Scope :

USER MANUAL

DE8-BC Ex d Empty Enclosure

Date:

02.04.2022

Ver.:

3

QA Code:

5

Checked by:

E.T.

Approved by:

S.Gr.

Page:

4 of 8

Document no. :

21469

The passing on and copying of this document and the use or communication of it’s contents are forbidden without express authority.

Offenders are liable to payment of damages. All rights are reserved in the event of the registration of a patent .

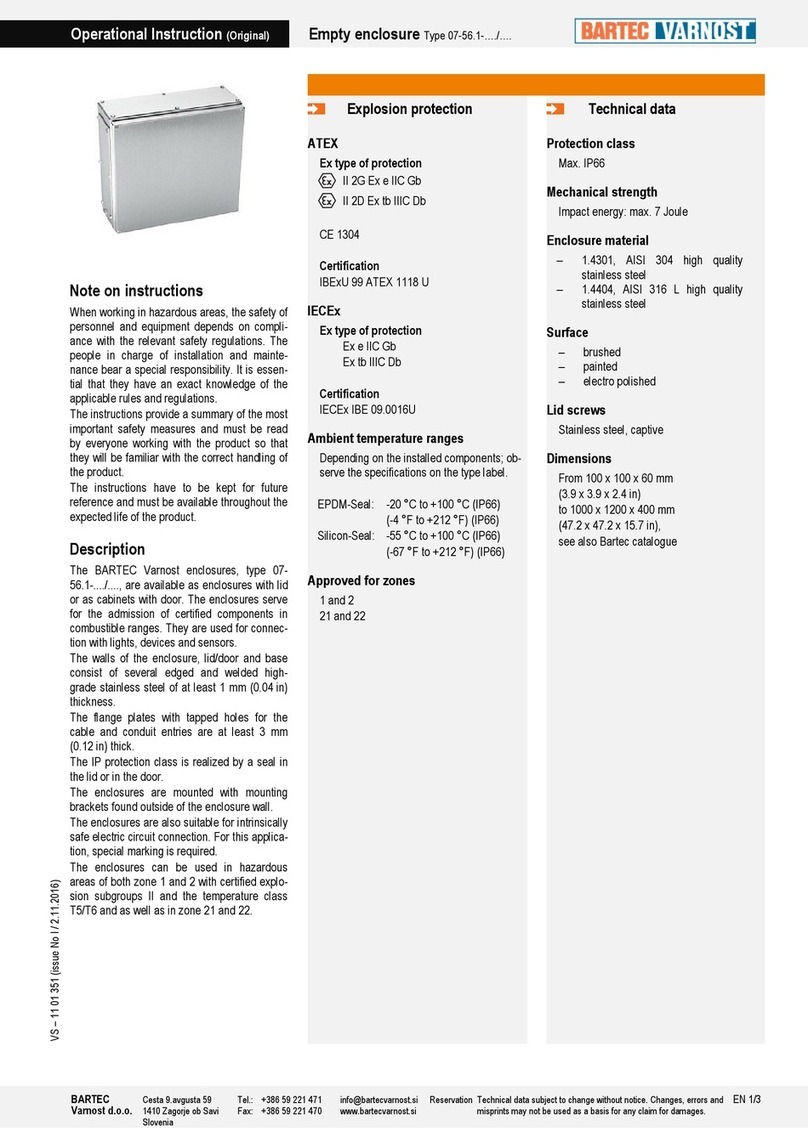

•A defective or abnormal use as well as the non compliance with the instructions of the

present document exclude any clause of guarantee and do not engage our

responsibility

•The use of the device in case of excessive deposits of dusts superior at 50mm

according to EN / IEC 60079-31 is not authorized

•Liability for manufacturer traceability is ensured only at the first known delivery

destination (serial number specified on the certification label)

•It is also required to observe the regulations of the country of use

•The doors of the DE8-BC enclosures are relatively heavy, to avoid sagging of the

doors, potentially making the door not align with the flange of the enclosure, the doors

shall be closed and secured during any moving and shfting of the enclosures. It is

also strongly advisable to close and secure the doors when the daily working shift is

over

•The flame paths of the doors and of the flanges of the enclosures must be well

protected whilst work is performed and ongoing inside the enclosures

Transport, storage

•Check it the product has been damaged during transport. If any damage is observed,

do the statutory reserves to the carrier

•Do not put damaged products into service

Open In a covered location, clean (without contact with

external substances) and closed with temperature a

constant humidity (-40°C < T < +70°C). Shielded from

important temperature variations

2 years and more with regular inspection (cleanliness

and mechanical damage)

Before starting

•Make sure the unit has been correctly settled and not damaged

•The device may include any foreign body and no part is damaged

•The cable gland(s) must be tightened (see description of the gland torque)

Maintenance

The maintenance and repairs works on devices must be made only by authorized and

trained persons for that purpose.

Before any work the devices must be switched off. In addition:

•Prevent and avoid any formation of layers of dusts: make a periodic cleaning with a

wet cloth

•Do not take apart the command and control units (push buttons, pilot light, etc.)

It is adviseable that the following checks must be made at least once a year:

•The external equipment and surfaces must not be damaged

•The cable entry devices and blanking plugs must be securely fastened

•Prior to closing, check the cleanliness of the flame path (machined part of the cover in

contact with the machined part of the box). Grease these 2 parts with a thin layer of

grease resistant to oxidation (acid free white Vaseline or Gleitmo 165).

Check the gasket for any damage. Replace if damaged. Grease the gasket using acid

free Vaseline.

•

Screw the cover on the box using the original bolts as listed in the table below.

Ensure that the bolts are clean and are greased (grease like Gleitmo 165). Ensure

that all the bolts are fitted. Torque all bolts to the correct torque as listed in the table