Argo 2011 ver.02 4 2011

7. CONNECTION AND STARTING

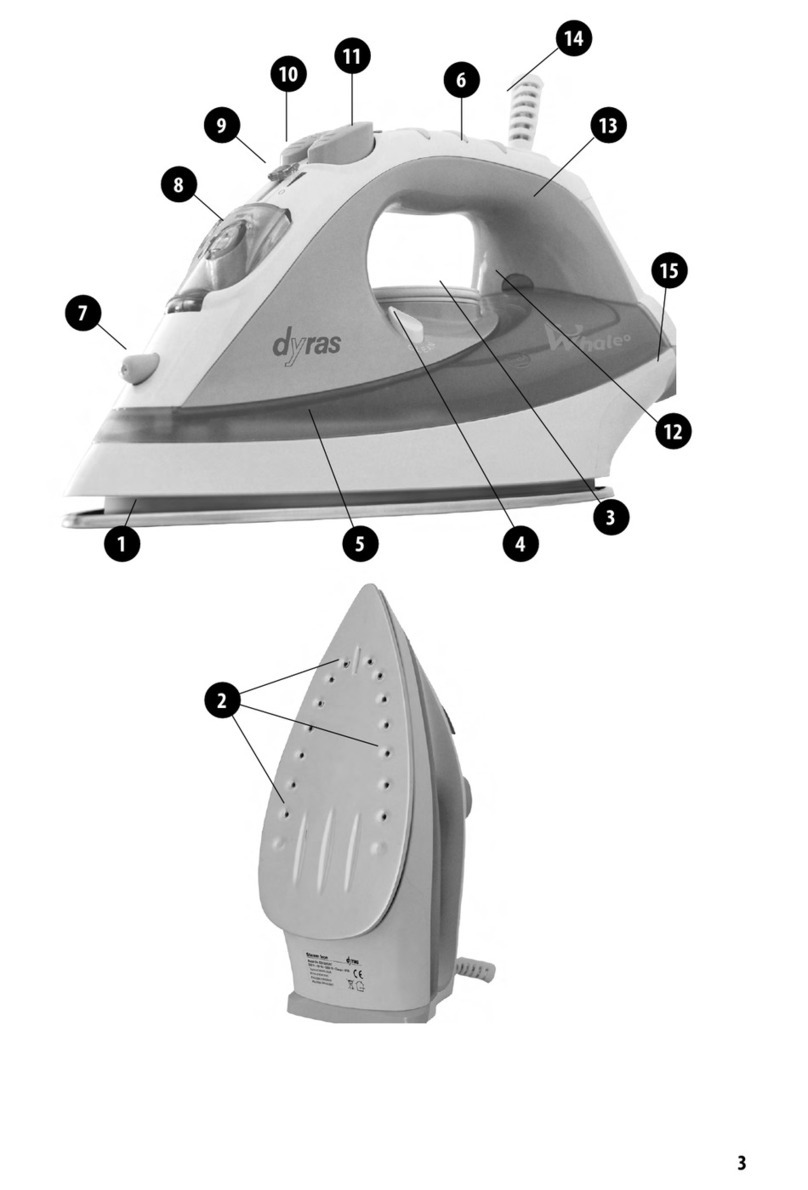

1. Connect the rubber hose to the hose-holder indicated as WATER INLET placed on

the ARGO (fig. 1) and turn the water tap on. For ARGO equipped with water tank,

you just have to fill it and connect the machine to the mains supply. N.B. make

sure there is always water inside the water tank.

2. Connect the power supply cable to a protected outlet with earth protector switch ,

with observance of the law in force and a voltage suitable to ARGO.

3. Turn on the main switch (fig. 1) and select the functions which are to be

activated. N.B. the settings of the electronic card are memorized every time the

main switch is turned off. Once the machine is turned on again, it will start with the

settings memorized before the machine was turned off (e.g. if the boiler was on, it

will be on upon switching on the machine). WARNING the electronic card

automatically performs a check of the software installed. This is why it takes 2

seconds for the machine to turn on.

If an error or fault is found, the “safety” device blocks the electronic card and does

not allow normal functioning. “SOFTWARE ERROR” will be displayed. Contact the

Authorized Service Centre to update the software.

4. Wait until the boiler light is fixed (not intermittent). Seize the iron by the cork

handle and press the micro-switch 3 or 4 times (fig. 3), so that steam comes out:

this operation must be carried out in order to heat up the hoses which take steam

to the iron. This prevents also the falling of small drops of water on garments (iron

must always be held in such a way as not to harm operator, that is with iron

always pointed downwards).

5. To adjust the steam flux you must work on the steam adjustment tap (fig. 1

solenoid valve).

6. After this, ARGO is ready for use. During ironing the icon of the boiler may remain

intermittent (card is raising steam) or fixed (optimum pressure), indicating that

ARGO is working properly.

N.B. during ironing the warning light will switch on and “WATER PUMPING”

will be displayed. This means that the card is automatically pumping water into the

boiler.

N.B. in the event the pump should remain without water for a long time, the

“pump saving” device will be activated and the pump will not work. This is shown

by the icon and the warning “PUMP BLOCKED” will be displayed. An

intermittent acoustic alarm is also audible.

If this device is activated, check that there is enough pressure in the water system

or that there is water inside the water tank. If one of the previous is the cause of

the blockage, turn the card off and on by using the main switch. If the problem

remains, do not insist and contact the manufacturer or Authorized Service Centre.

FOR ARGO CONNECTED TO THE WATER SYSTEM

For ARGO connected to the water system, verify that the water pressure is not

more than 2,5 Bar. If so, the pump will be blocked and this will prevent the water

from entering the boiler.

FOR ARGO CONNECTED TO THE WATER BOTTLE SUPPLY

In case of missing water completely from the water bottle-refill the bottle.

Release all steam from the boiler-the pressure must be 0 bar.

The pump will restart.