8 9

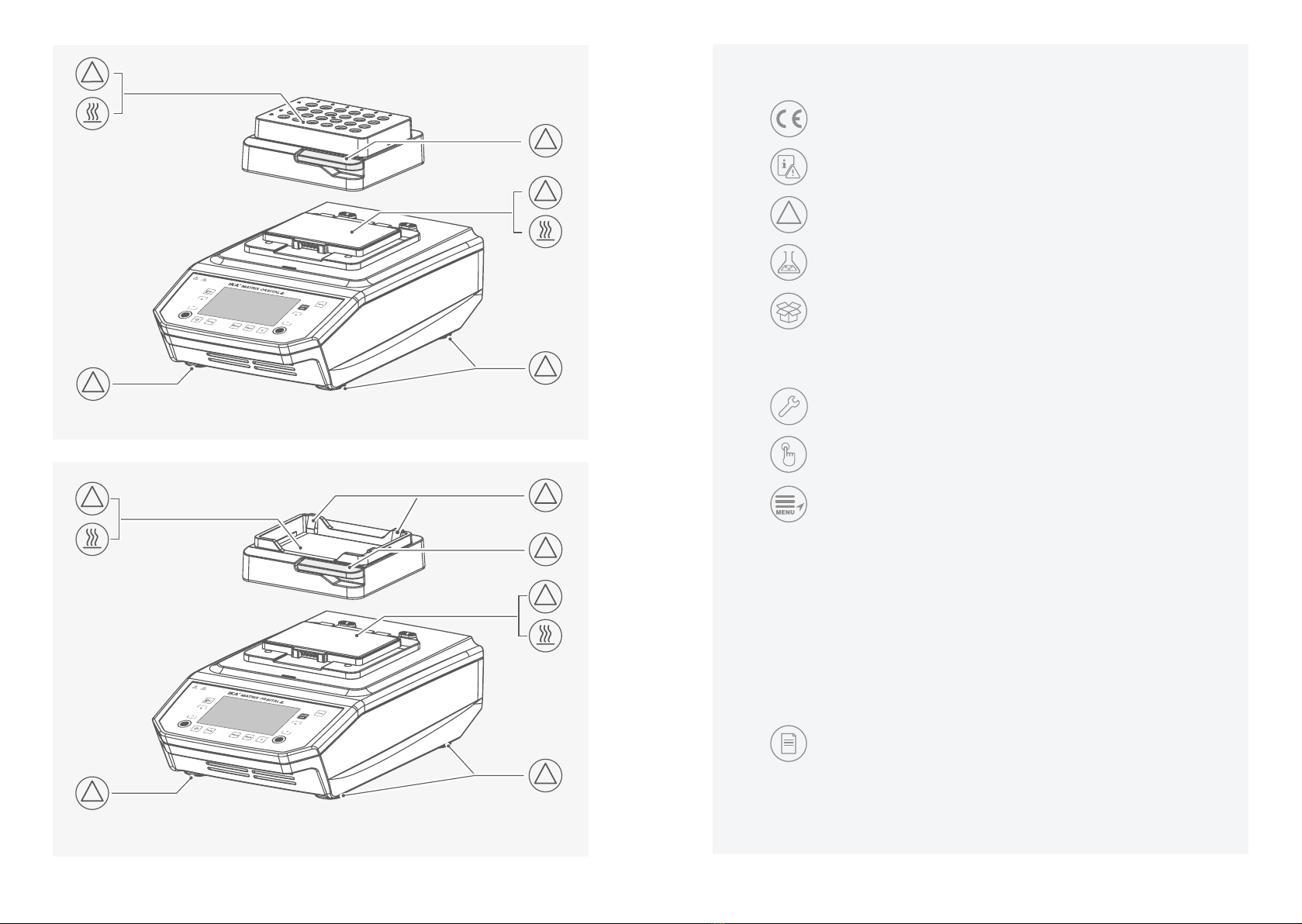

Intended use

///

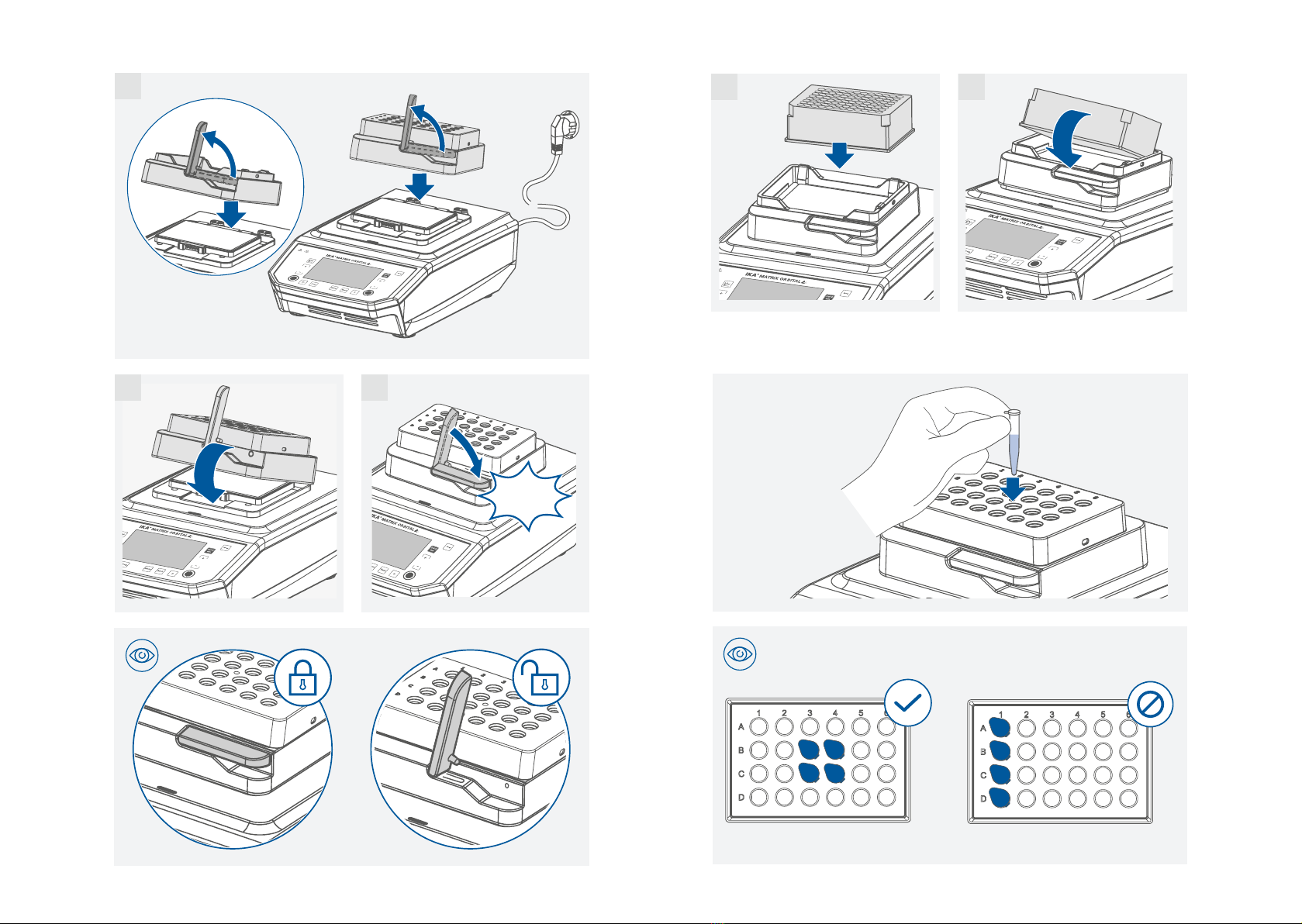

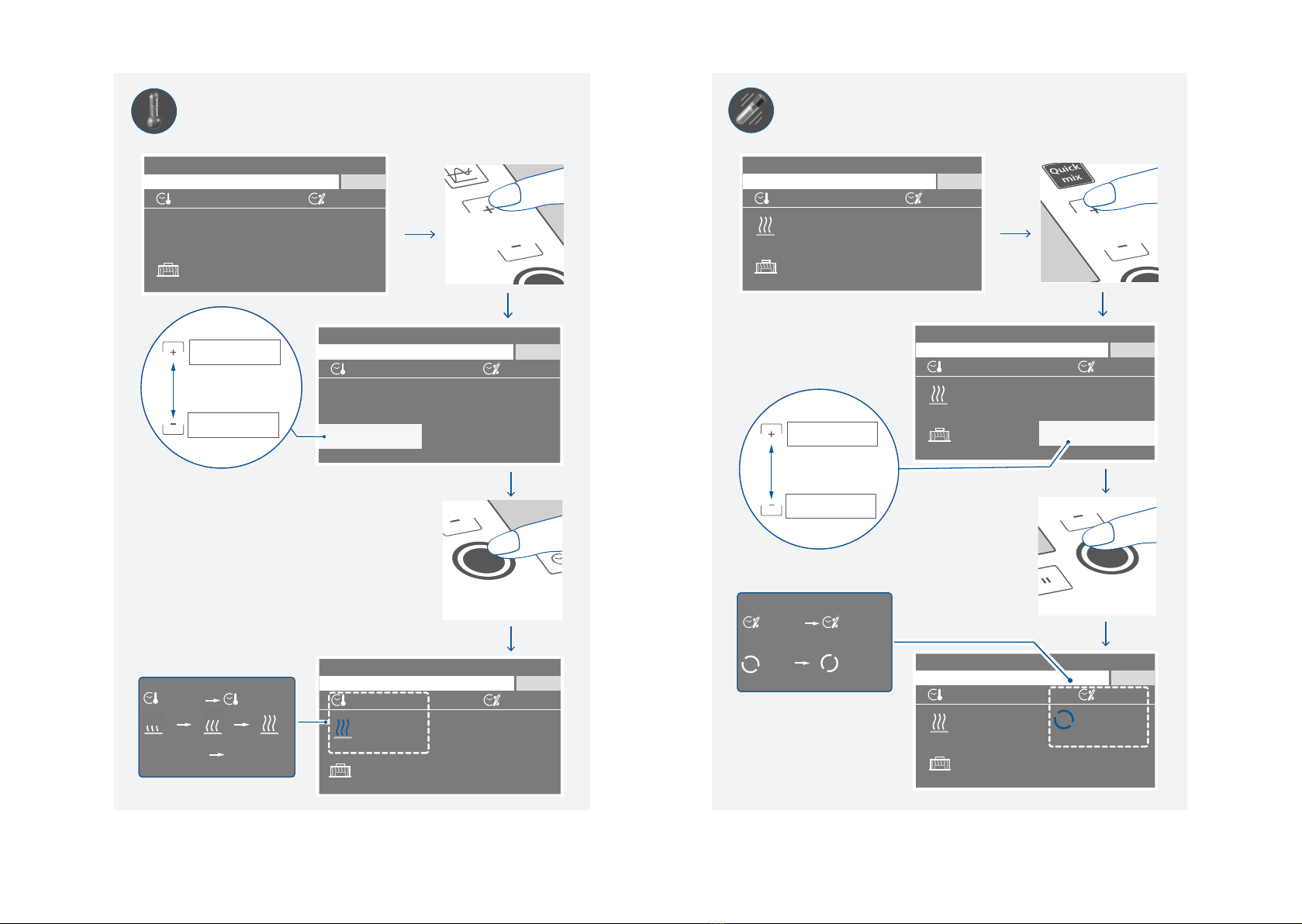

Use

The MATRIX ORBITAL DELTA PLUS device is used for mixing / tempering liquids in closed

tubes and closed plates in the preparation of samples�

Intended use: Tabletop device

/// Working with the device

Danger!

› Do not use the device in explosive atmospheres, it is not EX-protected�

› With substances capable of forming an explosive mixture, appropriate safety measures

must be applied, e�g� working under a fume hood�

› To avoid body injury and property damage, observe the relevant safety and accident

prevention measures when processing hazardous materials�

Warning!

› Only process samples that will not react dangerously to the extra energy produced through

processing� This also applies to any extra energy produced in other ways, e�g� through light

irradiation�

› Only media whose flash point lies above 170 ºC can be heated with this device (according

to EN 61010-2-010)�

› When handling hazardous substances or mixtures of substances which are toxic or

are contaminated with pathogenic micro-organisms, the user should take appropriate

precautions� Observe the national regulations, the biosafety level of your laboratory, the

material safety data sheets�

›For germs or biological material or risk goup II or higher, please observe the “Laboratory

Biosafety Manual” issued by the World Heath Organisation)�

Caution!

› Please pay attention to avoiding hand injury when operate the device�

› The heating plate and the attachments can be very hot and cause injuries� Be careful when

touching the attachments�

› Pay attention to the residual heat after switching off the device�

› Allow the attachments to cool down completely before removing them�

!Notice!

› The device must be operated on flat surface and must not be moved during operation�

› Covers or parts that can be removed from the device without tools must later be refitted to

ensure safe operation� This will prevent the infiltration of foreign objects, liquids and other

contaminants�

› Never use tubes made of glass or other fragile material� Glass tubes can be smash�

› Only use sealed micro test tube and sealed microplate / deepwell plate�

› The micro test tube / microplate / deepwell plate must always be closed during operation�

Switch off the device immediately if any material leaks from the vessel� Clean the device

after disconnected power plug�

› The feet of the device must be clean and undamaged�

/// Disposal instructions

› The device, accessories and packaging must be disposed of in accordance with local and

national regulations�

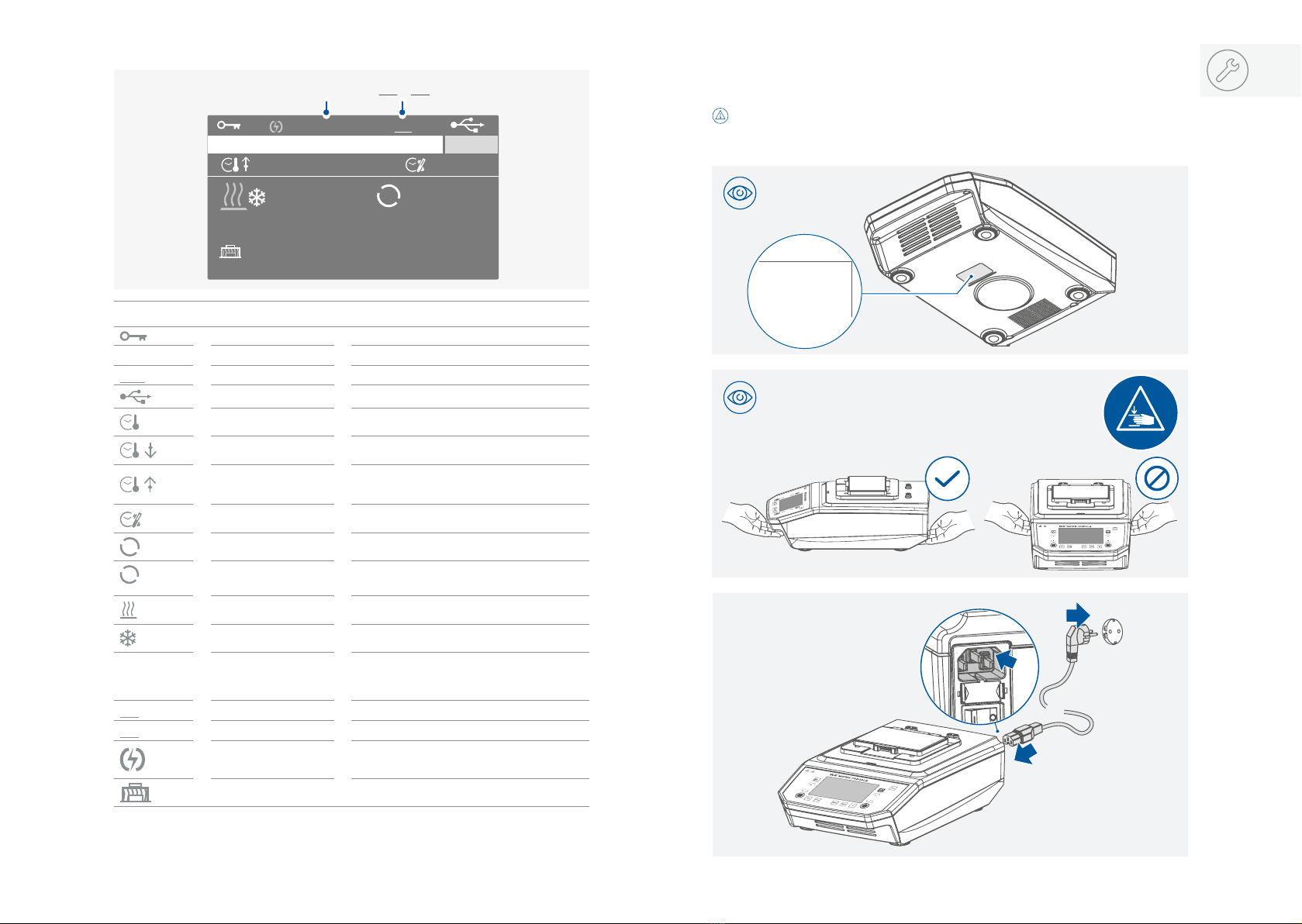

/// Maintenance

› The device must only be opened by trained specialists, even during repair� The device must

be unplugged from the power supply before opening� Live parts inside the device may still

be live for some time after unplugging from the power supply�

› Only use original IKA spare parts!

/// Power supply / switching off the device

› The voltage stated on the type plate must correspond to the power voltage�

› The device can only be disconnected from the power supply by pulling out the power plug

or the connector plug�

› The device must only be operated with the original power cord set�

› The socket for the power cord must be easily accessible�

› Socket must be earthed (protective ground contact)�

› The device will automatically restart in mode B and C following any interruption to the

power supply�

/// Accessories

› Protect the device and accessories from bumping and impacting�

› Check the device and accessories beforehand for damage each time when you use them�

Do not use damaged components�

› Safe operation is only guaranteed with the accessories described in the ”Accessories” section�

/// Range of use

Indoor environments similar to that of a laboratory in research, education, commerce or

industry�

The safety of the user cannot be guaranteed:

›

if the device is operated with accessories that are not supplied or recommended by the

manufacturer�

›

if the device is operated improperly or contrary to the manufacture’s specifications�

›

if the device or the printed circuit board are modified by third parties�