PNEUMATIC ZEUS mod. 2009 page 7 January 2009

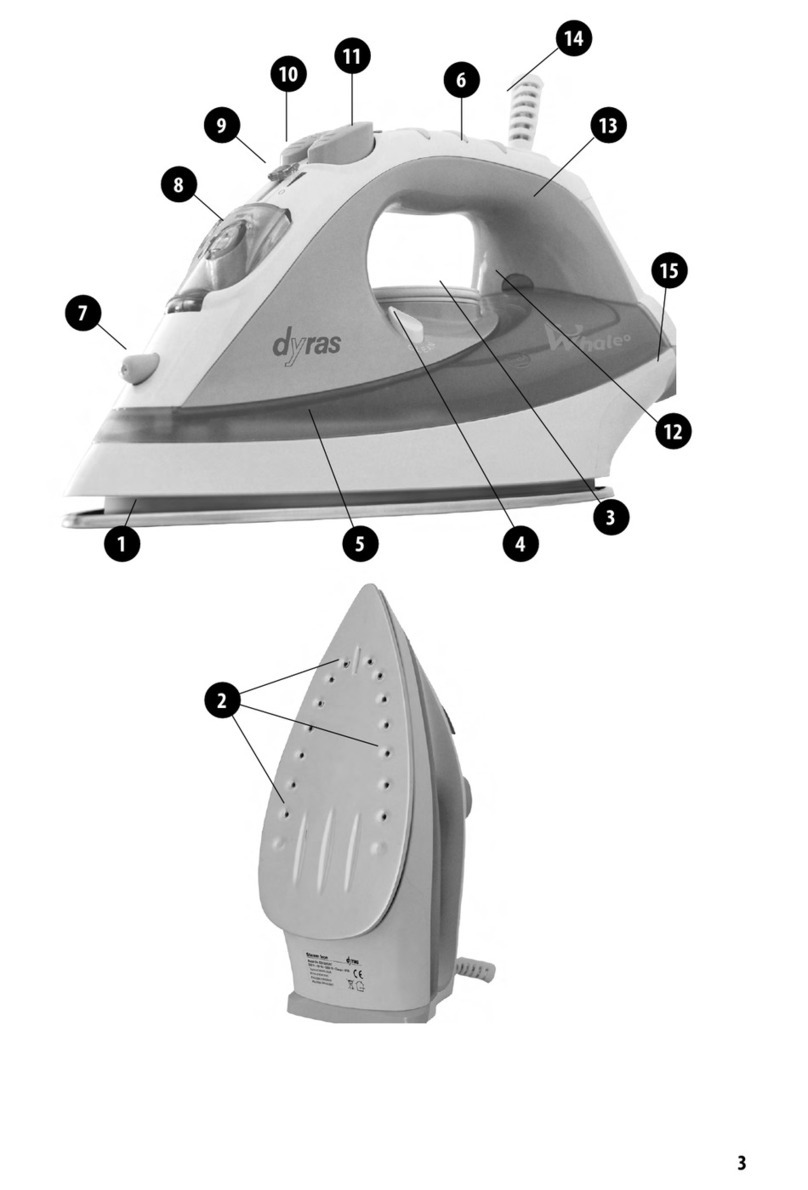

11. USE OF CLAMPS

The functioning of clamps and arms is

automatic. You just need to insert the

garments sleeves into the special slit;

as soon as Zeus notices the presence of

the sleeves, it will tighten the clamps.

If the sleeves are inserted incorrectly,

by pushing for a couple of seconds the

clamps opening button, the sleeves will

be freed. It is possible to adjust height

and distance of the clamps by using the

special knobs (fig. 2). You can also

turn the clamps on vertical position.

12. USE OF PADDLE

The dummy is fitted with two paddles (fig. 1): the front paddle is used for closing the

opening of the garment without having to button it, whereas the back one is used for

fastening of the slits or the central pleat of the garment. The operator can release the

paddle by grasping the handle and pulling the racket with one’s thumb (fig. 3). In

addition, by turning the handle clockwise or anticlockwise, you can adjust the

pressure exerted by the paddle on the garment, preventing it from slipping away or

being marked.

13. SHOULDERS AND BLOWING MOTOR ADJUSTMENT

Upon the first working cycle and each time the fabric to iron is

changed, it is necessary to set up the following adjustments:

1. Place the garment on the body former and adjust the shoulders

width by means of the proper knob (fig. 1). The body former

shoulders must coincide with the garment shoulders.

2. Regulate the paddle (see point 12).

3. Adjust the air register according to the program which has been

chosen or according to your requirements. Example: when

program 1 is selected, “CHILDRENS SWEATSHIRT ADJ. AIR 1”will

be displayed.

N.B. The blowing motor is three-phase. Should it work,

but not blow, invert two phases on the electric feeding.