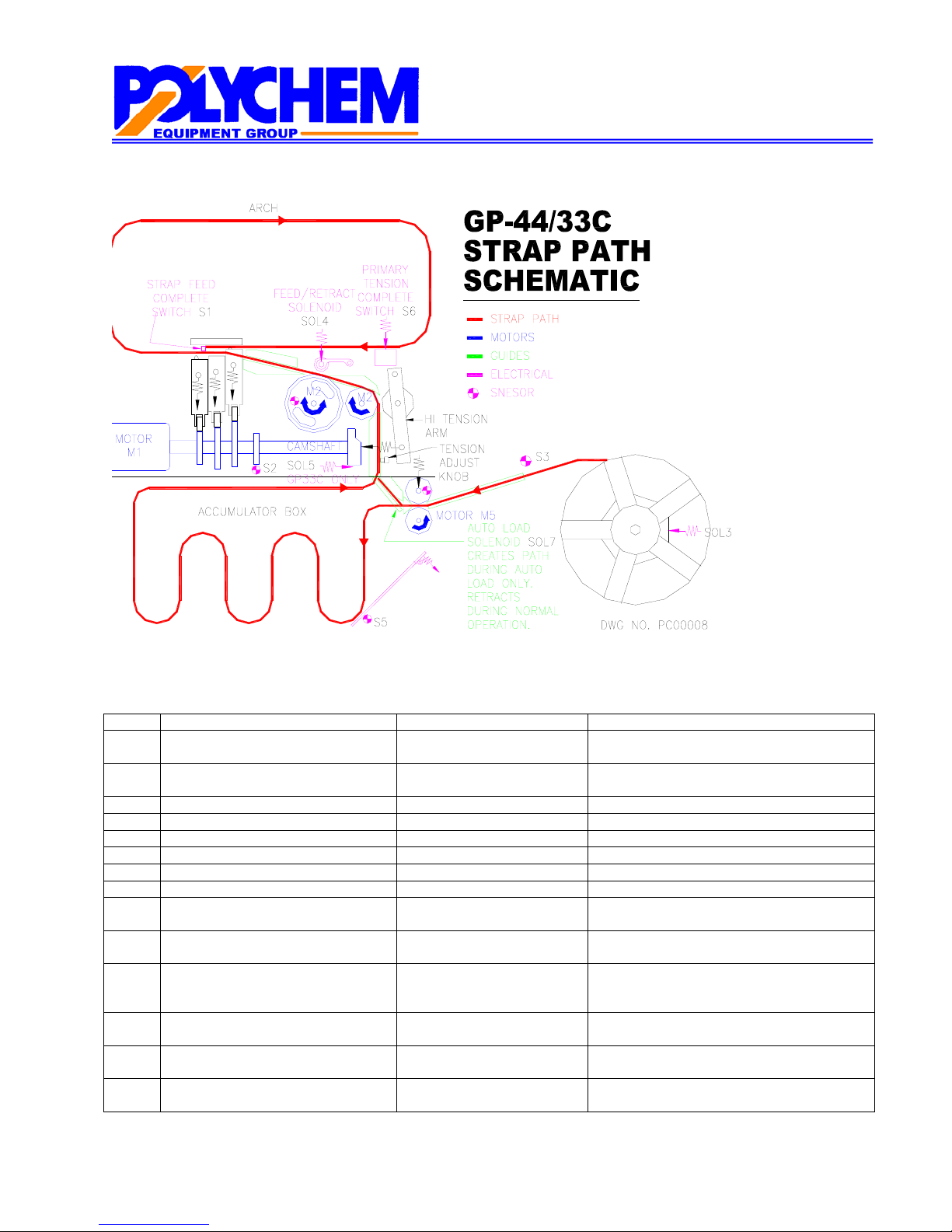

GP44 Semi-Automatic Strapping Machine

OPERATION -8-

KEY COMPONENTS (Refer to Strap Path Schematic)

Ref Description Location Function

EB1 Electric Brake Cam Motor (M1) In back of M1 Stops cam in home position, primary

tension position and final tension position.

EB2 Electric Brake Feed/Retract Motor

(M2)

In back of M2 Stops feed/retract motor when strap is not

feeding or retracting

EB3 Reel Brake On reel shaft Stops reel when not loading strap

M1 Cam Shaft Motor Under conveyor Rotates camshaft

M2 Strap Feed/Retract Motor Under conveyor Rotates feed/retract wheels

M5 Accumulator Load Motor Before accumulator box Feeds strap into the accumulator box

SA 1 Tabletop Safety Switch Side of conveyor top Verifies that the tabletop is closed

SA2 Tabletop Safety Switch Side of conveyor top Verifies that the tabletop is closed

SOL3 Real Brake Solenoid On reel shaft Provides some drag on the reel to prevent

it form “free wheeling”

SOL4 Strap Feed/Retract Solenoid Under conveyor Presses the strap against the feed/retract

wheel to feed/retract strap

SOL7 Initial Feed Solenoid Behind accumulator box Engages only during initial load to create a

path for strap to initially load into the

strapping head/arch.

S1 Strap End Detect Switch Under slide plate Detects if the end of the strap has made it

entirely around the arch

S2 Camshaft Home Proximity Switch Near camshaft Stops the cam in the home position (TR12)

and the primary tension position (TR 93).

S3 Strap Present Proximity Switch After reel Verifies that strap is present and flowing

into the accumulator box