1. 소개.........................................................................................................................................................................................................................4

1. INTRODUCTION....................................................................................................................................................................................................4

1.1 범위 ...............................................................................................................................................................................................................................................................4

1.1 Scope............................................................................................................................................................................................................................................................4

1.2 일반경고 ........................................................................................................................................................................................................................................................4

1.2 General warnings...........................................................................................................................................................................................................................................4

1.3 보증 ...............................................................................................................................................................................................................................................................5

1.3 Guarantee......................................................................................................................................................................................................................................................5

2. 식별.........................................................................................................................................................................................................................5

2. IDENTIFICATION...................................................................................................................................................................................................5

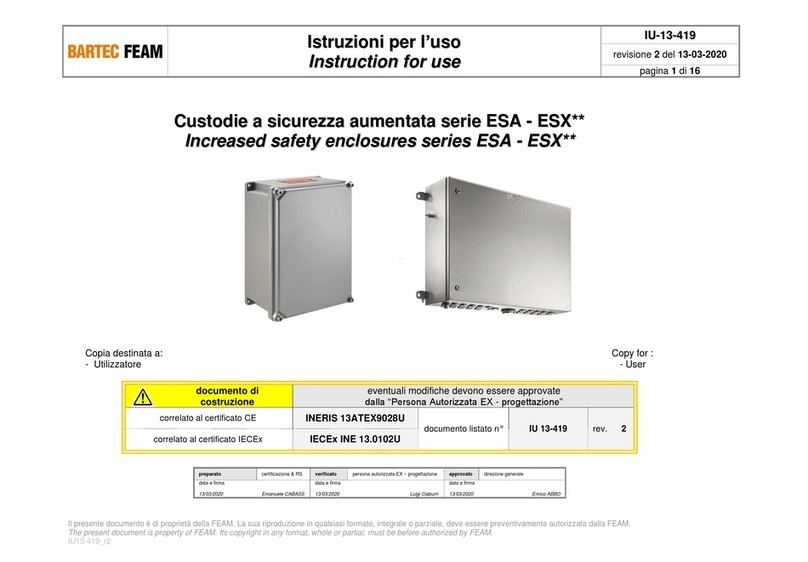

2.1 제품브랜드및형식지정 ...................................................................................................................................................................................................................................5

2.1 Product brand and type designation...............................................................................................................................................................................................................5

2.2 제조업체이름및주소.......................................................................................................................................................................................................................................5

2.2 Producer name and address..........................................................................................................................................................................................................................5

3. 제품사양 .................................................................................................................................................................................................................5

3. SPECIFICATION OF THE PRODUCT...................................................................................................................................................................5

3.1Norme di riferimento......................................................................................................................................................................................................................................5

3.1 Standards......................................................................................................................................................................................................................................................5

3.2 유지보수및설치..............................................................................................................................................................................................................................................6

3.2 Maintenance and installation..........................................................................................................................................................................................................................6

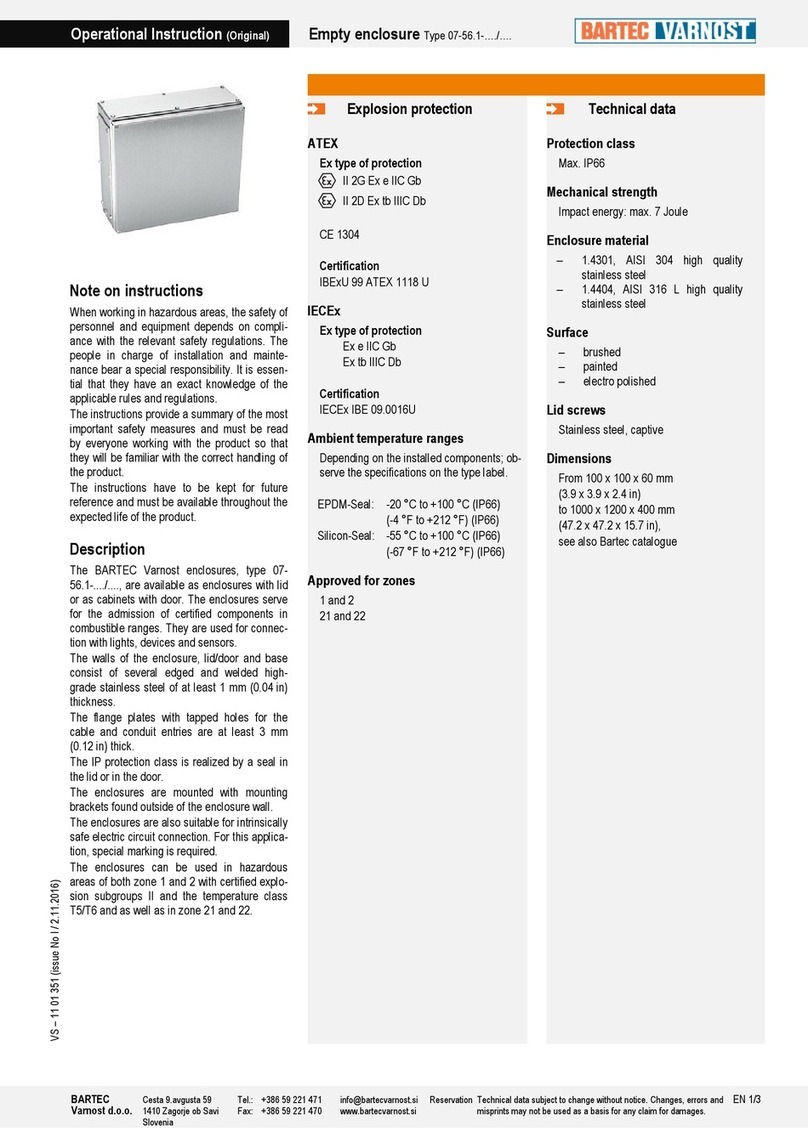

3.3 일반기능, 적용범위및용도..............................................................................................................................................................................................................................6

3.3 General functions and range of applications, intended use ............................................................................................................................................................................6

3.4 케이블진입구멍및부속품장착 ........................................................................................................................................................................................................................8

3.4 Cable entry holes and mounting of accessories.............................................................................................................................................................................................8

3.5 나사가공 ........................................................................................................................................................................................................................................................9

3.5 Threading ......................................................................................................................................................................................................................................................9

3.6 중요한참고사항............................................................................................................................................................................................................................................10

3.6 Important notes............................................................................................................................................................................................................................................10

3.7 빈인클로저의치수및중량 (운송용)................................................................................................................................................................................................................12

3.7 Dimensions and weight enclosures empty (for transport purpose) ...............................................................................................................................................................12

3.8 기술데이터...................................................................................................................................................................................................................................................12

3.8 Technical data.............................................................................................................................................................................................................................................12

3.9 전기적특성...................................................................................................................................................................................................................................................12

3.9 Electrical characteristics ..............................................................................................................................................................................................................................12

3.10 IP 코드, 평문................................................................................................................................................................................................................................................13

3.10 IP code, clear text........................................................................................................................................................................................................................................13