10 EN-IST-BZAW3-0123

3 Technical data

3 Technical data

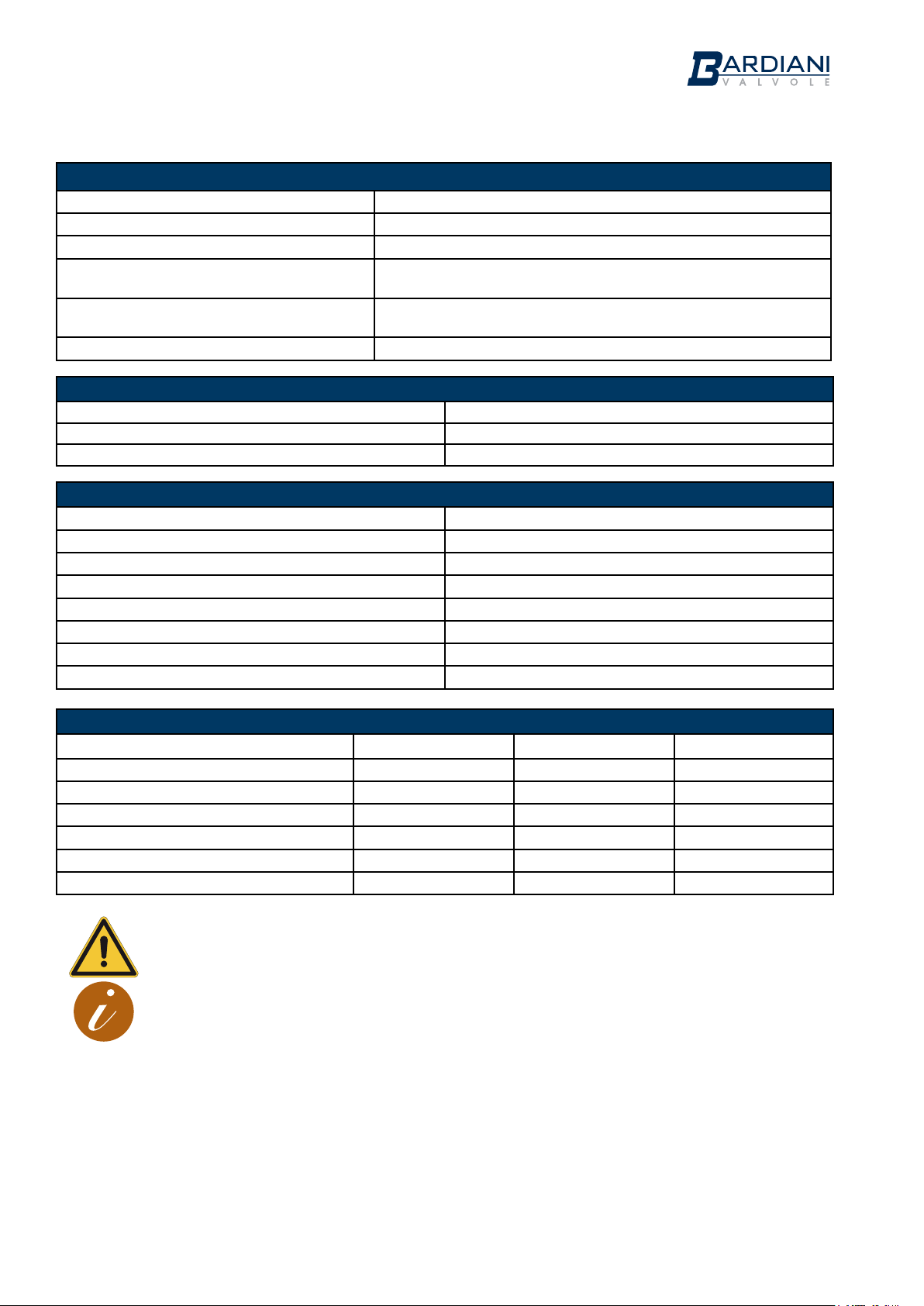

VALVE DATA

Maximum pressure 10 bar

Maximum seal pressure See catalogue

Storage temperature from -10°C to 25°C

Material in contact with the product AISI 316L (1.4404). Check the resistance to corrosion in relation to

products and detergents

Gasket material in contact with the product EPDM, FKM, HNBR and other gaskets on request. Check compatibility

with products and detergents

Surface finish in contact with the product Ra 0.8 µm. Other finishes available on request

VAPOUR BARRIER DATA

Connectors 1/8” BSP

Steam maximum temperature 130°C (266°F)

Gaskets material FKM

PNEUMATIC ACTUATOR DATA

Connectors 1/8” BSP

Pipe dimensions 6 mm external diameter, 4 mm internal diameter

Air pressure from 6 bar (87 psi) to 8 bar (116 psi)

Air quality Class 2, 4, 3 ISO8573-1

External material AISI 304L (1.4307)

Seals NBR

Noise levels 76 dB

Electrical supply See Giotto Top

GASKET MATERIALS COMPATIBILITY

Product EPDM FKM HNBR

Temperature (applications with air) from -10°C to +140°C from -10°C to +200°C from -10°C to +130°C

Caustic soda 2% 60°C 30°C To be checked

Nitric Acid 2% 60°C 80°C To be checked

Saturated steam 125°C Suitable To be checked Suitable

Greases Unsuitable Suitable Suitable

Alcohols Suitable Unsuitable Suitable

The valve complies with PED 2014/68/EU directive, with special reference to

Annex III, Module A, concerning internal manufacturing checks as indicated in the

Conformity Assessment Procedures.

Valves with DN equal or smaller than DN25 are not included in compliance with Article 4, paragraph 3.

Valves designed for use with gases, liquefied gases, gases dissolved under pressure, vapours and also those liquids whose

vapour pressure at the maximum allowable temperature is greater than 0,5 bar above normal atmospheric pressure (1

013 mbar) are included within the following limits:

- valves with DN between DN32 and DN100 (included) with group 1 fluids;

- valves with DN125 or bigger with group 2 fluids.

The end user is asked to carry out the acoustic emission tests once the valve has been installed in the destination

plant.

In the event of any doubt, please contact Bardiani Valvole S.p.A.