Operational Instruction (Original) / EN2Empty enclosure Type 07-56.1-…./…. Type 07-55.1-..../.... 3

Note on instructions

When working in hazardous areas, the safety of personnel

and equipment depends on compliance with the relevant

safety regulations. The people in charge of installation and

maintenance bear a special responsibility. It is essential that

they have an exact knowledge of the applicable rules and

regulations.

The instructions provide a summary of the most important

safety measures and must be read by everyone working with the

product so that they will be familiar with the correct handling of

the product.

The instructions have to be kept for future reference and must

be available throughout the expected life of the product.

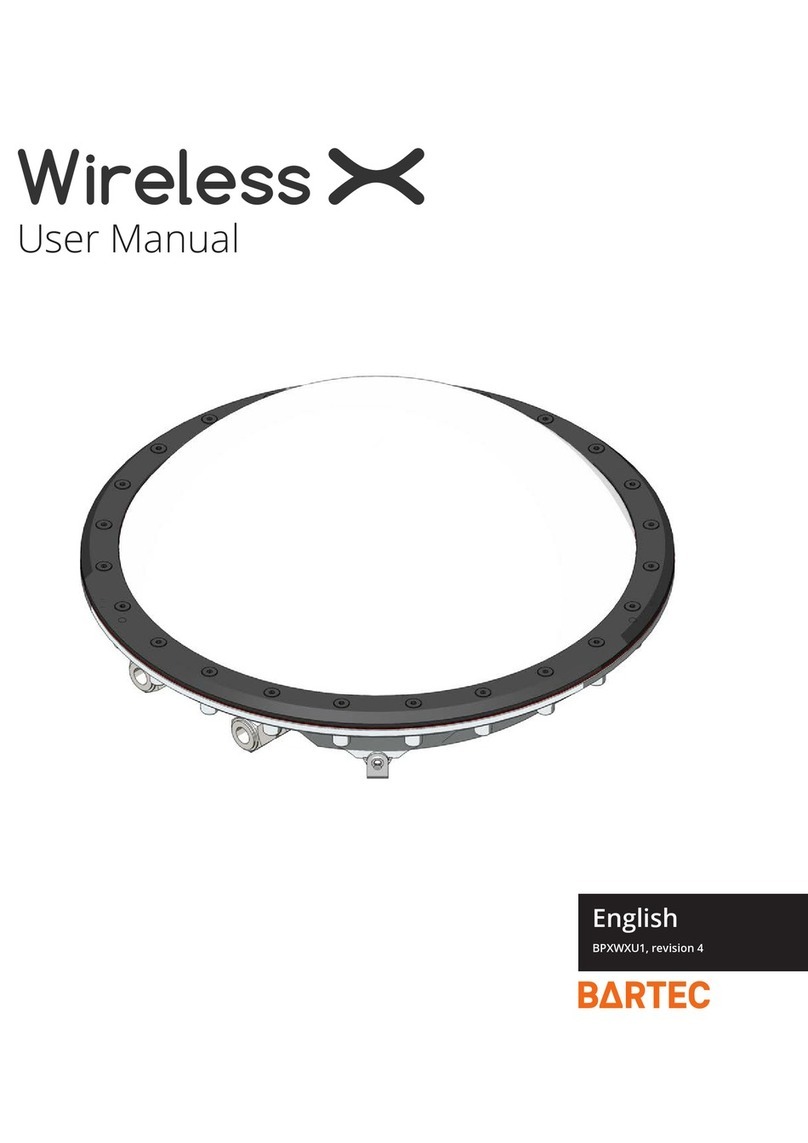

Description

The BARTEC Varnost enclosures, type 07-56.1-…./…. and

type 07-55.1-…./…., are available as enclosures with lid or as

cabinets with door. The enclosures serve for the admission of

certified components in combustible ranges. They are used for

connection with lights, devices and sensors.

The walls of the enclosure, lid/door and base consist of several

edged and welded high-grade stainless steel of at least 1 mm

(0.04 in) thickness.

The flange plates with tapped holes for the cable and conduit

entries are at least 3 mm (0.12 in) thick.

The IP protection class is realized by a seal in the lid or in the

door.

The enclosures are mounted with mounting brackets found

outside of the enclosure wall.

The enclosures are also suitable for intrinsically safe electric

circuit connection. For this application, special marking is

required.

The enclosures can be used in hazardous areas of both zone 1

and 2 with certified explosion subgroups II and the temperature

class T5/T6 and as well as in zone 21 and 22. Enclosures and

cabinets with windows shall only be used in conditions with low

level mechanical risk.

Safety instructions

The supplied Ex empty enclosures are U-certified components

which serve as a basis for completely certified devices which

then in their entirety must still be tested and approved by a

specified agency for capability for use in potentially explosive

areas.

The enclosure may be operated only if it is clean and not

damaged in any way. Dust deposits > 5 mm (> 0.2 in) must be

removed.

Utilization in areas other than those specified or the modifica-

tion of the product by anyone other than the manufacturer is

not permitted and will exempt BARTEC Varnost from liability for

defects and any further liability.

The generally applicable statutory rules and other binding

directives relating to workplace safety, accident prevention and

environmental protection must be observed.

Observe the applicable laws and directives when commissioning

or restarting operation.

Always follow the safety instructions on the operating

equipment.

Marking

Particularly important points in these instructions are marked

with a symbol:

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in deat or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may reult in death or serious injury.

NOTICE indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

NOTE Important instructions and information on effective,

economical and environmentally compatible handling.

Standards conformed to

2014/34/EU

EN 60079-0:2012+A11:2013/IEC 60079-0:2011

EN 60079-7:2015 / IEC 60079-7:2015

EN 60079-31:2014 / IEC 60079-31:2013

as well as

EN 61439-1:2011

EN 62208:2011/IEC 62208:2011

EN 60445:2010/IEC 60445:2010

EN 60529:1991 + A2:2013

Explosion protection

ATEX Ex II 2G Ex eb IIC Gb

Ex II 2D Ex tb IIIC Db

CE 1304

Certification IBExU 99 ATEX 1118 U

IECEx Ex eb IIC Gb

Ex tb IIIC Db

Certification IECEx IBE 09.0016U

Ambient temperature

ranges

Depending on the installed components; observe

the specifications on the type label.

EPDM-Seal:

-20 °C to +100 °C (IP66) (-4 °F to +212 °F) (IP66)

Silicon-Seal:

-55 °C to +100 °C (IP66) (-67 °F to +212 °F) (IP66)

Only for type 07-55.1-…./…. Raku-PUR:

-40 °C to + 80 °C (IP66) (-40 °F to +176 °F) (IP66)

For built-in Vision panels:

-20 °C to +95 °C (IP66) (-4 °F to +203 °F) (IP66)

Approved for zones 1 and 2

21 and 22

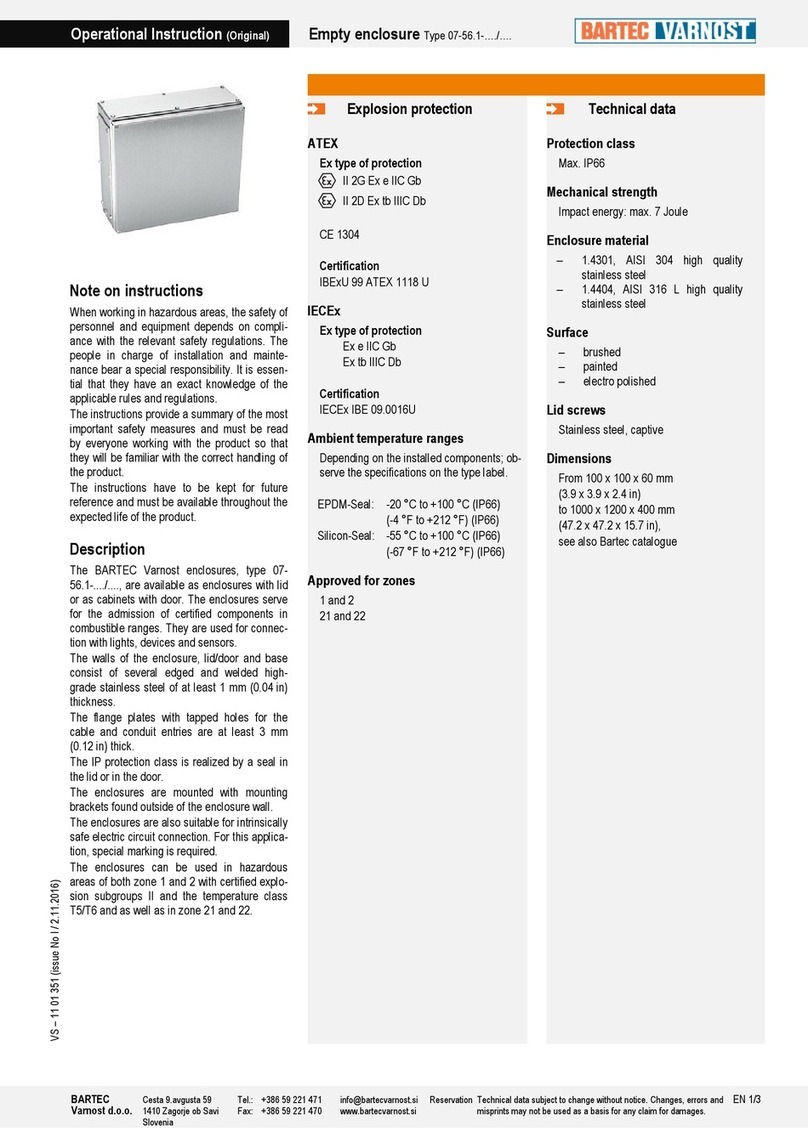

Technical data

Protection class Max. IP66

Mechanical strength Impact energy: 7 Joule

Enclosure material/

manufacturing process

1.4301, AISI 304 high quality stainless steel

1.4404, AISI 316 L high quality stainless steel

Surface brushed

painted

electro polished

Lid screws Stainless steel, captive

Dimensions From 100 x 100 x 60 mm

(3.9 x 3.9 x 2.4 in)

to 1200 x 1200 x 400 mm

(47.2 x 47.2 x 15.7 in),

see also BARTEC catalogue

Operational Instruction

Empty enclosure Type 07-56.1-…./…. Type 07-55.1-..../....

Transport, storage

CAUTION

Risk of injury due to heavy loads.

• Use an appropriate carrying aid or an appropriate means

of transport (e.g. a fork-lift) with an adequate load-carrying

ability.

• Ensure that the lifted load will not tip over or slip off.

NOTICE

Damage through incorrect transport or incorrect storage.

• Transport the distribution box in original packaging, handle

with care, and do not drop.

• Store the distribution box dry in original packaging.

Assembly, installation, and

commissioning

WARNING

Risk of serious injury due to incorrect proceedings.

• Only qualified personnel who are authorized and trained to

assemble electrical components in hazardous (potentially

explosive) areas may do any of the assembly, disassembly,

installation and commissioning work.

• For assembly and operation of explosion protected

electrical equipment, relevant installation and operating

regulations are to adhere (e.g. Betr.SichV, IEC/EN 60079-14

and series DIN VDE 0100).

• The data on the label and the EEC design test data are to be

observed. Further technical information is provided in the

BARTEC catalog and on the product itself.

• Do not open the distribution box when energized.

• Follow the components mounting instructions/operating

instructions.

Assembly / disassembly

DANGER

Death or serious injury because of a missing protective

earth connection.

• Metallic conductor entries must be connected to the

ground. With plastic enclosures, BARTEC Earth loc or

appropriate ground plates serve the similar purpose.

• Protective earth connections have to be protected against

self-loosening.

• By assembling/disassembling of cable glands and/or plugs

with counter nuts tighten always counter nuts and NOT

plugs or cable glands - otherwise the seal may be damaged.

NOTICE

Damage to elements due to incorrect installation

dimensions.

• The minimum spacing between the mounting holes must be

observed, see manufacturer`s instructions.

When processing the enclosures, attention must be paid to

ensuring that there is suitable minimum spacing between

individual boreholes and from the sealing edge of the enclosure

so that enclosure with the fittings will be able to withstand an

impact test.