Barry-Wehmiller Thiele Streamfeeder HV User manual

Manual

AutoStream - Model HV

Part Number: 901546

This Product Guide supports autoloader part number 311-0314 with serial numbers beginning

with B1011Axxx

© 2009 Thiele Technologies, Inc. - Streamfeeder. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on a retrieval system, or

transmitted without the express written consent of Thiele Technologies, Inc. - Streamfeeder.

Thiele Technologies, Inc. - Streamfeeder

103 Osborne Road

Minneapolis, MN 55432-3120 USA

Tel:763.502.0000

Fax:763.502.0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

i

AutoStreAm HV mAnuAl

Contents

Before You Begin.................................................................................ii

Specications ......................................................................................v

Section 1: About the Machine .......................................................1

Section 2: Preparing for Operation ...............................................5

Section 3: Operation.....................................................................15

Section 4: Inspection and Care ...................................................17

Section 5: Mechanical Components ...........................................19

Section 6: Electrical Diagrams ....................................................33

ii AutoStreAm HV mAnuAl

Message

Conventions

DANGER signies an action or specic equipment area that can result

in serious injury or death if proper precautions are not taken.

WARNING signies an action or specic equipment area that can

result in personal injury if proper precautions are not taken.

CAUTION signies an action or specic equipment area that can

result in equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signies an action or specic equipment

area that can result in personal injury or death from an electrical haz-

ard if proper precautions are not taken.

TIP signies information that is provided to help minimize problems

in the installation or operation of the equipment.

NOTE provides useful additional information that the installer or

operator should be aware of to perform a certain task.

IMPORTANT alerts the installer or operator to actions that can po-

tentially lead to problems or equipment damage if instructions are not

followed properly.

Before You Begin

iii

AutoStreAm HV mAnuAl

Warning Label

Descriptions WARNING LABELS afxed to this product signify an action or spe-

cic equipment area that can result in serious injury or death if proper

precautions are not taken.

Hazardous voltage. Contact will cause electric shock or burn. Turn off

and lock out power before servicing.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

iv AutoStreAm HV mAnuAl

Make sure you thoroughly read this section to become familiar with

all the safety issues relating to the safe operation of this product.

Please read all of the warnings that follow to avoid possible injury.

Although Streamfeeder has made every effort to incorporate safety

features in the design of this equipment, there are residual risks that an

installer or operator should be aware of to prevent personal injury.

Please read all of the cautions that follow to prevent damage to this

product. This product is built with the highest quality materials.

However, damage can occur if the system is not operated and cared for

within design guidelines as recommended by Streamfeeder.

To insure proper machine operation make sure that all the safety de-

vices are installed properly and functioning. Do not attempt to defeat a

safety interlock or safety feature.

Equipment interior contains incoming 115VAC electrical power.

Bodily contact with these high voltages can cause electrocution,

which can result in serious injury or death.

safetY

Danger

Electrical Noise Electromagnetic interference (EMI) and radio frequency interference

(RFI), also known as electrical noise, do not usually cause problems.

If intense enough, however, it can cause problems for other electrical

equipment.

v

AutoStreAm HV mAnuAl

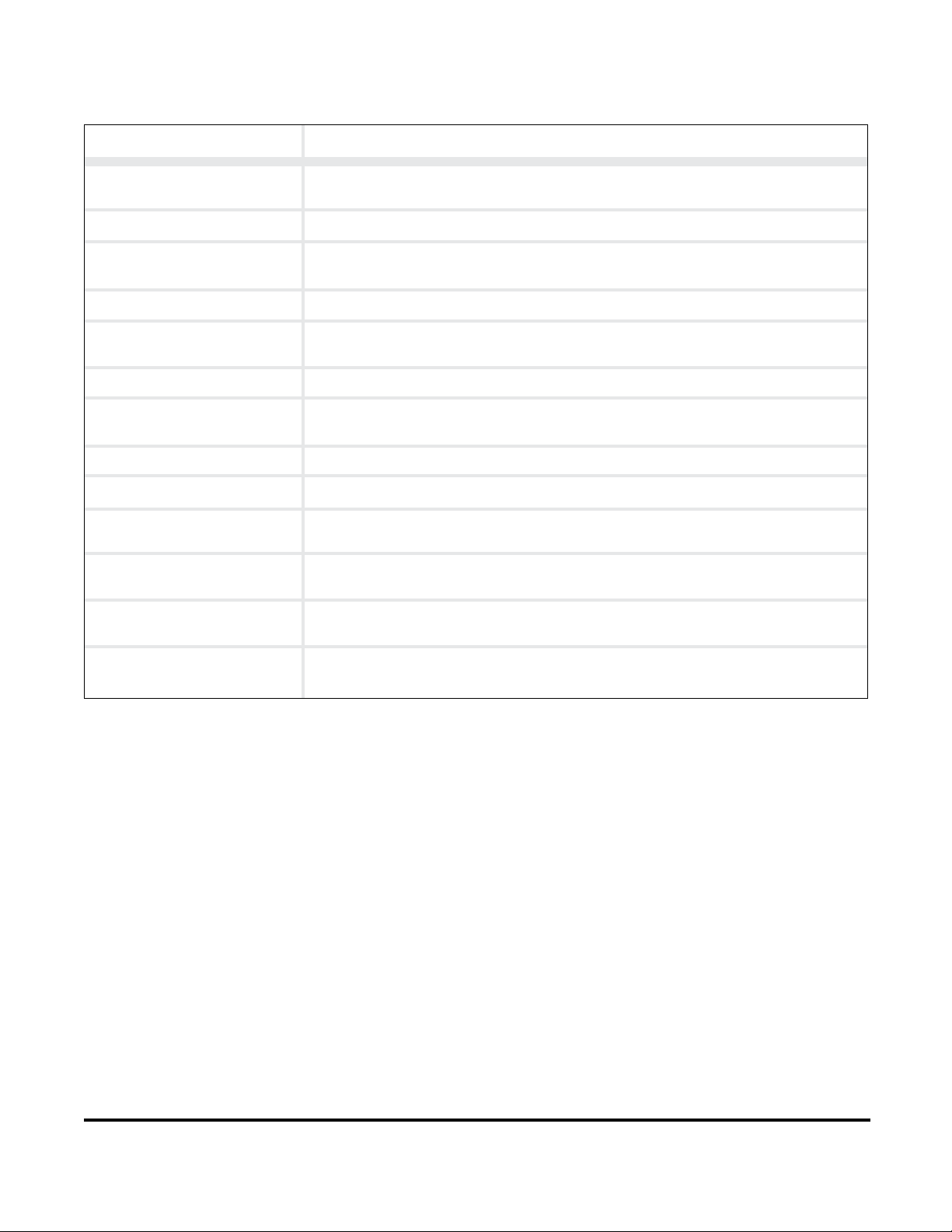

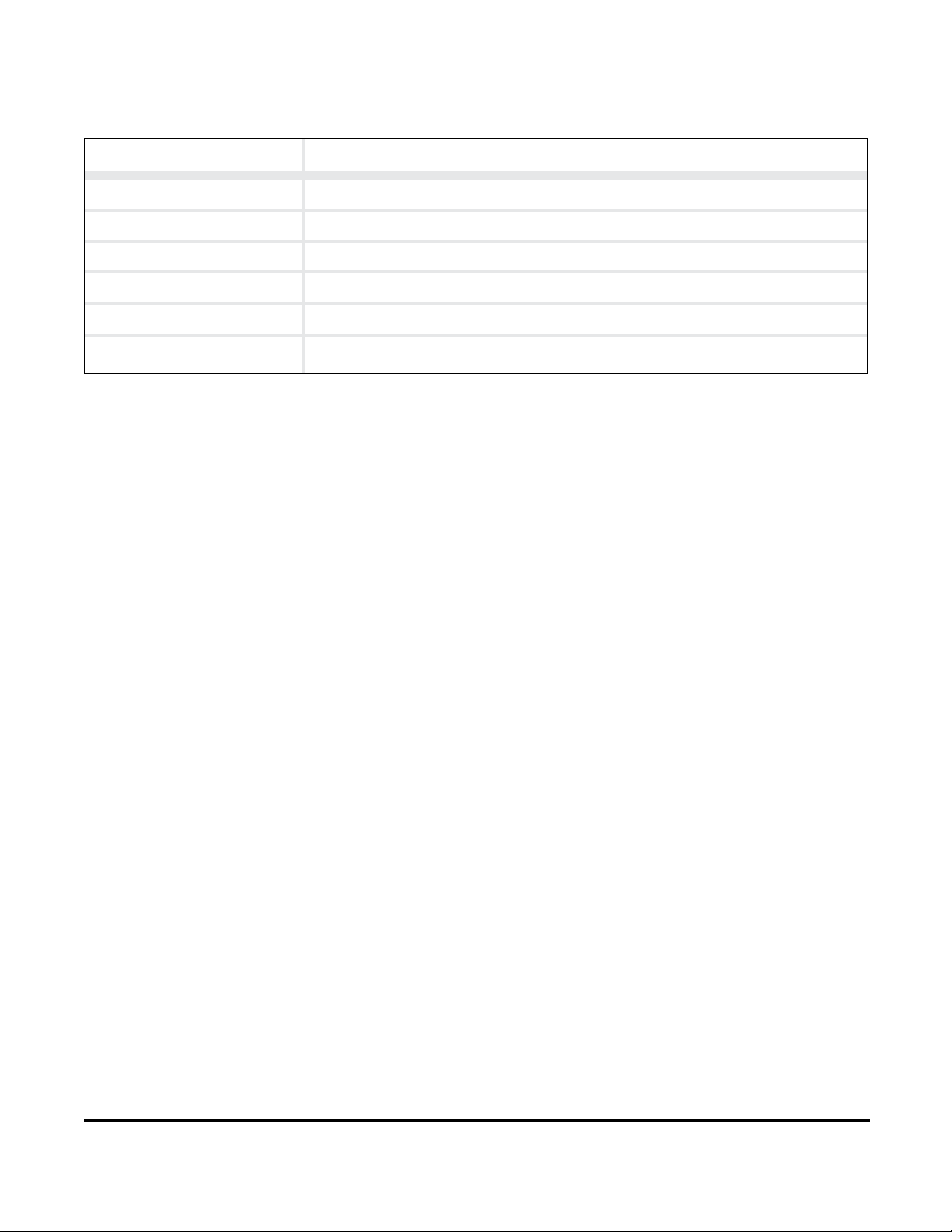

Maximum Product Size: 12 in. W x 12 in. L (305 mm x 305 mm)

Minimum Product Size: 3 in. W x 5 in. L (76 mm x 127 mm)

Min/Max Product Thickness: .003 in to .3125 in. (.076 mm - 8 mm)

Feed Belt Speed: 0-120 fpm (0-36,576 mm/min)

Load Belt Speed: 0-10 fpm (0-3,048 mm/min)

Load Belt Capacity: 300 lbs. (136 kg)

Electrical Requirements: 115vac, 60Hz, 7A

Weight: 225 lbs. (102 kg.)

Warranty: One-year limited

speCifiCations

1AutoStreAm HV mAnuAl

1About the Machine

Overview

Horizontal

Conveyor

Incline

Conveyor

Discharge

Area

Horizontal

Conveyor

Belt

Hydraulic

Height

Adjustment

(refer to page 7)

Docking

Bracket

Conveyor

Side

Guides

Discharge

Belt

Discharge

Side

Guides

Product Sensor

(refer to page 13)

Separator

Hold Down

Rollers

Incline

Conveyor

Belt

Review the diagrams in this section to become familiar with names

and locations of the parts and adjustments. This will help to prepare

you for initial setup.

Locking

Casters

Control Panel

(refer to page 3)

2

AutoStreAm HV mAnuAl

Feature Description

Main Assemblies Feature Descriptions

Conveyor Side Guides The conveyor side guides help direct the product in a straight line of movement on the

horizontal conveyor.

Discharge Belt

Discharge Side Guides The discharge side guides help direct the product in a straight line of movement in the

discharge area.

Docking Bracket The docking bracket keeps the autoloader and feeder connected at the desired distance.

Hold Down Rollers Theholddownrollersoatalongthetopsurfaceoftheshingledstreamofproducttohelp

control it as it is moved upward on the incline conveyor belt to the discharge area.

Horizontal Conveyor Belt The horizontal conveyor belt moves the loaded product toward the separator gate.

Incline Conveyor Belt The incline conveyor belt lifts product from the horizontal conveyor and delivers it to the

discharge belt.

Locking Casters Four locking casters keep the autoloader in place next to the feeder

Separator The separator shingles the loaded product for its upward travel on the incline conveyor belt.

Control Panel The control panel contains the electrical connection and breaker for the unit.

(not shown, refer to page 3)

Operator Station Houses controls to operate autoloader.

(not shown, refer to page 3)

Hydraulic Height Adjustment The hydraulic height adjustment is used to change the vertical height of the autoloader.

(not shown, refer to page 7)

Product Sensor The product sensor detects when the product in the feeder hopper is low. When detected, the

(not shown, refer to page 13) autoloader will advance to feed more product.

3AutoStreAm HV mAnuAl

Operator Station

Control Panel

Controls Overview

Speed Start/Jog Emergency

Stop

On/Off

Main Power

Sensor

Connector

4

AutoStreAm HV mAnuAl

Feature Description

Controls Feature Descriptions

Speed Increases and decreases both belt speeds while maintaining the set ratio.

Start/Jog Starts or jogs conveyor belts.

Emergency Stop Emergency stop cuts power to unit.

On/Off

Main Power

Sensor Connector

5AutoStreAm HV mAnuAl

2Preparing for Operation

Overview

Condition of installment:

Warning decals must be visible to equipment

operator.

DO NOT attempt to make any adjustments while the

equipment is running. Serious injury can be caused by

exposure to moving parts.

DO NOT wear loose clothing when operating the

equipment.

When performing adjustments, always make sure to

turn off the main power switch and disconnect the

equipment from the power source. Failure to do so

can cause the risk of an unintentional start-up and

therefore exposure to moving parts which can cause

serious injury.

Any attempt to make adjustments while the equipment

is in operation could potentially damage to equipment

or parts.

To prepare the autoloader for operation, the follow-

ing setups should be made in order:

1. Positioning with the Feeder

2. Discharge Side Guide Assembly and Setup

3. Docking

4. Conveyor Side Guide Setup

5. Separator Setup

6. Hold Down Rollers Setup

7. Product Sensor Setup

8. Connect Power

9. Test to Verify Proper Setup

6

AutoStreAm HV mAnuAl

Step 1:

Positioning with the Feeder

Review

The discharge belt on the autoloader must be set

slightly higher than the feeder hopper. The correct

height depends on the product being fed and the

clearance of the wedge being used.

Objective

Correctly adjust the height of the autoloader so the

product being fed falls evenly and freely, without skew,

into the feeder hopper.

Procedure

1. Swivel the hydraulic height adjustment handle

out to the extended position.

2. Turn the handle to raise or lower the autoloader

to the desired height.

3. Swivel the handle back into place.

4. Position the side guides between the feeder side

guides.

Swivel the height adjustment handle.

Turn the height adjustment handle.

Position side guides inside feeder hopper.

7AutoStreAm HV mAnuAl

Step 2:

Discharge Side Guide

Assembly and Setup

Review

The discharge side guides help direct the product in

a straight line of movement along the discharge belt.

Each side guide is independently adjustable, both

horizontally and vertically, to accommodate different

product widths. There are two locking levers on each

side guide.

Objective

Adjust the discharge side guides to maintain uniformity

in the loaded product with no drifting or binding.

Procedure

1. Attach each side guide by sliding the mounting

holes onto the socket head cap screws on the

inside of the mounting blocks.

2. While holding the side guide in place adjust to

the desired height above the belt and tighten the

screws.

3. Thecurvedareaofthesideguideshouldt

closely to the discharge belt without making

contact.Ifthecurvedareadoesnottwell,

adjust the side guide assembly mounting block

forward or back by loosening the four socket

head cap screws on the outside of each mount-

ing block, sliding the assembly to the desired

position and retightening the socket head cap

screws.

4. Tighten socket head cap screws.

Vertical and horizontal adjustment points.

Side guides spacing with discharge belt.

Curved area

close to belt

8

AutoStreAm HV mAnuAl

Step 2:

Discharge Side Guide

Assembly and Setup

(continued)

5. Loosen the lock levers on each side guide.

6. To adjust the side guides for width, indepen-

dently adjust each side guide to within ap-

proximately 1/8” of the product positioned as it

will be received from the incline conveyor belt.

The side guides should be equidistant from the

center of the conveyor belt.

7. Tighten the locking levers.

Horizontal lock levers.

Proper horizontal side guide adjustment.

9AutoStreAm HV mAnuAl

Step 3:

Docking

Review

The autoloader and feeder are connected together by

a docking bracket, adjustable for the distance between

the feeder and the autoloader. The proper extension of

the bracket will allow the proper amount of clearance

for the product to fall, evenly and aligned, from the

autoloader discharge belt into the hopper on the feeder.

The autoloader discharge belt should be tangent to the

product stack and the returning side of the discharge

belt should slightly clear the wedge on the feeder.

Objective

Properly connect the autoloader and feeder together

using the adjustable docking bracket.

Procedure

1. Disassemble the feeder end of the docking

bracket by loosening the socket head cap

screws as shown.

2. Place docking bracket over the frame of the

feeder.

3. Tighten the socket head cap screws to secure it

in place.

4. Lock the four casters on the autoloader.

To reduce overall setup time and issues, it

is important to set up and test the feeder

before beginning setup of the autoloader.

Loosen

Docking bracket.

Docking bracket re-assembeld on feeder.

Loosen

Adjust

height

Adjust

depth

10

AutoStreAm HV mAnuAl

Step 4:

Conveyor Side Guide Setup

Review

The side guides help direct the product in a straight

line of movement along the horizontal conveyor belt.

Each side guide is independently adjustable, both

horizontally and vertically, to accommodate different

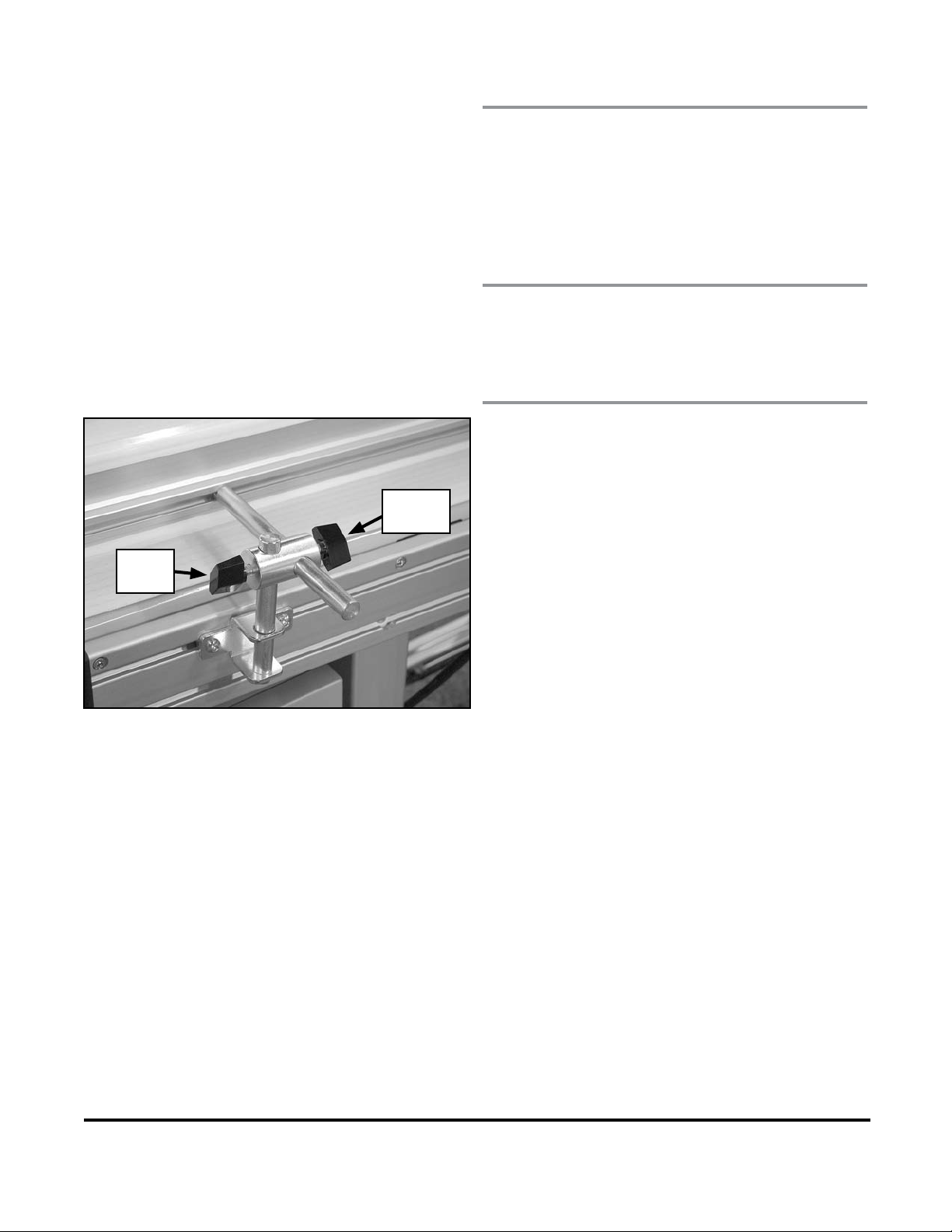

products. There are two locking knobs on each side

guide for each adjustment.

Objective

Adjust the horizontal conveyor side guides to maintain

uniformity in the loaded product with no drifting or

binding.

Procedure

1. On each horizontal conveyor side guide, loosen

the two horizontal locking kobs.

2. Move each conveyor side guide to a width

greater than the product width and equal dis-

tance from the center point of the feeder.

3. Place one piece of product on the conveyor in

the desired feeding orientation. The edges of

the product should rest equally on both sides of

the belt.

4. Move each guide as close as possible to the

sides of the product without causing binding,

curling of edges or resistance of movement. A

good starting point is 1/8” (1.6mm) from each

edge.

5. Tighten the locking knobs.

6. Loosen the two vertical locking knobs.

7. Stand the piece of product on its end on the

conveyor in the desired feeding orientation.

8. Raise or lower each side guide to support the

vertical height and weight of the product.

9. Tight the locking knobs.

Vertical

locking

knob

Horizontal

locking

knob

11 AutoStreAm HV mAnuAl

Step 5:

Separator Setup

Review

The separator shingles the product for its upward travel

on the incline conveyor belt. By moving the separator

up and down along the hold down frame, the height of

the separator is adjusted for the height of the product as

it has been loaded along the horizontal belt. To adjust

the separator for the thickness of the product, choose

one of the three slot sets. Finely adjust for the thickness

of the product by raising or lowering the gate by turning

the adjustment knob.

Objective

Adjust the separator for height and thickness of product.

Procedure

1. Loosen the locking levers on each side of the

separator.

2. Slide the separator up and down along the hold

down frame to approximately ½” above the

height of the product as it is loaded on the hori-

zontal belt.

3. Tighten the locking levers.

4. If the shingling gate is not in the desired slot set

to accommodate the product thickness, loosen

the socket head cap screws on each side.

5. Position the shingling in the desired slot set.

6. Tighten the socket head cap screws.

7. Turntheknobtoneadjusttheshinglingby

lowering it toward or raising it away from the

incline conveyor belt.

Locking levers.

12

AutoStreAm HV mAnuAl

Step 6:

Hold Down Rollers

Setup

Review

Theholddownrollersoatalongthetopsurfaceof

the shingled stream of product to help control it as it

is moved upward on the incline conveyor belt to the

discharge area. The hold down rollers can be spaced as

close as 3 inches along the hold down frame. The ideal

set up would use the least rollers necessary to manage

the product.

Objective

Set the spacing of the hold down rollers.

Procedure

1. For each hold down roller assembly, loosen the

shoulder head cap screw on each side.

2. Move each hold down roller assembly to the

desired position.

3. Tighten the shoulder head cap screws.

Adjusting hold down rollers.

Loosen

Move up

or down

13 AutoStreAm HV mAnuAl

Step 7:

Product Sensor Setup

Review

The product sensor detects when the product in the

feeder hopper is low. When detected, the autoloader

will advance to feed more product.

Objective

Properly install and adjust the autoloader product

sensor.

Procedure

1. Connect the sensor to the sensor output recep-

tacle on the external upper right side of the

control box.

2. Install the sensor mounting hardware onto the

feeder.

3. Direct the sensor at the stack of product in the

feeder hopper and adjust to the desired height.

Attach to feeder and adjust height.

Sensor

Connector

Table of contents

Other Barry-Wehmiller Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

HSM

HSM ProfiPack C400 operating instructions

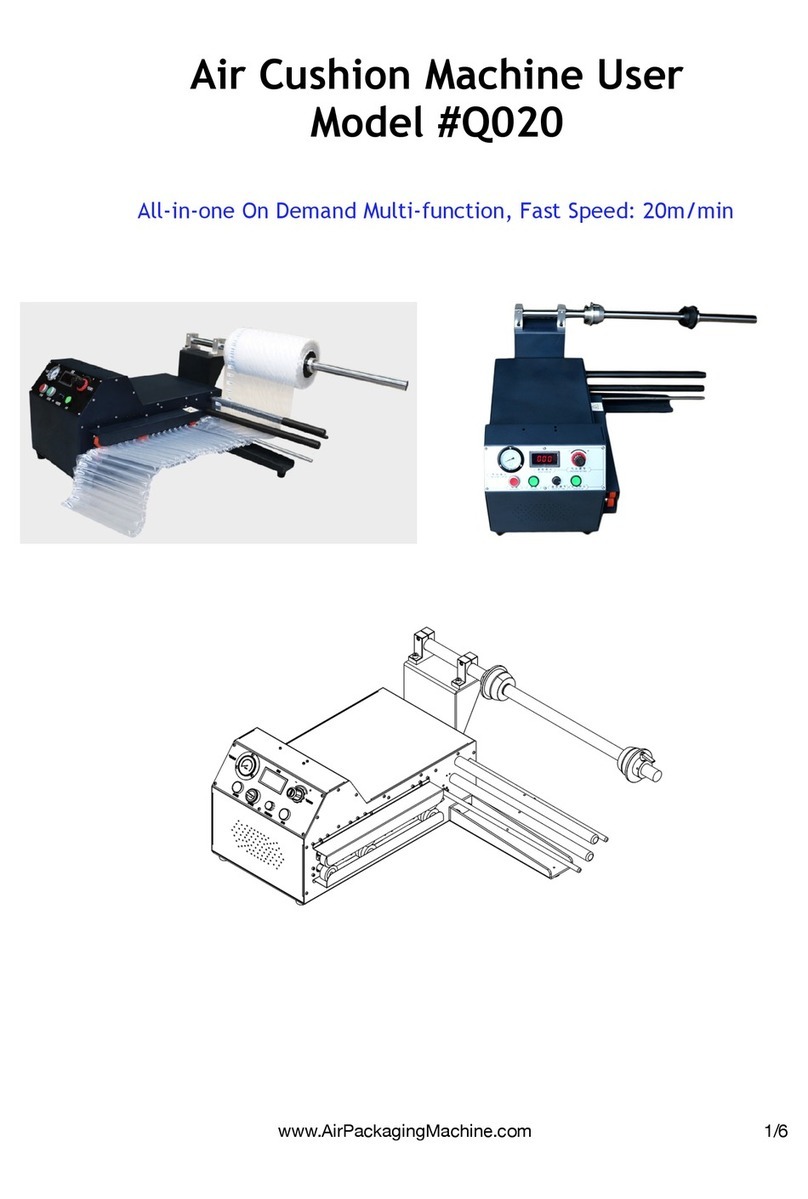

PackBest

PackBest Q020 instruction manual

AETNAGROUP

AETNAGROUP ROBOPAC ROTOPLAT Use and maintenance manual

Polychem

Polychem GP44 Operation and maintenance manual

Air Packaging Machine

Air Packaging Machine H035 manual

Francotyp-Postalia

Francotyp-Postalia FPi 5020 Operator's manual