Installation Operation Method 安装操作法

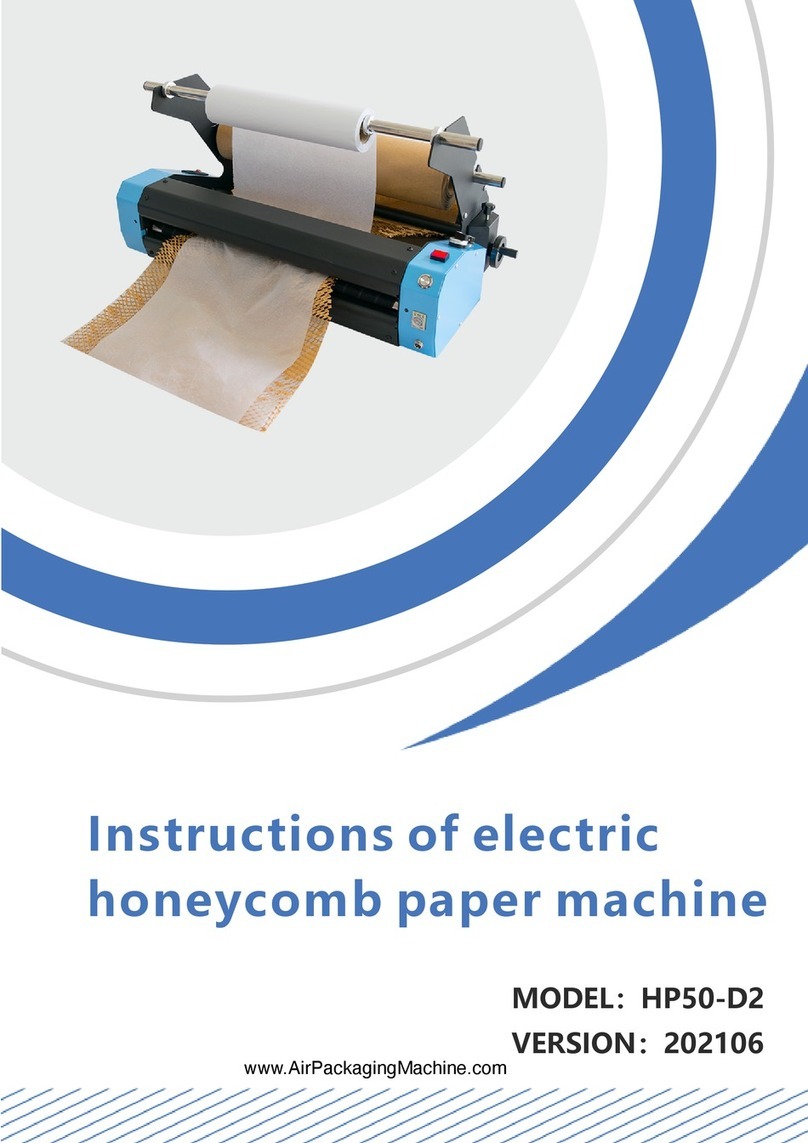

1, Install material holder, the material pole 1, the material pole 2 and material axle at the

positions shown in Photo 1(auxiliary tool: inner hexagon).

将放轴、导杆1、导杆2以及导轴分别安装于图1所示位置(辅助具:六)

2, Connect the power cord to turn on the power supply, install the film on the material

holder, pull the film through the feeding head and into the middle of the belt, press the

button of IN-Material (Green button), wait for the film to be pulled out of the machine

and press the START button to start inflating the film.

接上电源线开启电源,将膜装上放轴,膜穿过导头并拉带中间,按点动进键,

待膜拉充机外再按启动键开始吹膜。

Note:

If the power switch light is on and the LCD screen is not on, please check whether the

emergency stop switch is on.

注:若电源开关灯亮起,LCD屏亮,请检查急停开关是否打开。

Fault code diagnosis and processing 故障代码诊断及处

ERR 01:

Temperature sensor abnormal, cold start in the low-temperature state there is a probability

of false alarm, press the pause key to exit and then start. If this alarm occurs frequently

during operation or when the ambient temperature is relatively high, it indicates that the

temperature sensor has failed.

温度传感异常,在低温状态下冷启动时有概率出现误报警,按暂停键退出后再启动即可。

如果在运时或者环境温度相对较时频繁出现此报警说明温度传感已经失效。

ERR 02:

If the heating wire is over-current, in the case of this alarm, firstly check whether the high

temperature belt is damaged, whether the high-temperature adhesive tape on the surface

of the heating wire is damaged, please replace the damaged, if the above is intact, please

replace the heating wire.

加热丝过流,出现此报警先检查温带是否破损以及发热丝表的温胶布是否破损,

破损的请换,如果上述是完好的,请换发热丝。

ERR 03:

When the heating wire is disconnected, in the case of this alarm, firstly check whether the

upper and lower heating wires have been broken. If they are broken, please replace them.

If they are not broken after checking, then check whether the power supply wire

connecting the heating wire is broken. If all of the above are normal, the control panel

needs to be replaced.

加热丝断开,出现此报警先检查上下发热丝是否已断,如已断请换,若检查后发现没有

断再检查连接发热丝的供电线是否断,如上述都正常就需要换控制板。