Barry-Wehmiller BW Integrated Systems Streamfeeder V-1400IJ User manual

V-1400IJ

Inkjet Feeder

Manual

© 2018 Streamfeeder - BW Integrated Systems. All rights reserved.

No part of this publication may be reproduced, photocopied, stored on

a retrieval system, or transmitted without the express written consent of

Thiele Technologies, Inc. - Streamfeeder.

Streamfeeder - BW Integrated Systems

315 27th Avenue NE

Minneapolis, MN 55418 USA

Tel:(763) 502-0000

Fax:(763) 502-0100

e-Mail: service@streamfeeder.com

Web: www.streamfeeder.com

Printed in the USA.

i

V-1400IJ Manual

Contents

Safety Information ........................................................ii

Specications ..............................................................iv

Section 1: About the Machine .......................................................1

Section2: InstallingtheMachine ..................................................5

Section3: PreparingforOperation ............................................. 11

Section4: HowtoOperate ...........................................................17

Section5: Troubleshooting .........................................................20

Section6: InspectionandCare ...................................................22

Section7: MechanicalComponents ...........................................29

Section8: ElectricalComponents...............................................45

ii V-1400IJ Manual

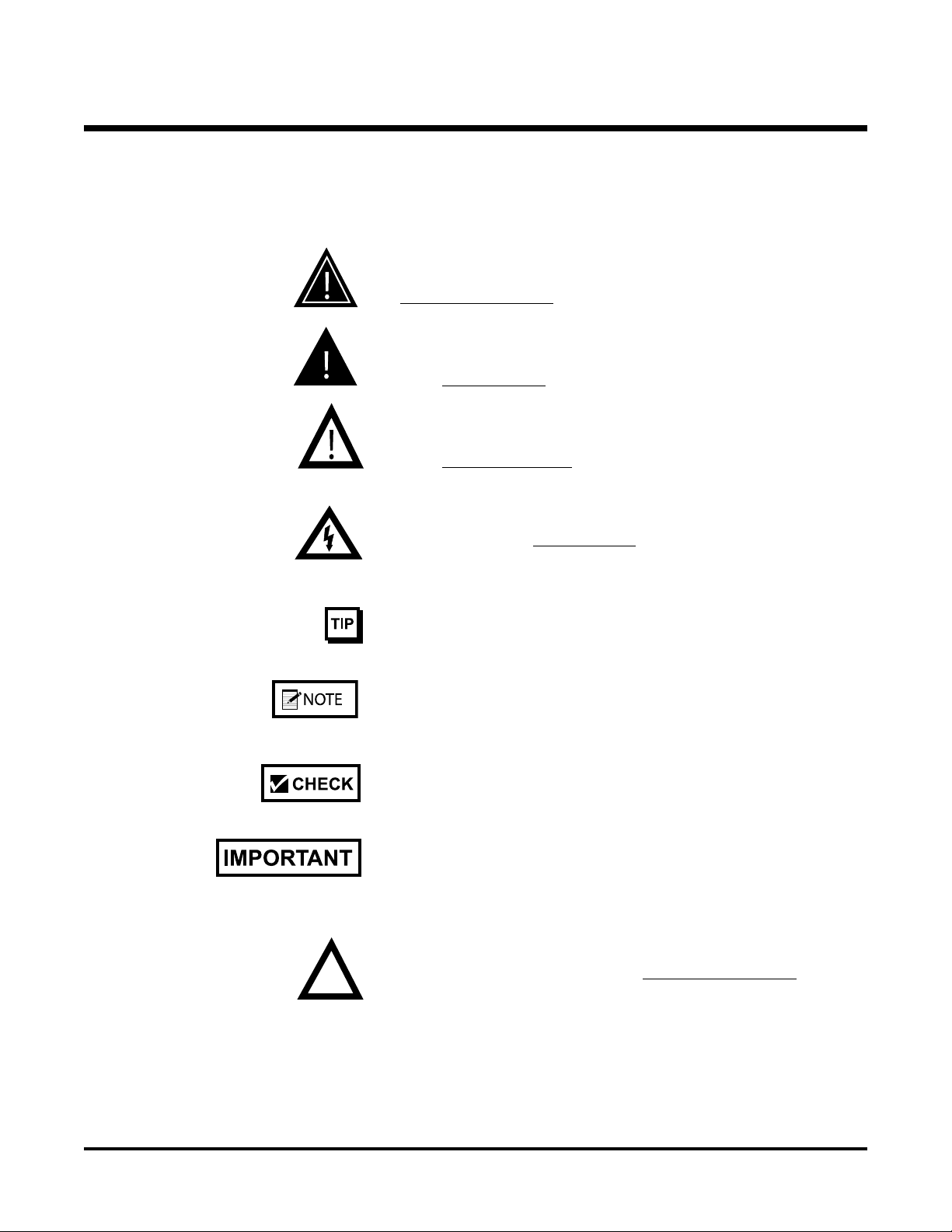

Message

Conventions

DANGER signies an action or specic equipment area that can result

in serious injury or death if proper precautions are not taken.

WARNING signies an action or specic equipment area that can

result in personal injury if proper precautions are not taken.

CAUTION signies an action or specic equipment area that can

result in equipment damage if proper precautions are not taken.

ELECTRICAL DANGER signies an action or specic equipment

area that can result in personal injury or death from an electrical haz-

ard if proper precautions are not taken.

TIP signies information that is provided to help minimize problems

in the installation or operation of the feeder.

NOTE provides useful additional information that the installer or

operator should be aware of to perform a certain task.

CHECK signies an action that should be reviewed by the operator

before proceeding.

IMPORTANT alerts the installer or operator to actions that can poten-

tially lead to problems or equipment damage if instructions are not

followed properly.

WARNING LABELS afxed to this product signify an action or spe-

cic equipment area that can result in serious injury or death if proper

precautions are not taken.

Before You Begin

iii

V-1400IJ Manual

Message

Conventions

Before You Begin

Avoid injury. Do not reach around guards.

Hazardous voltage. Contact will cause electric shock or burn. Turn off

and lock out power before servicing.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

Pinch point. Keep hands and ngers clear.

Moving parts can crush and cut. Keep guards in place. Lock out power

before servicing.

iv V-1400IJ Manual

Maximum Product Size: ...................... 14 W x 18 L in (355 x 457 mm)

Minimum Product Size: ...................... 2 W x 3 L in (51 x 76.2 mm)

Min/Max Product Thickness: ............. .003 -1.0 in (.07 - 25.4 mm)

Belt Speed: ............................................. 7800 in/min (19,812 cm/min)

Drive: ...................................................... DC motor

Electrical Requirements: ...................... 115/230vac, 50/60Hz, 3A

Multiple Voltage Interface Relay: ........ 24vac, 115vac, 5vdc, 12vdc, 24vdc

Weight: ................................................... 47 lbs. (21.3 kg)

speCifiCations

v

V-1400IJ Manual

Make sure you thoroughly read this section to become familiar with

all the safety issues relating to the safe operation of this product.

Thiele Technologies - Streamfeeder hereby declares that this product

is in conformance with the following standards:

Machinery Directive 98/37/EC

Low Voltage Directive IEC/EN/CSA/UL 60950

Emissions - EN55014-1

Immunity - EN55014-2

The technical file for these products is maintained at the corporate

headquarters of Thiele Technologies - Streamfeeder in Minneapolis,

Minnesota USA.

Ce CertifiCation

1V-1400IJ Manual

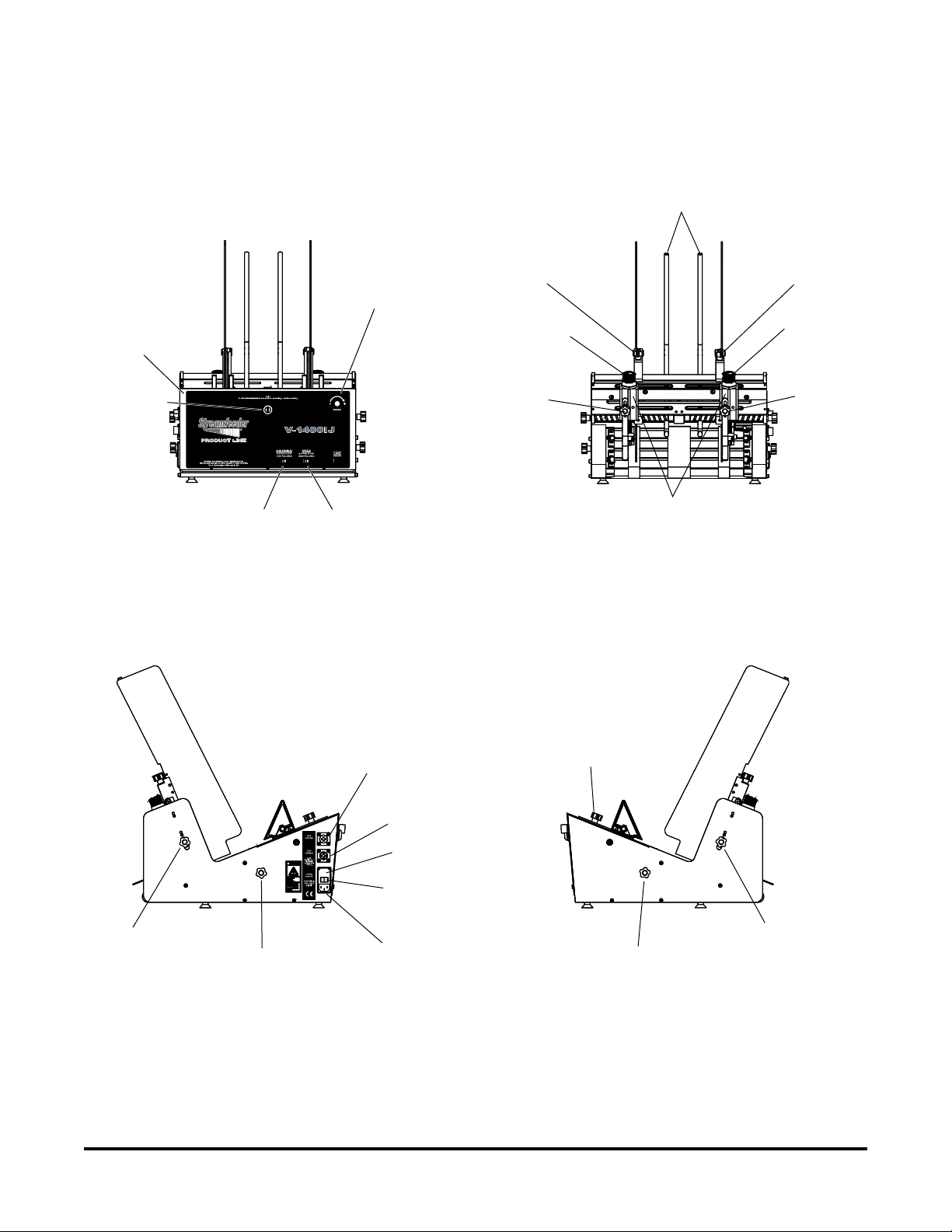

Gate

Gate

Table Top/Shell

Wedge

Carriage

Hinged Panel

(Controls Access)

Side Guides

Adjustable

Product

Support Rods

1About the Machine

The V-1400IJ is designed for reliability, exibility, and ease of use

with a variety of vacuum and non-vacuum bases.

All parts required for setup, loading, feeding, and easy operator con-

trol are combined into one compact unit.

Review the main assemblies below to become familiar with names

and locations of feeder parts and adjustments. This will help to prepare

you for initial setup.

Features

Main Assemblies

2

V-1400IJ Manual

Main Assemblies Feature Descriptions

Feature Description

Side guides Single knob adjust (one on each side) allows lateral adjustment from each

side for different size product.

Side guide adjustments Dual-knob design allows you to move side guides together or apart for

different size product. Can be positioned equally or offset. (Note: Single-

knob design also available.)

Gates and adjustments Single or double gates mounted above the carriage housing the feed belts.

This device provides a curvature to help preshingle stacked product.

When properly adjusted, a clearance is created to help singulate and feed

product.

Adjustable Product Support Rods Rods can be adjusted laterally for support of wider products.

Wedge and adjustments Lifts the product to keep it off the table top, reduces excessive contact with

the feed belts, and helps push the product against the curvature of the

gate assembly. To achieve proper lift, adjustment wing-nuts and locking

levers allow you to slide the wedge to various positions and angles.

Shell One piece shell for mounting of all sub-assemblies and components.

Easy access to controls Located in rear of feeder. Allows for easy assembly and servicing of

control and other electronic components.

Removable carriage Houses the feed belts which provides the friction and motion necessary to

pull individual product from the bottom of the stack and through the gate

assembly. Easy to remove for feed belt replacement.

Lateral feed belt positioning Single knob adjust (one on each side) allows for two outside belts to be

adjusted laterally depending on product size and feeding characteristics.

3V-1400IJ Manual

Control Features

Run Status

Connector

AC Power Cordset

Connector

Run Enable

Connector

Fuse Holder

Power On/Off

Switch

Gate

Adjust Knob

Gate

Adjust Knob

Side Guide

Lock Knob Side Guide

Lock Knob

Gate

Lock Knob

Gate

Lock Knob

Belt Adjustment

Knob

Side Guide

Adjustment

Knob Belt Adjustment

Knob

Side Guide

Adjustment

Knob

Gates

Wedge

Adjustment

Knob

Pre-gate Bars

Variable

Speed

Control

Speed

Switch

Run Enable

Switch

Panel

Open/Close

Latch

On Delay

Adjust

(inside panel

on circuit

board)

4

V-1400IJ Manual

Control Features Descriptions

On Delay Adjustment

Feature Description

Variable speed control This dial switch (labeled Speed) allows the feeder speed to be

synchronized with a vacuum or non-vacuum base. Turning counter-

clockwise decreases speed; clockwise increases speed. Note: Feeder

motor stops if turned completely counter-clockwise.

Run Enable switch This slide switch allows you to use the feeder “stand- alone” or with the

run enable input interface.

Speed switch This slide switch allows you to

AC power cordset connector Cordset plugs into this connector to provide feeder with power from a

grounded and fused outlet.

Power On/Off Toggles AC power On or Off.

Fuse holder Contains two replaceable 5-Amp, 5x20 mm time delay fuses.

IMPORTANT: Always make sure power module is replaced exactly as

removed so that “115” is always visible on 115V models and "230" is

always visible on 230V models. Failure to follow this caution can result in

damaged electrical parts.

Run Status connector An interface available for host systems. Provides feedback to host system

whether the feeder is running or not.

Run Enable connector This 4-pin connector is used to carry start/stop signals from a vacuum or

non-vacuum base to the feeder.

On delay adjust Located on circuit board on inside of panel. See photo below.

Used to delay (or synchronize) feeder startup with base startup. Range is

adjustable from 0 to 12 seconds (factory set at 0 seconds).

5V-1400IJ Manual

When performing initial installation, always make sure you turn Off the main power switch and disconnect all equipment from the electrical

power source. Failure to do so can expose you to a potential startup and moving parts which can cause serious injury.

Do not attempt feeder installation while the feeder and machine of application are running. Failure to do so can expose you to moving parts which

can cause serious injury. Do not wear loose clothing when operating the feeder.

Avoid turning on the feeder or making initial adjustments until all parts are secured. Failure to do so can cause damage to equipment.

This section provides information on installing the V-1400IJ onto a

vacuum or non-vacuum transport base.

Information for a particular application typically includes procedures

for basic parts removal, feeder mounting and alignment, and cable

connections for power and control interface. Information that relates

to specic adjustments you must make to feeder prior to startup and

operation is found in Section 3, “Preparing for Operation.”

2Installing the Machine

Vacuum Base

Installation for

Shuttle Feed Bases

Installation of the V-1400IJ onto various types of vacuum and non-

vacuum bases is a relatively simple procedure. Several minor modi-

cations to the vacuum base are required prior to mounting, wiring, and

aligning the feeder.

To install the feeder onto a shuttle feeder vacuum base, perform the

following steps:

1: Repositioning front side guides

2: Removing back jogging plate/back hopper guide

3: Raising hopping rollers

4: Disabling the shuttle

5: Initial positioning of feeder

6: Providing AC power to feeder

7: Connecting run enable input

8: Checking product discharge from feeder

Included with your V-1400IJ 230V feeder is an Allen Wrench Set (P/N 23511CC1). These tools are designated for Service Personnel only.

6

V-1400IJ Manual

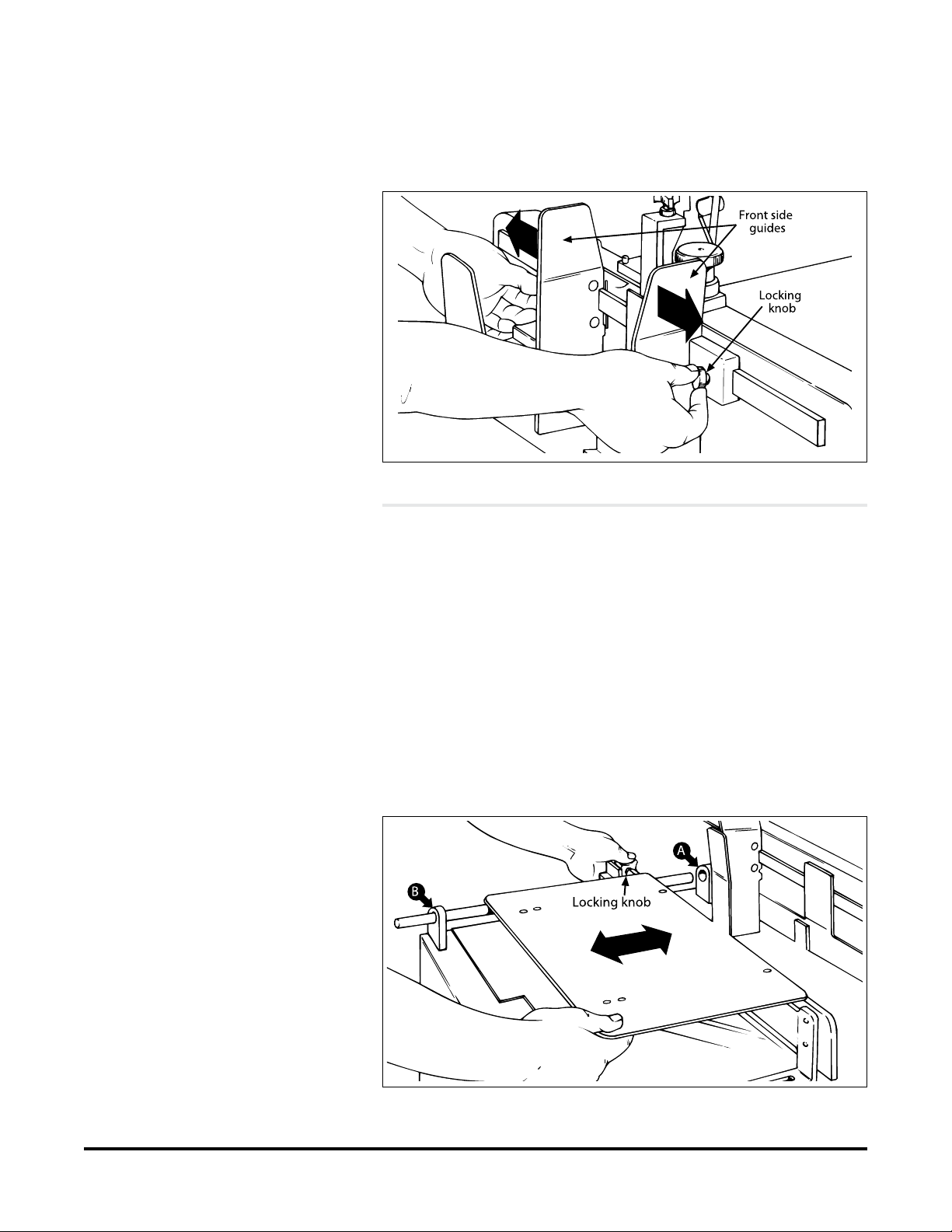

1. Loosen locking knobs at both side guides.

2. Slide each side guide to the outermost position. Do not lock in

place.

STEP 2:

Removing Back Jogging

Plate/Back Hopper Guide

STEP 1:

Repositioning Front

Side Guides

Front Side Guides Being Repositioned

1. Loosen each of the setscrews at the two shaft housing assem-

blies A and B.

2. Slide shaft end closest to the vacuum base gate out of housing

A (with jogging plate/hopper guides still attached). Slide shaft

back far enough on housing B to allow removal of jogging

plate/hopper guides.

3. Loosen locking knob and slide jogging plate/back hopper

guide off of shaft and away from the surface of the vacuum

base.

4. Return shaft end to housing B. Lock setscrews in both housing

assemblies.

Back Jogging Plate/Back Hopper Guide Removal

7V-1400IJ Manual

1. Locate the gate adjustment knobs and turn completely in a

clockwise direction to raise hopping rollers.

2. Then, locate the vertical adjustment lever on the hopping roll-

ers assembly and push down all the way. This will raise the

feed rollers to highest vertical position possible, thus making

for maximum clearance.

STEP 3:

Raising Hopping Rollers

If additional control of material is required

during feeding, you may choose to keep the base’s

hopping roller assembly in the down (or normal)

position.

1. Remove side access panel from vacuum base enclosure.

2. Locate the reciprocating arm and reciprocating block directly

beneath the underside of shuttle.

3. Using a box wrench, remove the hex-head rod end bearing

bolt holding the reciprocating arm to the reciprocating block.

4. Once the bearing bolt is removed, the reciprocating arm is ef-

fectively disconnected. As the shaft is connected to the shuttle

base plate on the other end, simply allow the shaft to hang

in-position, with no further disassembly.

5. Make sure the base plate of shuttle is all the way forward

(toward the vacuum base gate).

Using the Adjustments to Raise Hopping Rollers

STEP 4:

Disabling the Shuttle

To prevent any accidental startup of shuttle

motor and to eliminate the hazard of moving

parts, you can prevent accidental startup by

either disconnecting vacuum base from AC

power at the outlet, or you can remove the

internal AC power fuse (located behind the

access door of the vacuum base).

Disabling the Shuttle from Inside the Access Panel

8

V-1400IJ Manual

1. Lift the feeder onto the top plate of the vacuum base and slide

forward toward the vacuum base gate.

2. Center the feeder between the two side guides as you posi-

tion the feeder fully forward. To verify centering, sight down

the center of the feeder gate, making sure it is in-line with the

vacuum base gate.

3. Trap the feeder in-between the vacuum base side guides by

sliding each in toward the side plates of the feeder until they

gently touch. Tighten side guide knobs to secure in position.

STEP 5:

Initial Positioning

of Feeder

1. Connect IEC320 end of power cord to the feeder (at the power

inlet module).

2. Connect three-prong end to nearest AC voltage power source.

Positioning the Feeder on the Vacuum Base

STEP 6:

Providing AC Power

to Feeder

Please verify that the voltage shown at the power

inlet module matches the incoming voltage from

the power source.

9V-1400IJ Manual

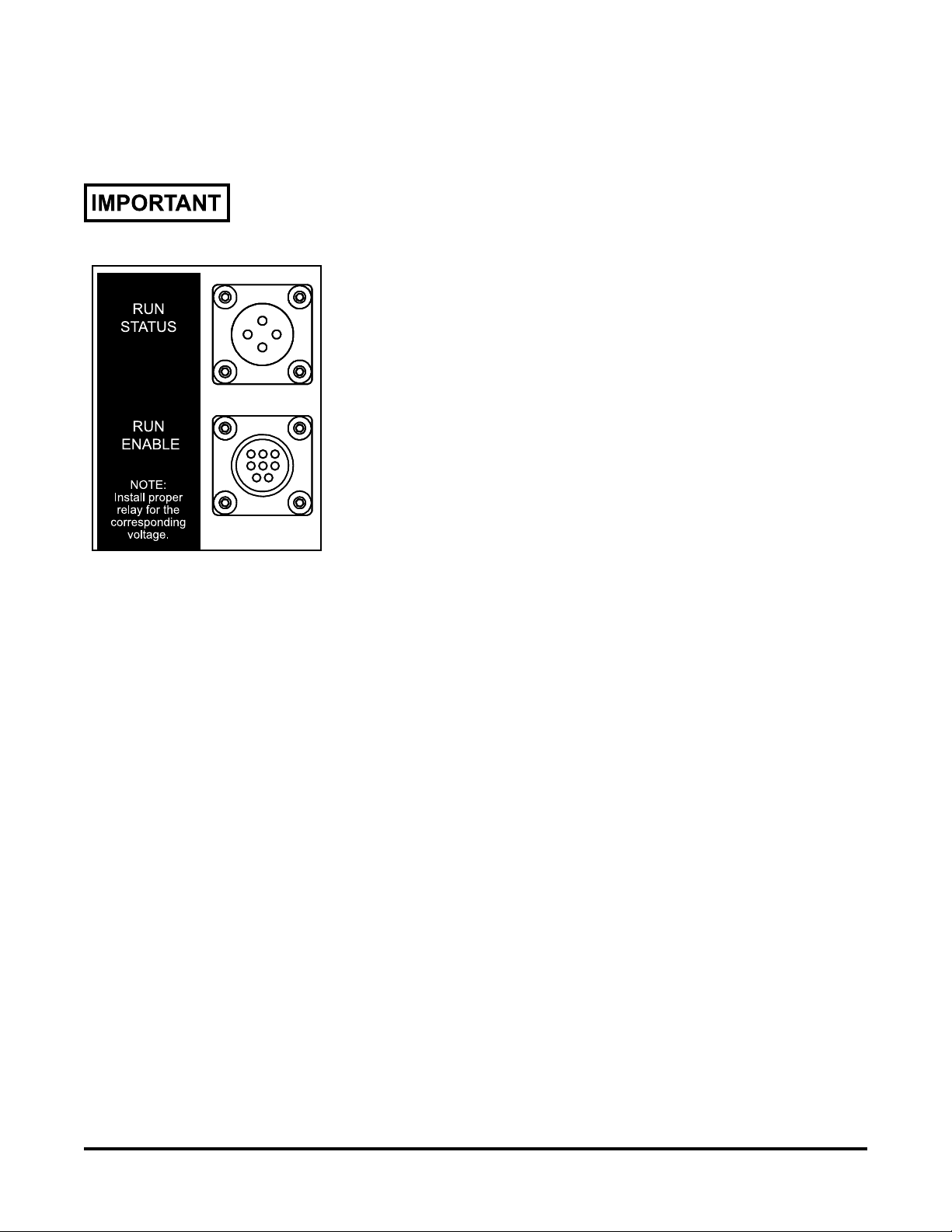

Using the run enable cables supplied for host interface applications:

Dry Contact Run Enable

1. Ensure power is not applied and power cord is disconnected

from feeder.

2. Connect the run enable cable to the top male eight-pin thread-

ed connector on the feeder.

3. At the host equipment, locate start/stop control circuit.

4. Route run enable input cable from the feeder to the host sys-

tem.

5. Interface the leads of the interface cable to the host start/stop

circuit.

6. Connect power cord to feeder.

AC/DC Run Enable

1. Ensure power is not applied and power cord is disconnected

from feeder.

2. Connect the run enable cable to the bottom female eight pin

threaded connector on the feeder.

3. At the host equipment, locate start/stop control circuit.

4. Determine the exact run input voltage required by checking

host start/stop control circuit.

5. Interface the leads of the interface cable to the host start/stop

circuit.

6. The appropriate coil relay must be installed into the feeder. To

do this, carefully open panel door.

7. Locate K1 relay slot on the control board and insert the appro-

priate relay from the supplied kit (P/N 311-0090). Close panel

door on the feeder. (See electrical diagram).

8. Connect power cord to feeder. As product leaves the feeder

gate cylinder, the trailing edge must be under the hold-down

as the leading edge is entering the vacuum base transfer sec-

tion. In otherwords, there must be a good transfer of product

from the feeder hold-down to the vacuum base transfer sec-

tion.

Run Status Signal

This is a congurable dry contact used to monitor the feeder’s

status.

The host equipment will connect to the green wire and the red

wire, which are located in both run enable cable sets.

STEP 7:

Connecting

Run Enable Input

This procedure should be performed only by a

qualied technician.

Run Status/Enable Connectors

10

V-1400IJ Manual

To verify:

1. Slide feeder back far enough to clear the vacuum base side

guides. If necessary, loosen the knobs on both side guides and

pull to the outside slightly to allow movement of the feeder.

2. Insert a piece of product under the hold-down in such a way

that approximately 2/3 of the leading edge is extending out

beyond the feeder (Figure 2-7).

3. Slide feeder back into position, making sure it is again cen-

tered between the side guides. As you do so, also make sure

that the leading edge of the product moves into the transfer

section of the vacuum base unobstructed.

STEP 8:

Checking Product

Discharge from Feeder

Make sure rollers on vacuum base are raised in

the highest vertical position so that it does not

interfere with the product.

Checking for Proper Product Discharge from Feeder to Vacuum Base

4. Check to make sure the product is still under the hold-down

roller bearings and also resting on the vacuum base transfer

section.

5. Trap the feeder in-between the side guides until they gently

touch. Tighten side guide knobs.

11 V-1400IJ Manual

3Preparing for Operation

When performing initial feeder adjustments prior to operation, always make sure you turn Off the main power switch and

disconnect all equipment from the electrical power source. Failure to do so can expose you to a potential startup and moving parts

which can cause serious injury.

Do not attempt to make any adjustments while the feeder and machine of application are running. Failure to do so can expose you

to moving parts which can cause serious injury. Do not wear loose clothing when operating the feeder.

Avoid making adjustments with loose or unsecured parts. This can potentially damage parts.

Once the V-1400IJ is installed on your host system, you are then ready

to prepare the machine for operation. To do so, perform the following

steps:

1: Lateral feed belt adjustment

2: Gate/knockdown adjustment

3: Side guide setting

4: Back wedge adjustment

5: Verifying proper installation

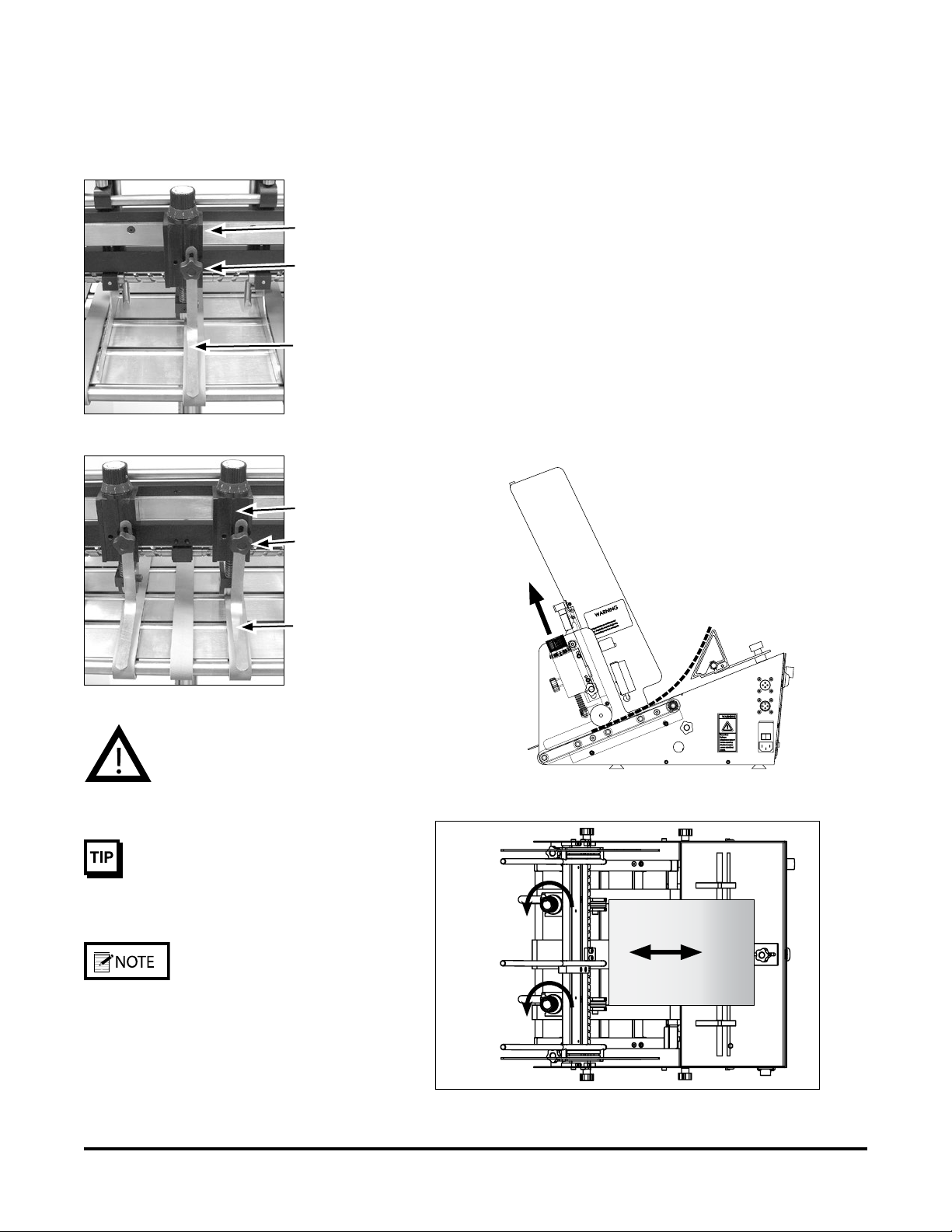

STEP 1:

Lateral Feed Belt

Adjustment

Smaller size product may use only the middle belt where as larger

product will likely use the two outside feed belts. The middle feed

belt is stationary and has no lateral adjustment. Since this belt is

located exactly in the center, it should be used as reference for the bal-

ance of the feed belt set-up. If the outside belts are used, they should

be positioned towards the outside edge of the product for the benet of

drive and support. They are adjusted using the knobs located on each

side of the feeder.

Belt adjustment knob

12

V-1400IJ Manual

Excessive lowering of the gate assembly can damage product or lead

to premature wear of the O-rings or feed belts.

A wider gap between product and belt provides

the highest tolerance for curled and bent edges.

Lift gate assembly upward to insert product

Feeding problems will occur with either too much

product in the hopper, or too large a gap between

the gate assembly and the product.

When feeding product with varying thickness,

it may be necessary to adjust the two gates

individually for the different thicknesses. Use one piece thickness to set gap

Slip product under

gate

Pull knob up

Move product back

and forth

Test for slight

drag

Turn knob

counterclock-

wise to lower

(or decrease

gap)

STEP 2:

Gate/Knockdown

Adjustment

Decide whether one or two gates will be needed. This is usually based

on the material size and the function of separating. They can be placed

either over the belts or over the void between belts.

1. Position the gate (either over the middle feed belt or the void

between the belts) and position the knockdown approximately

1/16" above product (or a gap which allows unimpeded feeding).

Tighten the lock knob.

2. Slide a single piece of product between the feed belt and the gate.

3. Rotate the gate adjustment knob either up or down until the

product can be pulled from under the gate assembly with a slight

amount of drag.

4. Repeat the drag tests and adjust as needed to achieve acceptable

clearance.

5. When using two gates, position each gate and repeat steps 1

through 4.

Single gate over the middle belt

Gate

Gate

Lock knob

Lock knob

Knockdown

Knockdown

Two gates over the outer belts

13 V-1400IJ Manual

STEP 3A:

Side Guide Adjustment

1. Loosen each side guide lock knob. This will allow you to move

each side guide individually from side to side.

2. Each guide is attached by a pin and slot mechanism allowing the

guide to adjust vertically approximately ½ inch. To move over

a feed belt, lift the side guide and move it laterally. After it has

passed over the belts, push the side guide down in the slot.

Side guide in down position

Side guide in up position

Center

product

on

middle

belt

Loosen

lock knob

Lift side

guides

Move side guides laterally over belts

Lift side

guides

Loosen

lock knob

Position

side

guides

3. Center the product to be run on the middle belt and position

both side guides close to the edge of the product (approximately

1/16th inch) by turning the side guide adjustment knobs.

4. Place a handful of pre-shingled product in the hopper and against

the gate(s).

5. Test run to assure proper feeding and singulation.

6. Tighten the side guide lock knobs to secure the position.

Table of contents

Other Barry-Wehmiller Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

Signode

Signode BXT3-13 Service manual

EDM Product

EDM Product 07586 instruction manual

Polychem

Polychem PHT801 Operation manual and spare parts list

quadient

quadient LAN installation guide

Lacor

Lacor EXTREME 69355 Instructions for use and maintenance

Pro Mach

Pro Mach Wexxar BEL Series Operation & service manual

Genesis

Genesis TP-501 Operation manual and spare parts list

Polychem

Polychem SP3100 Operation manual and spare parts list

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

Oliver

Oliver 1808-D User's operation

hawo

hawo hd 680 DE instruction manual

strapex

strapex STR 66 operating instructions