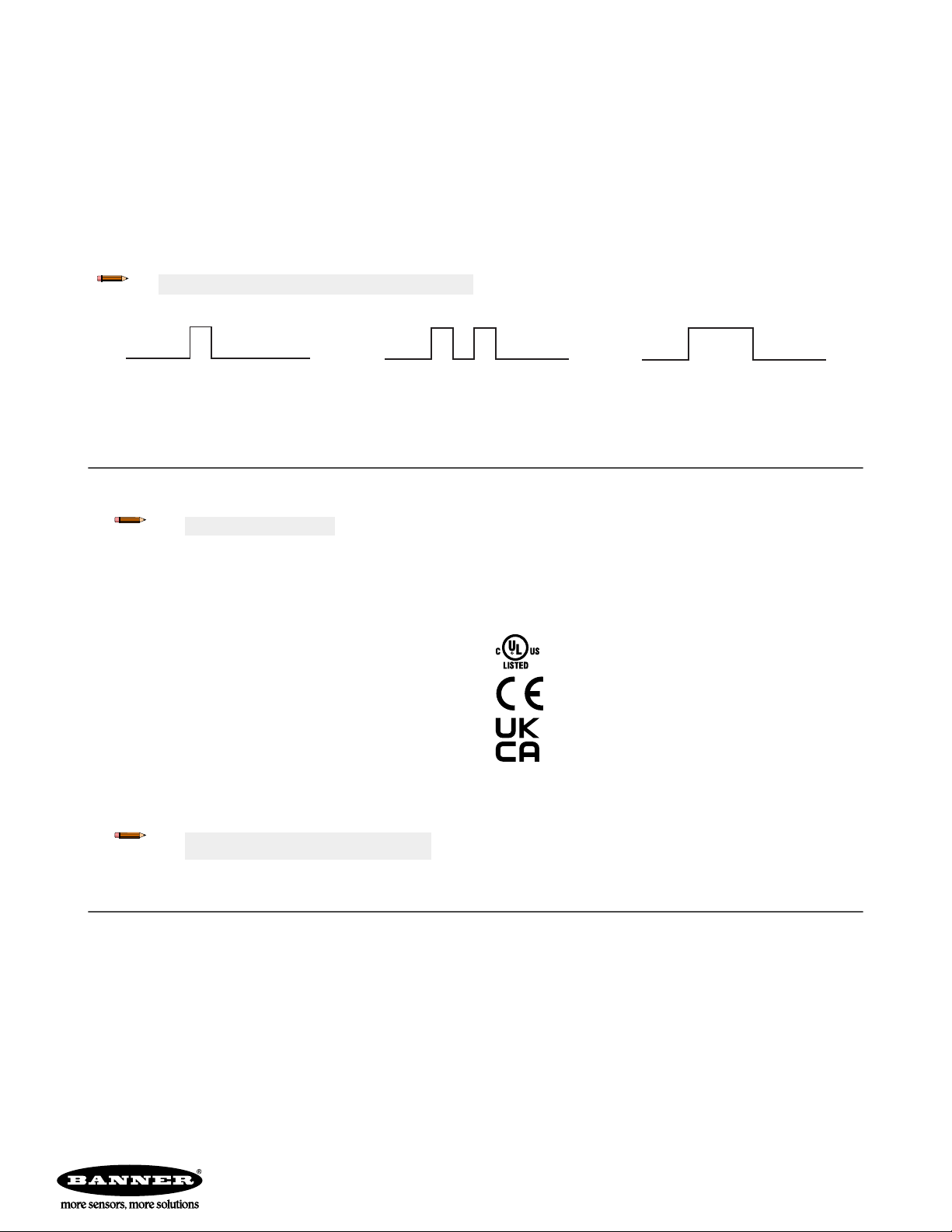

Remote Input Signals

Note: Waveforms shown correspond to PNP input mode.

Figure 10. Gap Set

Pulse once, 40 ms to 400 ms.

Figure 11. Label Set

Pulse twice, 40 ms to 400 ms, with 40 ms to

400 ms idle time between pulses.

Figure 12. Dynamic Set

Hold the remote input on for more than 750 ms,

while pulling the labels and gaps through the

sensor, then release the remote input line. The

sensor returns to Run mode.

Specifications

Supply Voltage and Current

12 V DC to 30 V DC

Polarity Protected

Note: For use in Class 2 circuits

95 mA at 12 V DC, 45 mA at 30 V DC

Digital Outputs

(1) NPN and (1) PNP open collector output 150mA maximum; <2 V residual voltage

On SLU4-BM-Q7, NPN & PNP are user-selectable

Protected against output short-circuit

Remote TEACH Input

Momentary sinking or sourcing input;1.2 mA maximum; software selectable

Hysteresis

Dynamic, adjusted by TEACH

Response Time

200 μs

Repeatability

125 μs

Threshold Set

1-Point, 2-Point, or Dynamic TEACH; manually or remotely

Threshold Adjust

Manual or AUTO adjust

Output Timers

On Delay, Off Delay, One Shot, or Debounce

Slot Width

4 mm

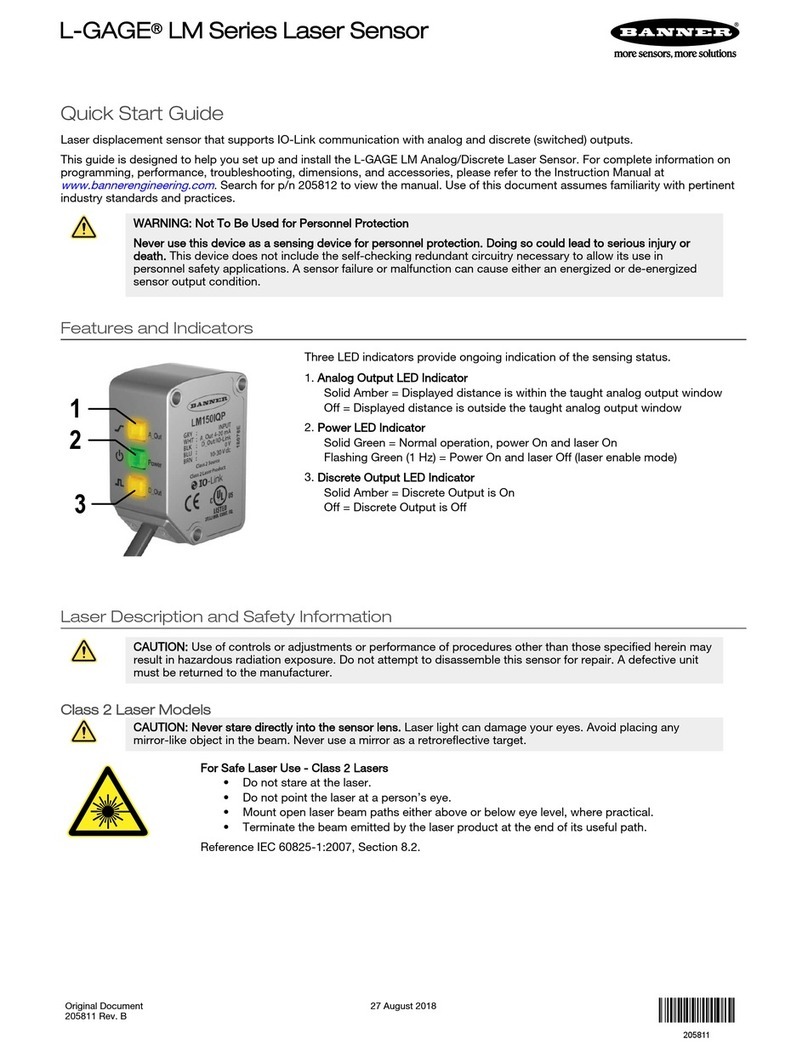

Indicators

Display: Includes contrast indicator, numerical display, set point and trigger point, and

all sensor options and modes

Amber LED output indicator: Illuminates when the sensor’s output transistors are ON

Note: Note: If output LED flashes on power up, a short

circuit condition exists.

Construction

Chemical resistant, high impact aluminum housing

Conforms to heavy industry grade CE requirements

Connection

Integral 5-pin M12 male quick-disconnect connector, Integral 4-pin M8 male quick-

disconnect connector, or 1.8 m (6 ft) unterminated 5-wire PVC cable, depending on

model

Environmental Rating

NEMA 4X, NEMA 6P, and IP65

Ambient Temperature

+4 °C to +50 °C (+39 °F to +122 °F)

Certifications

RoHS compliant

Banner Engineering Europe Park

Lane, Culliganlaan 2F bus 3, 1831

Diegem, BELGIUM

Turck Banner LTD Blenheim House,

Blenheim Court, Wickford, Essex

SS11 8YT, Great Britain

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or replace, free of charge,

any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty does not cover damage or liability for misuse, abuse, or the

improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER

PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR

FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously manufactured by Banner

Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection applications when the product is identified as not intended for such

purposes will void the product warranty. Any modifications to this product without prior express approval by Banner Engineering Corp will void the product warranties. All specifications published in this

document are subject to change; Banner reserves the right to modify product specifications or update documentation at any time. Specifications and product information in English supersede that which is

provided in any other language. For the most recent version of any documentation, refer to: www.bannerengineering.com.

For patent information, see www.bannerengineering.com/patents.

SLU4 Slot Sensor

©Banner Engineering Corp. All rights reserved