Barkey warming center III DTM User manual

Service manual

Barkey warming center III DTM

with digital temperature display

From SN 160 5986

Version 1.00 EN

Manufactured by:

Barkey GmbH & Co. KG

Gewerbestrasse 8

D - -33818 Leopoldshoehe

Germany

Contents

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

Contents

1 Introduction .......................................................................................................................... 1

1.1 Important things to observe ................................................................................................... 1

1.2 Pictograms, signal words and symbols................................................................................. 2

1.3 Target groups......................................................................................................................... 2

1.4 Disclaimer of liability .............................................................................................................. 3

1.5 Copyright................................................................................................................................ 3

2 Safety information ............................................................................................................... 4

2.1 Safety information for the carrying out of service work.......................................................... 4

2.2 Safety information regarding environmental influences......................................................... 5

3 Displays and controls and symbols .................................................................................. 6

3.1 Operating panel ..................................................................................................................... 6

3.2 Symbols used ........................................................................................................................ 7

4 Operation .............................................................................................................................. 8

4.1 Display elements.................................................................................................................... 8

4.1.1 Operating display ................................................................................................................... 8

4.1.2 Heating activity display .......................................................................................................... 9

4.1.3 Fault display........................................................................................................................... 9

4.1.4 Temperature display .............................................................................................................. 9

4.2 Displays and controls........................................................................................................... 10

5 Technical safety inspections (TSI)................................................................................... 11

5.1 Visual inspection .................................................................................................................. 11

5.2 Temperature check .............................................................................................................. 12

5.3 Checking the overtemperature protection............................................................................ 13

5.4 Measurements in accordance with DIN EN 60601-1........................................................... 15

5.5 Functional inspection ........................................................................................................... 16

5.6 Comments............................................................................................................................ 16

5.7 TSI has been passed ........................................................................................................... 16

5.8 Affixing the test sticker ......................................................................................................... 16

6 Adjustments ....................................................................................................................... 17

6.1 Adjusting the temperature display ....................................................................................... 17

6.2 Adjusting the temperature in the heating chamber.............................................................. 18

6.3 Adjusting the electronic overtemperature protection ........................................................... 19

7 Service work....................................................................................................................... 20

7.1 Functional circuit diagram.................................................................................................... 21

7.2 Removing and refitting the heater insert.............................................................................. 22

7.3 Replacing the regulator circuit board ................................................................................... 24

7.4 Replacing the heater............................................................................................................ 26

7.5 Replacing the transverse airflow fan.................................................................................... 27

7.6 Replacing the mechanical overtemperature protection ....................................................... 30

7.7 Replacing the power switch ................................................................................................. 32

7.8 Replacing the fuseholder .....................................................................................................33

7.9 Replacing the microswitch ................................................................................................... 34

7.10 Replacing the keyswitch ...................................................................................................... 35

7.11 Replacing fuses ................................................................................................................... 37

7.12 Cleaning and disinfection..................................................................................................... 38

Contents

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

7.13 Service tools.........................................................................................................................39

8 Appendix .............................................................................................................................42

8.1 Cross-section of Barkey warming center III DTM ................................................................42

8.2 Spare parts list .....................................................................................................................43

8.3 Address / contact..................................................................................................................44

8.4 Inspection log for technical safety inspection.......................................................................44

Introduction

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 1

Service manual

Barkey warming center III DTM

1 Introduction

This service manual is intended as an introduction to carrying out technical safety inspec-

tions (in brief TSI) and to carrying out service work on the Barkey warming center III

DTM.

1.1 Important things to observe

WARNING

Read this service manual and the instruction manual thoroughly through before

you operate the device or carry out service work.

This should ensure that no incorrect handling can take place which could lead to

faults or damages.

You should also observe the requirements made on the qualifications of service

personnel as stated in Chapter 1.3.

It is imperative that the installation conditions and safety information described in the

service manual and in the instruction manual are observed during service work on the

device. This ensures that the device is not used improperly such that patients and users

of the device could be endangered, and prevents damage to the device.

WARNING

Medical electrical devices are subject to particular precautionary measures with re-

gard to EMC (electromagnetic compatibility). Please ensure that the device is in-

stalled and operated in accordance with the EMC guidelines contained in this in-

struction manual.

Barkey GmbH & Co. KG accepts no liability for damages which are caused by disregard-

ing this service manual or the instruction manual.

Introduction

2Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

1.2 Pictograms, signal words and symbols

Warnings, and especially advice, are labelled using the following pictograms and symbol

words in this service manual .

WARNING

If not observed: hazards to personnel.

CAUTION

If not observed: hazards for equipment, the device or elementary

device functions.

NOTE

Additional helpful guidelines and information.

(the "i" stands for "information".

You will find the following symbol in instructions about the use and maintenance of the

device:

►Instruction stage.

carry out this stage as indicated.

NOTE

The symbols representing the displays and controls and device displays, in addi-

tion to the symbols on device labels, are listed in Chapter 3 of this service manual

together with their meanings.

1.3 Target groups

These service manuals are intended for specialist medical technicians who:

•can substantiate a recognised qualification as an electrical appliance electrician or

equivalent

•have been trained by the manufacturer through training courses in the implemen-

tation of

technical safety inspections and in the implementation of service work on the

Barkey warming center III DTM.

WARNING

Only personnel who have fulfilled these qualifications may carry out service work

on the device.

Introduction

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 3

Service manual

Barkey warming center III DTM

1.4 Disclaimer of liability

The manufacturer and/or its subsidiary companies are only then liable for the safety, reli-

ability and performance of the system if all operating procedures, adjustments and repairs

are carried out by suitably trained and qualified personnel; if all alterations to the device

have been approved in writing by the manufacturer and have been carried out by suitably

trained and qualified personnel; if the electrical installation within the treatment room sat-

isfies local regulations and, if applicable, IEC requirements; if the device is used in accor-

dance with the published operation and service manual (this documentation).

1.5 Copyright

This service manual, including all images contained within, is protected by copyright

regulations. Translation, duplication, reprinting, extraction of images, reproduction using

photographic technology and saving and processing in electronic systems, even only ex-

cerpts, in addition to any alterations requires the written authorisation of

Barkey GmbH & Co. KG. Any further usage which goes beyond using the contents de-

scribed in connection with the product purchased is not permitted.

Third party products, protected trademarks etc. are always stated without reference to the

registration or copyright status. Existing industrial property rights and registered trade-

marks will be explicitly acknowledged.

We reserve the right to make printing errors, mistakes and revisions which serve techni-

cal progress, or which are necessary due to changes in regulations.

Safety information

4Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

2 Safety information

2.1 Safety information for the carrying out of service work

WARNING

Read this service manual and the instruction manual thor-

oughly through before carrying out a TSI or service work.

Observe the safety information and the information on electro-

magnetic characteristics and protective distances in the in-

struction manual.

All electrical installations must comply with the relevant appli-

cable regulations and standards in addition to the specifica-

tions stated by the manufacturer.

Only mains power cables supplied by Barkey GmbH & Co. KG

which are designed for the device rated voltage and rated cur-

rent may be used.

You must remove the plug from the mains before opening the

device.

A technical safety inspection must be carried out annually by

qualified service personnel or employees of Barkey GmbH &

Co. KG.

All inspection steps for the TSI which have to do with tem-

perature measurements must be carried out at a room tem-

perature of

22° Celsius ± 1.0 K.

During measurements, the device may not be subjected to

direct sunlight or draughts, or any other influences which might

influence the measurement.

The heating device must be located on a level, horizontal sur-

face. When the device is in location, the front castors must be

locked.

Before the heating device is moved, the mains power cable

must be unplugged from the wall socket.

Moving the heating device may only take place slowly and

without temperature-regulated goods at a pace slower than

walking pace. If moving takes place too quickly, or abrupt ac-

celeration or braking is used, the doors can open unintention-

ally despite the closing technology used (magnetic sealing

frame).

Only move the heating device across level surfaces. Do not

move it across steps, inclines or cables etc.

If the temperature display is blinking, the heating device may

not be used for the warming of heating goods.

If the fault display illuminates or flashes, the heating device

must be inspected in the manufacturer's works or by medical

technicians who have been trained in the overhaul and exami-

nation of this device, and overhauled if necessary.

Safety information

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 5

Service manual

Barkey warming center III DTM

WARNING

Temperature-regulated goods which are stored in the tem-

perature-regulated space when a fault message is displayed

must be inspected for usability before use, because they were

subjected to a temperature higher than 46°C.

CAUTION

Overhaul measures and device modifications may only be

carried out by qualified service personnel or employees of

Barkey GmbH & Co. KG.

2.2 Safety information regarding environmental influences

WARNING

The influence of stronger electromagnetic fields (e.g. through

the use of HF therapy or surgical devices) can lead to malfunc-

tions in the device. If such malfunctions occur, increase the

distance between the device and the device causing the dis-

turbance, or operate the devices at separate times. The device

works perfectly within the limit values set in the EN 60601-1-2

standard. The device can be influenced outside the limit values

set by EN 60601-1-2.

Portable and mobile high-frequency communication equipment

such as mobile telephones can influence the device.

The device may not be used in the immediate vicinity of

•flammable materials (e.g. gases, liquids),

•flammable mixtures of anaesthetic substances with air,

•flammable mixtures of anaesthetic substances with oxygen

or laughing gas

whose point of ignition is below 50°C. It is imperative that the

device is not used in areas in which alcoholic disinfectants or

anaesthetising substances are being used simultaneously.

Observe the safety information and the information on electro-

magnetic characteristics and protective distances in the in-

struction manual.

The device may not be set up or operated in the immediate

vicinity of devices with high heat output.

Displays and controls and symbols

6Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

3 Displays and controls and symbols

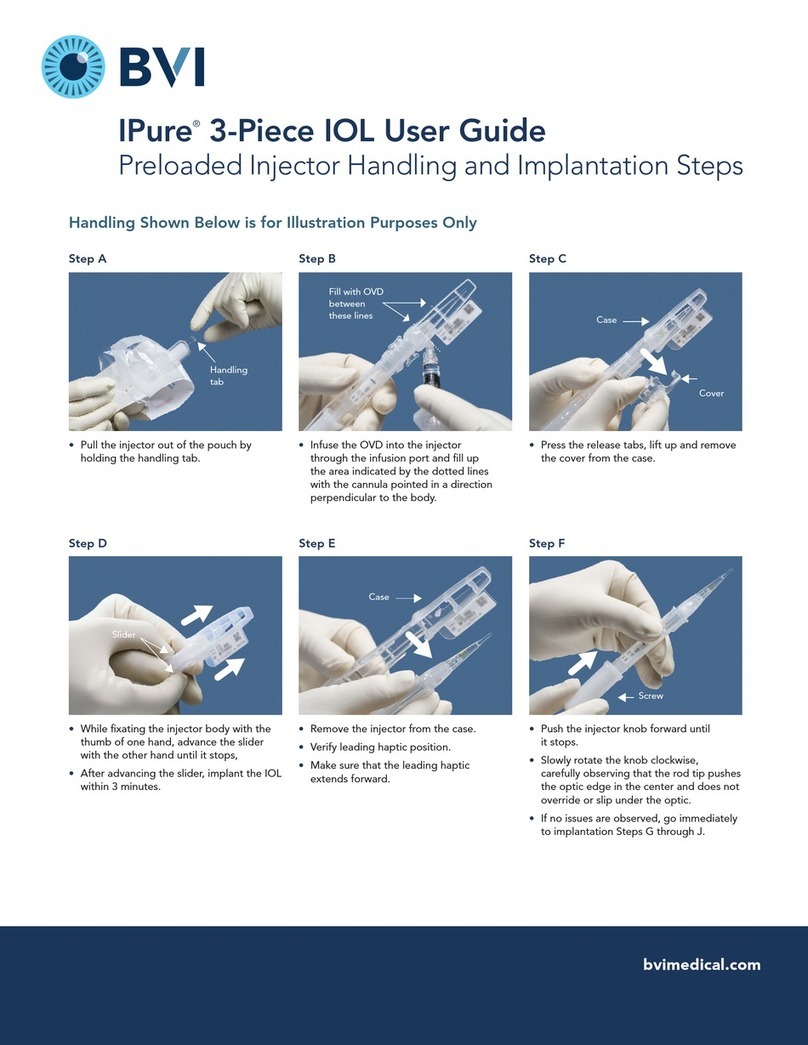

3.1 Operating panel

The operating panel of the Barkey warming center III DTM is located on the front of the

device. It is integrated into the heating cabinet front face. The following figure shows the

complete operating panel as an overview.

Figure 1: Barkey warming center III DTM operating panel

An acoustic signal transmitter signals faults in the device.

Please also see the following table for the displays and controls.

Toggle switch for turning the device on and off.

I = on

0 = off

Operating display. The green light (LED) shows that the device has

been switched on. It shows the device operating condition.

Heating activity display. The yellow lamp (LED) shows the heater activ-

ity. It illuminates when the heater is active.

Fault display. The red light (LED shows that a fault has occurred. The

red LED illuminates or blinks if a fault occurs. An acoustic signal is also

sounded.

The temperature display displays the current air temperature in the

temperature-regulated space in°C.

STK-e: Inspection of the electronic overtemperature protection takes

place in this keyswitch position. The temperature display blinks.

The Barkey warming centre III DTM may not be used for warming

and keeping warm in this keyswitch position.

STK-m: Inspection of the mechanical overtemperature protection takes

place in this keyswitch position. The temperature display blinks.

The Barkey warming centre III DTM may not be used for warming

and keeping warm in this keyswitch position.

Operation: The Barkey warming center III DTM can be used for correct

and proper use with the keyswitch in this position.

Displays and controls and symbols

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 7

Service manual

Barkey warming center III DTM

3.2 Symbols used

Labels showing printed symbols are affixed to the device. These have the following

meaning:

IPX1 This symbol shows that the device is protected against dripping water in

accordance with IEC 601-1 in the intended operating conditions.

2008

This symbol shows the year of manufacture in the four-digit number.

0123

This symbol declares that the device conforms with EU Directive

93/42/EWG of 14th June 1993 for medical products. The four-digit

number identifies the stated location (TÜV Product Service) which

monitors the manufacturer's quality assurance system.

This symbol (on a label inside the device) informs you of the earth con-

nection.

This symbol identifies the month and the year in which the next safety

inspections must be carried out.

This symbol advises you that the instruction manual must be carefully

read through before operating the device.

This symbol indicates that the product may not be disposed of with

normal domestic waste. This product must be disposed of by specialist

disposal companies or returned to the manufacturer for disposal.

This symbol advises you that the device must be disconnected from the

mains before opening the device housing.

Operation

8Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

4 Operation

4.1 Display elements.

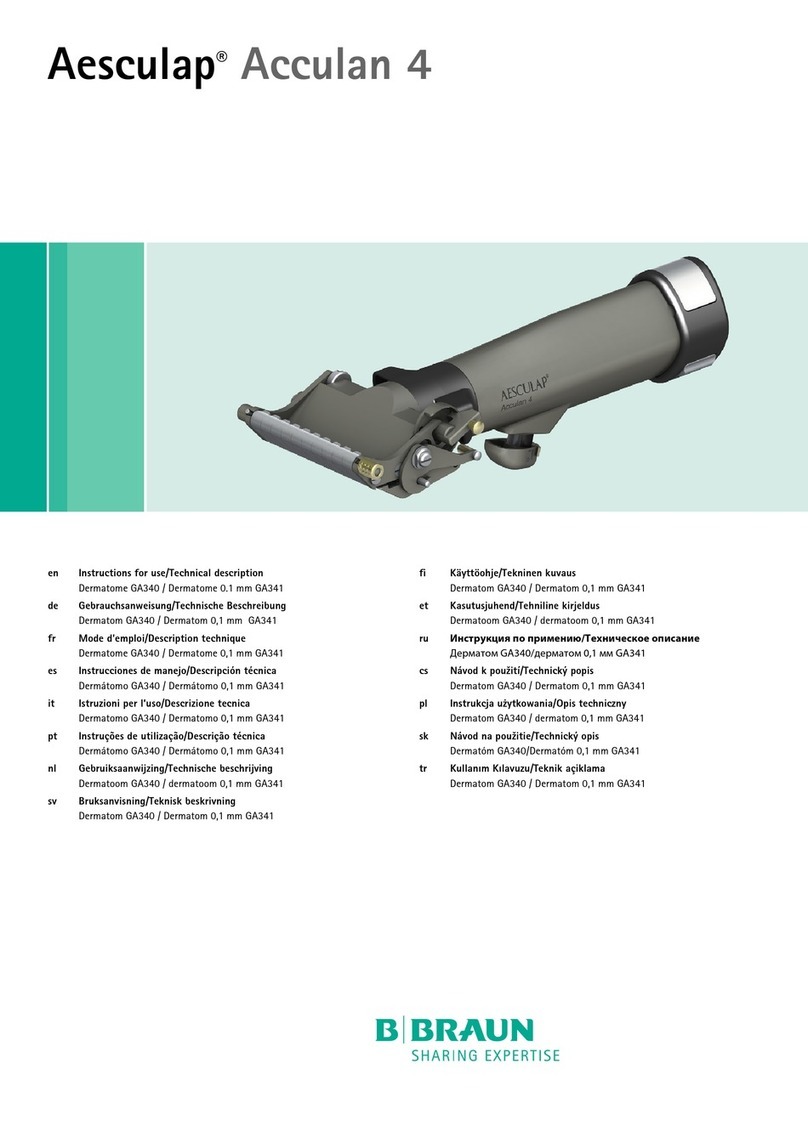

Display elements are located on the front of the Barkey warming center III DTM. They are

integrated in the front face of the control module. The following illustration shows an

overview of the display elements.

Operating display Fault display

Heating activity display Temperature display

Figure 2: Display panel

The following subsections explain the meaning of individual display elements.

4.1.1 Operating display

The operating display indicates the heating device operating status.

Status Meaning

Off Power supply is not available.

The heating device is not switched on.

On Power supply is available.

The heating device is switched on and active.

Flashing Power supply is available.

The heating device is switched on.

The door is open.

The circulating air temperature regulation is switched off.

An acoustic signal will sound after two minutes

Signal to remind you that the door is open.

Operation

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 9

Service manual

Barkey warming center III DTM

4.1.2 Heating activity display

The heating activity display indicates the current heater condition. If the heating device is

switched on and the operating display is permanently illuminated, the display has the fol-

lowing meaning:

Status Meaning

Off The heater is currently not active.

It is not being triggered by the temperature regulation

because the temperature is at the required setting.

On Blinking. It is being triggered

by the temperature regulation.

Blinking The heater is active. It is only triggered briefly by the

temperature regulating system.

4.1.3 Fault display

The faults display indicates malfunctions. If the heating device is switched on, this display

has the following meanings:

Status Meaning

Off There are no malfunctions.

On The mechanical overtemperature protection has triggered.

Blinking The temperature regulation temperature sensor is defective.

or

The electronic overtemperature protection has triggered.

WARNING

Temperature-regulated goods which are stored in the temperature-regulated space

when a fault message is displayed must be inspected for usability before use, be-

cause they were subjected to a temperature higher than 46°C.

4.1.4 Temperature display

The temperature display displays the current air temperature in the temperature-

regulated space in°C. The air temperature is measured representatively at the air duct

output.

WARNING

The temperature display flashes if the electronic or mechanical overtemperature

protection test function is activated via the keyswitch. The heating device may not

be used for heating temperature-regulated goods in this condition.

Operation

10 Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

4.2 Displays and controls

For normal operation, only the power switch on the right-hand side of the operating panel

of the Barkey warming center III DTM is of interest. The temperature has been set at the

works, so that once the device has been switched on no further displays and controls are

necessary.

If the door is opened, the circulating air temperature regulation switches off automatically

and the operating display (green lamps) flashes. If a fault is present, this is indicated by

the fault display (red lamps) illuminating or flashing.

To switch the device on, press the rocker

switch into position I.

Figure 3: Power switch

The TSI keyswitch on the right-hand side of the operating panel is also required for car-

rying out the TSI. The TSI keyswitch actuates special testing conditions in order to enable

checking of the electronic and mechanical overtemperature protection function.

Switching over to one of the two special

testing conditions can only take place

using the correct key. Testing of the elec-

tronic overtemperature protection takes

place in the "TSI-e" position. The "TSI-m"

position is used to test the mechanical

overtemperature protection.

Figure 4: TSI keyswitch.

WARNING

The temperature display flashes if the electronic or mechanical overtemperature

protection test function is activated via the keyswitch. The heating device may not

be used for heating temperature-regulated goods in this condition.

Technical safety inspections (TSI)

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 11

Service manual

Barkey warming center III DTM

5 Technical safety inspections (TSI)

The Barkey warming center III DTM temperature setting is dependent on normal ageing

and the tolerances of the electronic components, as are all electronic devices.

In order to guarantee the temperature settings on the Barkey warming center III DTM

permanently within the stated tolerances, an annual technical safety inspection (TSI)

must be carried out by qualified service personnel or employees of Barkey GmbH & Co.

KG (see § 6 of the German MPBetreibV*).

The safety inspection should include the prescribed annual electrical safety check on the

Barkey warming center III DTM in addition to other points listed here.

WARNING

Only qualified service personnel and employees of Barkey GmbH & Co. KG may

carry out technical safety inspections.

WARNING

In order to carry out safety inspections, you must remove all temperature-regulated

goods from the temperature-regulated cabinet and store them in accordance with

their respective manufacturer's instructions.

NOTE

The date for carrying out the next technical safety inspection is printed on the date

label on the inside of the device.

Technical safety inspections to be carried out on the Barkey warming center III DTM are

mainly concerned with a temperature check in the temperature-regulated cabinet using a

calibrated thermometer, and testing of the overtemperature protection functions.

Device data must be entered at the top of every page in the inspection log. This informa-

tion must be entered on every page so that all pages of an inspection log can be clearly

allocated to one particular device.

►Enter the name and address.

►Enter the serial number from the nameplate.

►Enter the setup measurement date in the "Setup measurement" box.

►The current date must be entered in the date box.

5.1 Visual inspection

►First, carry out a visual check on the Barkey warming center III DTM to be inspected.

The visual inspection must include all points stated in the inspection log in point 1.

Technical safety inspections (TSI)

12 Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

5.2 Temperature check

The temperature check is used to check correct settings of the temperature regulation

system. The temperature in the centre of the temperature-regulated cabinet is measured

using a reference thermometer.

The requirements on the reference thermometer are:

•temperature range of minimum 20°C ... 50°C

•accuracy of at least 0.1 K

•The thermometer must be calibrated.

You can order a suitable reference thermometer from Barkey GmbH & Co. KG.

WARNING

The room temperature must be at 22.0°C ±1.0 K during the entire temperature

check. Incorrect values will be measured if this is not the case.

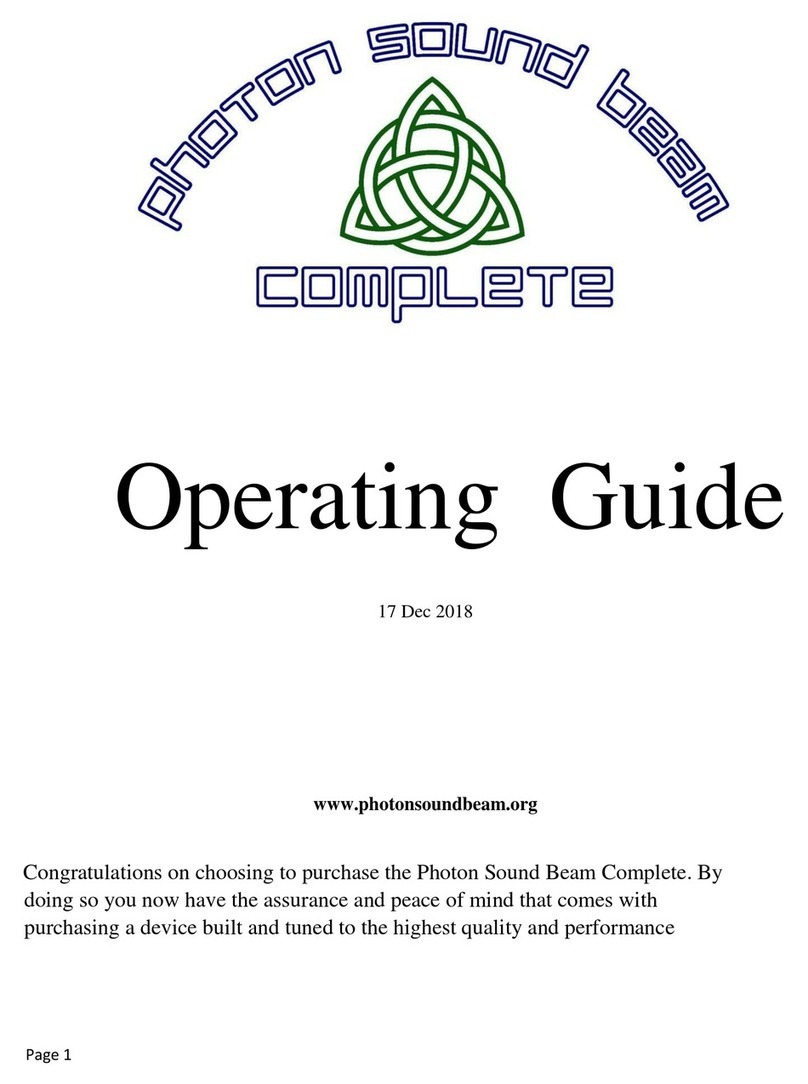

►Fix the thermometer in the middle of the centre shelf. When doing so, ensure that the

thermometer measuring head is located freely in the air to be warmed.

Locate the display section of the ther-

mometer inside the temperature-regulated

cabinet so you can read the temperature

through the glass door when it is closed.

When using the thermometer, and when

evaluating the measured values, observe

the information supplied by the ther-

mometer manufacturer about surrounding

conditions.

Figure 5: Reference thermometer

►Enter the type and the serial number of the reference thermometer in the inspection

log.

►Measure the current room temperature and enter it in the inspection log.

►You can now operate the Barkey warming center III DTM again as described in the

instruction manual.

Technical safety inspections (TSI)

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 13

Service manual

Barkey warming center III DTM

►Wait until the display shows a temperature of 42°C and the measured temperature in

the heating chamber is stable. If the heating chamber is cold, this will take around 60

minutes. If the device is warm, the waiting period will be shorter.

►Once the temperature reached has become stable, enter the temperature of the ref-

erence thermometer and the temperature displayed in the Barkey warming center III

DTM in the inspection log.

WARNING

If the temperature shown by the reference thermometer lies outside the prescribed

tolerance of 42°C ± 3°C, the Barkey warming center III DTM needs to be read-

justed (see chapter 6.2). The values shown on the device temperature display

must agree with the measured value of the reference thermometer by ± 1°C. If the

discrepancy is larger, the Barkey warming center III DTM needs to be readjusted

(see chapter 6.1). The TSI must be repeated afterwards.

►Take the reference thermometer out of the Barkey warming center III DTM heating

chamber.

5.3 Checking the overtemperature protection

The Barkey warming center III DTM is fitted with two independent mechanisms to protect

it from high temperatures.

One of these is the electronic overtemperature protection. In this case, an independent

electronic system continuously checks the temperature in the air duct. If the measured

temperature becomes higher than 46°C, the heater is switched off. The error display on

the front panel also blinks.

The electronic overtemperature protection fault message can be reset by turning the de-

vice off and then on again. If the cause of the fault has not been rectified, the error mes-

sage will be displayed once again.

There is also an independent mechanical overtemperature protection system. The me-

chanical overtemperature protection is fitted directly on the heater and serves to protect

the entire device. If the temperature of 63°C at the heater is exceeded, this is switched off

permanently. The error display on the front panel also illuminates permanently. A tem-

perature of 63°C at the heater is equivalent to a temperature of around 51°C in the heat-

ing chamber.

WARNING

The room temperature must be at 22.0°C ± 1.0 K during the entire overtemperature

protection check. Incorrect values will be measured if this is not the case.

WARNING

Any overtemperature protection checks must be carried out when the

Barkey warming center III DTM has been heated up to 42°C. If this is not the case,

incorrect values will be measured during the overtemperature protection check.

Technical safety inspections (TSI)

14 Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

►If the Barkey warming center III DTM heating chamber has not already been warmed

up to 42°C, operate the device as described in the instruction manual. Wait until the

display shows a temperature of 42°C and the measured temperature in the heating

chamber is stable. If the heating chamber is cold, this will take around 60 minutes. If

the device is warm, the waiting period will be shorter.

►Switch the Barkey warming center III DTM off.

►Turn the keyswitch to the "TSI-e" position.

►Switch the Barkey warming center III DTM on.

The heater is permanently in operation at this "TSI-e" setting, and the temperature in the

heating cabinet increases. The temperature display will flash to show that the TSI test

function is activated.

As soon as the electronic overtemperature protection triggers, the fault display flashes

and an acoustic signal sounds for around six seconds.

►Read the value of the temperature display when the electronic overtemperature pro-

tection is triggered and enter this in the inspection log.

WARNING

If the value determined lies outside the prescribed tolerance of 46°C ± 1°C, the

Barkey warming center III DTM needs to be readjusted (see chapter 6.3). The TSI

must be repeated afterwards.

►Switch the Barkey warming center III DTM off.

►Turn the keyswitch to the "TSI-m" position.

►Switch the Barkey warming center III DTM on.

In "TSI-m" check status, the heater is permanently triggered and the electronic overtem-

perature protection is bypassed. The temperature in the heating cabinet increases, and

activation of the TSI check function is indicated by the temperature display blinking.

As soon as the mechanical overtemperature protection triggers, the fault display illumi-

nates permanently and an acoustic signal sounds for around six seconds.

►Read the value of the temperature display at the time the mechanical overtempera-

ture protection is triggered.

►Enter the trigger value in the inspection log.

WARNING

If the value determined lies outside the prescribed tolerance of 51°C ± 3°C, the

mechanical overtemperature protection needs to be replaced (see

chapter 7.5). The TSI must be repeated afterwards.

►Switch the Barkey warming center III DTM off.

►Turn the keyswitch to the "Operation" position.

Technical safety inspections (TSI)

Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe – Germany - Head Office: +49 (5202) 9801-0 15

Service manual

Barkey warming center III DTM

►Allow the Barkey warming center III DTM to cool down for 30 minutes with the door

open.

►Reset the triggered mechanical overtemperature protection.

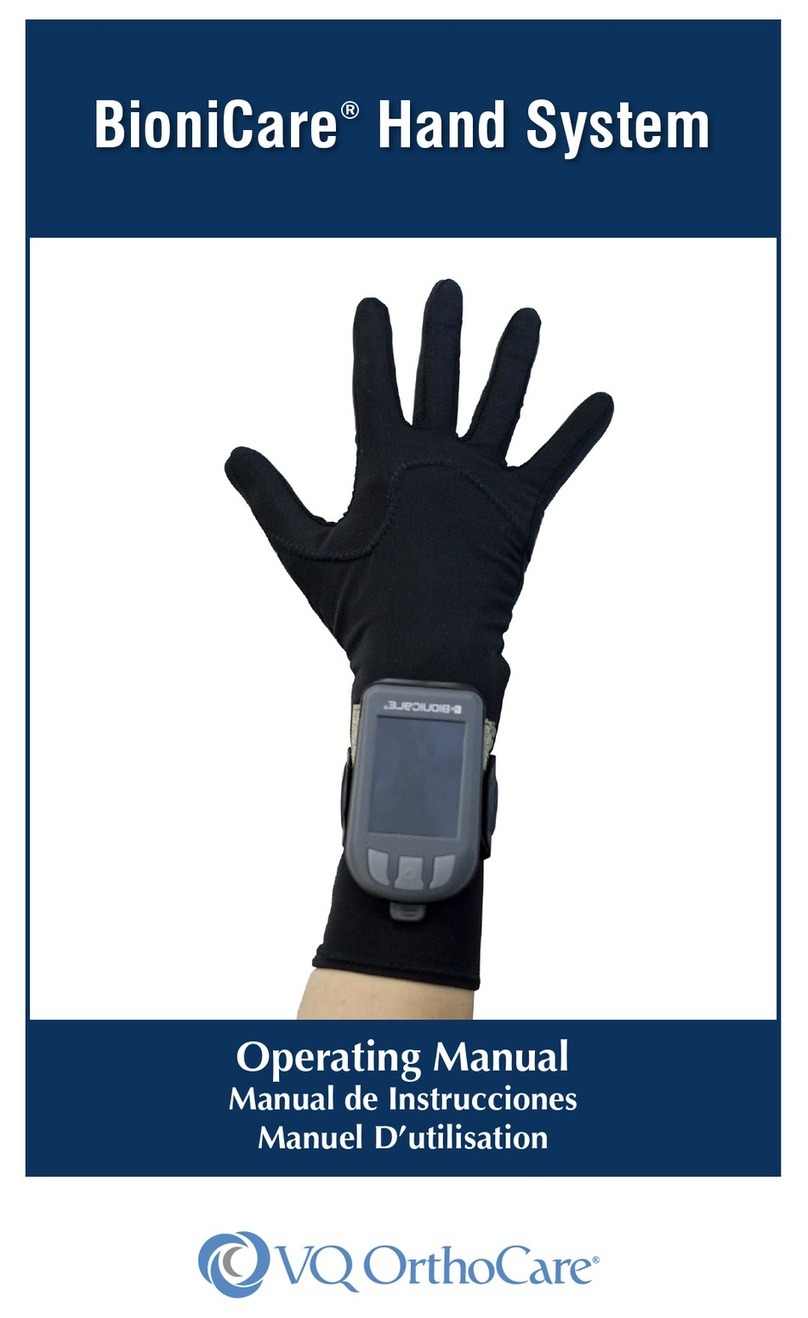

The overtemperature protection reset pin

is located on the underside of the heater

inset. Press the reset pin in with a pointed

object such as a ballpoint pen about 1

mm.

Figure 6: Reset pin for mechanical overtemperature protection

5.4 Measurements in accordance with DIN EN 60601-1

Safety inspections must be carried out in accordance with DIN EN 60601-1 in its valid

edition. When carrying out the inspection, you must also read and observe the test

equipment operating manual.

►Enter the type and serial number of the test equipment in the inspection log.

►Connect the Barkey warming center mains cable to your test equipment.

NOTE

The power switch must be switched on during the test (position "I").

►Carry out all measurements in accordance with your test equipment operating man-

ual.

In the adjacent figure you can see the

measuring points which the test equip-

ment probe must be connected to for

measuring the protective earth and

ground conductor resistance.

Figure 7: Measuring points for safety check

►Enter the values determined for the earth conductor resistance, insulation resistance,

earth and housing leakage current in the inspection log.

►Carry out an evaluation based on the measured results, and taking into account pre-

vious electrical safety measurements, to determine whether the device meets the

safety requirements.

Technical safety inspections (TSI)

16 Barkey GmbH & Co. KG - Gewerbestrasse 8 - 33818 Leopoldshoehe - Germany - Head Office: +49 (5202) 9801-0

Service manual

Barkey warming center III DTM

5.5 Functional inspection

►Switch the Barkey warming center III DTM on.

►The green LED on the display panel illuminates to confirm that the device has been

switched on. Enter whether the green LED illuminates in the inspection log.

►The temperature of the Barkey warming center III DTM must be displayed in the tem-

perature display after switching on. The temperature display should not be blinking.

Enter whether the temperature display is permanently illuminated in the inspection

log.

►Open the cabinet door.

►If the door is open, the green LED in the display panel blinks. In addition, an acoustic

signal is given off after 2 minutes to remind you that the cabinet door is open. Enter

whether the green LED is blinking in the inspection log.

►Enter whether an acoustic signal was sounded after 2 minutes in the inspection log.

►Close the cabinet door.

►The acoustic signal will stop and the green LED on the display panel will be perma-

nently illuminated. The circulating air temperature regulation will be activated at the

same time. This will be audible due to the ventilator noise. Enter whether the circu-

lating air temperature regulation is functioning in the inspection log.

5.6 Comments

►This is for entering comments, for example information relevant to subsequent tests.

5.7 TSI has been passed

►If all the points for the TSI listed above were completed positively, then the TSI in-

spection has been passed. Please tick the box marked "yes".

5.8 Affixing the test sticker

If the TSI test has been passed, the test sticker must be affixed. The test sticker shows

the user the date for the next TSI.

►Attach the test sticker with the date of the next inspection to the Barkey warming

center III DTM. The best location to this is the left-hand side of the incline on the

heater insert. The label should be fixed so that the arrow is pointing to the month in

which the inspection is due.

The name and address of those carrying out the test must be entered in the inspection

log. Correct implementation of the TSI inspection must be confirmed in the inspection log

with statement of name, date and signature.

WARNING

The Barkey warming center III DTM must be allowed to cool down to a temperature

below 42°C in the heating chamber after the TSI before it is used for warming

again.

Table of contents

Other Barkey Medical Equipment manuals