Scope:

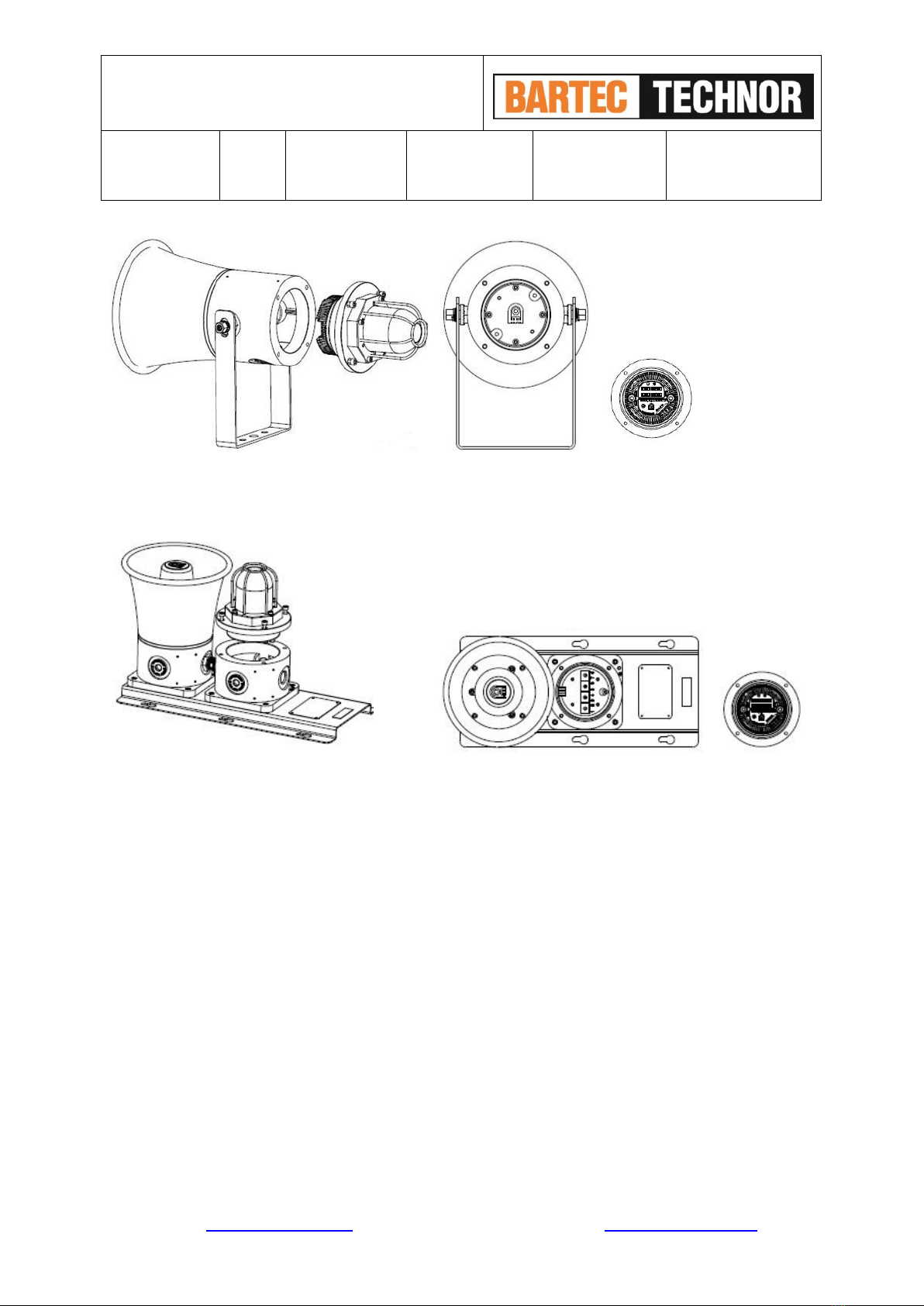

EXcite

USER MANUAL

BHB 125 / BHB 150

WEB: www.bartec-technor.no PHONE: +47 51 84 41 00 E-MAIL: mail@bartec-technor.no

1.0 INTRODUCTION

BHB-125 / 150 series Explosion-proof sounder/horn & beacon are designed according to EN/IEC 60079-0,

EN/IEC 60079-1 and EN/IEC 60079-31 standards. Enclosure material is Stainless Steel (BHB 125) or GRP

(BPB 150). This product is certified for use and installation in Zone 1 and Zone 2 areas with gases groups

of IIA, IIB, IIC and temperature classification of T4~T6. It specially applies to Oil & Gas, Offshore Platform,

Chemical, Petrochemical, Refinery and Marine Industries etc. Users can choose from single or combination

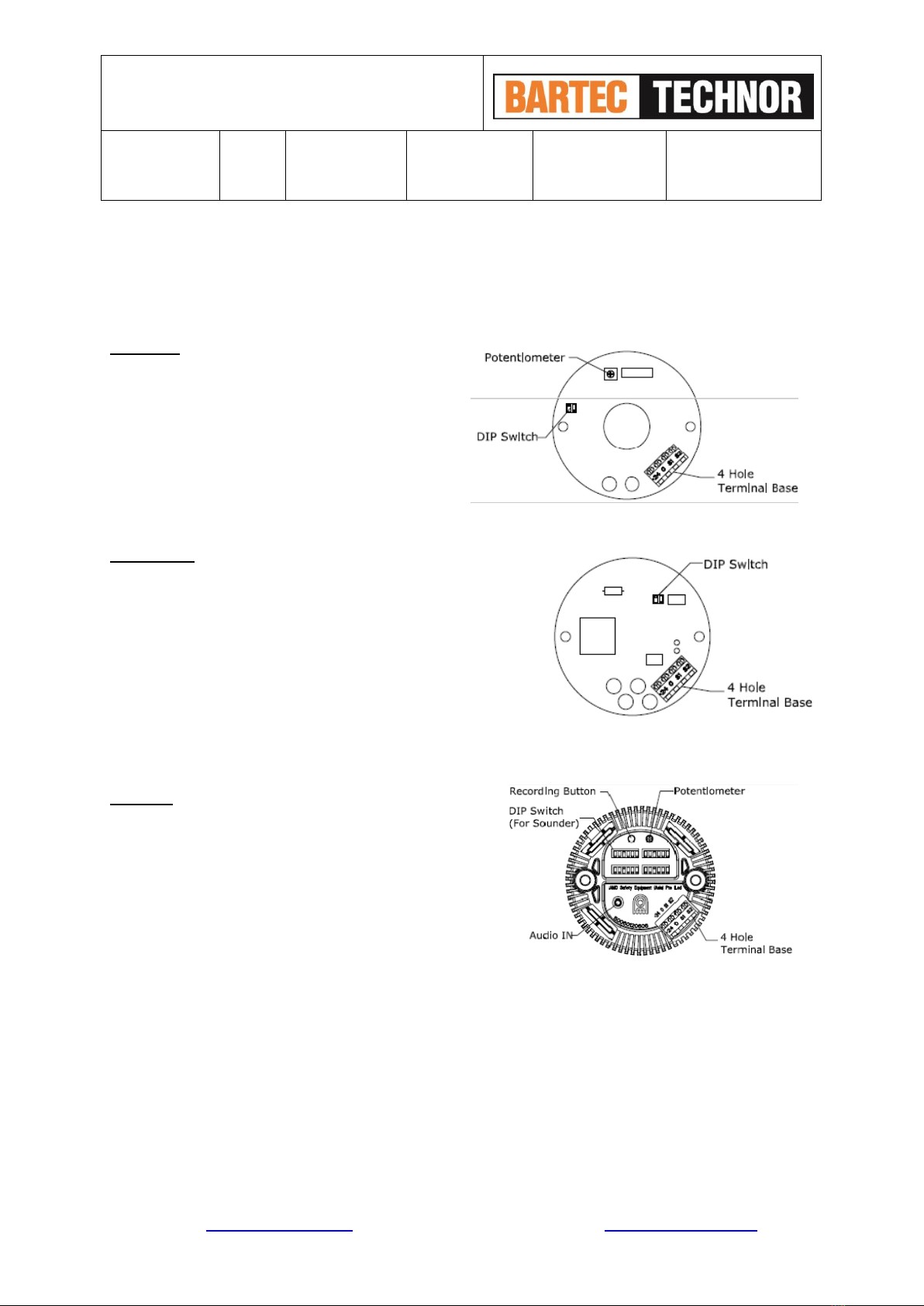

types. The design of 3 in 1 sounder, loudspeaker and beacon is unique. According to user control system, 4

stages of alarm tones can be sent out, from less critical stage (stage 1) to the most critical stage (stage

4). 64 tones are selectable. Tone can be preset during installation. At the same time, four stages of alarm

light can also be sent out.

2.0 EXPLOSION PROOF LABELING

All products have a rating label which carries the following important information:

Product order no.: e.g.

BHB125RX10DCARDN

(Refer to the datasheet for product order selection)

Input voltage: up to 48V DC or 100-254V AC

Code: Ex d IIC Txx Gb

Ex tb IIIC Txx

ATEX Marking: Gas Group and Category: II 2GD

CE Mark:

Warning: DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE IS PRESENT

Note; exact information is given on the actual label, ref also example on page 1

3.0 TYPE APPROVAL STANDARD

The BHB 125/150 series have been approved to the following standards:

IEC/ EN 60079-0General requirements

IEC/ EN 60079-1Flameproof enclosure “d“’

IEC/ EN 60079-31 Dust atmosphere “t”