i

Contents

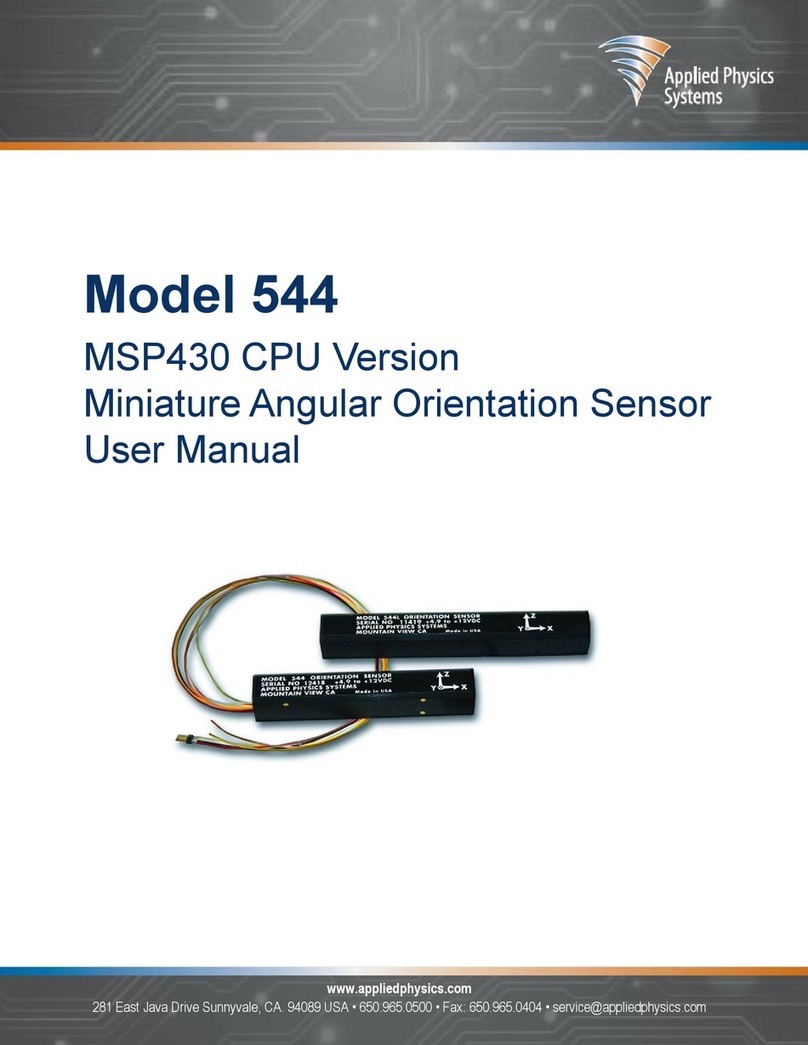

Chapter: 1 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Class 2 Laser Description and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Display and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter: 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sensor Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mount the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Button Map from RSD1 to Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter: 3 Sensor Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Channel 1 and Channel 2 (CH1/CH2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TEACH Procedures (Analog) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Two-Point (2-Pt) TEACH (Channel 1 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

One-Point (1-PT) TEACH (Channel 1 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TEACH (tch2) Mode (Discrete) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Two-Point Static Background Suppression (2-Pt) (Channel 2 Only) . . . . . . . . . . . . . . . . . 11

Dynamic Background Suppression (dYn) (Channel 2 Only) . . . . . . . . . . . . . . . . . . . . . . . 12

One-Point Window (FGS) (Foreground Suppression) (Channel 2 Only) . . . . . . . . . . . . . 13

One-Point Background Suppression (bGS) (Channel 2 Only) . . . . . . . . . . . . . . . . . . . . . 15

Dual (Intensity + Distance) (duAL) (Channel 2 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loss of Signal (LOS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Input Wire Function (inPt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Trigger (trG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Slope (SLPE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output (out2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adaptive Tracking (trc2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Window Size (und2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Base Measurement Rate (SPd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Output Timing Delays (dLY2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Delay Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Totalizer (totL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hysteresis (hYS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Zero Reference Location (ZEro) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Shift the Zero Reference Location after a TEACH (ShFt) . . . . . . . . . . . . . . . . . . . 23

Offset (oFS1 or oFS2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display View (diSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Units (unIt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Output Type Polarity (PoL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Exit Setup Mode (End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reset to Factory Defaults (rSEt) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Manual Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Remote Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Select the TEACH Mode Using the Remote Input . . . . . . . . . . . . . . . . . . . . . . . 27

Reset to Factory Defaults Using the Remote Input . . . . . . . . . . . . . . . . . . . . . . . 27

Locking and Unlocking the Sensor Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Button Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27